Dual-motor power assembly for pure electric automobile and operating mode thereof

A pure electric vehicle and powertrain technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of low CVT efficiency, high cost, complex CVT and DCT structures, etc., to improve ride comfort and comfort performance, eliminate power interruptions, and provide efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

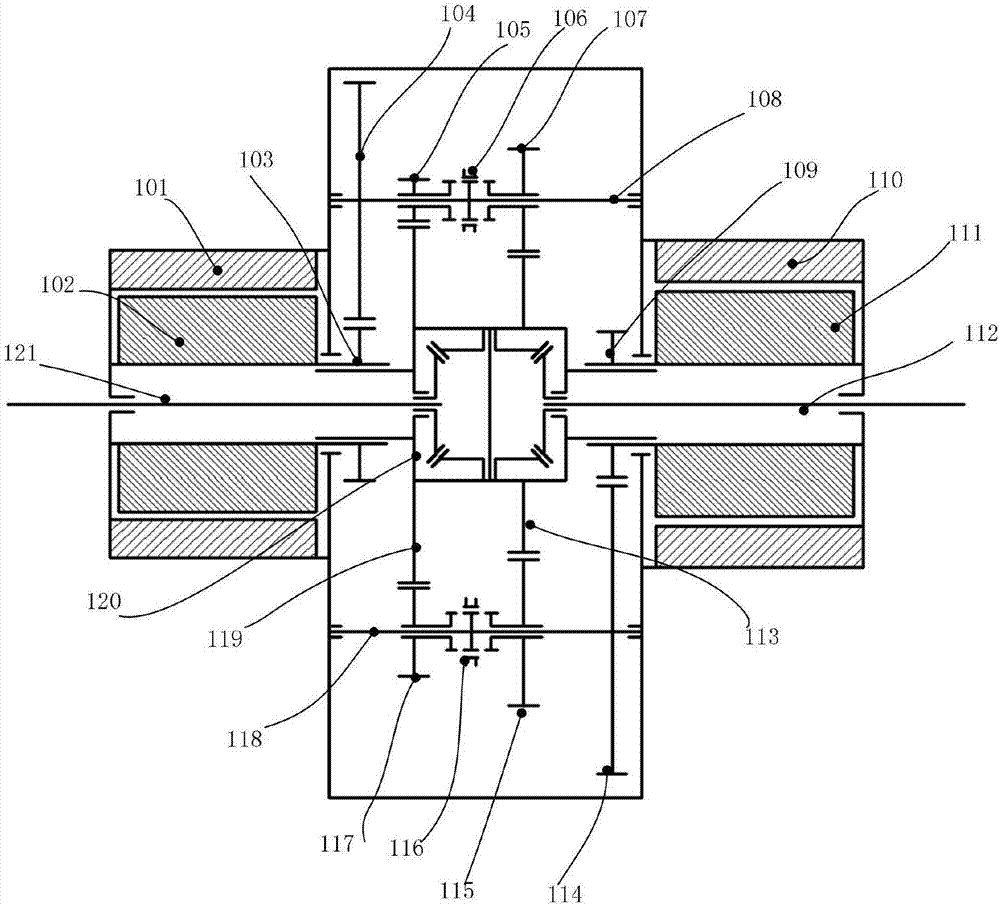

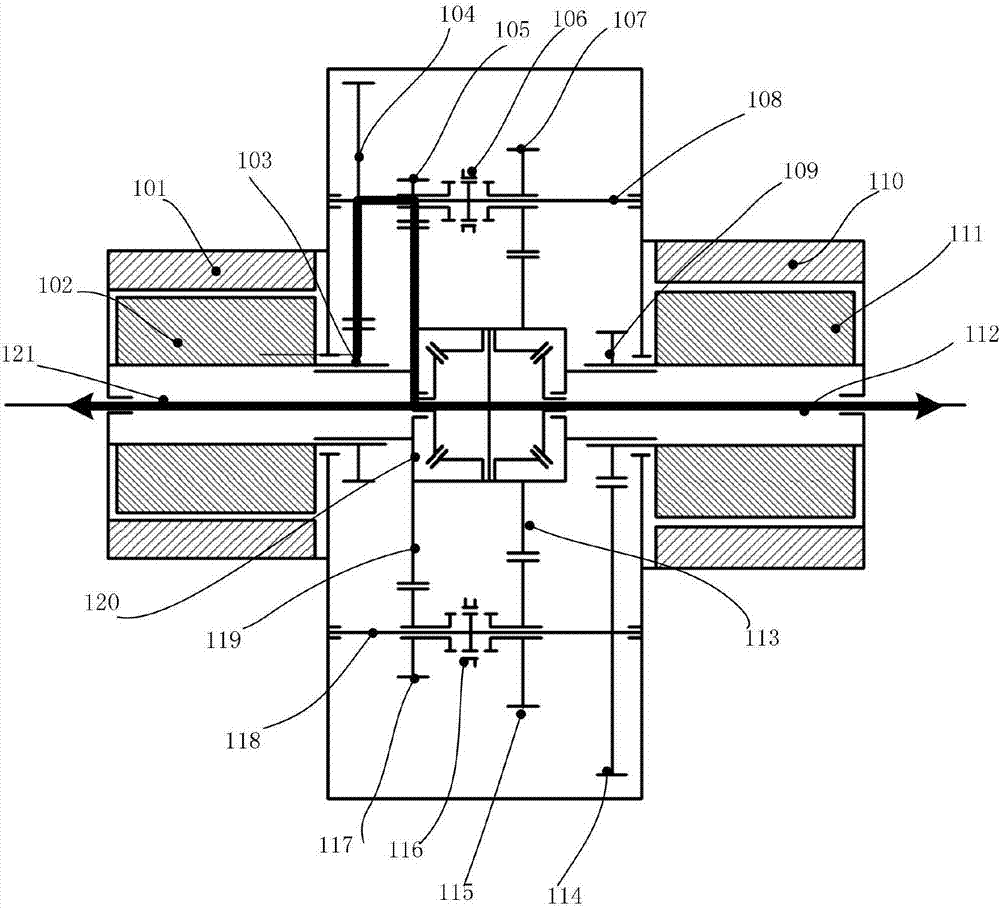

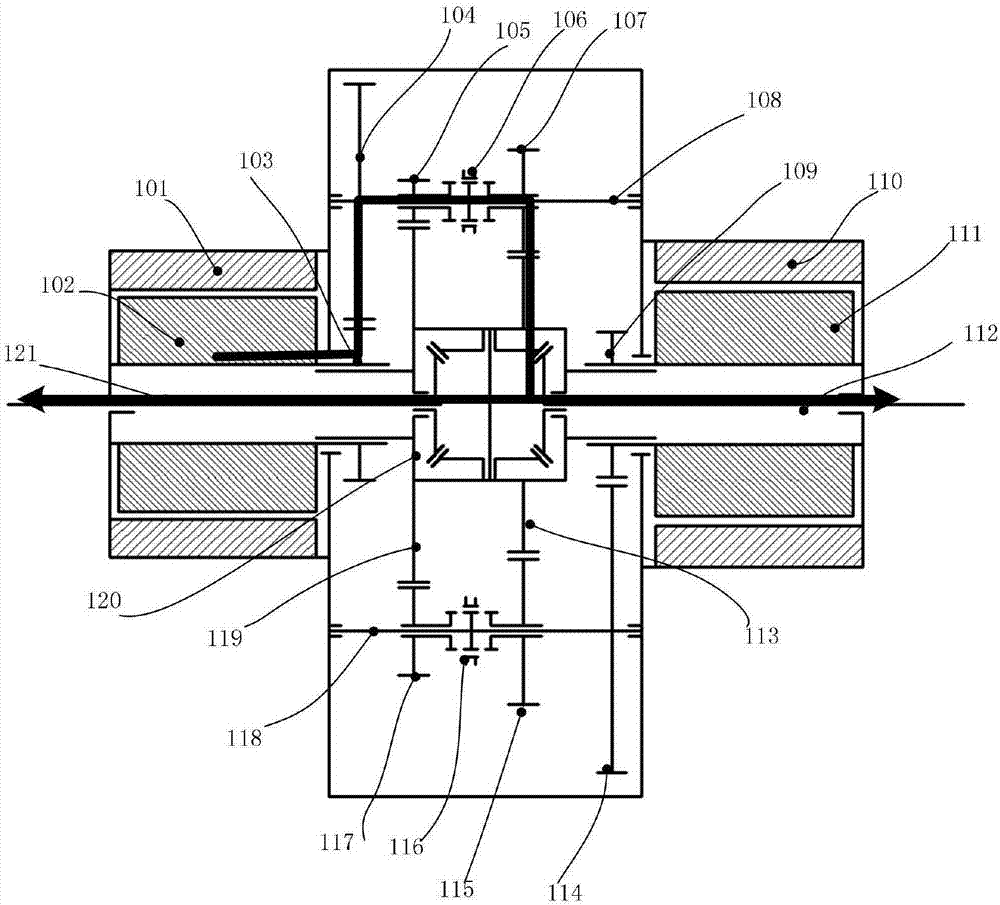

[0074] Such as figure 1 As shown, a powertrain of a pure electric vehicle dual-motor configuration includes a first drive motor, a second drive motor, a first input gear 103, a second input gear 109, a first gear shaft 108, and a second gear shaft 118, double row gear differential 120, left side transmission half shaft 121, right side transmission half shaft 112, first shift coupling sleeve 106, second shift coupling sleeve 116;

[0075] The first drive motor is an inner rotor motor, and the motor rotor 102 of the first drive motor is hollow or hollow, and is connected with the first input gear 103 through spline fit; as a preference, the first drive motor selects a kind of inner rotor that is hollow permanent magnet synchronous motor with a rated power of 30kw, and motors of other power levels can also be selected according to needs; the first input gear 103 is nested with one side of the double row gear differential 120 casing; the first gear shaft 108 is provided with Thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com