Molten aluminum refining degassing and slag-removing device

A technology of liquid aluminum and pores, which is applied in the field of degassing and slag removal devices for liquid aluminum refining, can solve the problems of affecting the quality of liquid aluminum, the content of easily eroded metal elements, and exceeding the standard, so as to reduce scrap, improve market competitiveness, and improve internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

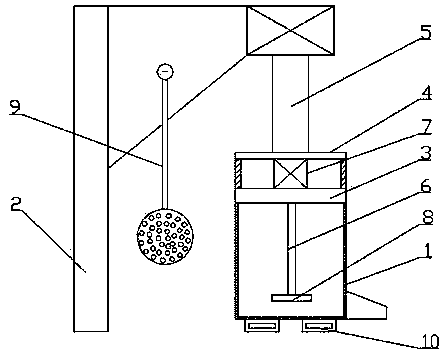

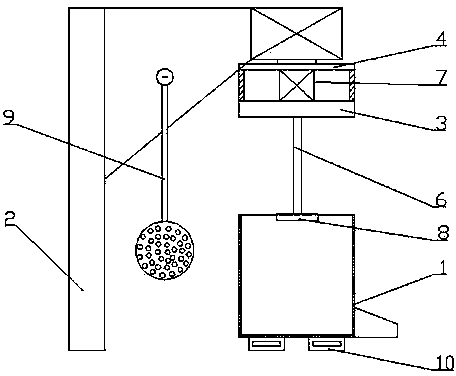

[0012] As shown in the figure: a degassing and slag removal device for aluminum liquid refining, including a holding furnace 1 with an open upper end and a support 2, the holding furnace 1 has a cover 3, and the bottom of the holding furnace 1 is also provided with a forklift for transportation Jack 10. The cover body 3 is connected with the lifting plate 4 through the connecting rod, and the lifting plate 4 is connected with the support 2 through the hydraulic telescopic rod 5, and the cover body 3 can be driven to move up and down by the hydraulic telescopic rod 5 and the lifting plate 4. The lower end of the cover body 3 is connected with a stirring shaft 6, and the upper end of the cover body 3 is provided with a drive motor 7, and the upper end of the stirring shaft 6 passes through the cover body 3 vertically and is connected with the drive motor 7, and the lower end of the stirring shaft 6 is placed in the holding furnace 1 Inside, the lower end of the stirring shaft 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com