Ultrasonic motor vibrator with plate cantilever beam combined structure and excitation method thereof

An ultrasonic motor, combined structure technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of rotation, large width and thickness, and difficult to overlap problem, to achieve the effect of simple structure, moderate length and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

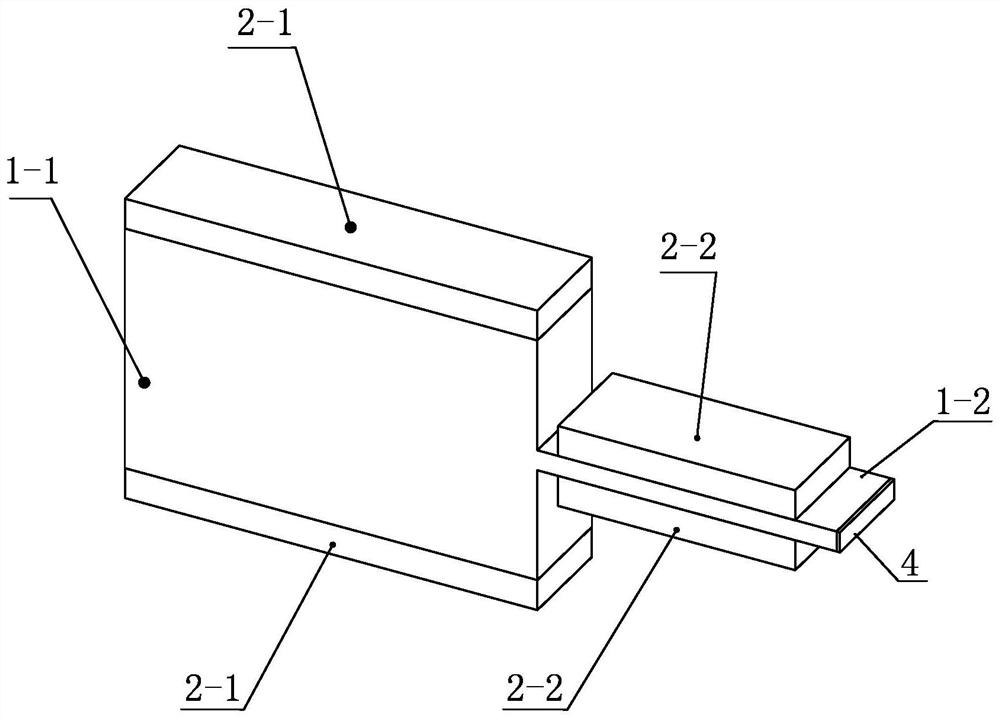

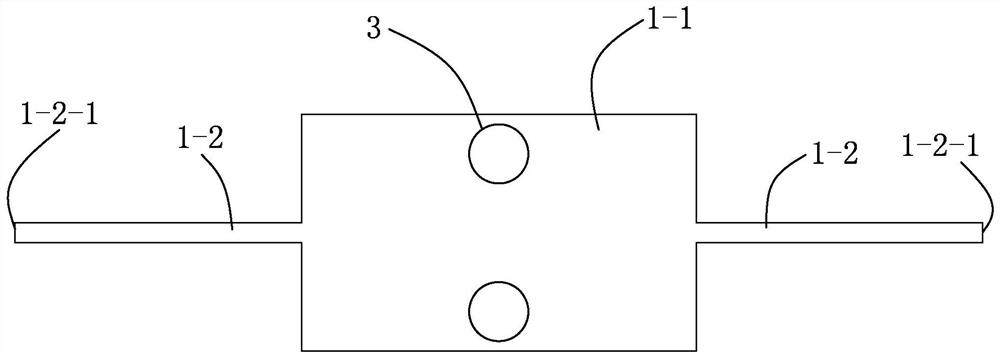

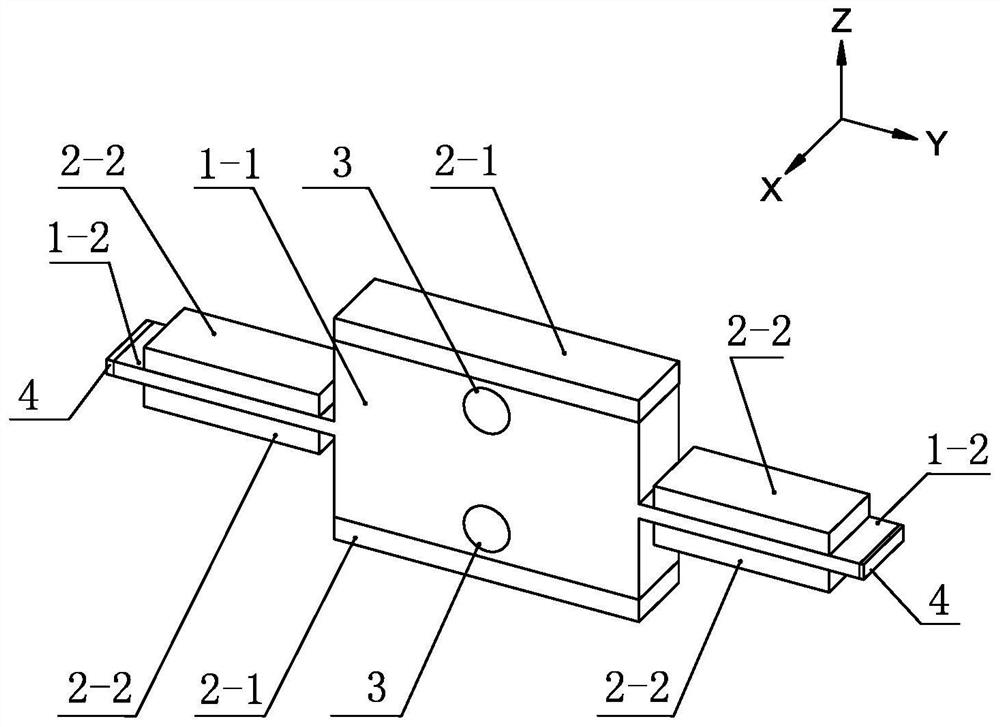

[0018] Such as figure 1 As shown, an ultrasonic motor vibrator with a combined structure of plate cantilever beams includes a piezoelectric ceramic sheet, and the piezoelectric ceramic sheet is divided into a first piezoelectric ceramic sheet 2-1 and a second piezoelectric ceramic sheet 2-2, and also includes an elastic Plate 1-1 and elastic cantilever beam 1-2; the two sides perpendicular to and opposite to the side of the elastic plate 1-1 in the thickness direction are respectively fixed with a first piezoelectric ceramic sheet 2-1, and the elastic plate 1-1 The side in the thickness direction is vertical and one of the other two opposite sides is fixed with an elastic cantilever beam 1-2, and the two opposite surfaces of the elastic cantilever beam 1-2 are respectively fixed with a second piezoelectric ceramic sheet 2-2 , the first piezoelectric ceramic sheet 2-1 and the second piezoelectric ceramic sheet 2-2 are arranged in parallel, and the end surface 1-2-1 of the elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com