Flash device and heat pump device including same

A technology of heat pump device and flasher, which is applied in the field of heat pumps, and can solve problems such as large changes in compressor pressure ratio, large ranges of changes in evaporation temperature and condensation temperature, and excessive discharge temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The purpose of this specific embodiment is to provide a flasher, which can ensure that the heat pump device operates in an optimal state, thereby improving the reliability of the heat pump system. The purpose of this specific embodiment is also to provide a heat pump device including the above-mentioned flasher.

[0041] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

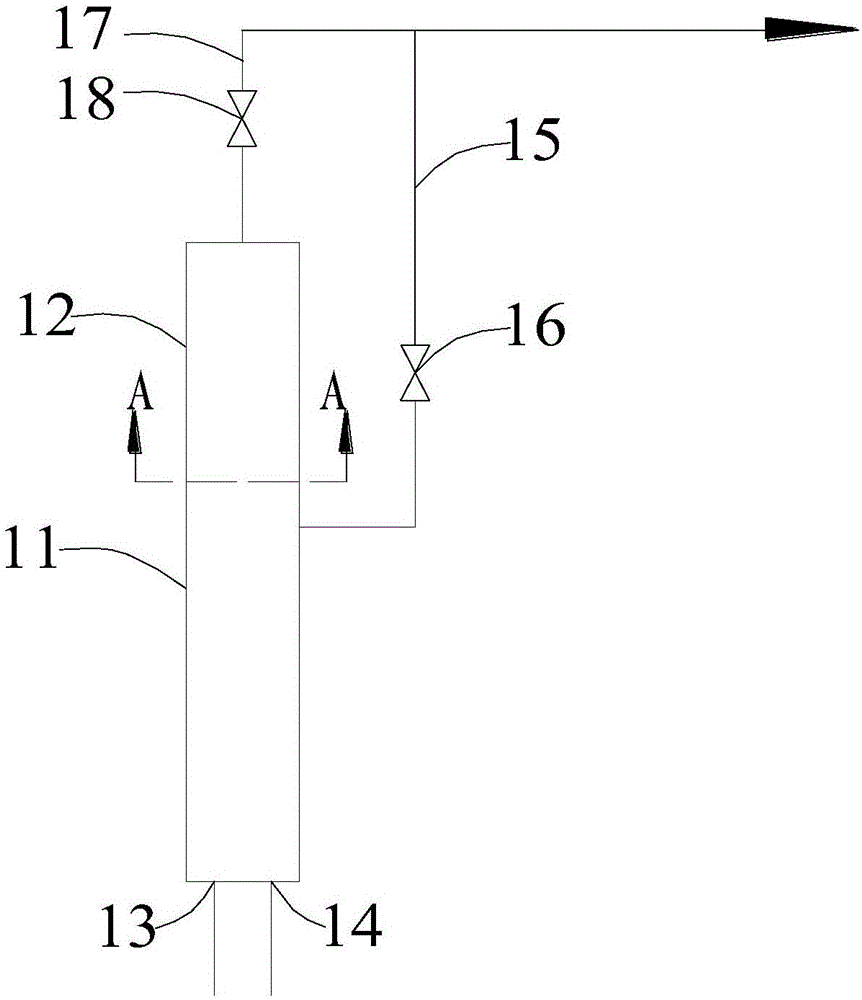

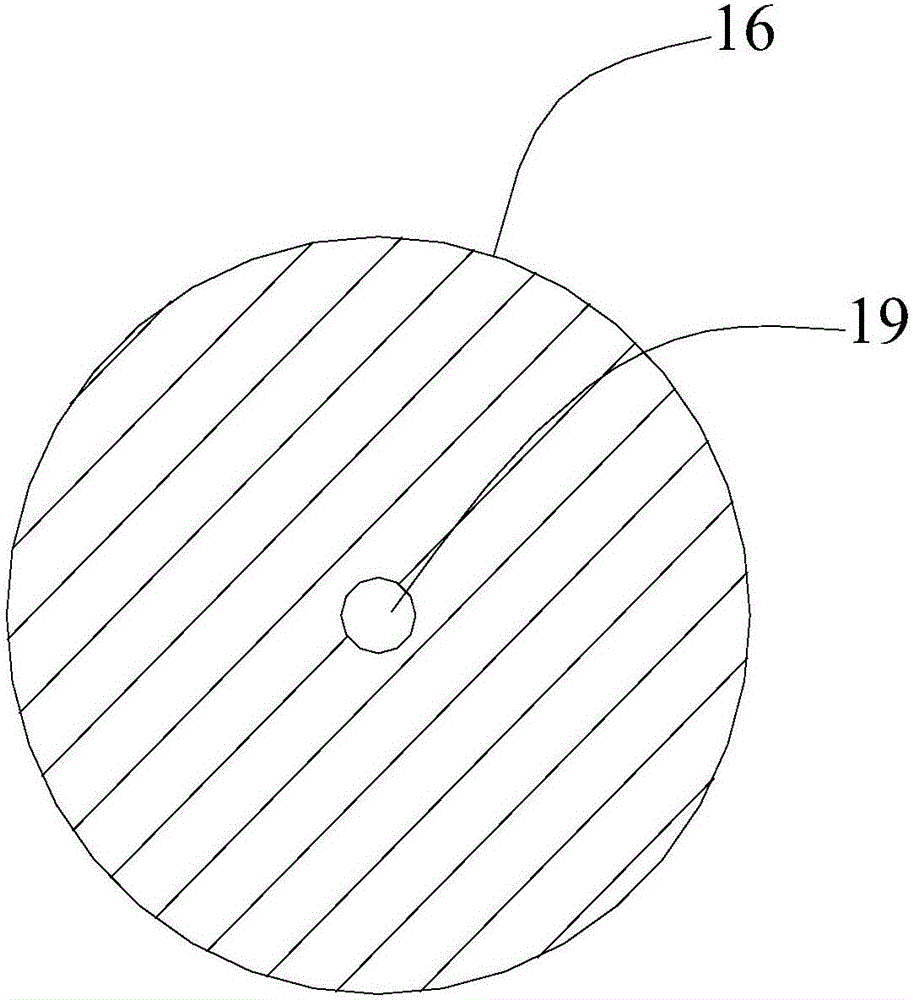

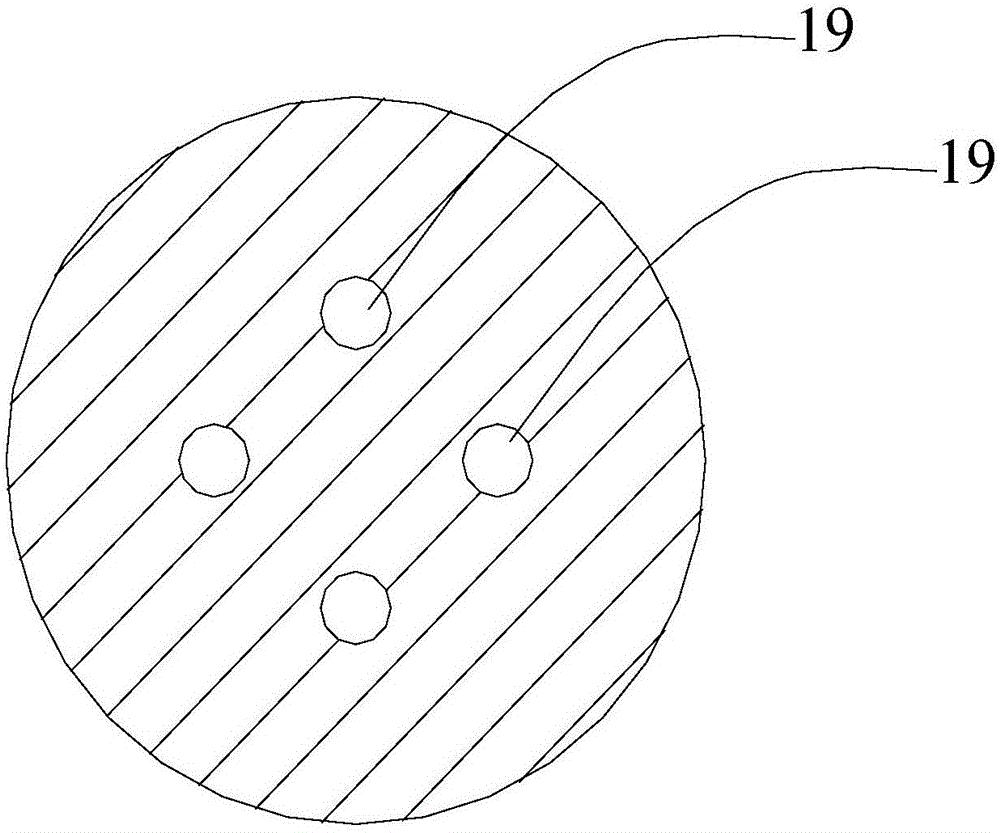

[0042] Please refer to Figure 1-Figure 13 , a flasher provided in this specific embodiment includes a first cavity 11 and a second cavity 12 , wherein the first cavity 11 is provided with a two-phase refrigerant inlet 13 and a liquid refrigerant outlet 14 . For example, when the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com