Cold isostatic compaction mould for multi-channel filter elements and method for producing multi-channel filter elements made of intermetallic compounds

A technology of cold isostatic pressing and intermetallic compound, applied in the direction of ceramic forming core, ceramic forming mandrel, ceramic forming machine, etc., can solve the problem of extremely high mold application, inability to release the core rod, insufficient structure to meet the requirements, etc. problems, to achieve the effect of favorable demoulding, high internal quality and uniform product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

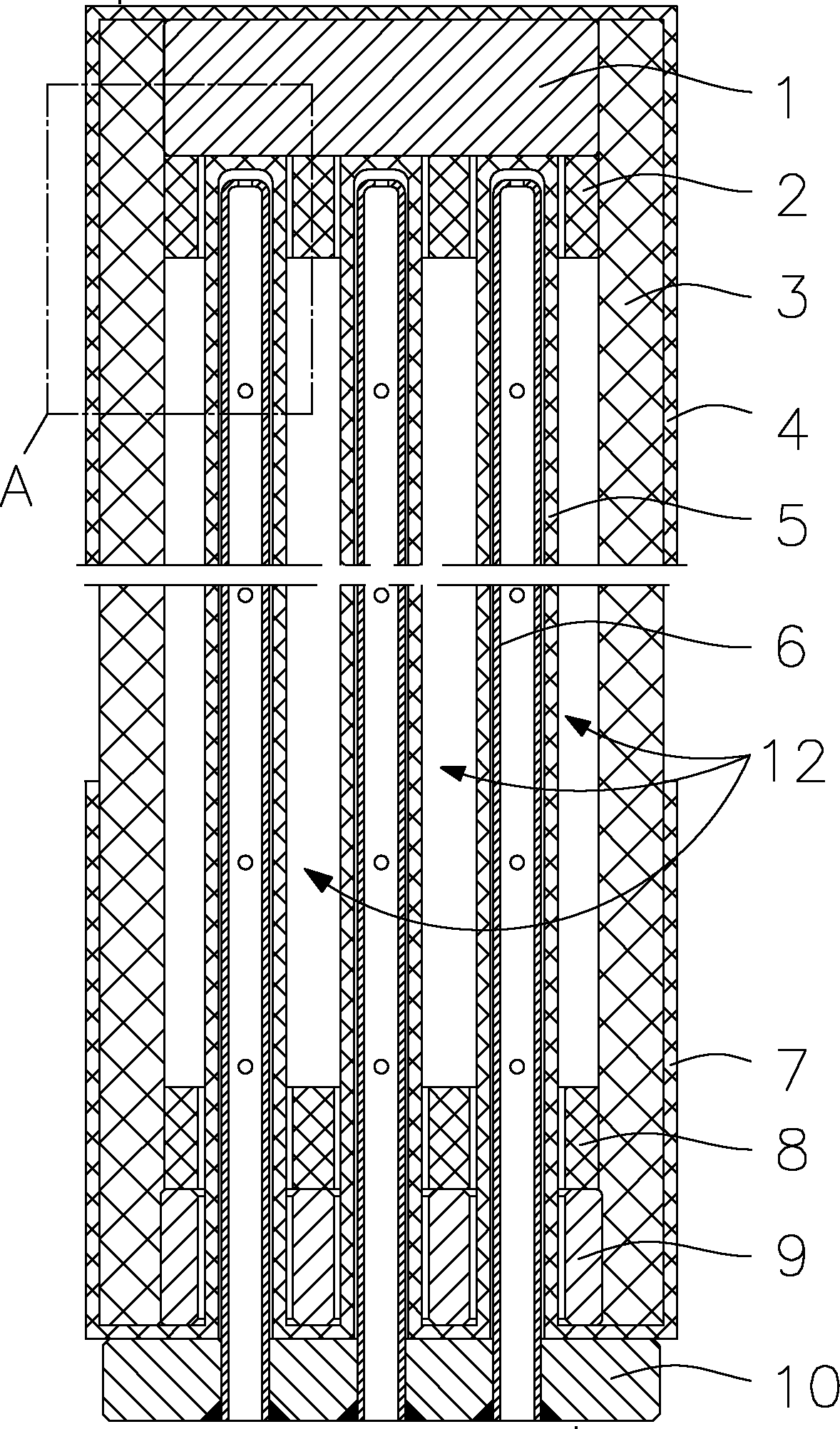

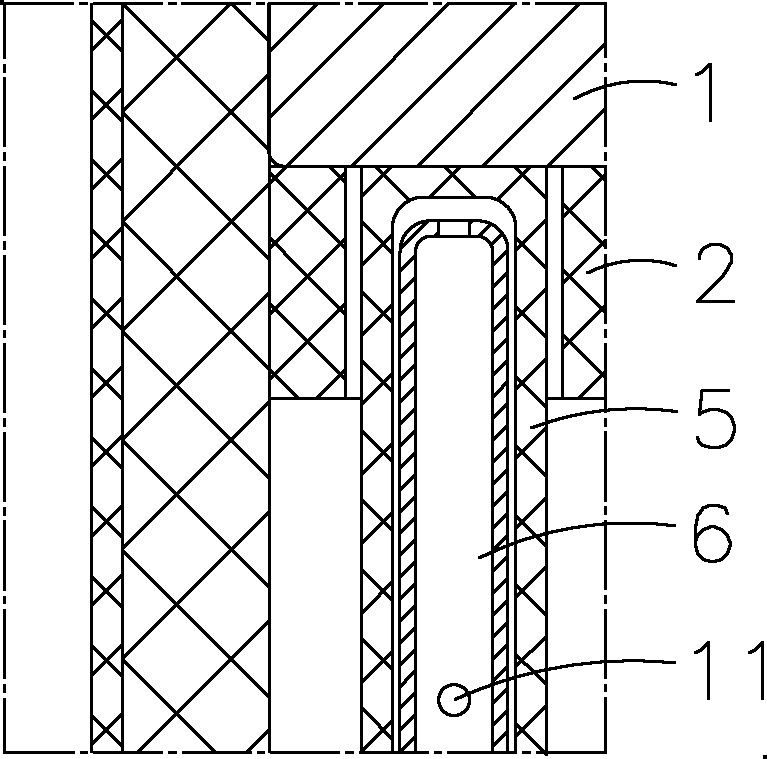

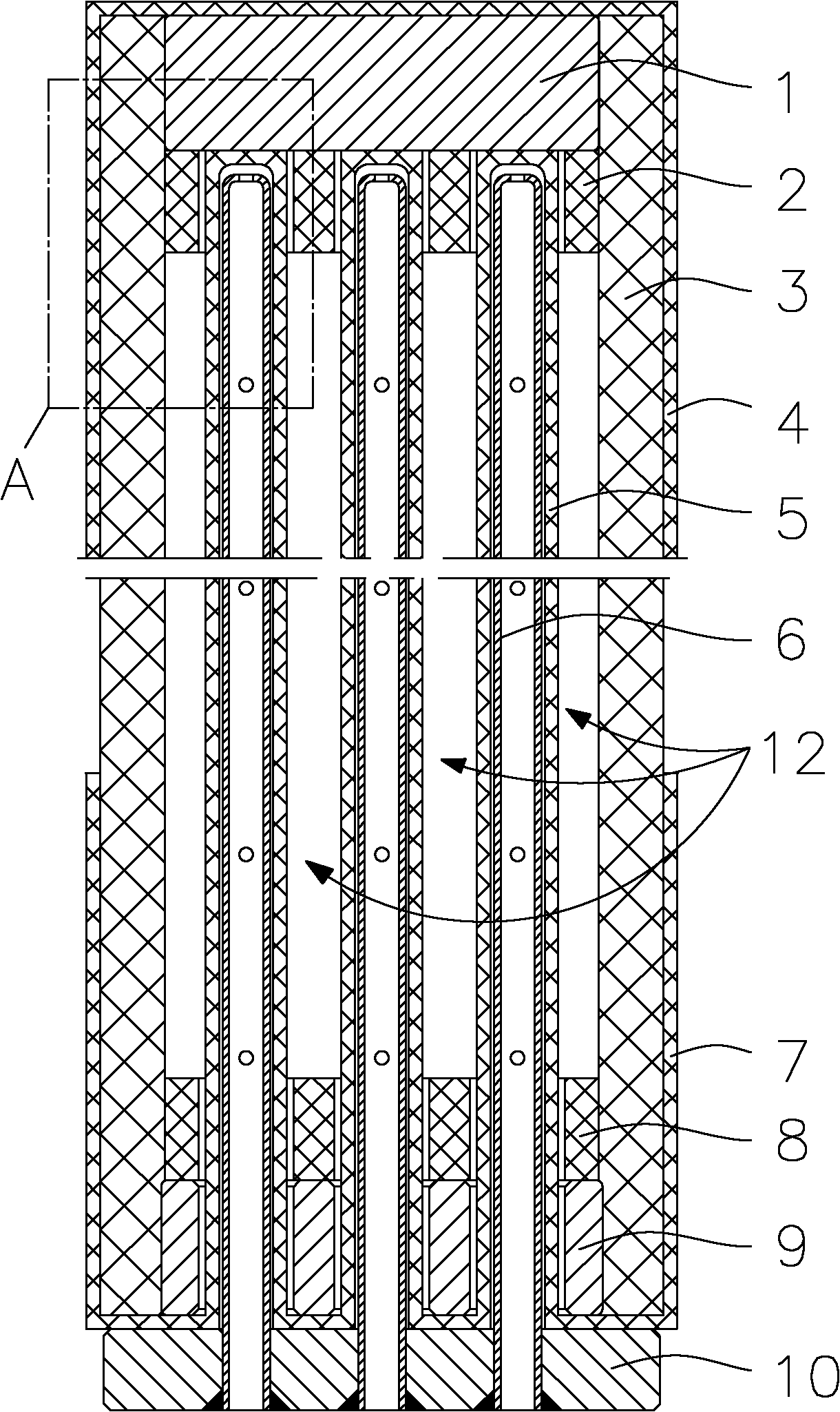

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1~2 The multi-channel filter element cold isostatic pressing molding mold shown, the mold includes an outer rubber sleeve 3 and a plurality of mandrels 12 with one end closed and the other end open, and the front end of the outer rubber sleeve 3 is sequentially equipped with front-end steel pipes from outside to inside. The plug 9 and the front rubber plug 8, the front steel plug 9 and the front rubber plug 8 respectively have mandrel installation positioning holes corresponding to the positions after installation; the rear end steel plug is installed in the rear port of the outer rubber sleeve 3 from outside to inside 1 and the rear end rubber plug 2, there are also mandrel installation positioning holes on the rear end rubber plug 2; the closed ends of the mandrels 12 are respectively inserted from the mandrel installation positioning holes on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com