Preparing method for oil-contamination adsorbing material

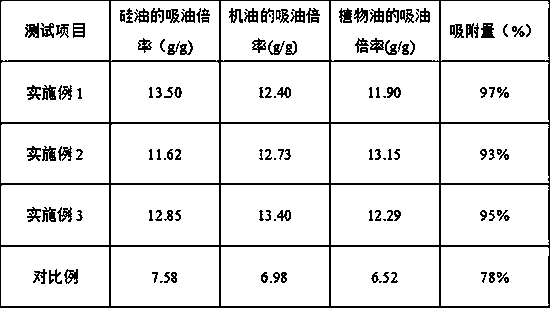

A technology for adsorbing materials and oil stains, which is applied in the field of preparation of oil stain adsorbing materials, which can solve the problems of low adsorption capacity and poor oil-water selectivity, and achieve the effect of fast adsorption and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A preparation method of oil pollution adsorption material, comprising the following steps:

[0016] (1) Take ferric oxide and add 60% ethanol solution by mass ratio of 1:80~90, and then add N-β(aminoethyl)-γ-ammonia with 8~10 times the mass of ferric oxide Propyltrimethoxysilane is mixed, ultrasonicated for 5~10min, heated to 65~70℃, stirred and mixed for 4~5h, cooled to room temperature, collected by magnet, dried to obtain a dry product;

[0017] (2) Take the dry matter and add xylene at a mass ratio of 1:50~60, ultrasonicate for 10~15min, then add toluene diisocyanate with a dry mass of 50~60%, and stir and mix at 35~40°C for 30~40min to obtain a mixture , take the mixture and add polyethylene glycol-1000 in a mass ratio of 90~100:1, stir and mix for 50~60min, to obtain a stirring mixture, take the stirring mixture and add hydroxyl-terminated polybutadiene in a mass ratio of 10~15:2~4, Stir and mix for 1 to 2 h to obtain a stirred mixture A. In parts by mass, stir 1...

Embodiment 1

[0021] Flexible polyurethane foam: density is 0.028g / cm 3 , purchased from Jiangsu Green Raw Materials Co., Ltd.

[0022] A preparation method of oil pollution adsorption material, comprising the following steps:

[0023] (1) Take ferric oxide and add 60% ethanol solution by mass ratio of 1:80, and then add N-β(aminoethyl)-γ-aminopropyltrimethoxy with 8 times the mass of ferric oxide. Silane was mixed, ultrasonicated for 5 min, heated to 65 °C, stirred and mixed for 4 h, cooled to room temperature, collected with a magnet, and dried to obtain a dry product;

[0024] (2) Take the dry matter and add xylene at a mass ratio of 1:50, ultrasonicate for 10 minutes, then add toluene diisocyanate with 50% of the dry matter mass, and stir and mix at 35 ° C for 30 minutes to obtain a mixture, take the mixture and add it at a mass ratio of 90:1 Polyethylene glycol-1000, stir and mix for 50min to obtain a stirred mixture, take the stirring mixture and add hydroxyl-terminated polybutadien...

Embodiment 2

[0028] Flexible polyurethane foam: density is 0.028g / cm 3 , purchased from Jiangsu Green Raw Materials Co., Ltd.

[0029] A preparation method of oil pollution adsorption material, comprising the following steps:

[0030] (1) Take ferric oxide and add 60% ethanol solution by mass ratio of 1:85, and then add N-β(aminoethyl)-γ-aminopropyltrimethoxy with 9 times the mass of ferric oxide. Silane was mixed, ultrasonicated for 8 min, heated to 68°C, stirred and mixed for 4.5 h, cooled to room temperature, collected by magnet, and dried to obtain a dry product;

[0031] (2) Take the dry matter and add xylene at a mass ratio of 1:55, ultrasonicate for 13 minutes, then add toluene diisocyanate with 55% of the dry matter mass, and stir and mix at 38°C for 35 minutes to obtain a mixture. The mixture is added at a mass ratio of 95:1 Polyethylene glycol-1000, stirred and mixed for 55 minutes to obtain a stirred mixture, take the stirred mixture and add hydroxyl-terminated polybutadiene i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com