Horizontal rotary compressor

A rotary compressor, horizontal technology, used in rotary piston machinery, rotary piston pumps, rotary piston/oscillating piston pump components, etc. Easy to burn and other problems, to achieve the effect of reducing oil output and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

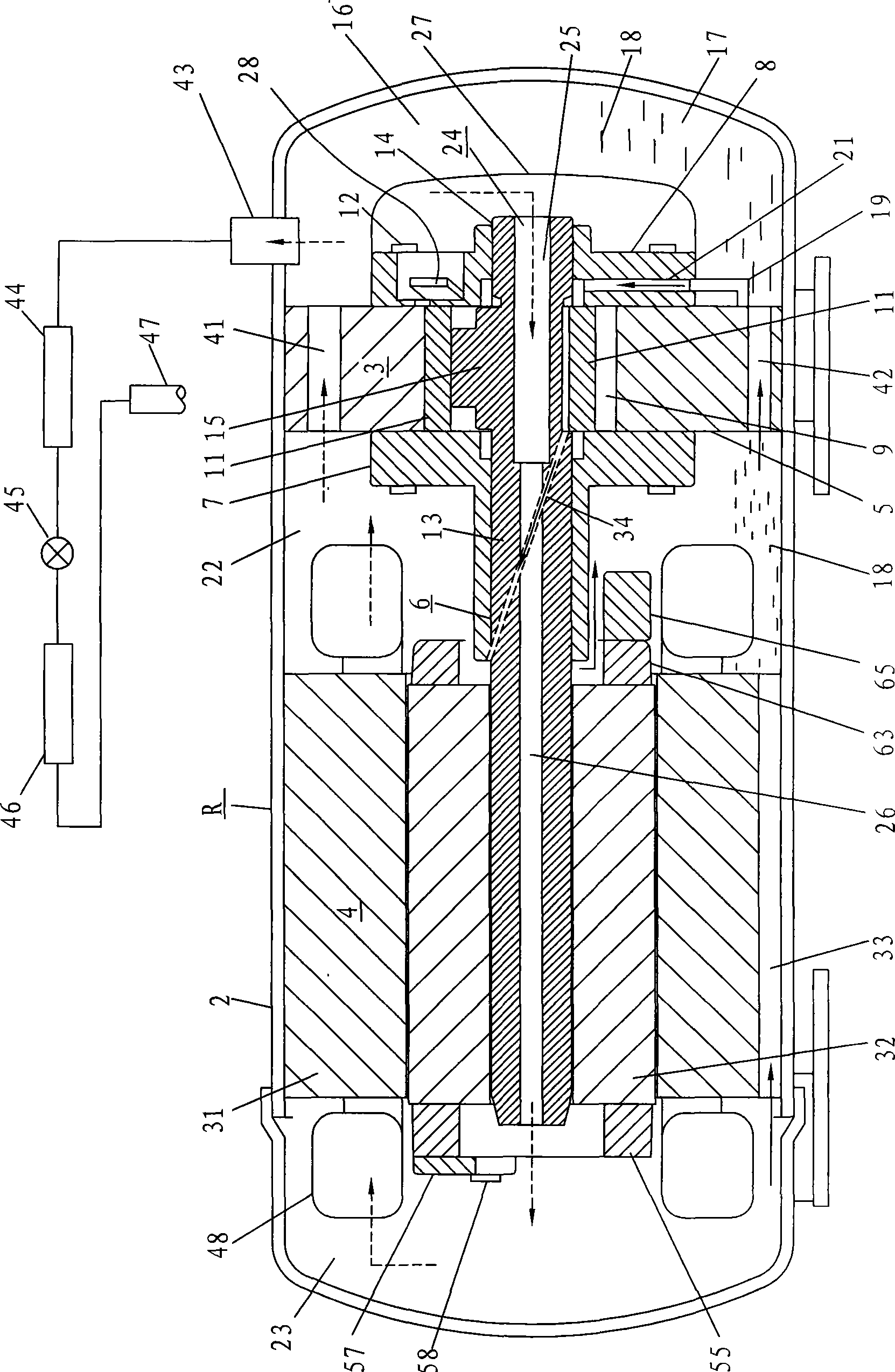

[0021] see figure 1 , the inner diameter of the sealed casing 2 of the horizontal rotary compressor R is fixed and accommodates the compression assembly 3 and the motor 4 . The compression assembly 3 consists of a cylinder 5, a main bearing 7 and an auxiliary bearing 8 that support the crankshaft 6 and are installed on the side of the cylinder 5, a circular piston 11 located at the center of the cylinder 5 and accommodated in the cylinder compression chamber 9, and the outer circumference of the piston. Contact slides (not shown in the figure) form. These components are connected by cylinder screws 12 to form a compression assembly 3 . In addition, the crankshaft 6 is composed of a main shaft 13 , a counter shaft 14 and an eccentric shaft 15 . The piston 11 is installed on the eccentric shaft 15 and revolves in the compression chamber of the cylinder.

[0022] The cylinder outer periphery of the cylinder 5 is in close contact with the inner diameter of the sealed casing 2 w...

no. 2 example

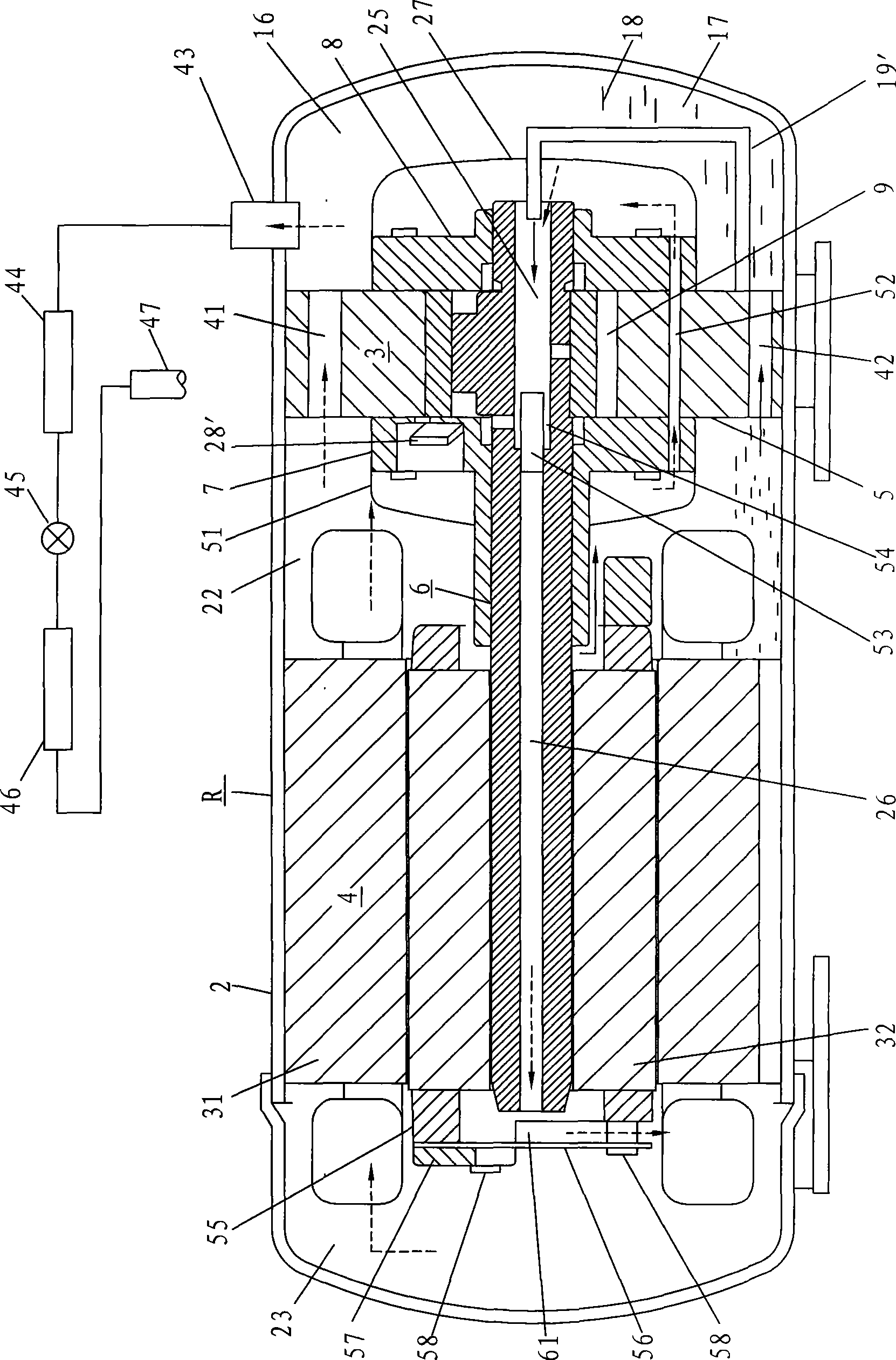

[0036] see figure 2 , the difference between it and the first embodiment will be mainly explained below.

[0037] The main bearing 7 is provided with a second exhaust device 28 ′, which is mounted on the main bearing 7 and covered by a second exhaust muffler 51 . A communication hole 52 is arranged in the cylinder 5, and one end of the communication hole communicates with the second exhaust muffler 51, and the other end communicates with the first exhaust muffler 27, so the high-pressure gas discharged from the cylinder cavity 9 can be exhausted from the second exhaust muffler. The muffler 51 moves into the first exhaust muffler 27 . The other end of the second oil supply pipe 19 ′ connected with the vane pump of the cylinder 5 is installed on the central portion of the first exhaust muffler 27 , and its opening end faces the opening of the first central hole 25 of the crankshaft 6 . Therefore, the oil 18 of the oil sump 17 is supplied into the first center hole 25 of the c...

no. 3 example

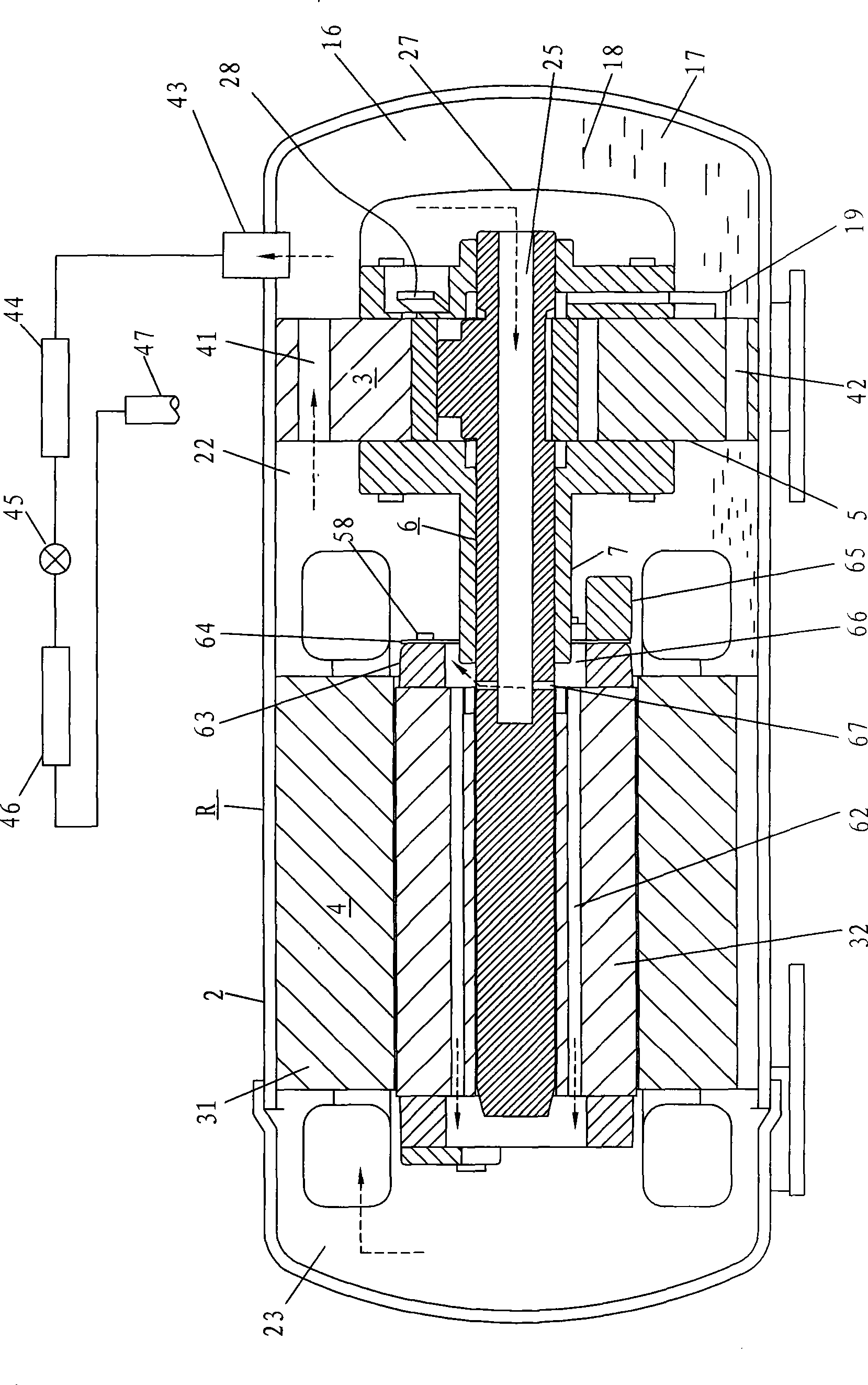

[0045] see image 3 Compared with the first embodiment, the feature of this embodiment is: the high-pressure gas flowing into the first center hole 25 of the crankshaft 6 from the first exhaust muffler 27 flows out to the second through the rotor vent hole 62 penetrating the inside of the rotor 32. Motor chamber 23.

[0046] Like the second embodiment, the first rotor end plate 64 located at the right end of the rotor 32 in the first motor cavity 22 is fixed on the first end ring 63 together with the first balance weight 65 . In order to prevent gas leakage from the gap between the central hole of the first rotor end plate 64 and the outer diameter of the main bearing 7, the gap should be reduced as much as possible. The rotor 32 is located in the inner diameter of the first end ring 63 , and is provided with a plurality of rotor ventilation holes 62 axially penetrating through the rotor 32 . One end of the rotor ventilation hole 62 is opened in the interior of the rotor cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com