Reinforced hollow fiber membrane, preparation method and device

A preparation device and fiber membrane technology, applied in the field of organic hollow fiber membrane preparation, can solve problems such as industrialization difficulties, polytetrafluoroethylene flat membrane preparation and complicated winding process, etc., to improve the application field, increase the effective membrane area, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

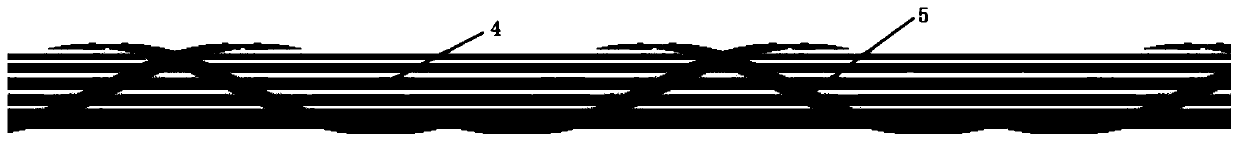

[0069] The preparation method of the present invention allows the polymer in the core cavity of the hollow fiber membrane to infiltrate into the membrane sublayer during the one-time molding process of the hollow fiber membrane, so that a mixture of PVDF and polymer is formed under the membrane sublayer. The bottom layer, the toughening polymer here, is obtained by the cross-linking reaction of polymerizable reactants and cross-linking agents. This polymer penetrates into the PVDF on the inner surface of the PVDF hollow fiber membrane to form a single The bottom layer is a bottom layer mixed with PVDF and polymer, which can improve the longitudinal tensile strength of the PVDF hollow fiber membrane. From the perspective of the cross-section, the bottom layer of the surface skin layer, membrane sublayer, PVDF and polymer is formed from the outside to the inside, because the surface skin layer and the membrane sublayer play a role of separation, and it is in the phase separation ...

Embodiment 1

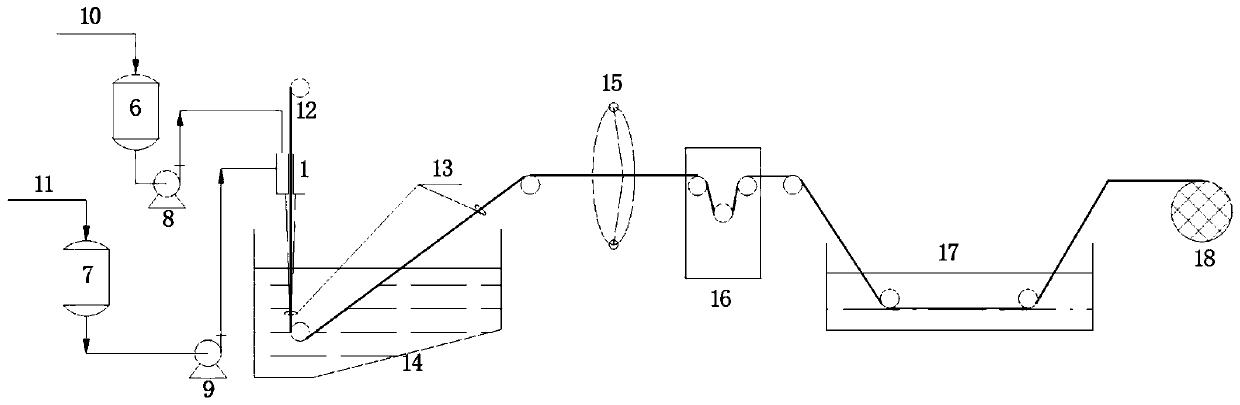

[0085] 1) Preparation of casting solution: Weigh 15% PVDF, 18% PVP-K90, 2% PEG-200, 75% DMAC, and stir in a stirring tank for 4-6 hours in a water bath at 80°C , dissolved evenly, vacuum defoaming to obtain polyvinylidene fluoride casting solution.

[0086] 2) Squeeze the casting liquid and core liquid into the spinneret through the metering pump, and at the same time, the braided rope also enters the spinneret. Driven by the winding roller of the solidification tank, the primary film filament and the braided rope enter the coagulation bath together, and wait for the primary When the membrane filament is solidified in the coagulation bath, it becomes a bundle with the braided rope under the action of the ceramic ring.

[0087] 3) Under the action of three rollers, the film bundle passes through the winding device. The winding device mainly consists of a ring. There is a rubber ring on the outside of the ring, and the ring is vertically fixed on a flat plate, which contains 4...

Embodiment 2

[0092] 1) Preparation of casting solution: weigh 20% PVDF, 18% PVP-K30, 2% PEG-200, 75% DMAC, and stir in a stirring tank for 4-6 hours in a water bath at 80°C , dissolved evenly, vacuum defoaming to obtain polyvinylidene fluoride casting solution.

[0093] 2) Squeeze the casting liquid and core liquid into the spinneret through the metering pump, and at the same time, the braided rope also enters the spinneret. Driven by the winding roller of the solidification tank, the primary film filament and the braided rope enter the coagulation bath together, and wait for the primary When the membrane filament is solidified in the coagulation bath, it becomes a bundle with the braided rope under the action of the ceramic ring.

[0094] 3) Under the action of the three rollers, the film bundle passes through the winding device to bundle the film filaments into a bundle.

[0095] 4) After the rinsing bath, the wire is collected by the wire-receiving wheel, and then cut into bundles of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com