Elliptic vibration machine with parallel shafts and double excitation motors

A vibration-exciting motor and elliptical vibration technology, which is applied in the direction of fluid, solid separation, and filter screens using vibration, can solve the problems of large difference in motor excitation force, large screen box stress, and reduced motor excitation force. Uniform output, convenient assembly and disassembly, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

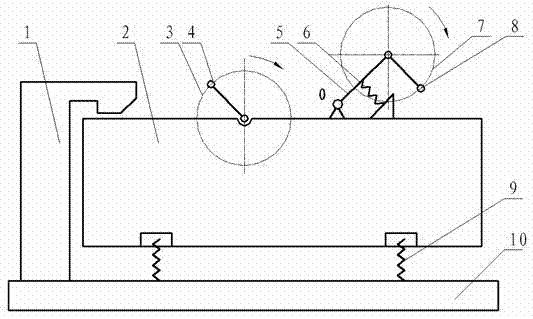

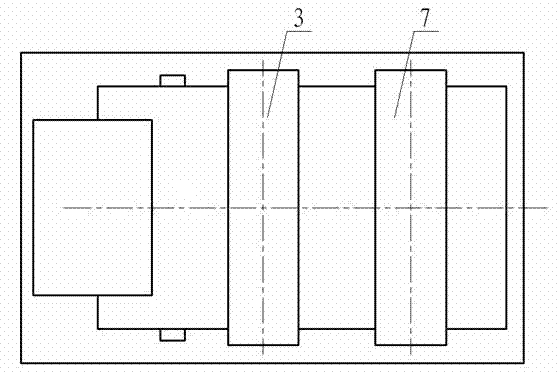

[0014] Further illustrate the present invention below in conjunction with accompanying drawing.

[0015] exist figure 1 , figure 2 Among them, the elliptical vibration machine with parallel shafts and double excitation motors of the present invention is mainly composed of a feed hopper 1, a vibrating body 2, a first excitation motor 3, a swing motor seat 5, a vibration damping spring 6 for a swing motor seat, and a second excitation motor 7. The vibrating body is composed of a support spring 9 and a base 10. The vibration body 2 is supported on the base 10 by the vibration body supporting spring 9, the first vibration excitation motor 3 is directly fixedly installed on the vibration body 2, the second vibration excitation motor 7 is fixedly installed on the swing motor base 5, and the swing motor base 5 passes through The hinge O is installed on the vibration body 2, and a group of vibration damping springs 6 of the swing motor base are installed between the swing motor bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com