Domestic garbage incinerator and method for treating domestic garbage

A domestic waste incineration and furnace bottom technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as complex components and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

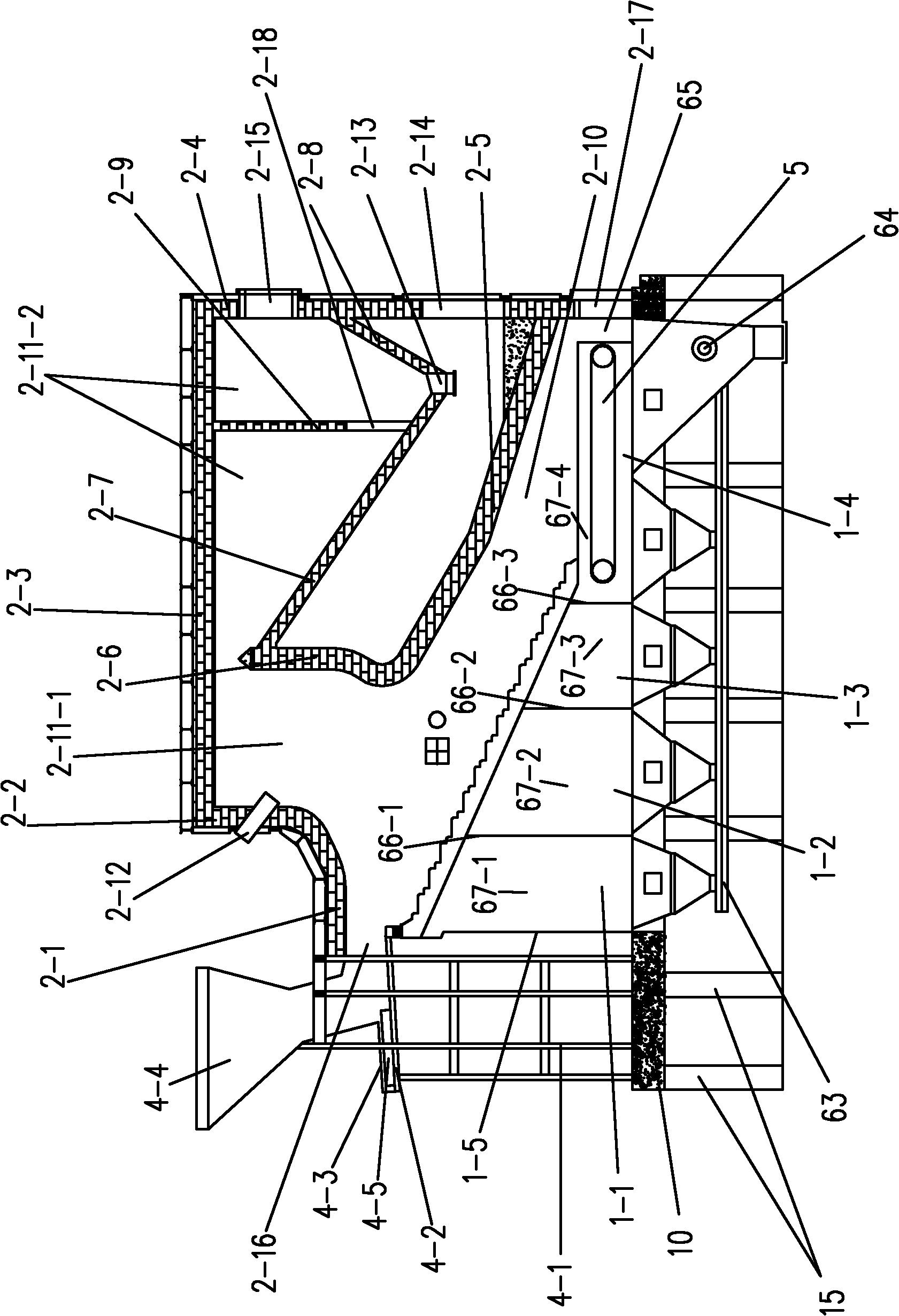

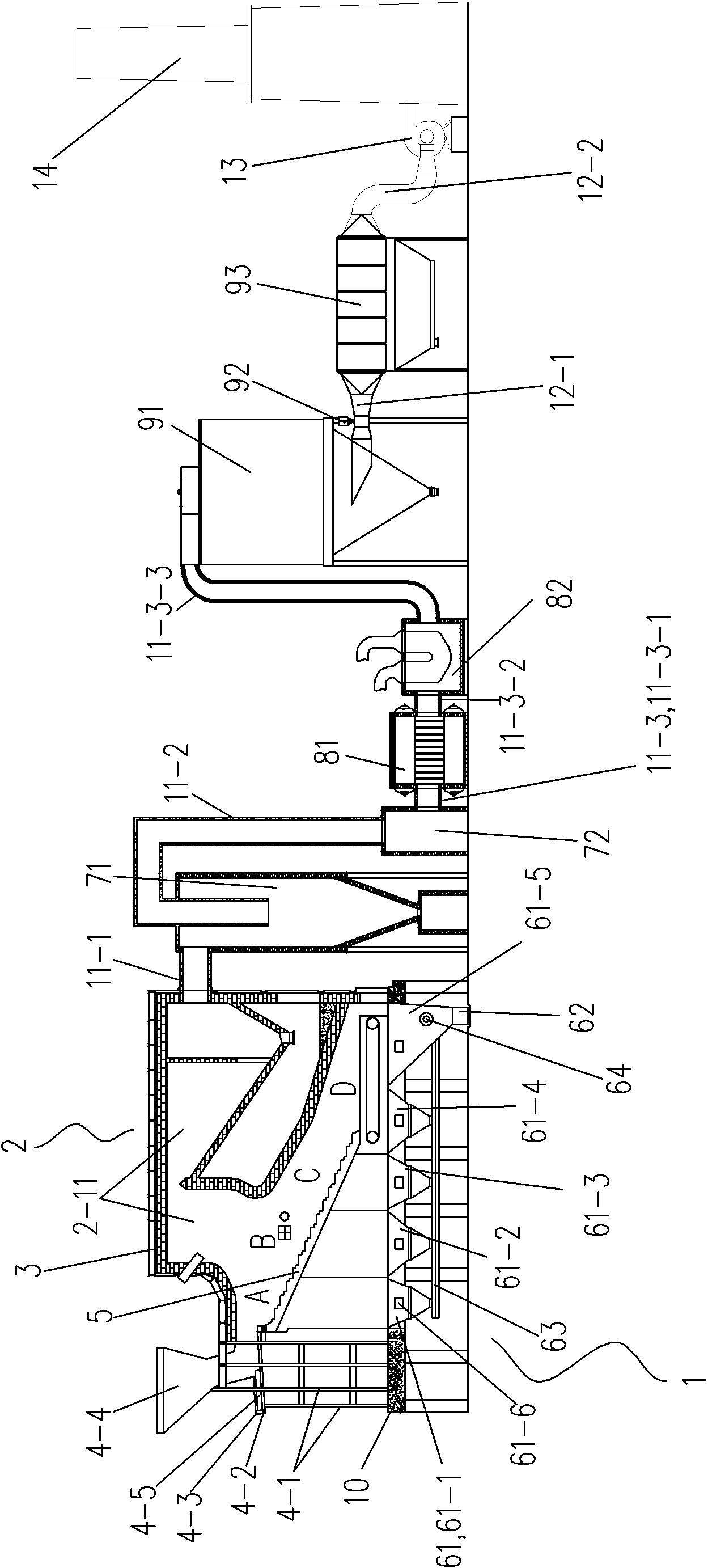

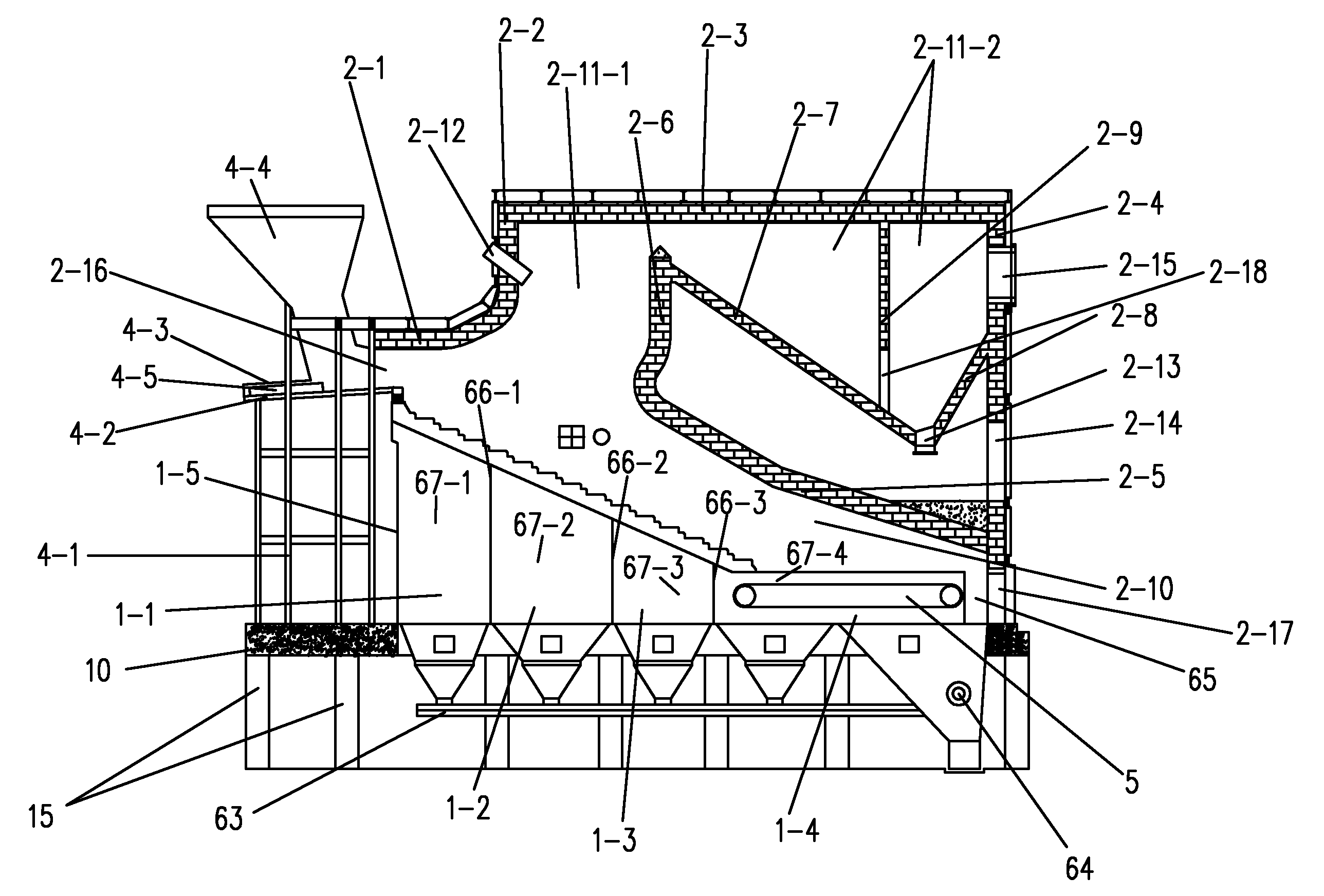

[0045] See figure 1 and figure 2 , the domestic waste incinerator of the present invention comprises a foundation base 10, a furnace base 1, a furnace body 2, a furnace frame 3, a feeding device 4, a combined grate mechanism 5, a bottom ash hopper 61, a slag hopper 62, a Ash mechanism 63, slag breaking mechanism 64, slag falling channel 65, air storehouse plate 66 and hot and cold air device, domestic waste incinerator of the present invention is also equipped with incineration intelligent control circuit in addition.

[0046] The foundation base 10 is formed by pouring concrete, and the foundation base 10 is in the shape of a square frame, and is supported by a support column 15 located on the ground. The furnace base 1 includes a front seat, a rear seat and a left end sealing plate 1-5. Both the front seat and the rear seat are composed of respective left section box girder 1-1, first middle section box girder 1-2, second middle section box girder 1-3 and right section bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com