Drag and noise reducing high-speed train pantograph based on multi-factor coupling bionics

A technology for high-speed trains and pantographs, used in current collectors, motor vehicles, electric vehicles, etc., can solve problems such as difficulty in reducing drag and noise reduction, and achieve the effects of being easy to implement, simple to manufacture, and reducing aerodynamic noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

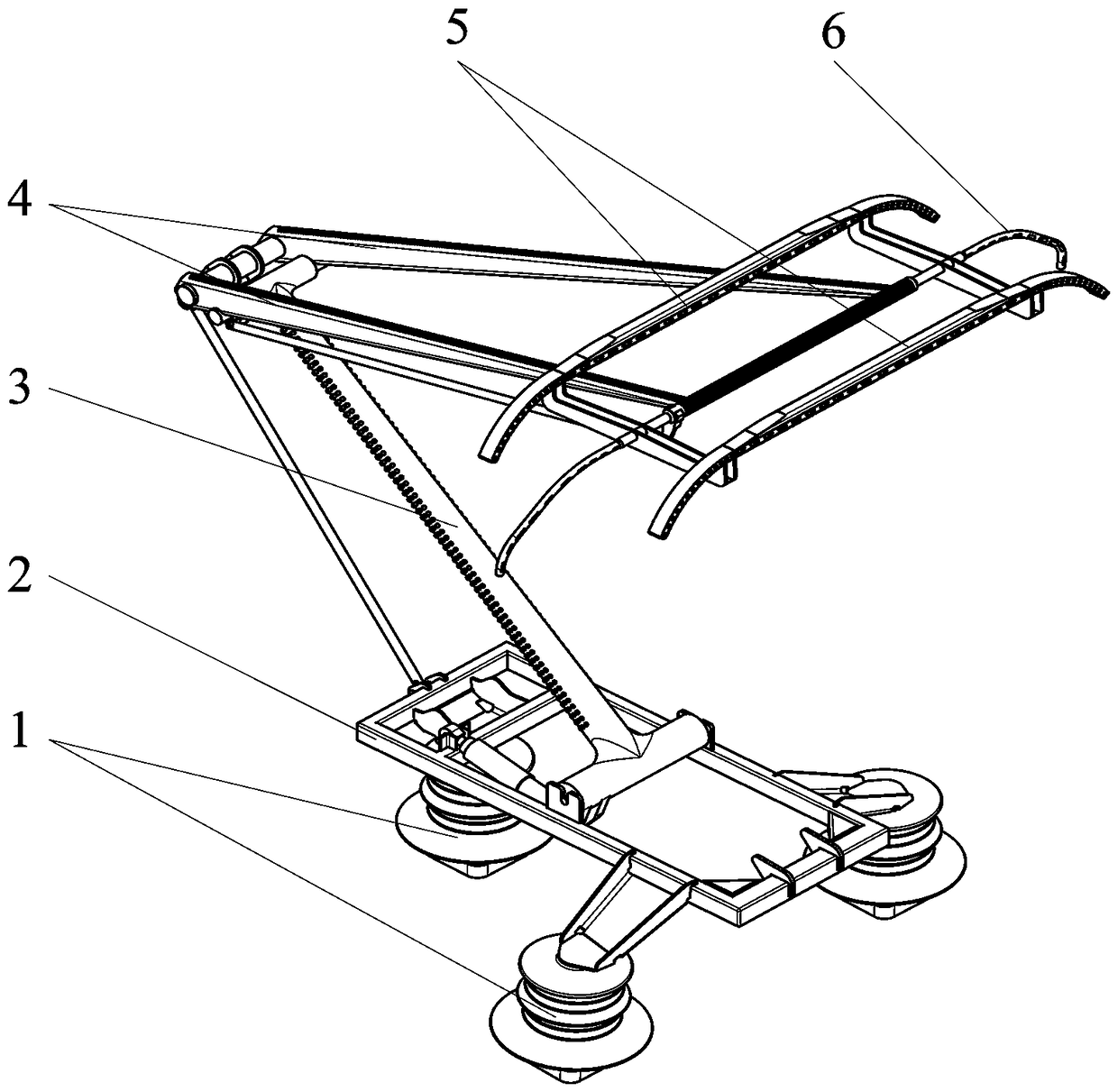

[0023] as attached figure 1 Shown, the present invention mainly is made up of insulator 1, underframe 2, lower arm bar 3, upper arm bar 4, bow head 5, support bar 6.

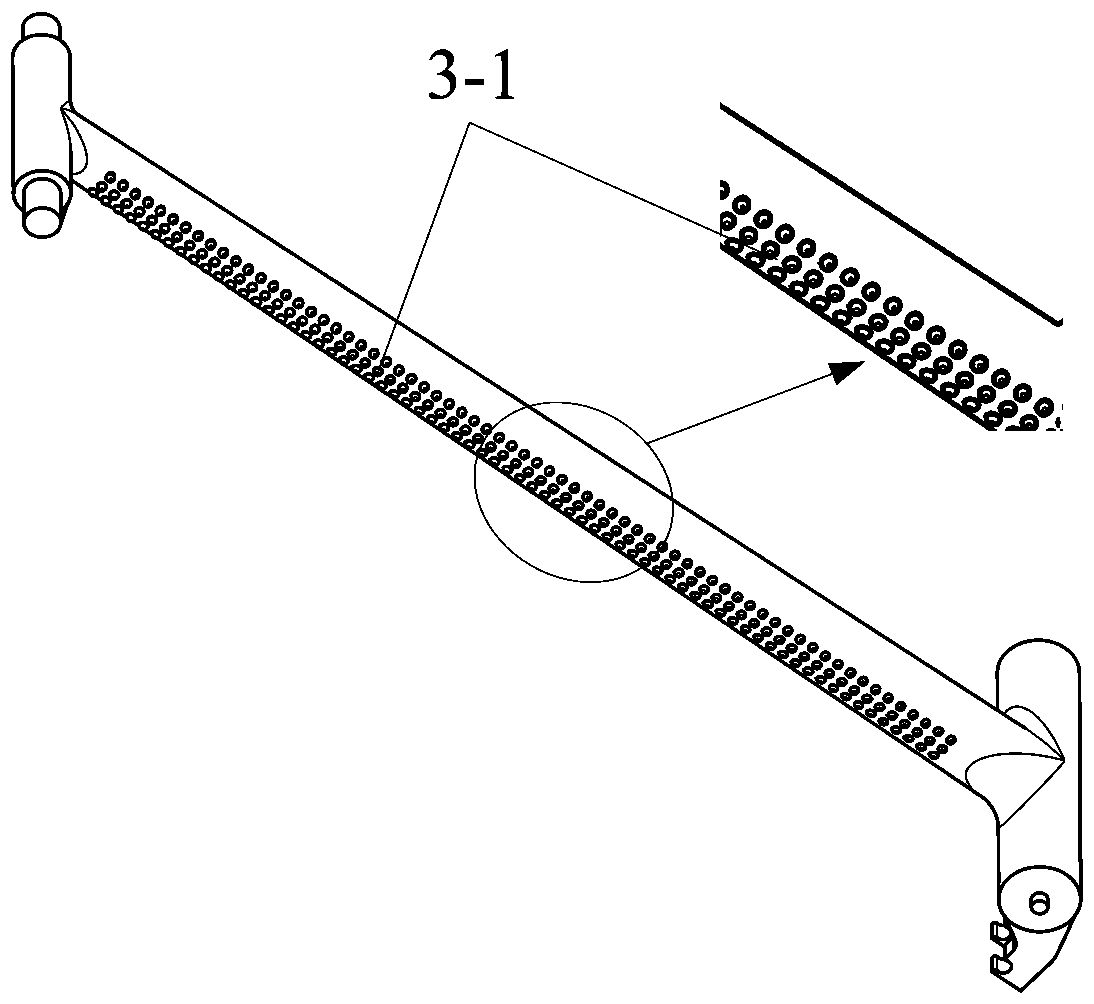

[0024] as attached figure 2 As shown, the lower arm 3 distributes spherical protrusion structures 3-1 on both sides of the flow-around. The spherical protrusion structure 3-1 is distributed on both sides of the incoming flow direction, and has an effect on the flow around the rod; the spherical protrusion structure 3-1 is uniformly distributed in a strip along the shaft axis, with a height of 3-6mm and a diameter of 5-10mm , spacing 5-20mm.

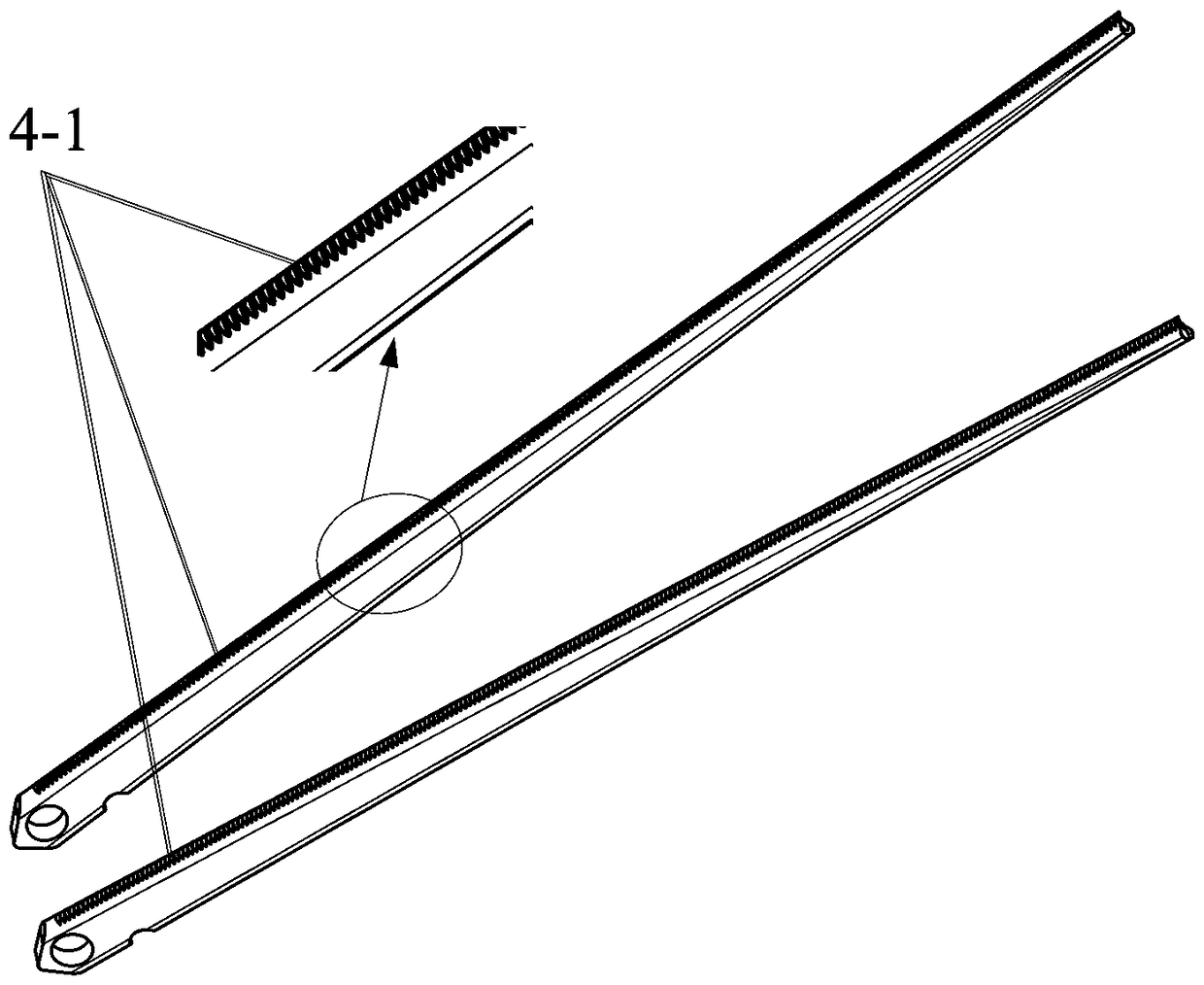

[0025] as attached image 3 As shown, the upper arm 4 is distributed with sawtooth groove structures 4-1 on the windward side surface, which rectifies the incoming flow; the sawtooth groove structures 4-1 are closely arranged along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com