Direct liquefaction process of coal mixed with high temperature coal tar

A technology for direct liquefaction of high-temperature coal tar and coal is applied in the petroleum industry, hydrotreating process, preparation of liquid hydrocarbon mixtures, etc., and can solve the problems of low production efficiency and low production efficiency of the two-stage hydrogenated coal direct liquefaction process, Achieve the effect of reducing nitrogen content, improving conversion rate and low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

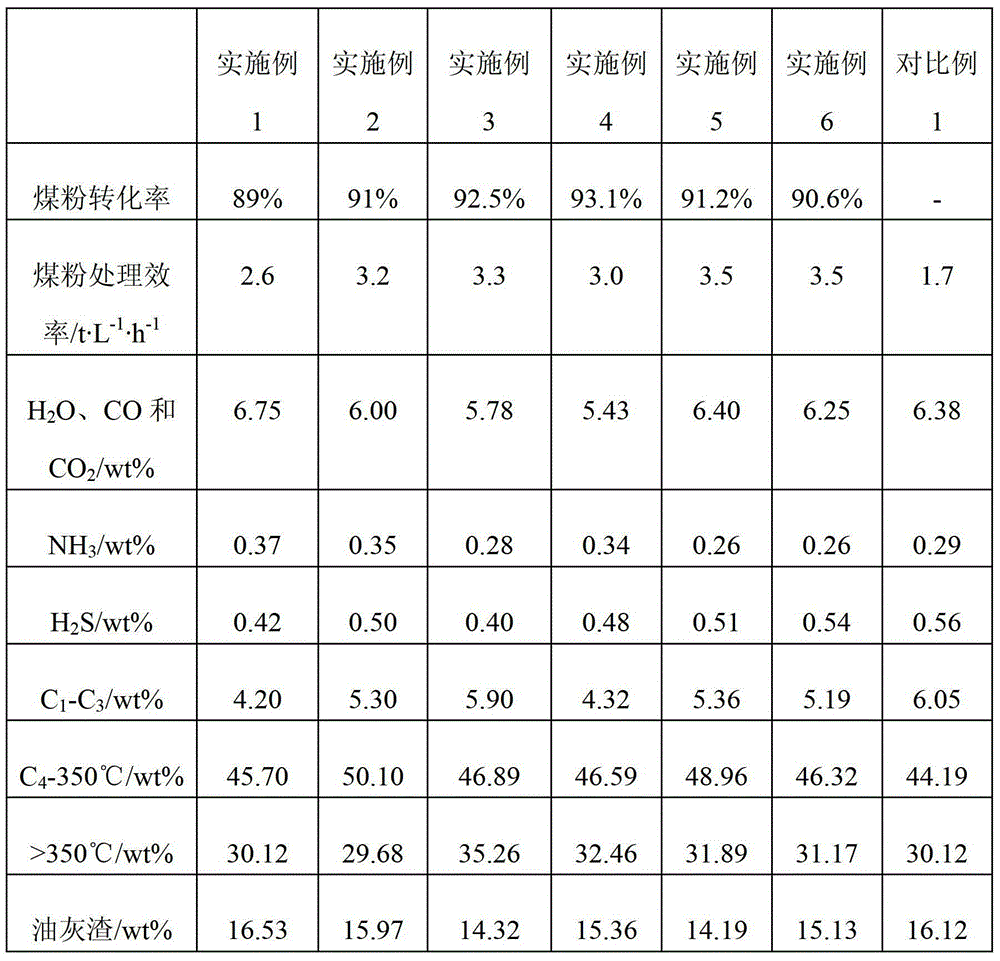

Embodiment 1

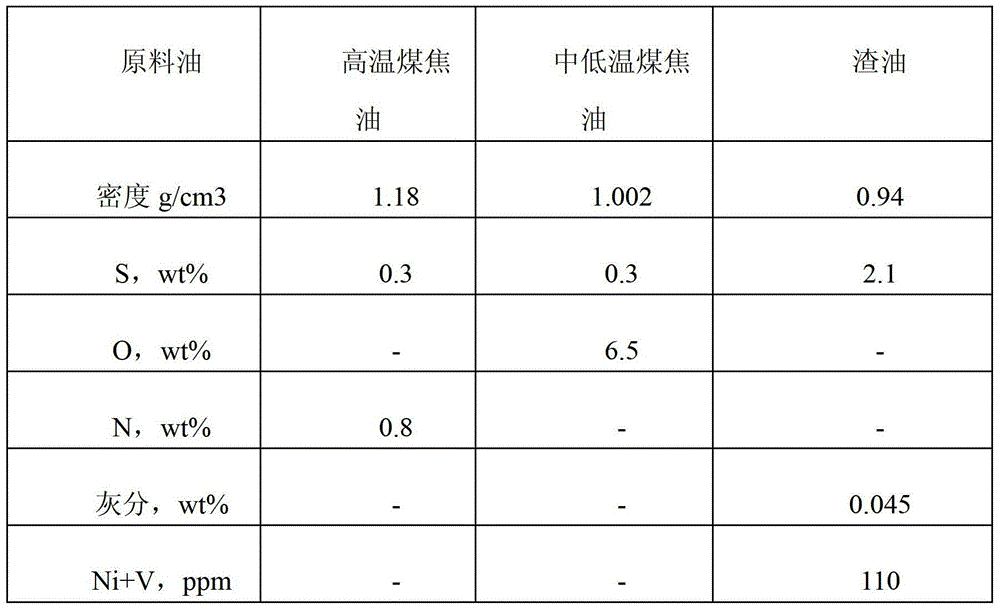

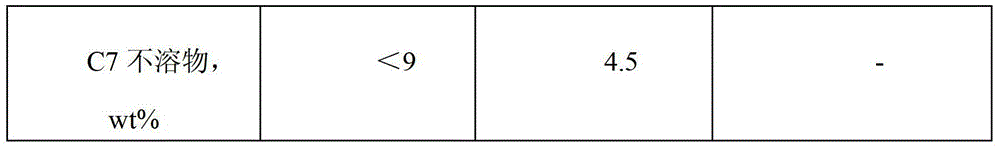

[0028] (1) Purify the high-temperature coal tar by dehydrating and removing impurities in the purification treatment equipment. The water content of the dehydrated high-temperature coal tar is less than 0.5wt%; the purified high-temperature coal tar is subjected to atmospheric distillation and cut into 350°C heavy oil fraction;

[0029] (2) Bituminous coal pulverized coal and heavy oil fraction >350°C are mixed to form coal oil slurry with a coal powder content of 30wt%, and 0.03wt% iron sulfide catalyst is mixed into the oil coal slurry and sent to 10L of first-stage reaction together with hydrogen. The reaction in the vessel, the reaction pressure is 15MPa, the hydrogen partial pressure is 10MPa, the reaction temperature is 420℃, and the volume space velocity is 0.25h -1 , the reaction finishes to obtain the first-order reaction product;

[0030] (3) The first-stage reaction product is sent to the upper part of the 8L second-stage reactor, the gas phase components in the firs...

Embodiment 2

[0032] (1) Purify the high-temperature coal tar by dehydration and impurity removal in the purification treatment equipment. The water content of the high-temperature coal tar after dehydration is less than 0.5wt%; the purified high-temperature coal tar is subjected to atmospheric distillation and cut into pieces. Light oil fractions 350°C;

[0033] (2) Bituminous coal pulverized coal and anthracite pulverized coal in a weight ratio of 1:1 are mixed with heavy oil fractions >350°C to form an oil-coal slurry with a total coal powder content of 50 wt%, and 5 wt% ZnCl is mixed into the oil-coal slurry 2 / S catalyst (in which ZnCl 2 It is an active component, S is an auxiliary agent, and the atomic ratio of S and Zn is 0.5) and then sent to a 10L primary reactor together with hydrogen for reaction. The reaction pressure is 20MPa, the hydrogen partial pressure is 15MPa, and the reaction temperature is 460℃ , the volumetric air velocity is 0.25h -1 , the reaction finishes to obtai...

Embodiment 3

[0037] (1) Purify the mixture of high-temperature coal tar, high-sulfur heavy residual oil, and high-heavy-metal-content heavy residual oil in purification treatment equipment, wherein the high-temperature coal tar, high-sulfur heavy residual oil, high-temperature coal tar, high-sulfur heavy The mass ratio of heavy metal content to heavy residual oil is 5:0.5:0.5, and the water content of the dehydrated mixture is less than 0.5wt%; the purified oil is subjected to atmospheric distillation, and cut into light oil fractions of 350 ℃ heavy oil fraction;

[0038] (2) Mix sub-bituminous coal pulverized coal with heavy oil fraction > 350°C to form an oil-coal slurry with a coal powder content of 40wt%, and mix 2wt% of iron-molybdenum metal catalyst (wherein the atomic ratio of iron and molybdenum) into the oil-coal slurry. 50), hydrogen and heated to 100°C, mixed together and sent to a 10L primary reactor from the bottom for reaction, the reaction pressure was 18MPa, the hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com