Coil winding machine control method based on BP nerve network, and coil winding machine

A BP neural network and control method technology, applied in the field of automatic control of winding machines, can solve problems such as time-consuming, complicated debugging, and single control mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

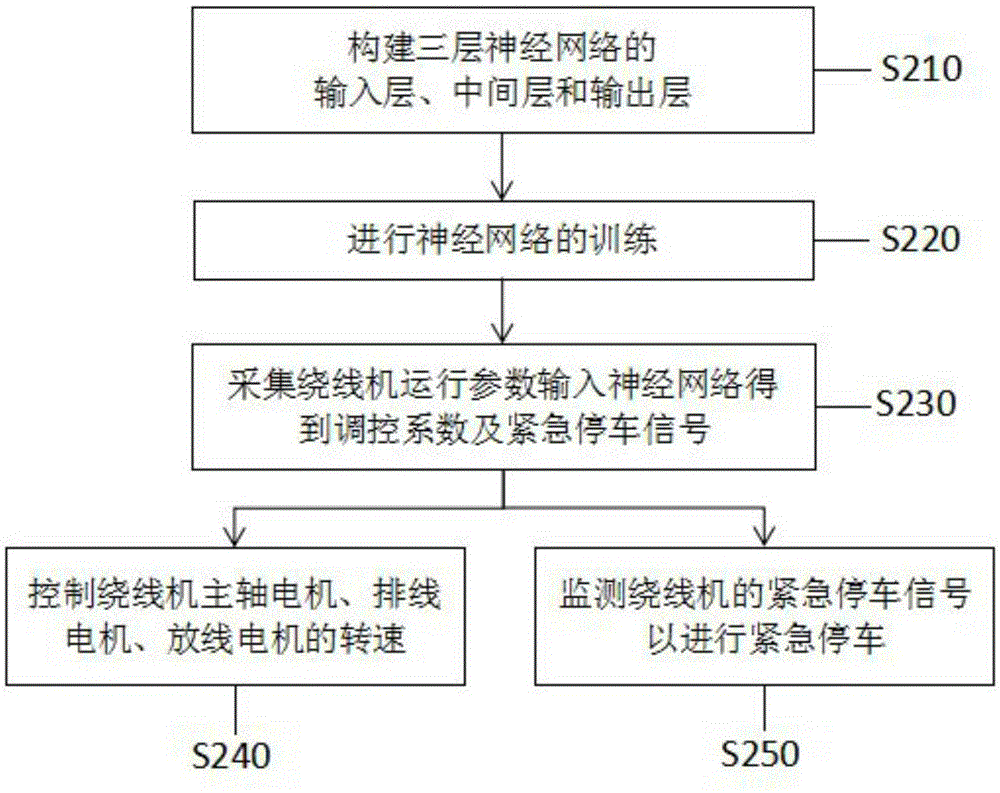

[0043] The invention provides a winding machine and a neural network-based control method for the winding machine, which uses a BP neural network to control the motion of the winding machine.

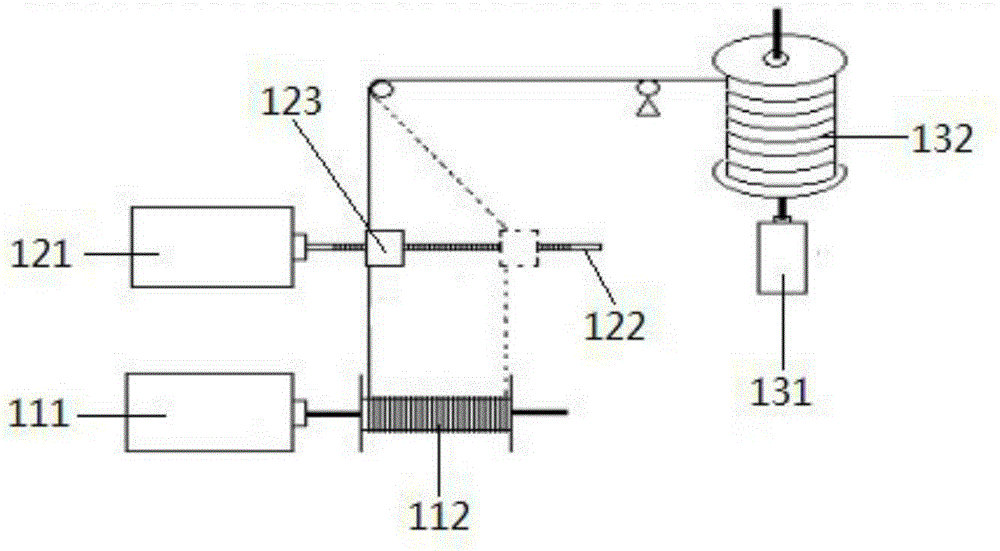

[0044] Such as figure 1 As shown, the winding machine provided by the present invention includes a main shaft, a wire puller, and a pay-off shaft. The main shaft is driven by the main shaft motor 111 to rotate the winding frame 112, and the wire arranging device is driven by the arranging motor 121 to drive the screw 122 to rotate, so that the nut 123 matched with the screw 122 moves left and right along the screw 122 to change the winding position of the wire rope. The winding position on the wire skeleton 112 . The pay-off shaft is driven by the pay-off motor 131 to rotate the pay-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com