Knitting method for tubular knitted fabric and tubular knitted fabric

A knitted fabric, tubular technology, applied in the field of knitting of tubular knitted fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

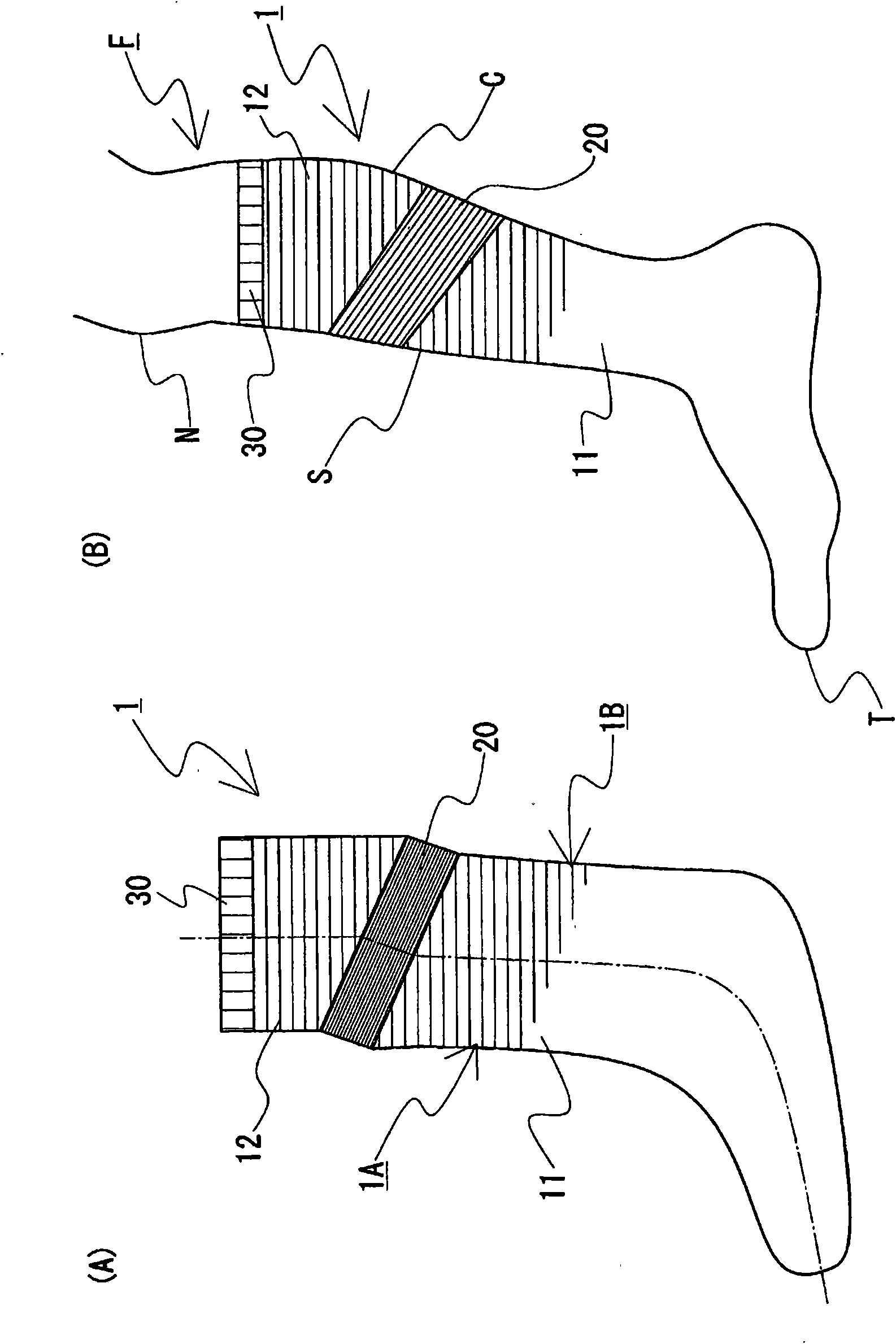

[0048] figure 1 (A) is a plan view of the sock, which is seen from the side corresponding to the position of the ankle during wearing. in addition, figure 1 (B) is a schematic diagram of a state of wearing socks seen from the ankle side.

[0049] As shown in the two figures, the sock 1 has: a lower knitted portion 11 covering the halfway from the toe T of the wearer’s foot F to the calf C and the calf S; an upper knitted portion 12 covering the calf C and the lower leg S; The upper part of the lower leg S; the ring-shaped elastic knitted part 20, which is arranged between these knitted parts 11, 12. The lower knit portion 11 corresponds to the first base knit portion, and the upper knit portion 12 corresponds to the second base knit portion.

[0050]Such as figure 1 As shown in (A), the elastic knit portion 20 does not extend coaxially with the lower knit portion 11 and the upper knit portion 12 , but is provided in an inclined axial direction with respect to the axial dir...

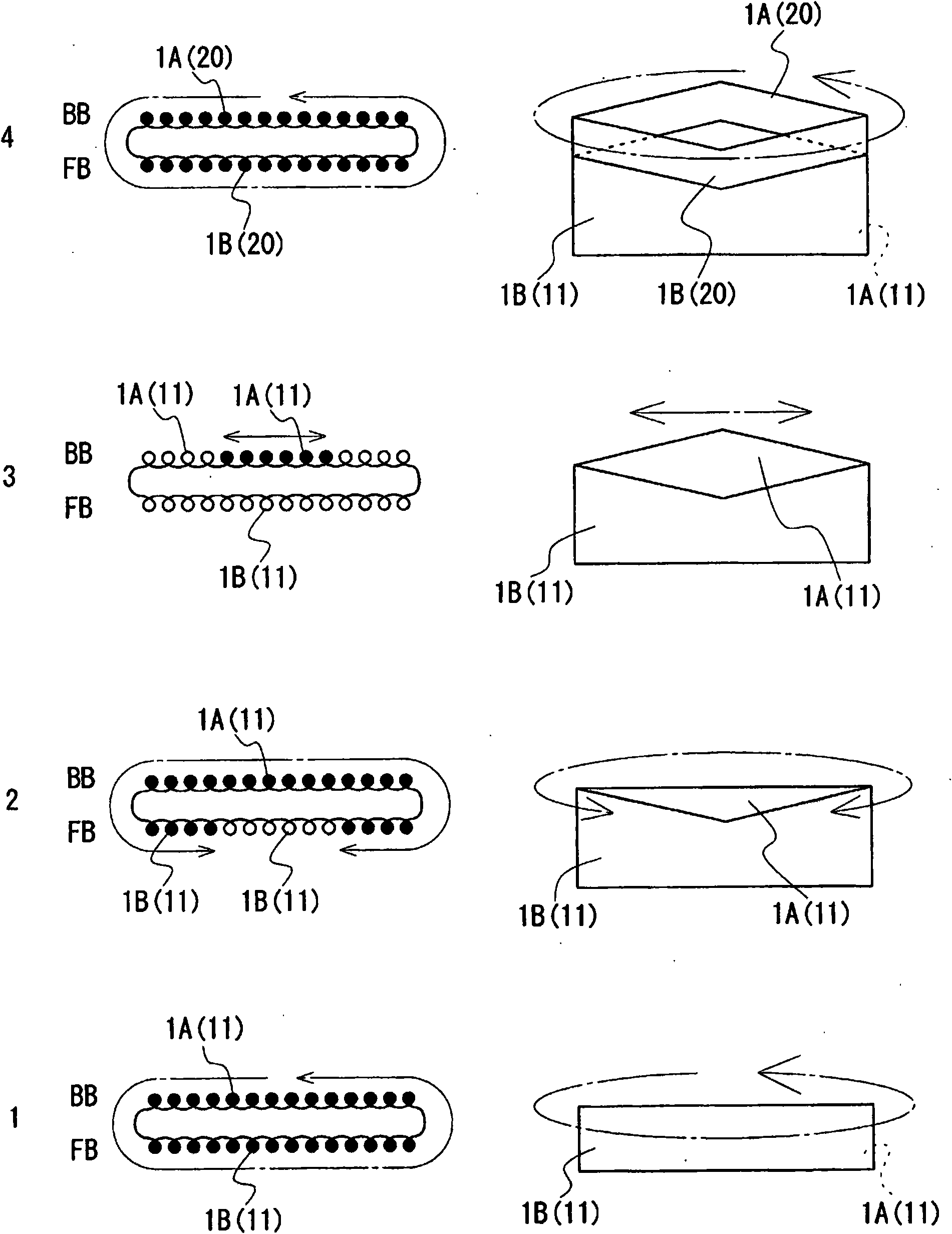

Embodiment 1

[0067] [Modification of Embodiment 1]

[0068] As a modified example of Embodiment 1, a method of knitting a tubular knitted product in which the direction in which the elastic knit portion extends obliquely is changed in the nail side knit portion and the back side knit portion will be described.

[0069] First, a method of knitting a sock in which the elastic knit portion forms a mountain shape when viewed from the ankle side, that is, a sock in which the elastic knit portion forms a valley shape when the sock is viewed from the front will be described. When knitting the elastic knit part of Yamagata, in figure 2 In step 2 of , similarly to the back side knitted portion 1B, the nail side knitted portion 1A also reduces stitches from the center of the knitted fabric to form the lower side knitted portion 11 . Furthermore, similarly to Embodiment 1, an elastic knit part 20 having the same number of stitches in each seaming direction is formed continuously to the lower side k...

Embodiment approach 2

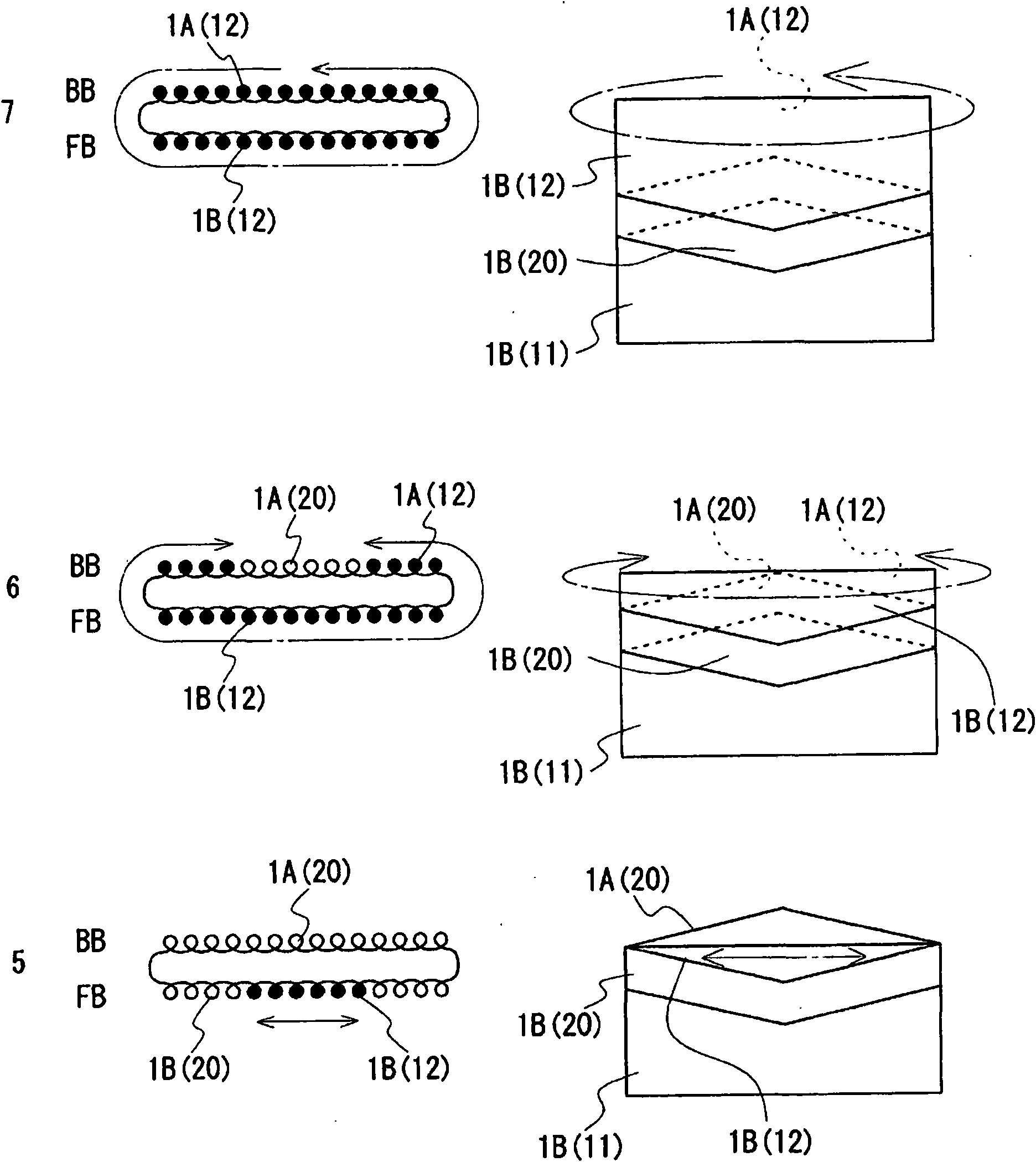

[0072] In Embodiment 2, it is explained that it is possible to alleviate figure 1 The illustrated method of knitting the tubular knitted fabric of the steps formed between the lower knit part 11 and the elastic knit part 20 and between the elastic knit part 20 and the upper knit part 12 in the sock 1 is shown.

[0073] Figure 4 It is a figure which shows the sock 1 of this Example, Figure 4 (A) is a plan view of the sock 1, Figure 4 (B) is a schematic diagram showing a state in which the socks 2 are worn. Additionally, for and figure 1 The same configurations are denoted by the same symbols, and descriptions thereof are omitted.

[0074] The sock 1 of the present embodiment has a flat portion 210 at the middle portion of the nail side knit portion 1A and the middle portion of the back side knit portion 1B at the position of the elastic knit portion 21 . The flat portion 210 is a portion substantially parallel to the course direction of the lower knitted portion 11 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com