General testing system of airplane direct-current generator

A DC generator and general testing technology, applied in the field of test systems, can solve the problems of inconvenient testing of aircraft DC generators, complicated expansion and modification of test software, lack of versatility, etc., to facilitate manual monitoring, function upgrade and expansion, The effect of broadening applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

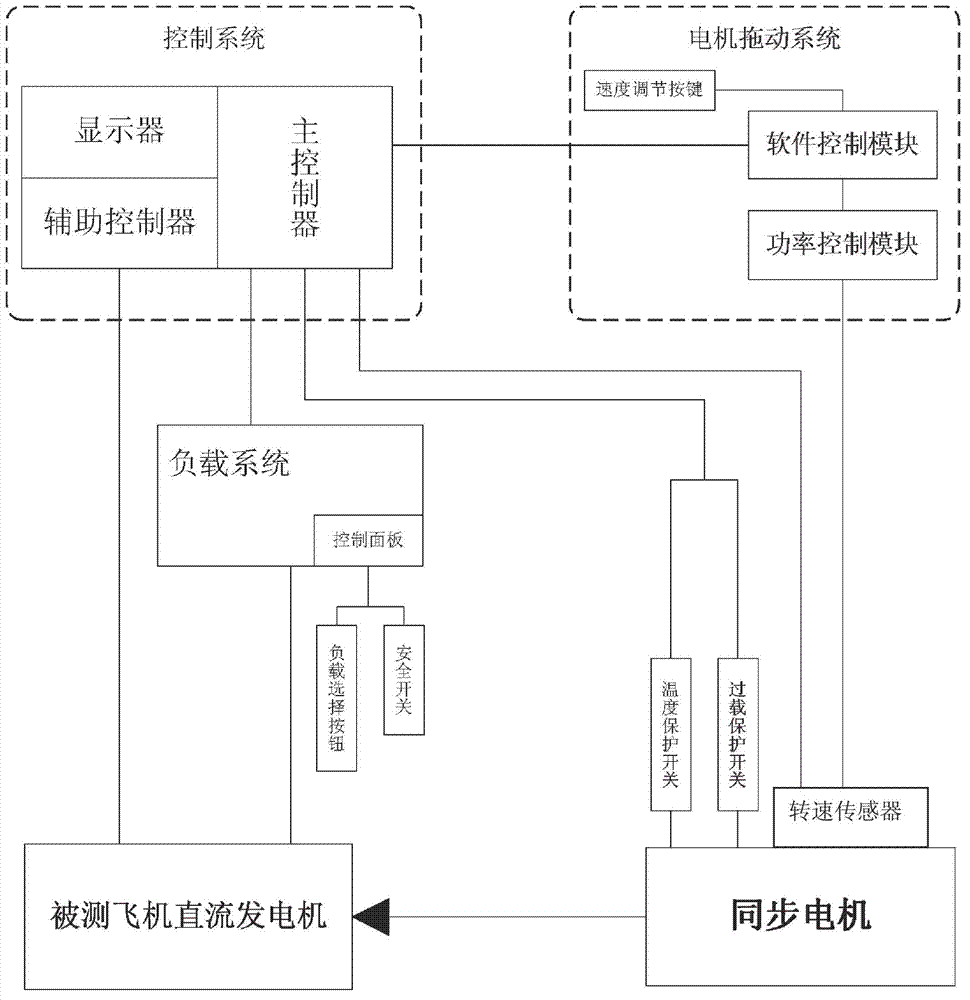

[0029] Such as figure 1 The general test system of the shown aircraft direct current generator, this general test system comprises: be used to drive the synchronous motor of the direct current generator of the tested aircraft, be used for speed regulation control described synchronous motor motor dragging system, be used for testing the aircraft The DC generator provides a load load system and a control system for controlling the test conditions of the tested aircraft DC generator and detecting the test results of the tested aircraft DC generator.

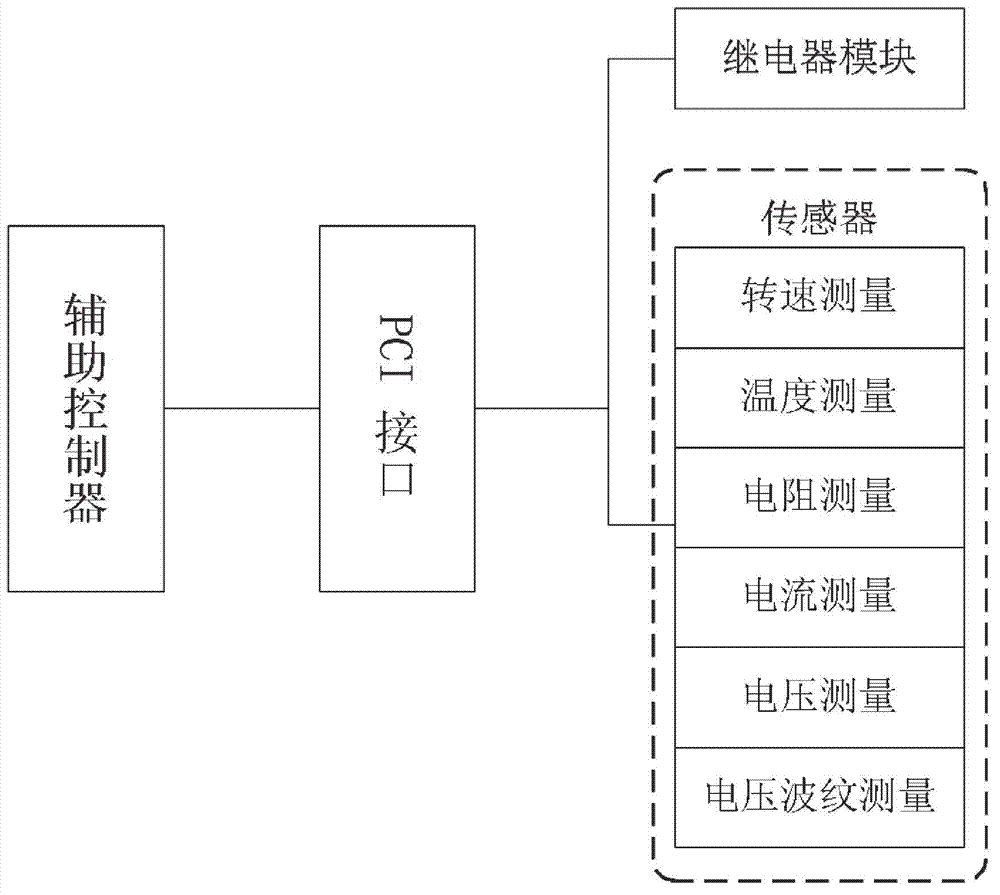

[0030] Control system The control system samples the control system of Avtron, including the main controller and auxiliary controller. The parameter data of the load system; the auxiliary controller is connected with the DC generator of the tested aircraft, and measures the parameter data of the DC generator of the aircraft. The control system of this embodiment adopts the LabVIEW secondary development software system of NI (Natio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com