Novel pipeline anti-corrosion protection technology

A pipeline and a new type of technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of economic benefit reduction, fire, oil and gas shackle loss, etc., and achieve the effect of uniform product density, easy operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

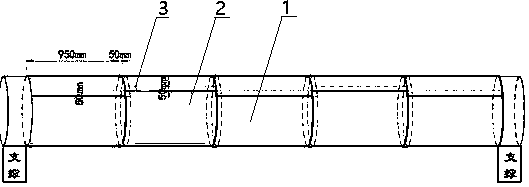

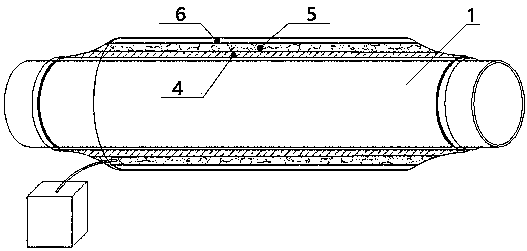

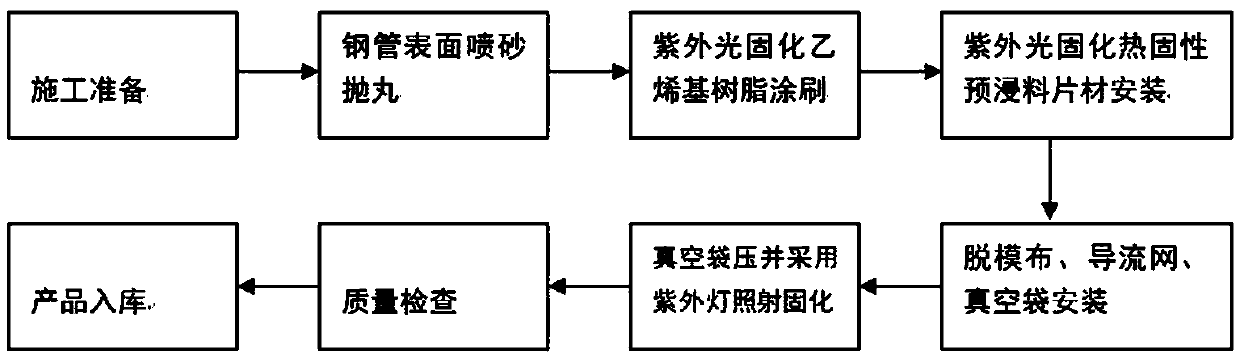

[0025] A novel pipeline anti-corrosion protection process, in which a layer of UV-cured vinyl resin is attached to the inside of the pipeline, the steps include:

[0026] 1) Construction preparations, including sharp edges of the steel pipe 1, polishing of the weld seam, and degreasing and cleaning of the outside of the steel pipe 1;

[0027] 2) Sand blasting and shot blasting on the surface of steel pipe 1, the surface of steel pipe 1 is required to be sand blasted to Sa2. After the surface treatment is qualified, the primer shall be sprayed within 4 hours;

[0028] 3) Brushing UV-curable vinyl resin, the total thickness of the dry film design is 100µm, divided into two continuous brushing construction;

[0029] 4) Install the UV-curable thermosetting prepreg sheet 2. After the second primer is applied, lay the UV-curable thermosetting prepreg sheet 2 immediately. One side is wrapped on the surface of the pipe to remove air bubbles and compacted repeatedly with rollers;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com