Preparation method of titanium matrix graphene alloy

A technology of titanium-based ene and titanium alloy, which is applied in the field of preparation of titanium-based ene alloy, can solve problems such as difficulty in large-scale production, affecting the performance of olefin alloy, and small size of graphene, achieving excellent engineering application prospects, good performance, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

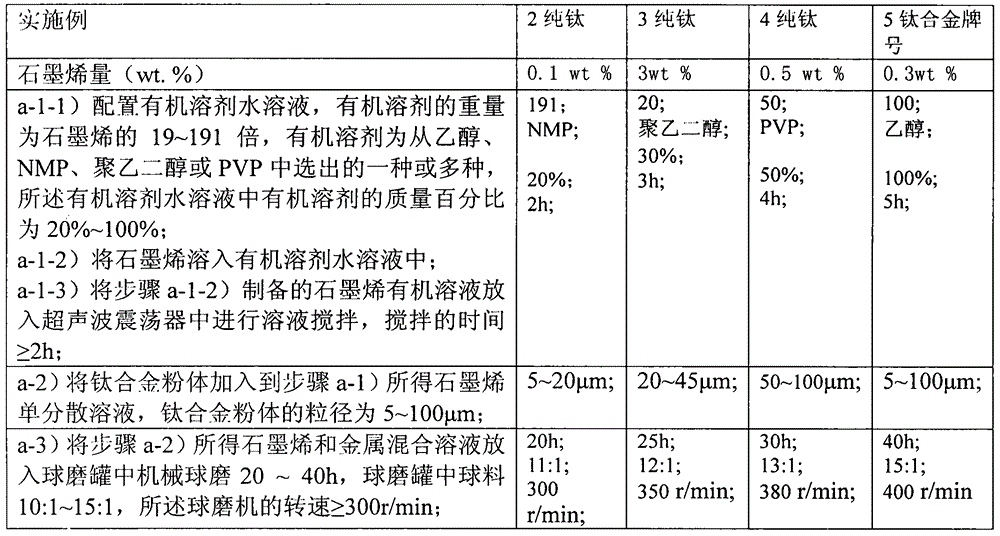

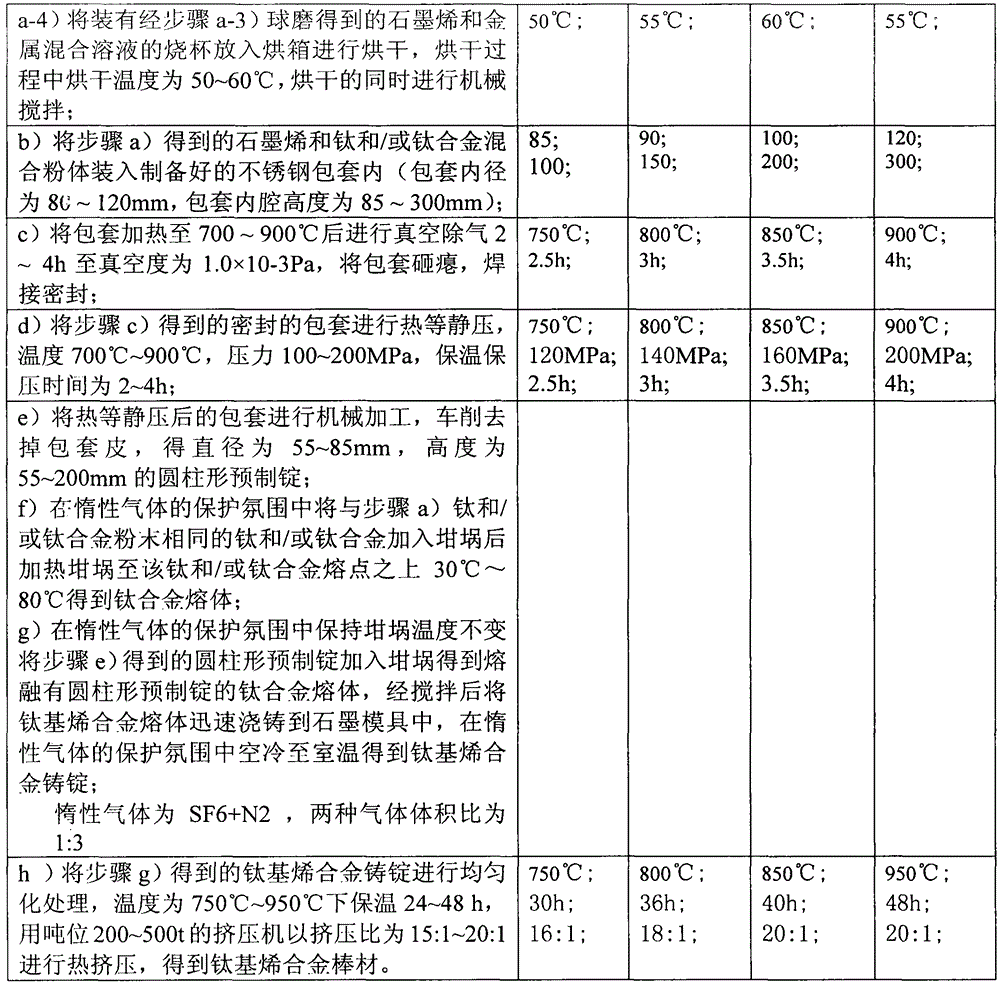

[0043] To prepare titanium-based graphene, the specific steps are as follows:

[0044] a) prepare graphene and titanium mixed powder, powder comprises: Graphene 10g (Hummer's method preparation), titanium alloy powder 1kg; Titanium alloy comprises the component of following percentage by weight:

[0045] Al4.0~6.0%; Sn2.0~3.0%; Fe≤0.50%; C≤0.08%; N≤0.05%; H≤0.015%; O≤0.20%; other elements (single species)≤0.10%; others Elements (total amount) ≤ 0.40%; Ti is the balance.

[0046] a-1) preparing graphene monodisperse solution;

[0047]a-1-1) configure organic solvent aqueous solution, the weight of organic solvent is 19 times of graphene, organic solvent is ethanol solution, the mass percent of organic solvent in organic solvent aqueous solution is 80%;

[0048] a-1-2) Graphene is dissolved in the organic solvent aqueous solution;

[0049] a-1-3) putting the graphene organic solution prepared in step a-1-2) into an ultrasonic oscillator and stirring the solution for 2 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com