Air conditioner filter screen filth blockage judgment method and device and air conditioner

A judging method and technology of judging device, applied in the direction of mechanical equipment, etc., can solve the problem of inability to judge that the filter is dirty and blocked, and achieve the effects of improving experience, accurate detection, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

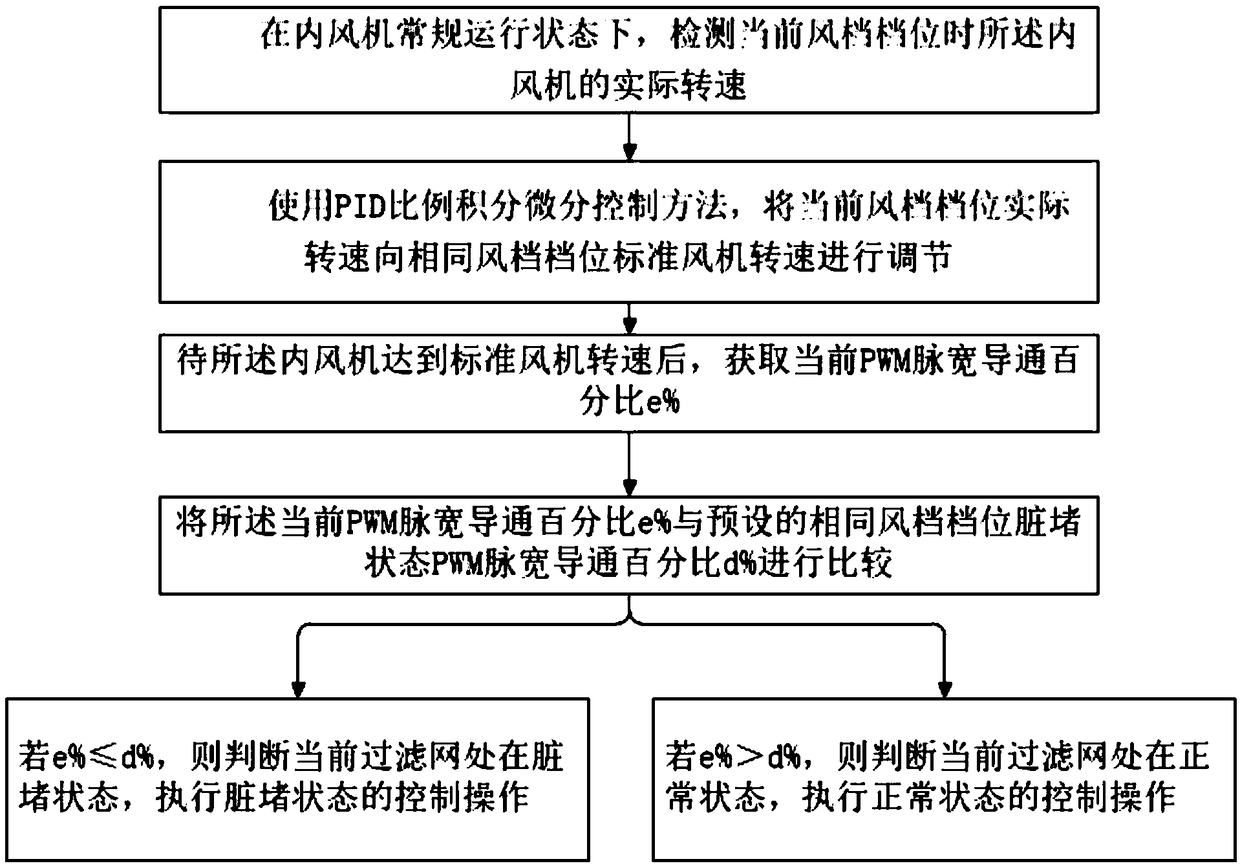

[0048] The invention provides a method for judging the dirty and clogged filter screen of an air conditioner, which combines figure 1 shown, including:

[0049] Under the normal operation state of the internal fan, detect the actual speed of the internal fan mentioned in the current wind gear;

[0050] Use the PID proportional integral differential control method to adjust the actual speed of the current wind gear to the standard fan speed of the same wind gear;

[0051] After the internal fan reaches the standard fan speed, obtain the current PWM pulse width conduction percentage e%;

[0052] Comparing the current PWM pulse width conduction percentage e% with the preset PWM pulse width conduction percentage d% in the same wind gear position dirty blockage state;

[0053] If e%≤d%, it is judged that the current filter is in a state of dirty blockage, and the control operation of the state of dirty blockage is performed;

[0054] If e%>d%, it is judged that the current filte...

Embodiment 2

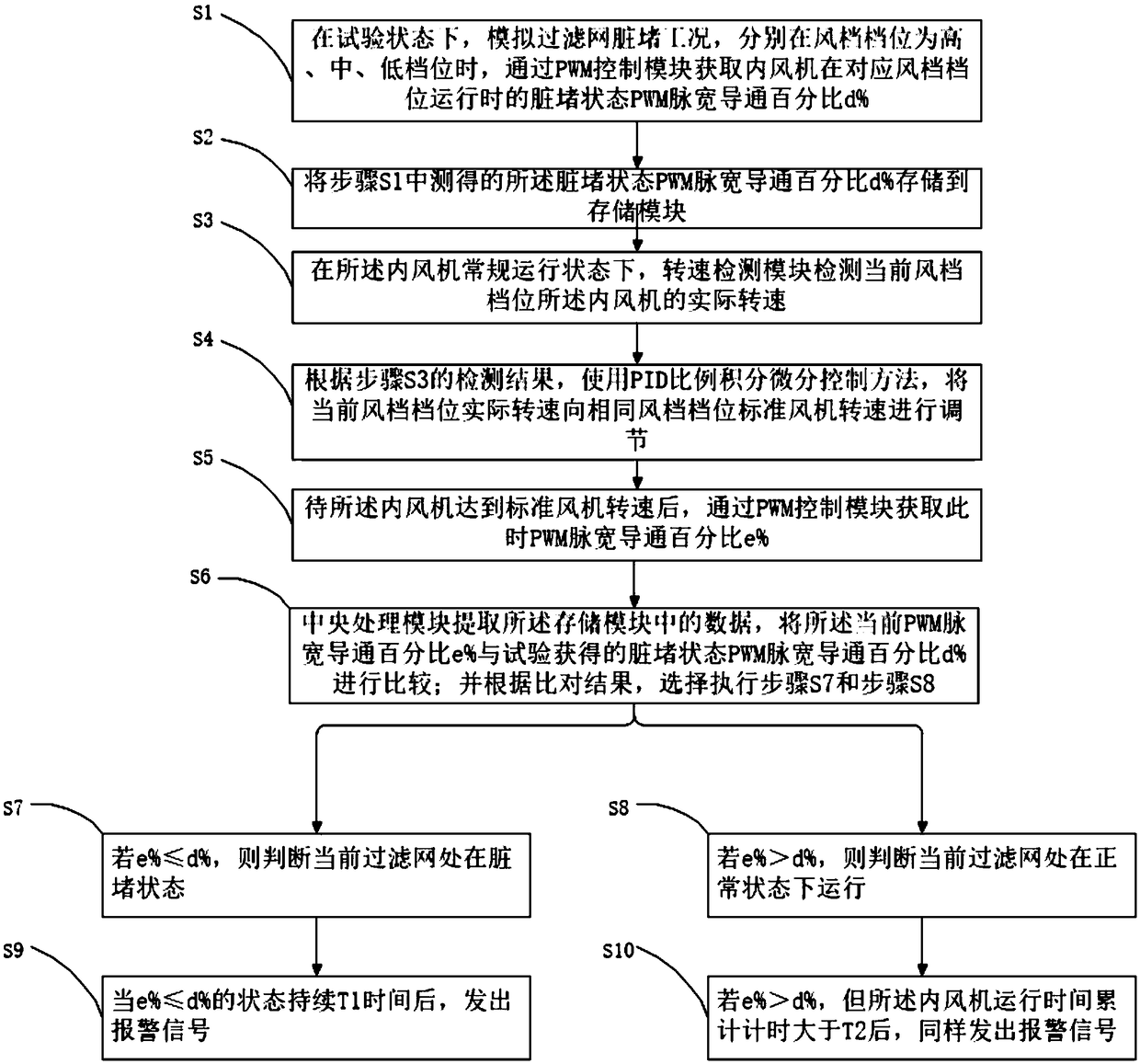

[0057] As described above, the method for judging dirty and clogged air conditioner filters differs from this embodiment in that, on the basis of Embodiment 1, the method for judging dirty and clogged air conditioner filters specifically includes the following steps:

[0058]Step S1: In the test state, simulate the working condition of the dirty and clogged filter, and obtain the dirty and clogged state of the internal fan when the wind gear is running in the corresponding wind gear through the PWM control module when the wind gear is in the high, medium and low gears respectively PWM pulse width conduction percentage d%;

[0059] Step S2: storing the PWM pulse width conduction percentage d% in the dirty blocking state measured in step S1 into a storage module;

[0060] Step S3: In the normal operation state of the internal fan, the speed detection module detects the actual speed of the internal fan in the current wind gear;

[0061] Step S4: According to the detection result...

Embodiment 3

[0076] As mentioned above, the difference of this embodiment is that the wind gears of the internal fan include high gear, middle gear and low gear, and the time when the filter screen is dirty and clogged is obtained respectively through the PWM control module. The PWM pulse width conduction percentage d% in the dirty blocking state of the internal fan when the current wind gear is running, the PWM pulse width conduction percentage d1% in the dirty blocking state of the high-grade position, and the dirty blocking state in the middle gear The PWM pulse width conduction percentage d2%, the PWM pulse width conduction percentage d3% in the low-gear dirty blockage state; and the PWM pulse when the filter screen is clean and the internal fan is running in the wind gear position is obtained through the PWM control module. Wide conduction percentage c%, the PWM pulse width conduction percentage c1% of the high-grade position in the clean state of the filter screen, the PWM pulse width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com