Clam meat processing production line

A production line and technology for clam meat, applied in the field of clam meat processing equipment, can solve the problems of clam shells being difficult to find, clam shells embedded in clam meat, affecting the quality of clam meat processing, etc., and achieving the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the drawings.

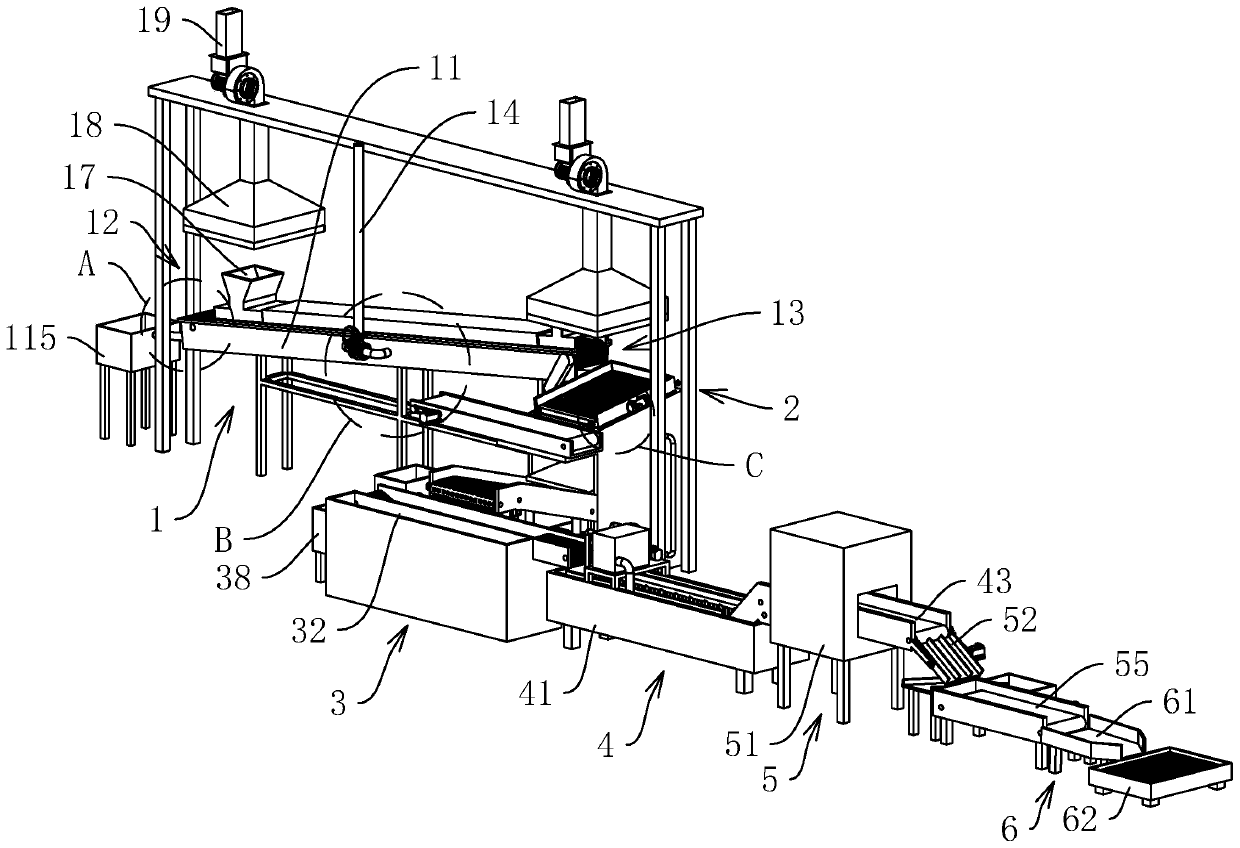

[0050] Reference figure 1 , Is a clam meat processing production line disclosed in the present invention, including a cooking machine 1, a clam clam shell separation device 2, a clam meat bleaching and salting machine 3, a bubble machine 4, an X-ray screening machine 5 and a receiving device 6 arranged in sequence.

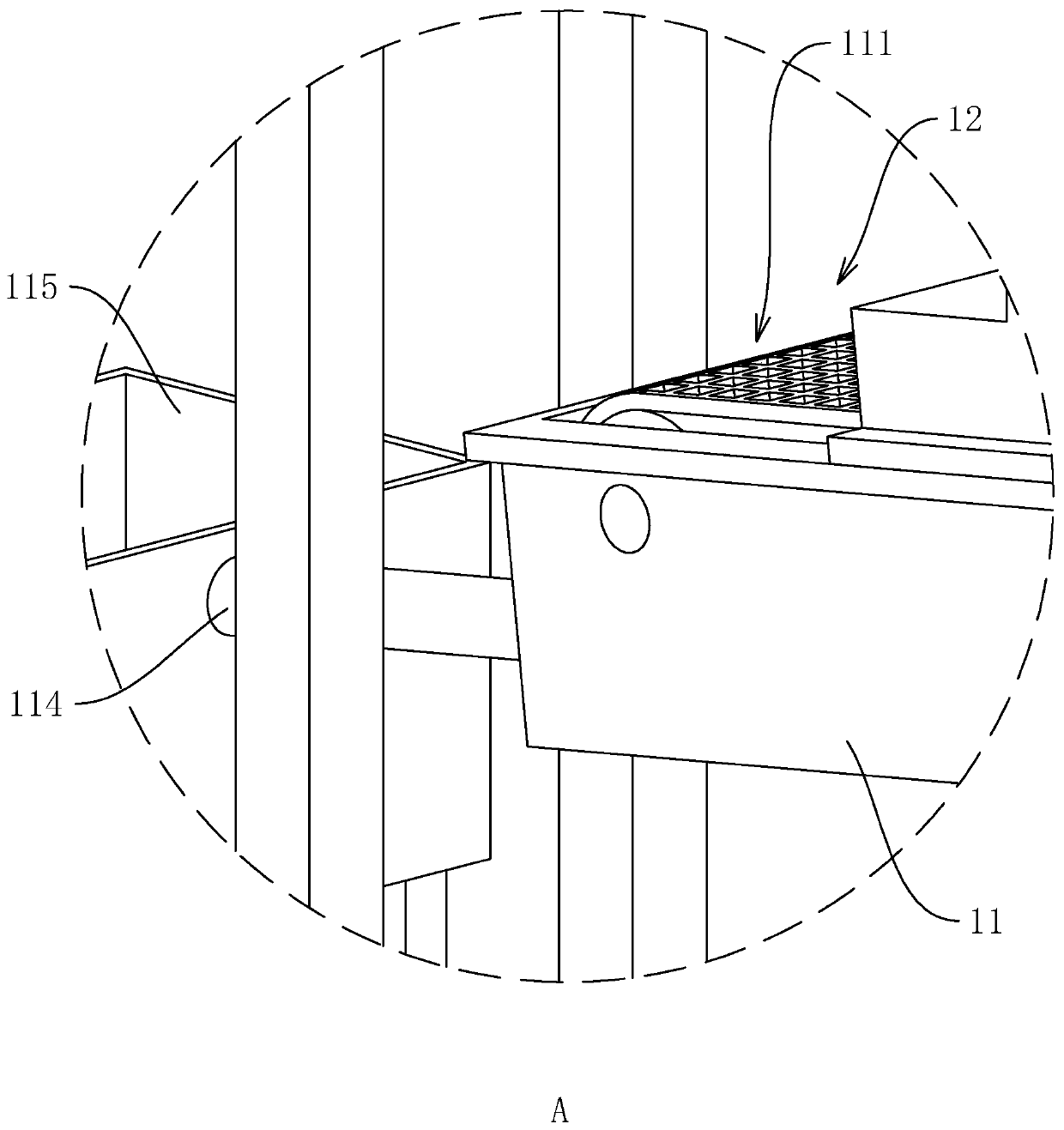

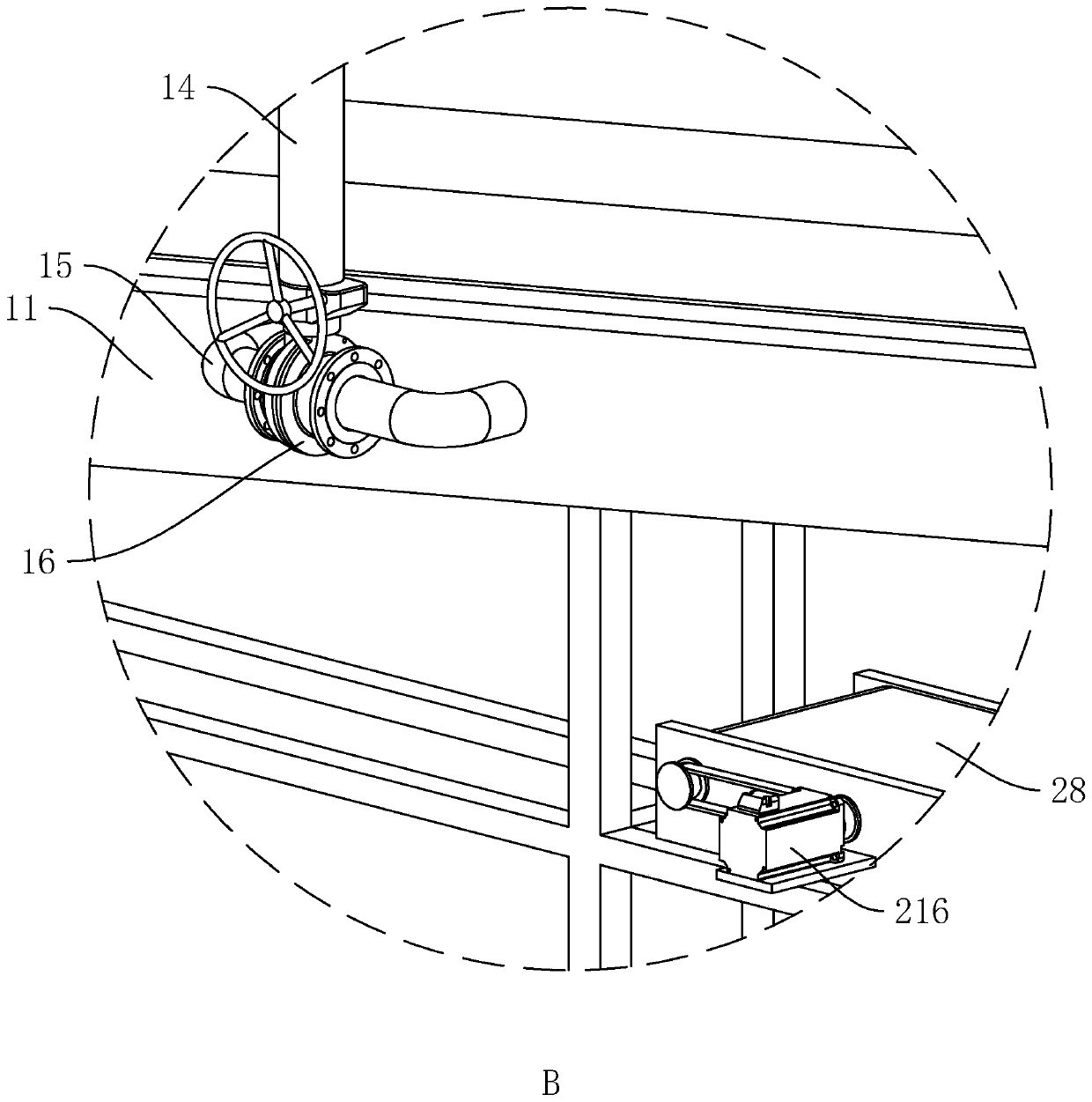

[0051] Reference figure 1 with image 3 The cooking machine 1 includes a cooking machine body 11, an inlet 12 and an outlet 13 provided at both ends of the cooking machine body 11 along its length direction, and a steam delivery pipe 14 is provided on the cooking machine body 11 and in the middle part thereof. The delivery pipe 14 is arranged in a vertical direction. One end of the steam delivery pipe 14 close to the digester body 11 is provided with an installation pipe 15 and communicates with the steam delivery pipe 14, and the other end of the steam delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com