Rotary compressor and control method thereof

A technology of rotary compressor and compression mechanism, applied in rotary piston machinery, rotary piston pump, rotary piston/oscillating piston pump components, etc., can solve the problem of oil viscosity drop, parts wear and compressor failure and other problems, to achieve the effect of reducing oil output, low manufacturing cost and control cost, and preventing the decline of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

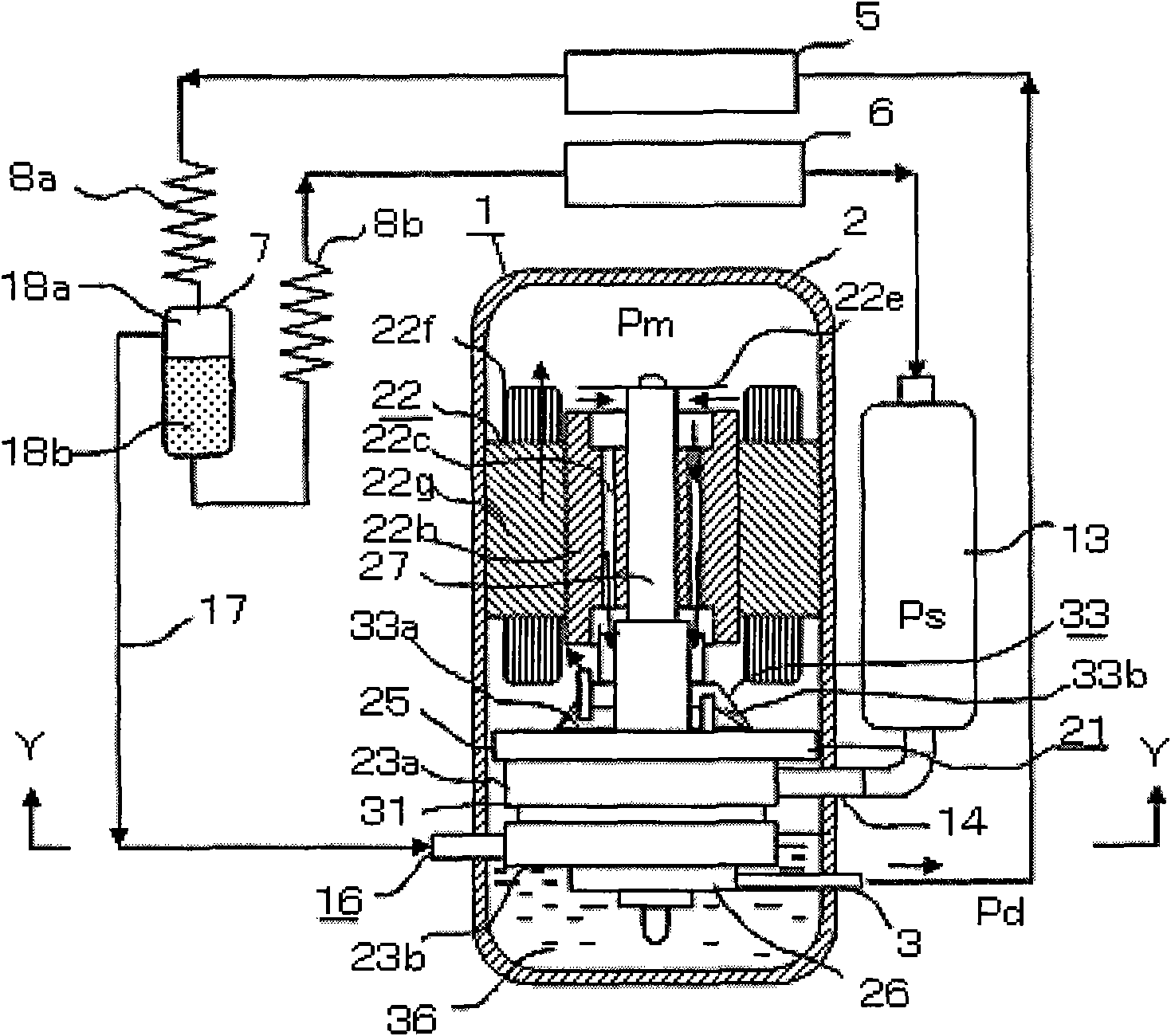

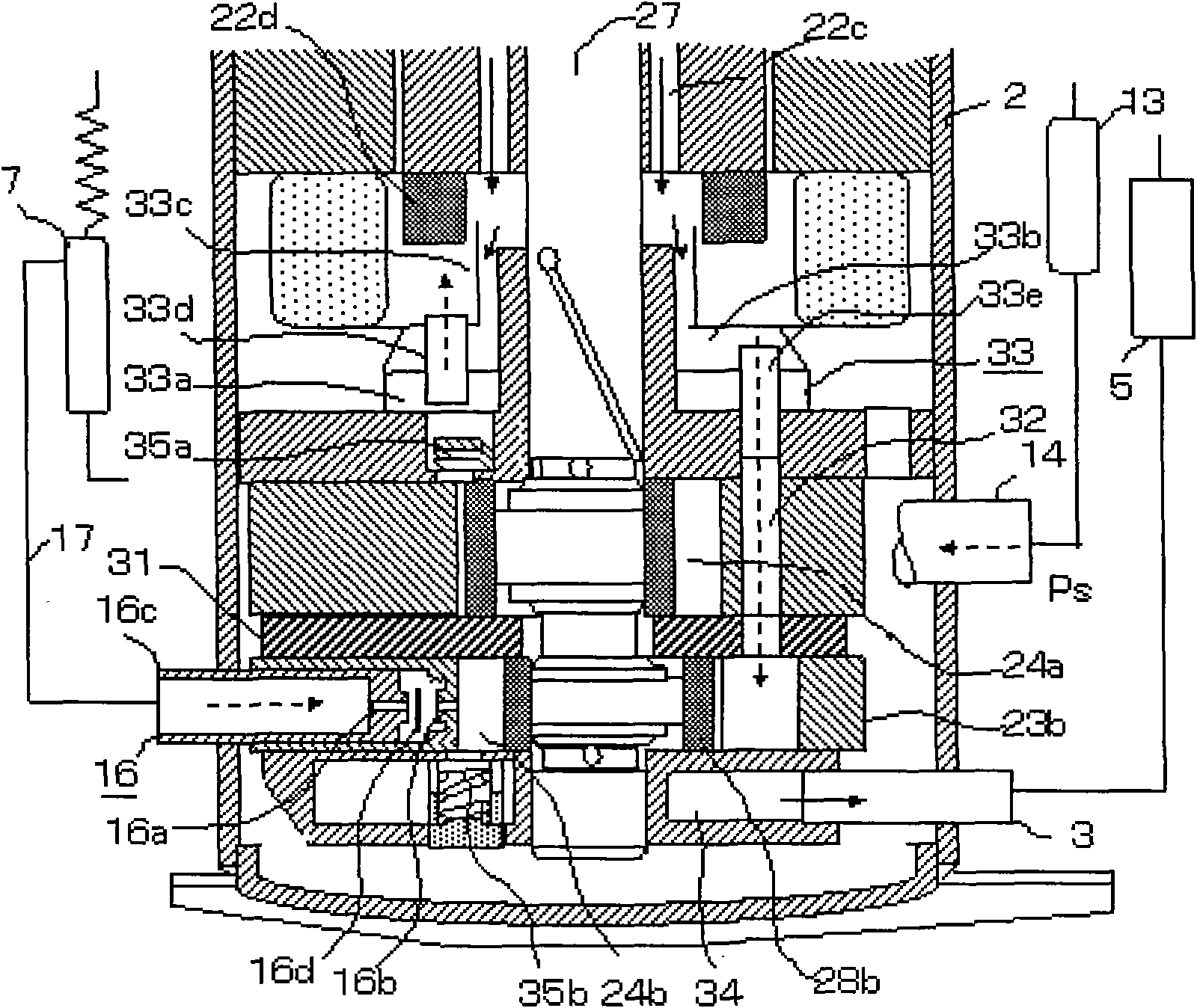

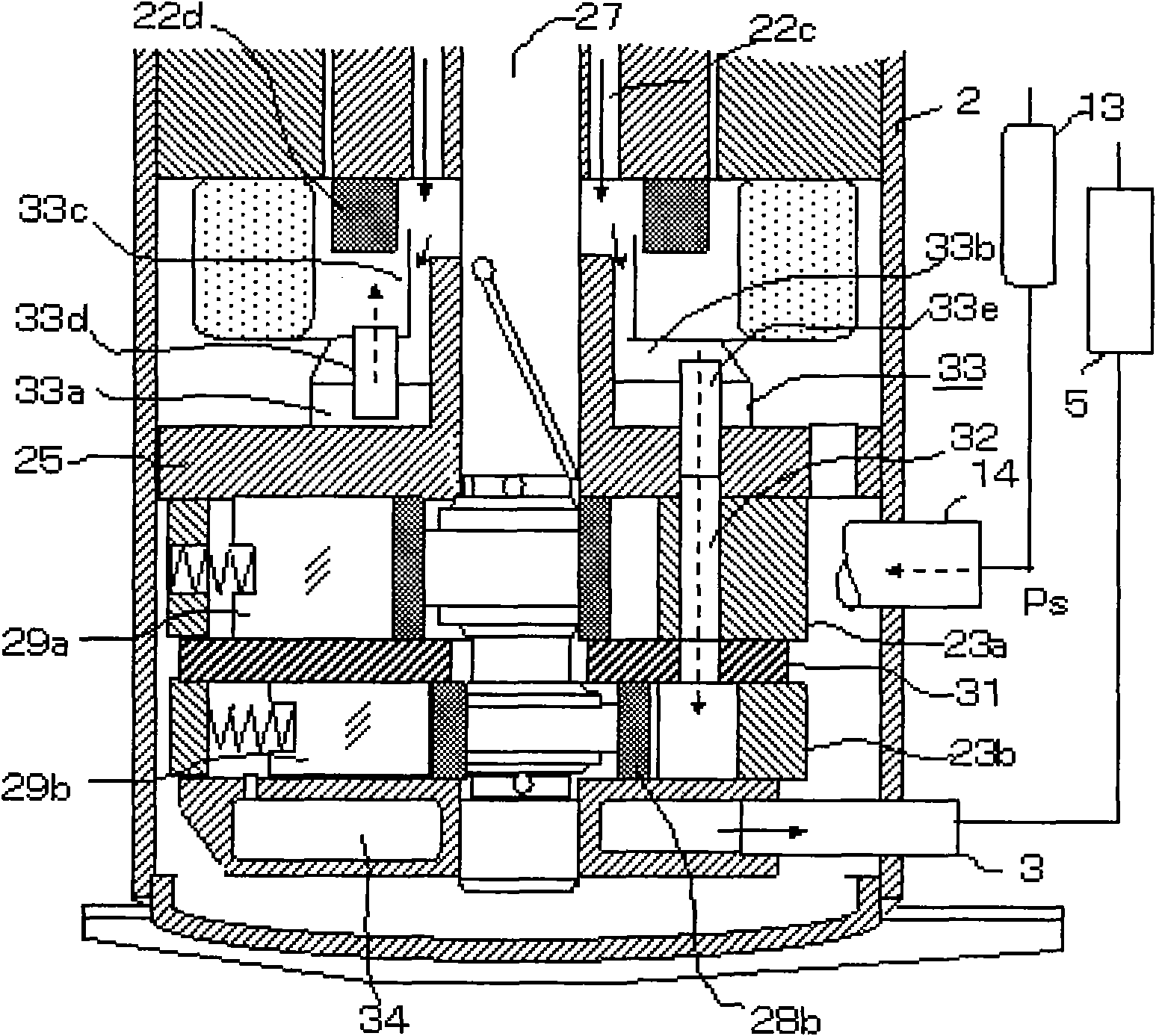

[0029] see figure 1 , is the internal structure of the rotary compressor 1 and the air-conditioning refrigeration cycle equipped with the rotary compressor. figure 2 with image 3 It is a detailed view of the compression mechanism part 21. Figure 4 for figure 1 The Y-Y section diagram in .

[0030] The rotary compressor 1 is composed of a two-stage compression type compression mechanism part 21 mounted on the inner wall of the hermetic casing 2, and a motor part 22 arranged above it.

[0031] The compression mechanism part 21 includes two cylinders: a first cylinder 23a and a second cylinder 23b, a first piston 28a and a second piston 28b housed in the first cylinder compression chamber 24a and the second cylinder compression chamber 24b, and a first slide plate. 29a and the second sliding piece 29b, the main bearing 25 and the sub bearing 26, and the crankshaft 27 supported by the main bearing 25 and the sub bearing 26 are constituted. The intermediate partition 31 san...

no. 2 example

[0067] see Image 6 , by using the U-shaped pipe 41, from the side of the second cylinder 23b suction motor part 22 upper intermediate pressure gas method, can obtain the same effect as the disclosed technology. However, according to this method, the rotor disk cannot be used, so the performance of the oil separator is greatly reduced, and the cost is increased.

[0068] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

[0069] To sum up, the technology disclosed in the present invention is easy to apply the air injection technology related to the rotary compressor to the system, and has great utilization value in the production business.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com