Fan heat dissipation device and method

A technology of heat dissipation device and heat dissipation method, which is applied in cooling/ventilation/heating transformation, pump control, non-variable-capacity pump, etc., can solve the problems of no alarm function, inability to adjust the fan speed, labor cost, etc., and achieve savings The effect of labor cost, simple structure and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

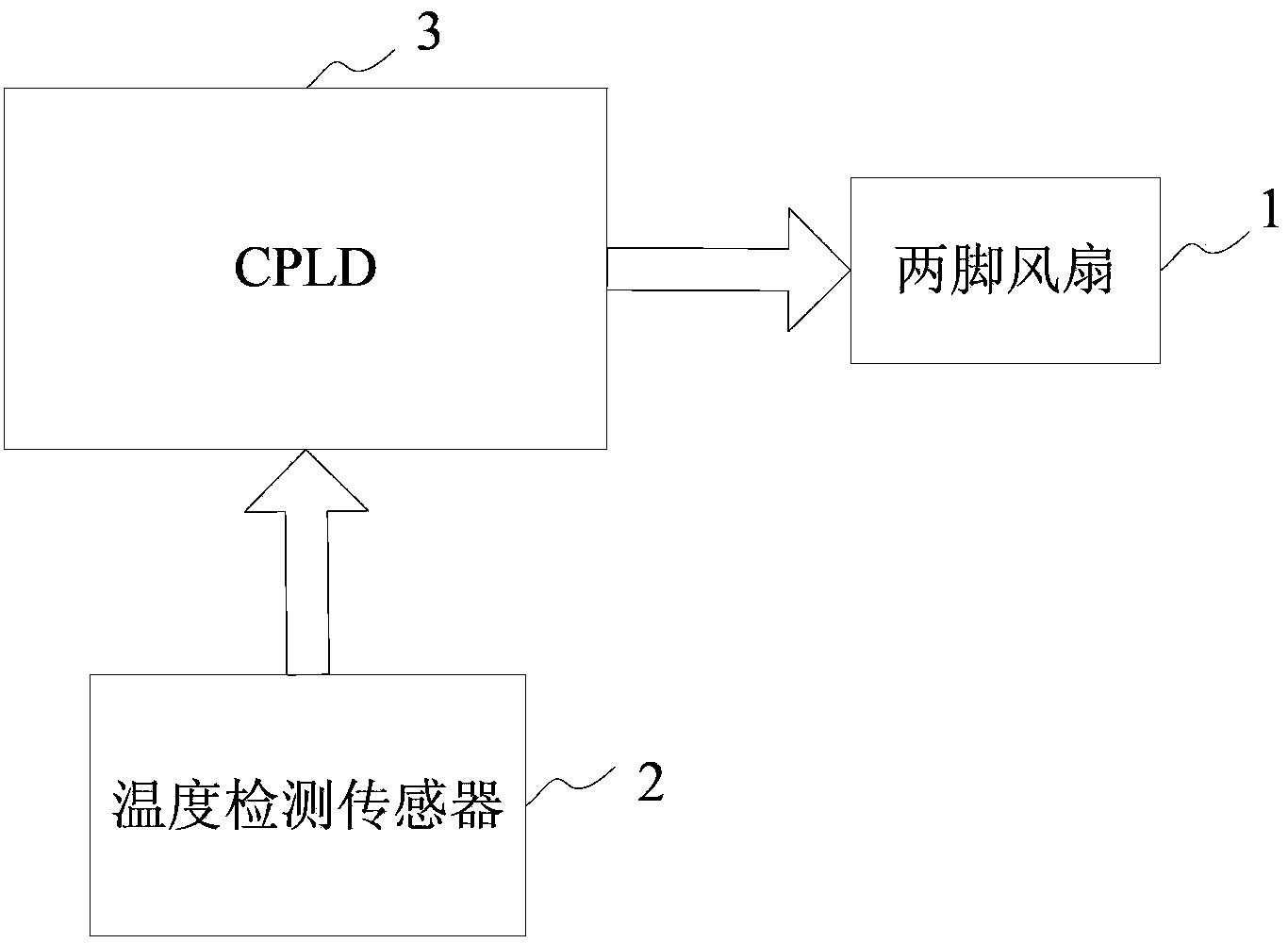

[0028] refer to figure 1 As shown, a fan cooling device includes a two-legged fan 1, a temperature detection sensor 2 and a CPLD3, the two-legged fan 1 is used to dissipate heat from a device (not shown in the figure), and the CPLD3 stores One-to-one correspondence of ten temperature ranges and ten rotational speeds;

[0029] The temperature detection sensor 2 is used to detect the temperature value of the device;

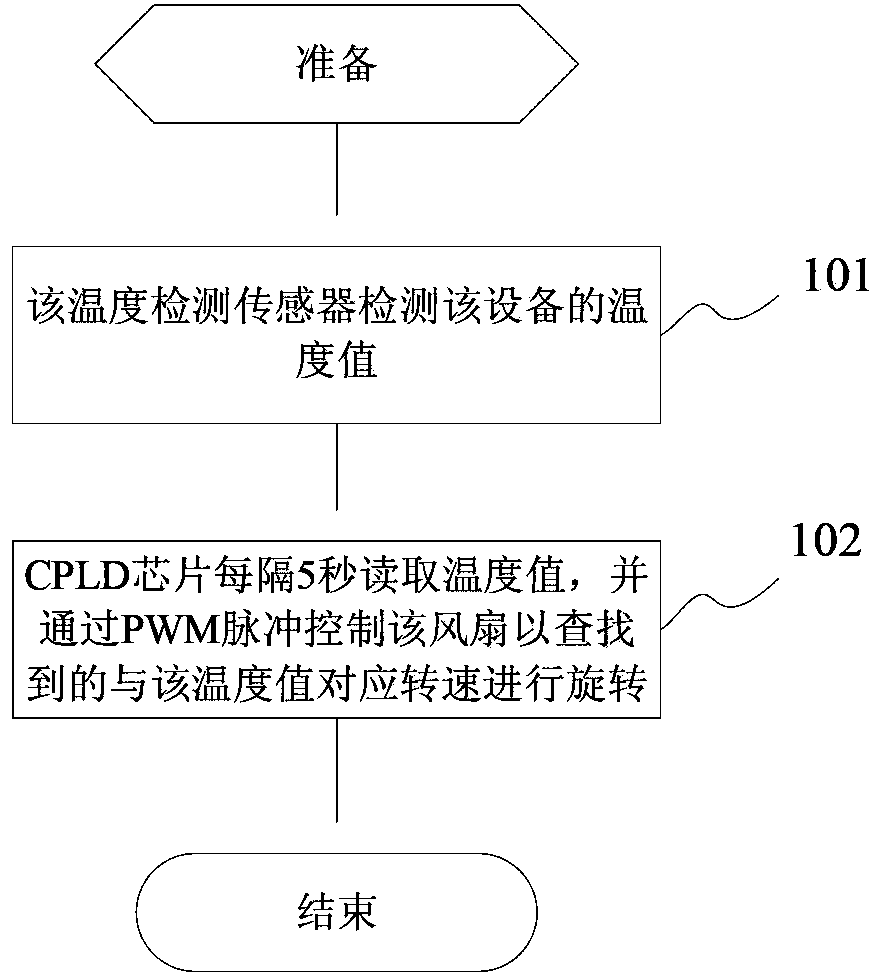

[0030] The CPLD3 is used to read the temperature value at intervals (such as 5 seconds), and find the speed corresponding to the temperature range that includes the temperature value in the ten temperature ranges, and control the two pins through PWM pulses Fan 1 rotates at the found rotation speed. Of course, the time period can also be set to other values.

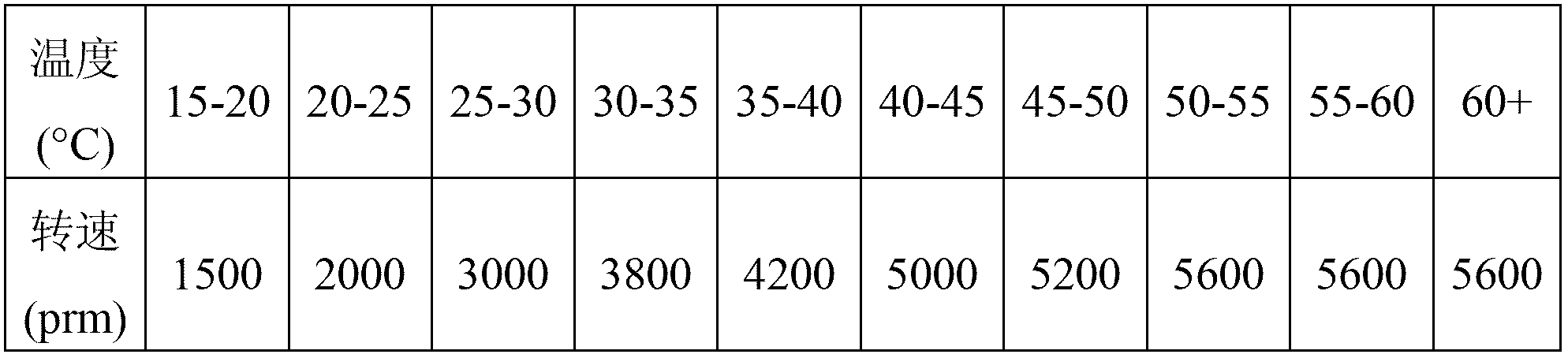

[0031] Among them, the corresponding relationship between the ten temperature ranges and ten rotational speeds stored in the CPLD3 is shown in the following table:

[0032]

[0033] figure 2 Shown is...

Embodiment 2

[0039] This embodiment differs from Embodiment 1 in that: the two-pin fan in the fan cooling device is replaced by a three-pin fan, the CPLD is replaced by an FPGA, and one of the three pins of the three-pin fan is an alarm pin, so in the device When the temperature is too high, the FPGA can realize the alarm function.

[0040] E.g:

[0041] When the temperature value of the device detected by the temperature detection sensor 2 is 75°C, after the FPGA reads the temperature value of 75°C, it finds the temperature interval including the temperature value of 75°C among the ten temperature intervals (60+)℃ corresponds to a speed of 5600 (prm), and the three-legged fan is controlled to rotate at the found speed of 5600 (prm) through PWM pulses. At the same time, the alarm pin included in the three-legged fan is passed through the I / O pin The high-level signal is transmitted to the FPGA, and the FPGA sends out an alarm reminder.

[0042] Other parts of this embodiment are identica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com