Bucket rod of excavator

A technology for excavators and sticks, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of complex casting structure, difficult pouring and molding, and high cost of mold opening, so as to achieve uniform stress distribution, reduce weight, and improve The effect of stick strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

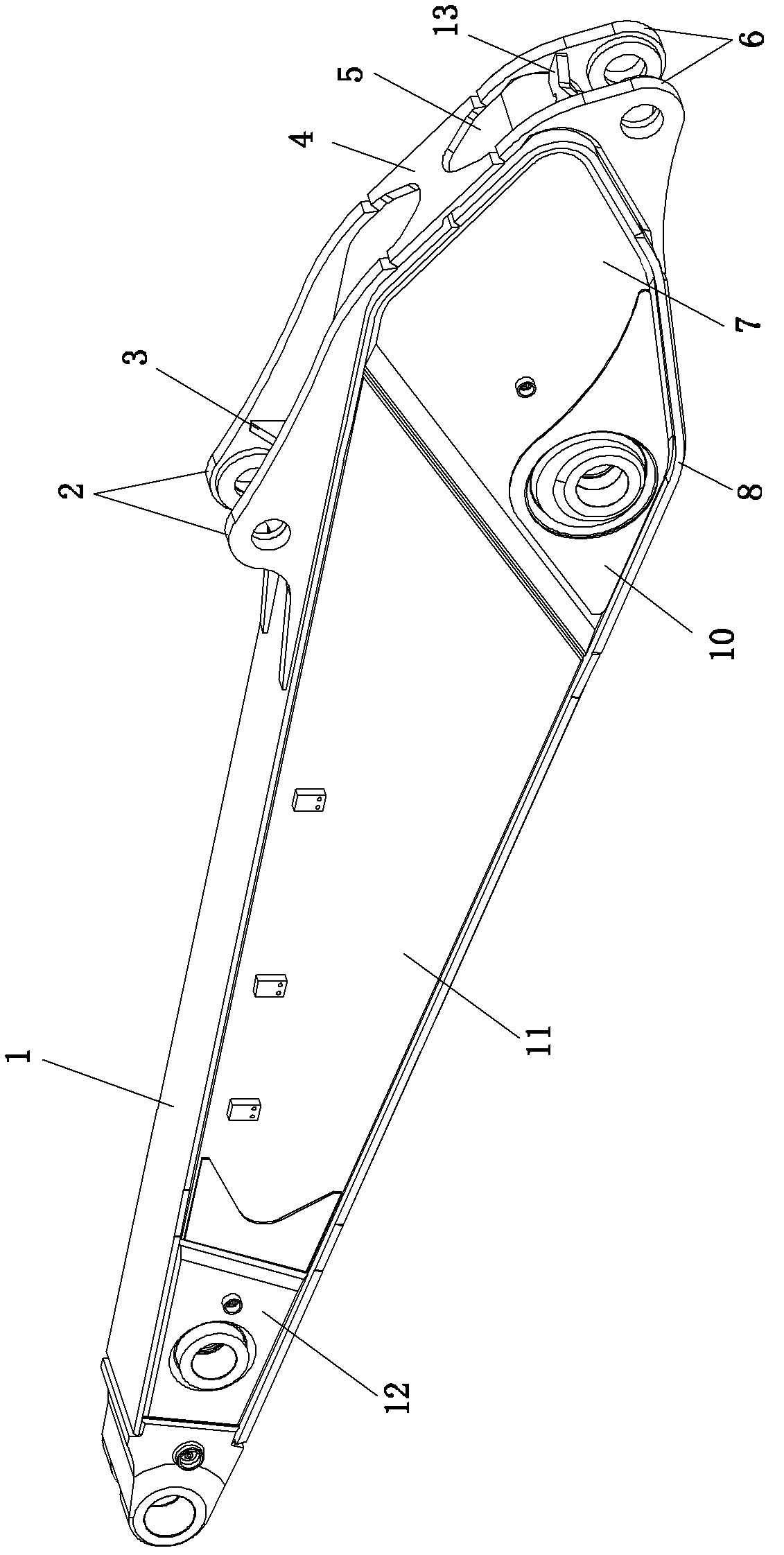

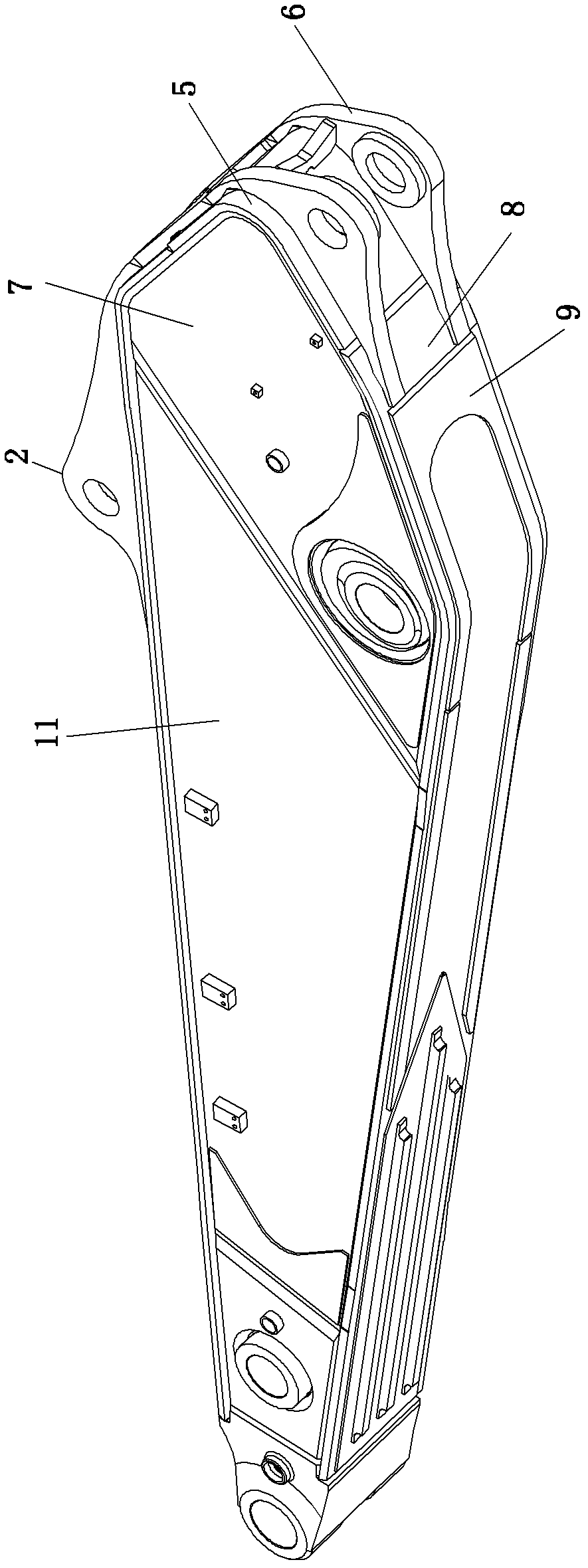

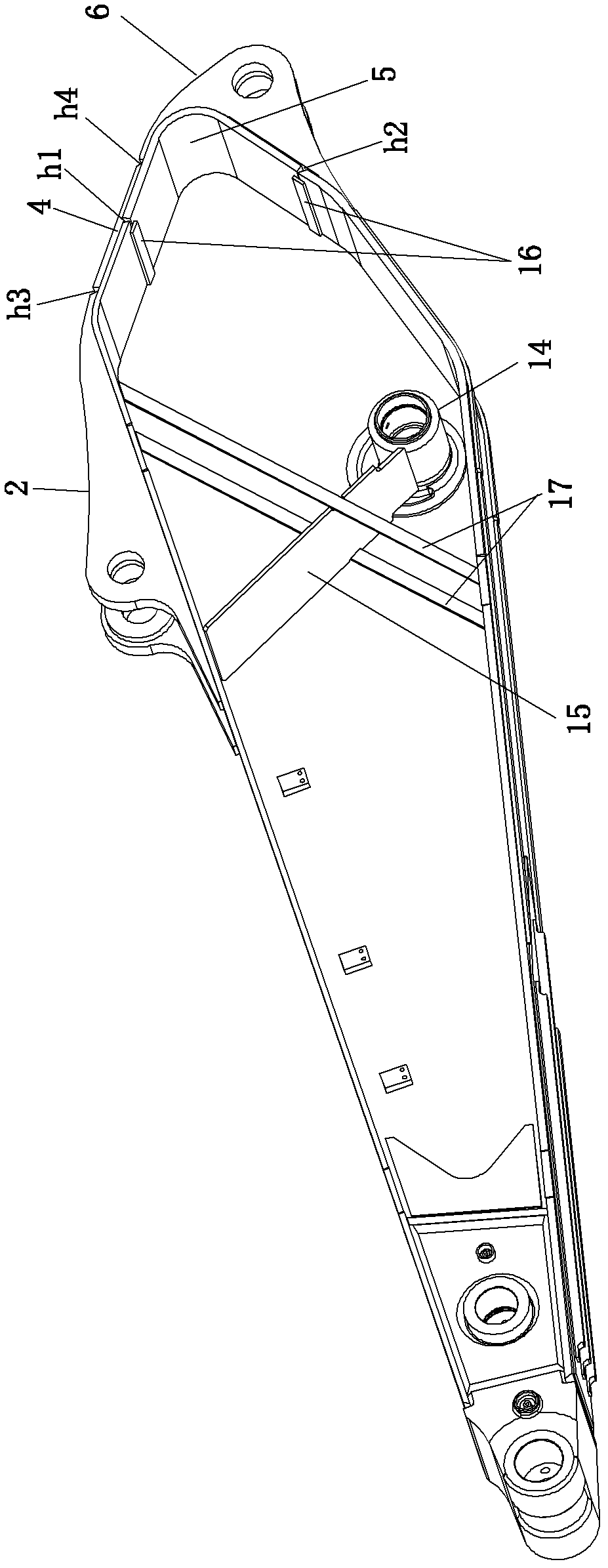

[0030] See Figure 1 to Figure 5 , this embodiment includes a stick main body composed of two side plates and surrounding plates enveloping the outer peripheries of the two side plates. A pair of bucket cylinder supports 2 and a pair of ear plates 6 are arranged on the main body of the arm. The two side plates are respectively welded by the front side plate 12, the middle side plate 11 and the rear side plate 7, wherein the rear side plate 7 is a special-shaped plate (see Figure 6 ), the profile surface at the back includes an upper plane 7a, a middle plane 7b and a lower plane 7c, and the upper plane 7a and the middle plane 7b, and the middle plane 7b and the lower plane 7c are connected by curved surfaces.

[0031] The coaming plate is welded by the upper cover plate 1, the bent plate 5 and the lower cover plate 8, the weld h1 between the upper cover plate 1 and the bent plate 5 corresponds to the middle part of the plane 7a on the rear side plate, and the bent plate 5 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com