Patents

Literature

51results about How to "Easy to achieve large-scale industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

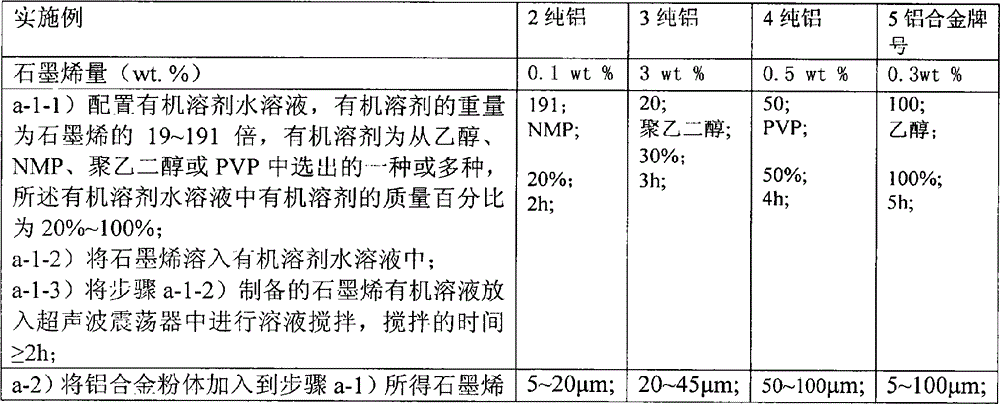

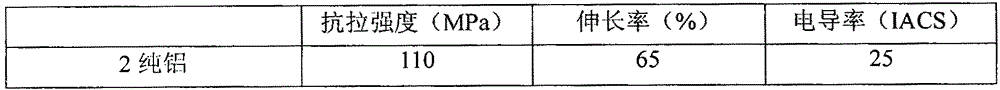

Preparation method of aluminum base graphene alloy

The invention provides a preparation method of aluminum base graphene alloy. The method comprises the following steps: preparing graphene and aluminum and / or aluminum alloy mixed powder, filling a jacket with the mixed powder, carrying out vacuum degassing, carrying out hot isostatic pressing, re-melting, and homogenizing. A certain amount of the aluminum base graphene alloy precast ingots are re-melted in aluminum alloy melt, the content of graphene in a composite material can be well controlled through calculating, and graphene cannot float, so the content of graphene in the aluminum base graphene alloy can be accurately controlled; and the preparation method is provided on the basis of semi-continuous melting casting, and has the advantages of simple operation, high production efficiency, low preparation cost, and easy realization of large scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

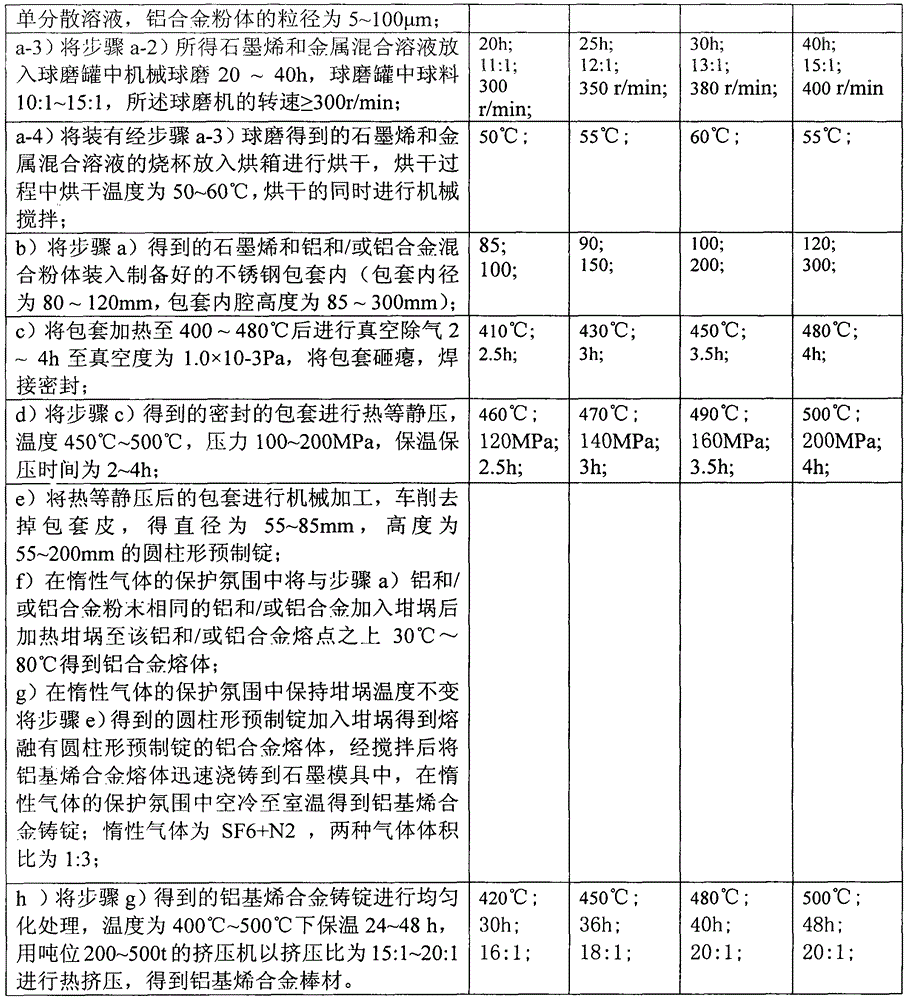

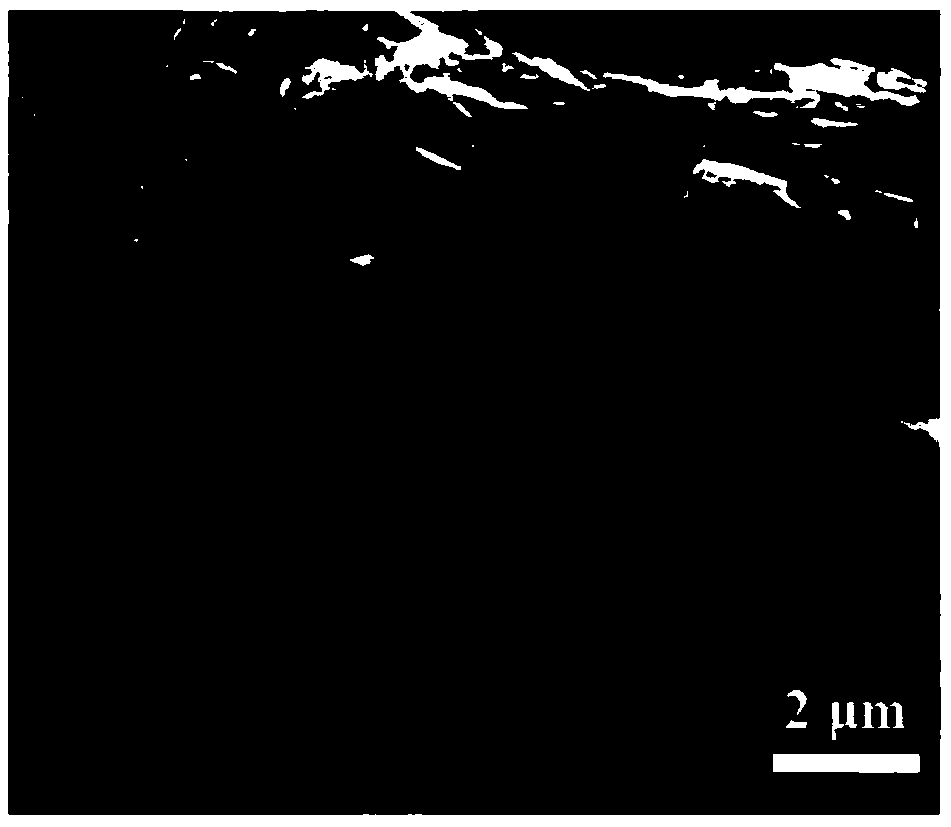

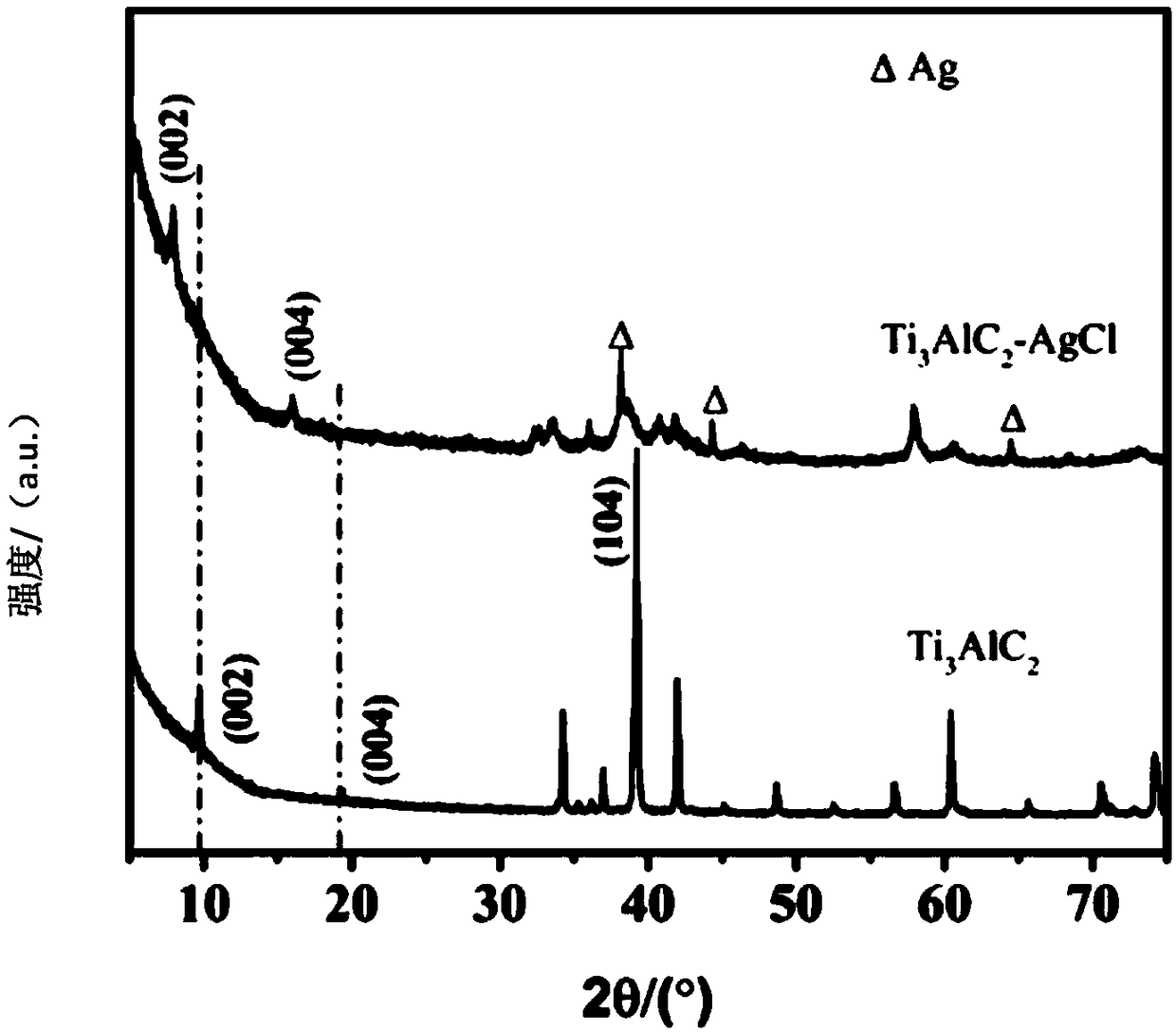

Composite material of sub-group metals compounded with MXenes and preparation method and application of composite material

ActiveCN108793166ARealize the structureRealize functionTitanium carbideMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsMolten salt

The invention discloses a composite material of sub-group metals compounded with MXenes and a preparation method of the composite material. The composite material of sub-group metals compounded with MXenes is prepared from MXenes materials and sub-group metals, wherein the surfaces of the MXenes materials are coated with the sub-group metals in situ, and the sub-group metals are also distributed among layers of the MXenes materials. The preparation method comprises the following steps: grinding precursor Mn+1AXn-phase materials, sub-group metal salts and inorganic salts for 5-60min by adoptinga molten salt method, enabling the obtained mixture to react for 1-48h at 300-800 DEG C in inert atmosphere, and then, performing post-treatment to obtain the composite material of the sub-group metals compounded with the MXenes. The composite material disclosed by the invention has the advantages of adjustable and uniform components, low cost, environmental protection, high efficiency and the like, and has application prospects in the fields of electrode materials for electrochemical energy storage, wave absorption materials, electromagnetic shielding materials, catalysts and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

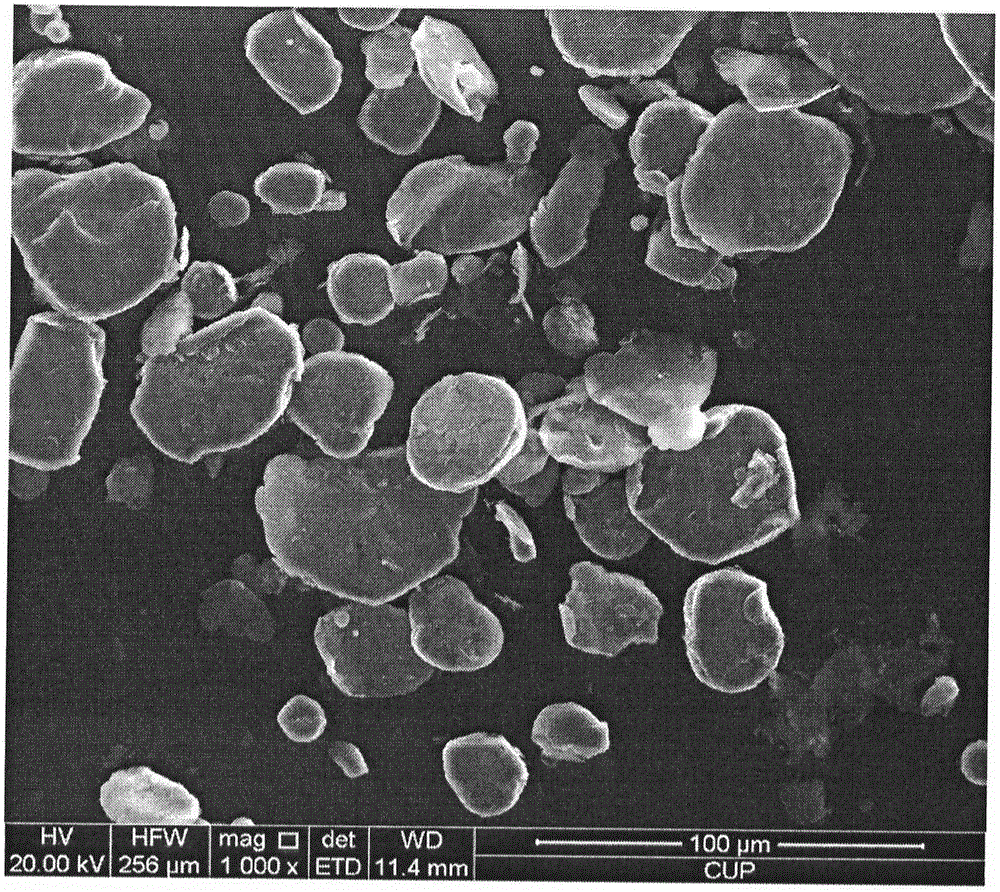

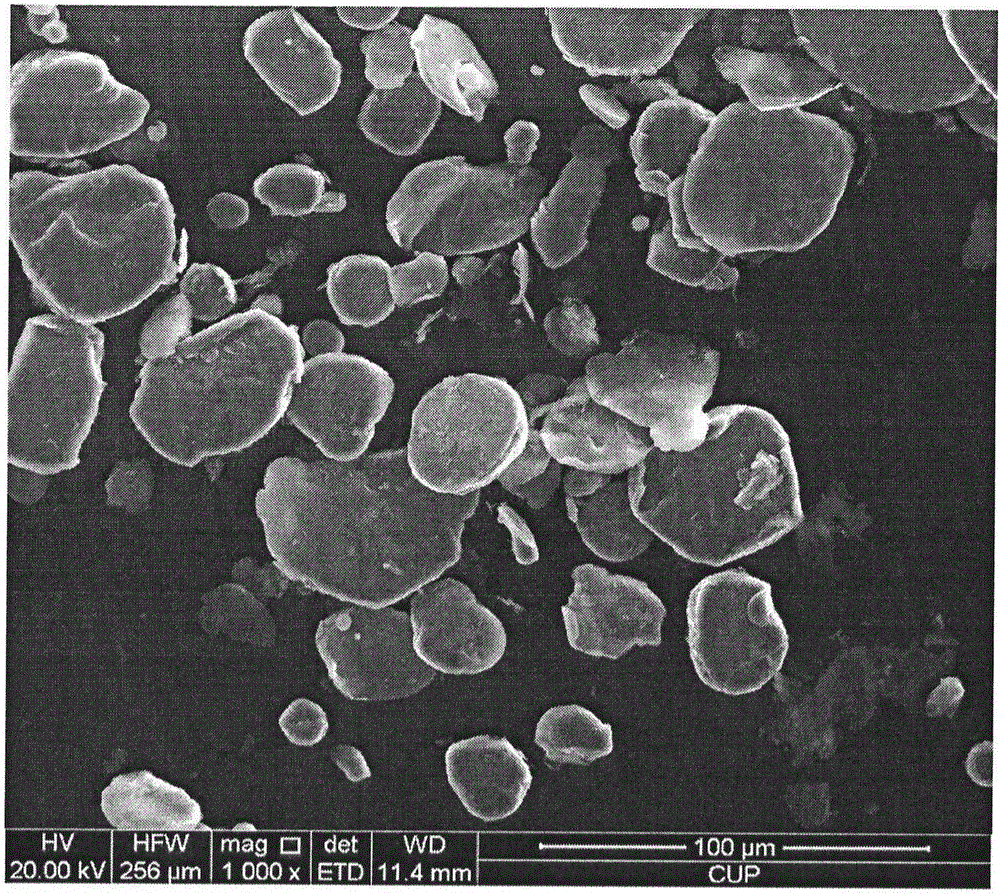

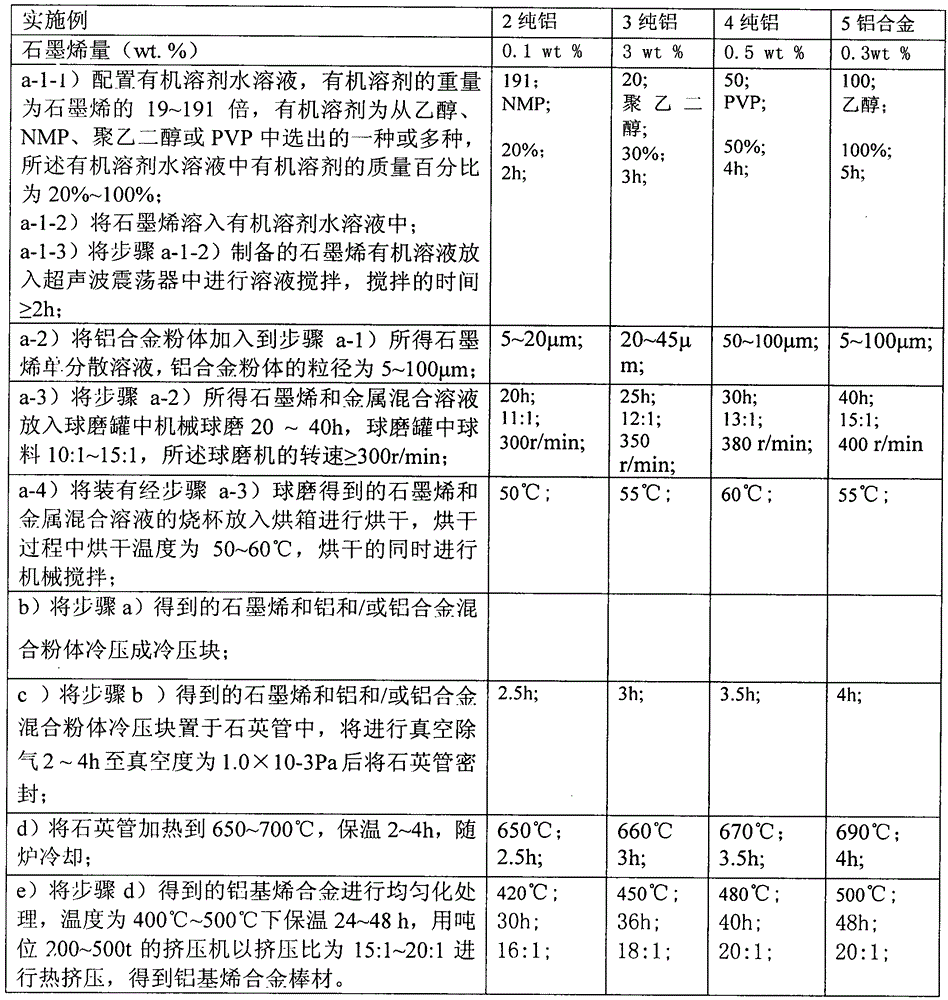

Preparation method of aluminum base graphene alloy

InactiveCN105063402AEvenly dispersedSolve the problem of easy reunion and difficult dispersionCvd grapheneProcess operation

The invention provides a preparation method of aluminum base graphene alloy. The method comprises the following steps: preparing graphene and aluminum and / or aluminum alloy mixed powder, carrying out cold pressing, and carrying out sintering molding. The method improves an original preparation technology of the aluminum base graphene alloy, and has the advantages of production period and cost reduction, simple process operation, simple required device, high production efficiency, low preparation cost, and easy realization of large-scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

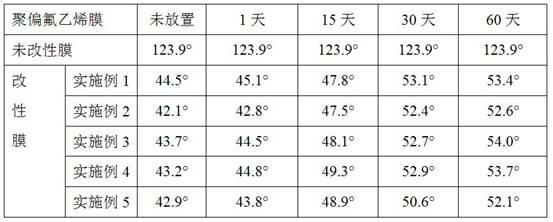

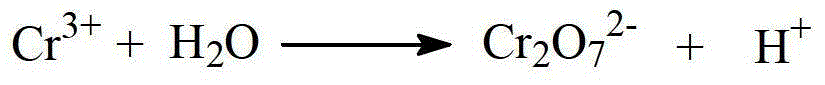

Method for performing hydrophilic modification on surface of polyvinylidene fluoride microporous membrane

The invention provides a method for performing hydrophilic modification on the surface of a polyvinylidene fluoride micro-porous membrane. The method is characterized by comprising the following specific steps of: cleaning a polyvinylidene fluoride micro-porous filter membrane with deionized water, dipping the cleaned filter membrane in solution of ethanol, dipping the dipped filter membrane in the deionized water, adding the polyvinylidene fluoride micro-porous membrane into solution of an alkali oxidant and reacting at the temperature of between 20 and 80 DEG C for 20 to 60 minutes, wherein the alkali oxidant contains alkali and potassium permanganate serving as an oxidant; dipping the polyvinylidene fluoride micro-porous membrane treated in the step one in solution of an acid reducing agent to remove the alkali and the potassium permanganate serving the oxidant on the surface, cleaning the dipped membrane with the deionized water and drying the cleaned membrane; and dipping the polyvinylidene fluoride micro-porous membrane treated in the step two in 5 to 20 volume percent solution of glycerin, reacting at normal temperature for 5 to 20 minutes, cleaning the membrane with the deionized water and drying the cleaned membrane. The method has the advantages of simple and efficient process, capability of improving the hydrophility of the polyvinylidene fluoride membrane and lasting effect.

Owner:DONGHUA UNIV

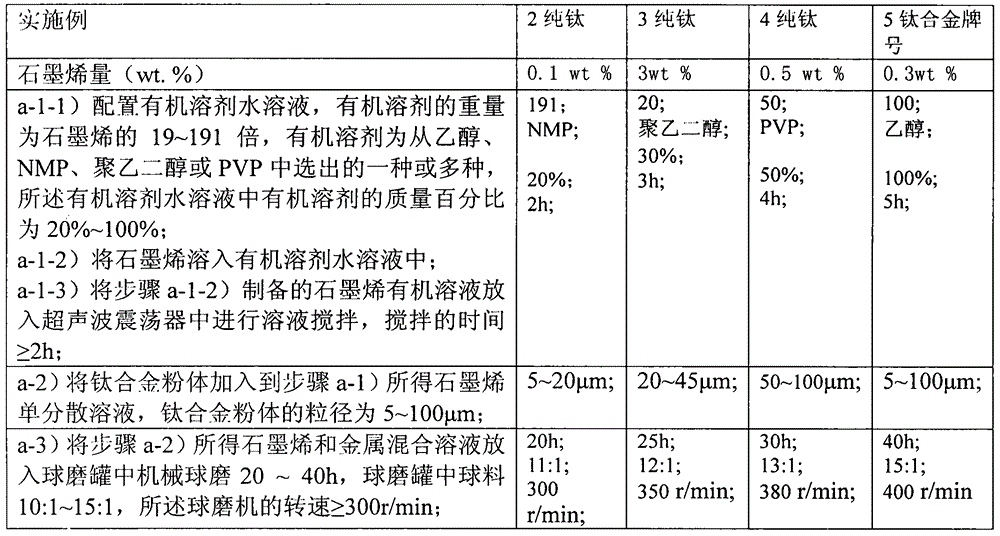

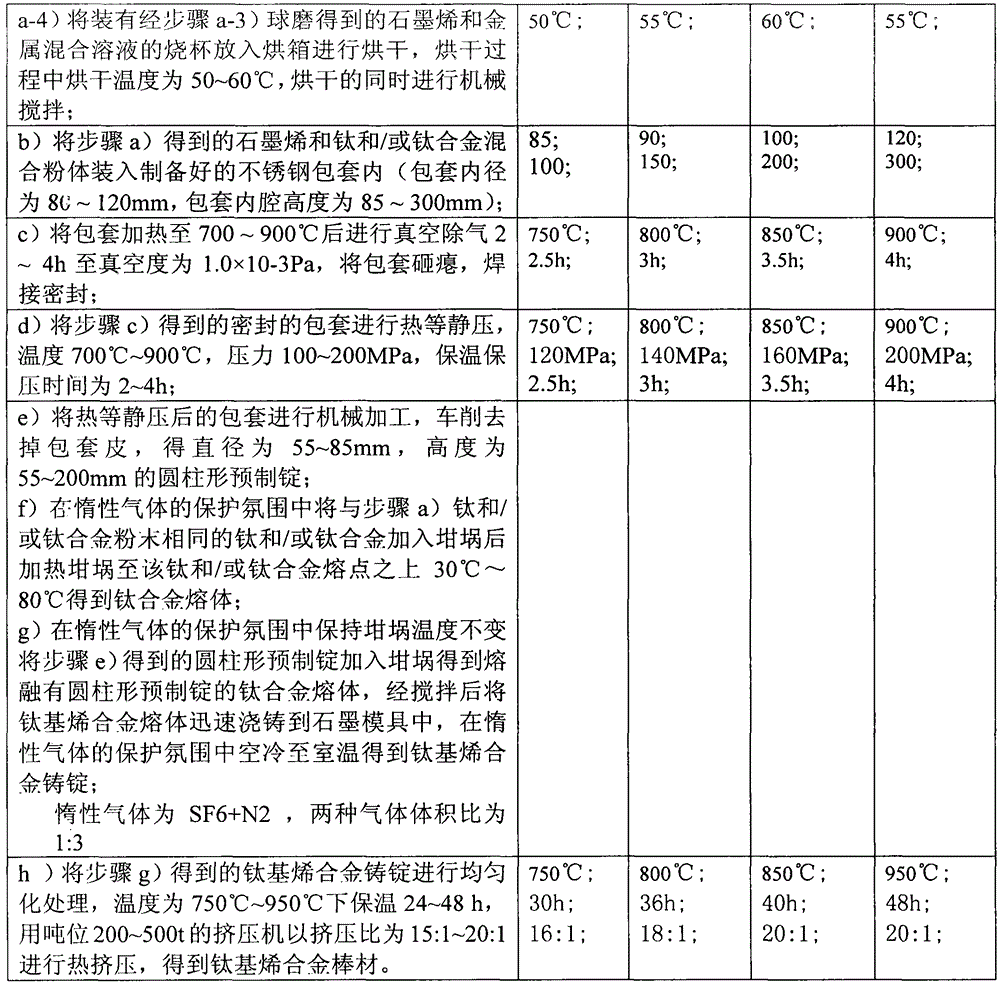

Preparation method of titanium matrix graphene alloy

The invention provides a preparation method of titanium matrix graphene alloy. The method comprises the following steps: preparing graphene and titanium and / or titanium alloy mixed powder, filling a jacket with the mixed powder, carrying out vacuum degassing, carrying out hot isostatic pressing, re-melting, and homogenizing. A certain amount of the titanium matrix graphene alloy precast ingots are re-melted in titanium alloy melt, the content of graphene in a composite material can be well controlled through calculating, and graphene cannot float, so the content of graphene in the titanium matrix graphene alloy can be accurately controlled; and the preparation method is provided on the basis of semi-continuous melting casting, and has the advantages of simple operation, high production efficiency, low preparation cost, and easy realization of large scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

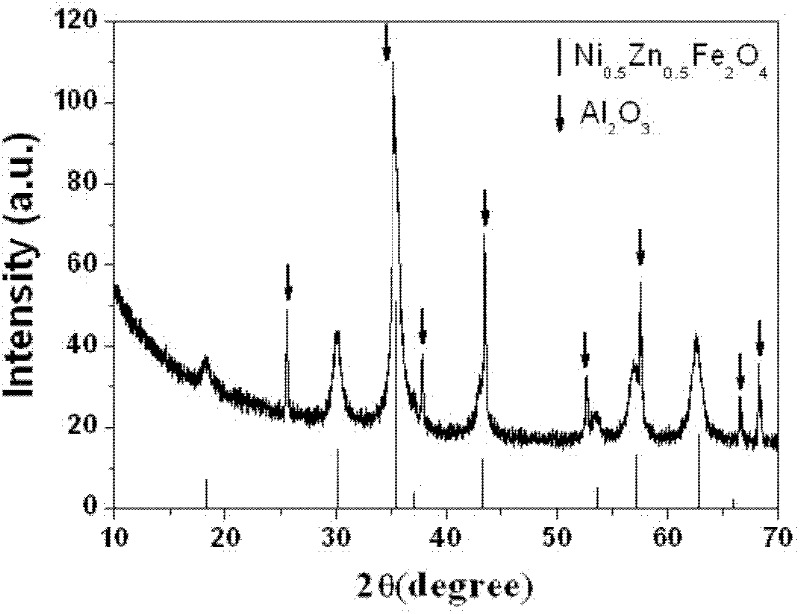

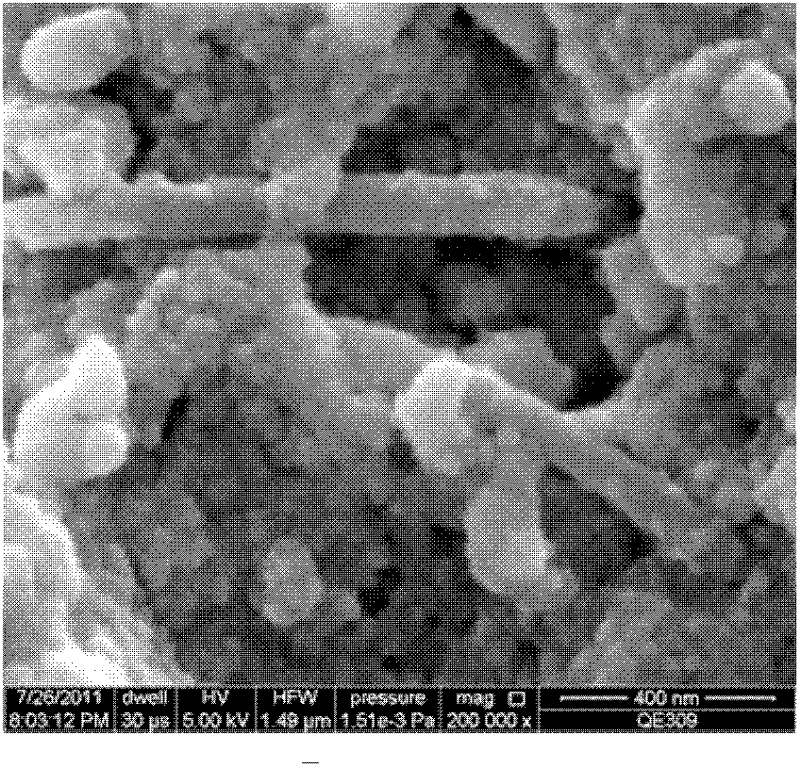

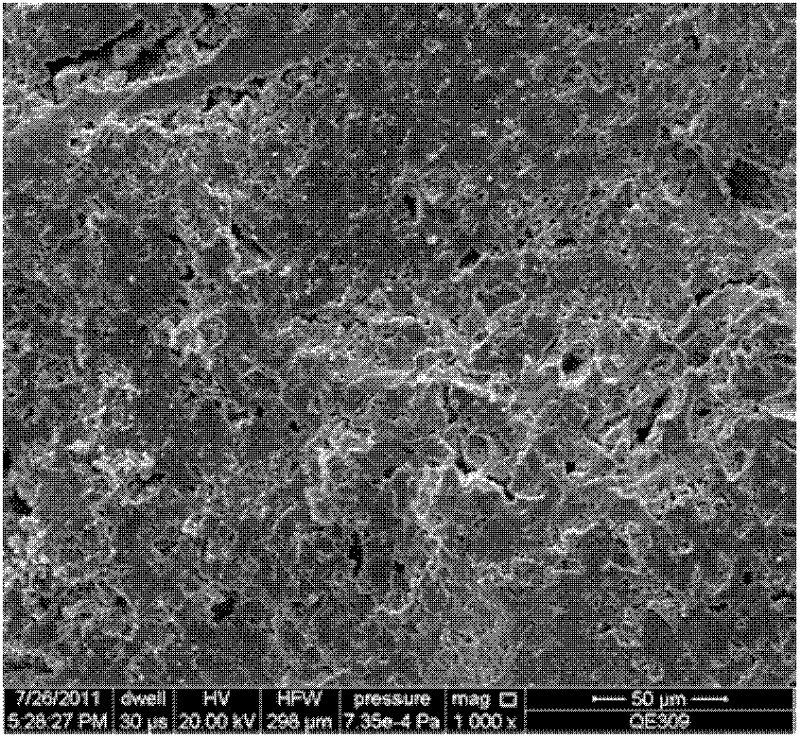

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

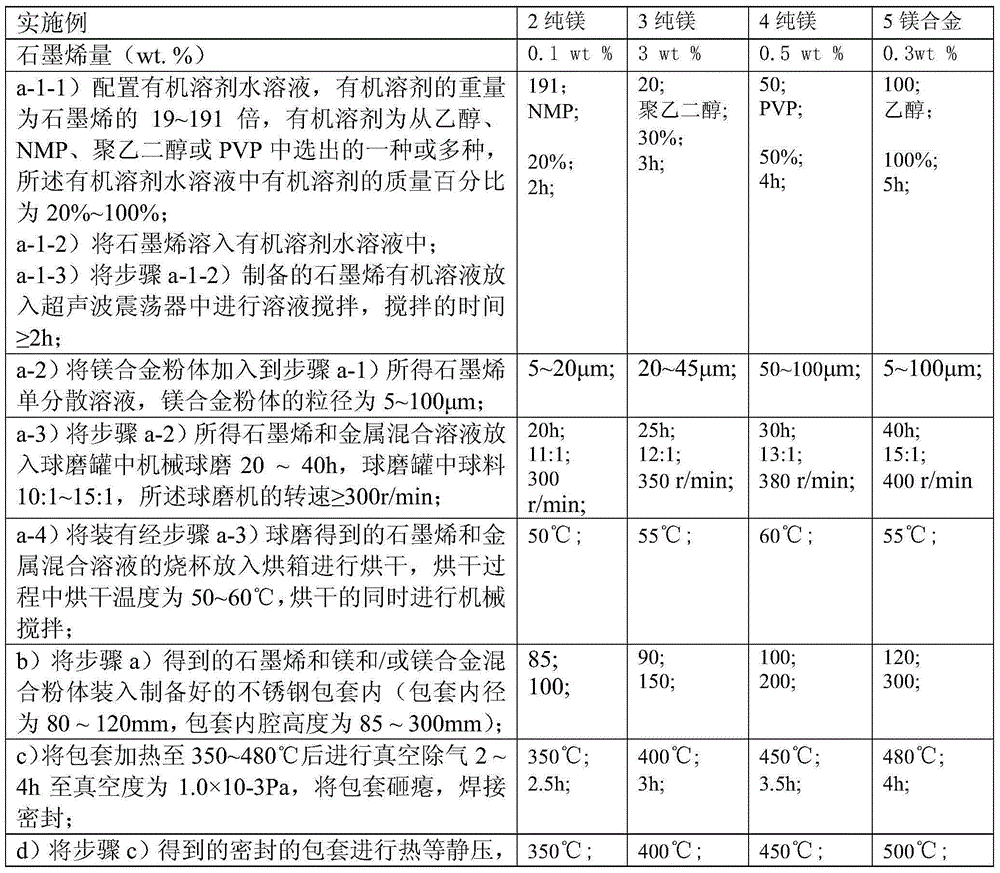

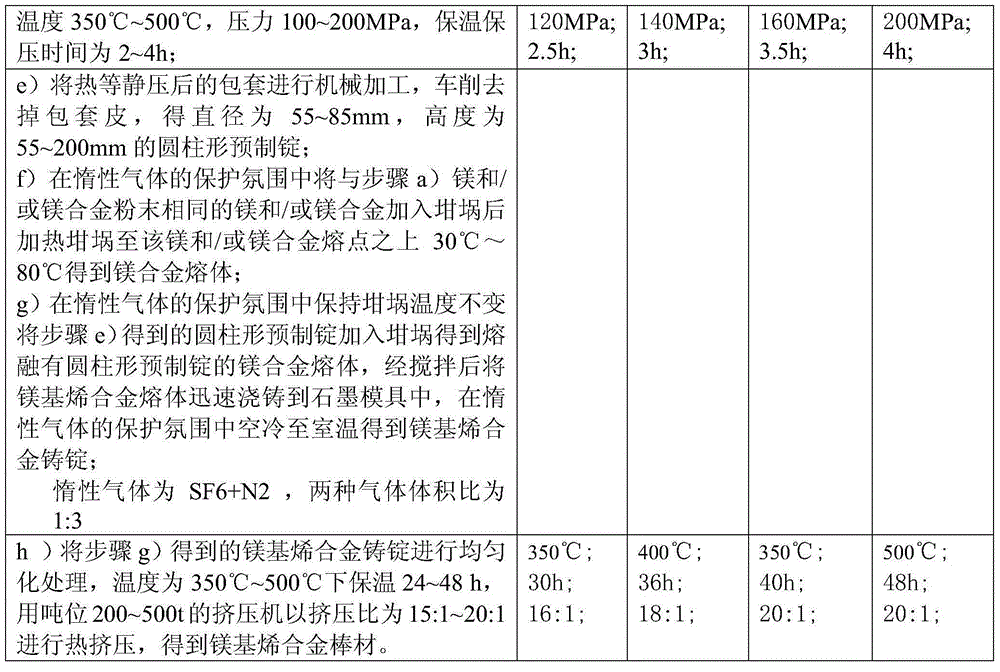

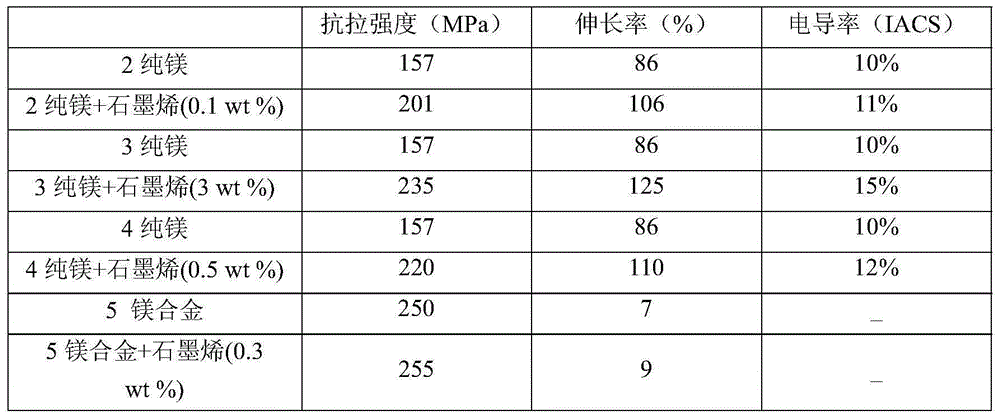

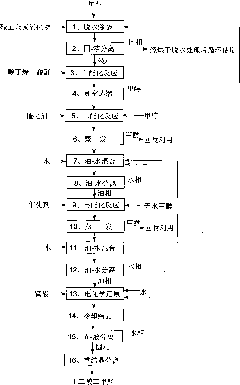

Preparation method of magnesium base graphene alloy

The invention provides a preparation method of a magnesium base graphene alloy. The method comprises the steps of: preparing mixed powder of graphene and magnesium and / or magnesium alloy, putting the mixed powder into a cover for vacuum degassing, performing hot isostatic pressing, remelting and performing homogenization treatment. According to the method, a certain quantity of magnesium base graphene alloy prefabricated ingot is remelted into magnesium alloy molten liquid; the content of graphene in a composite material is preferably controlled through calculation; as the graphene does not float out, the content in the magnesium base graphene alloy can be accurately controlled; and the preparation method is provided based on semi-continuous casting, and is simple in process operation, high in production efficiency, low in manufacturing cost and easy for realizing large-scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

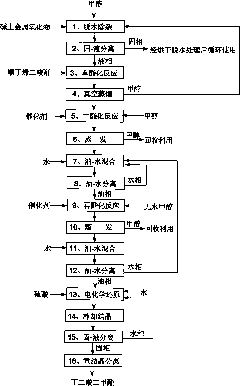

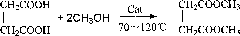

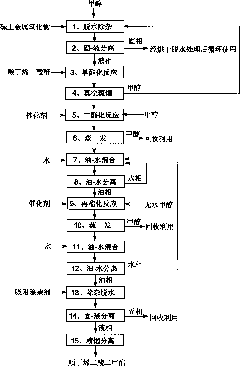

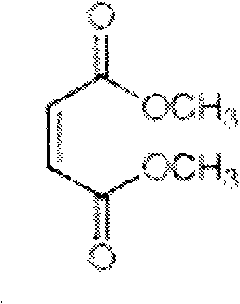

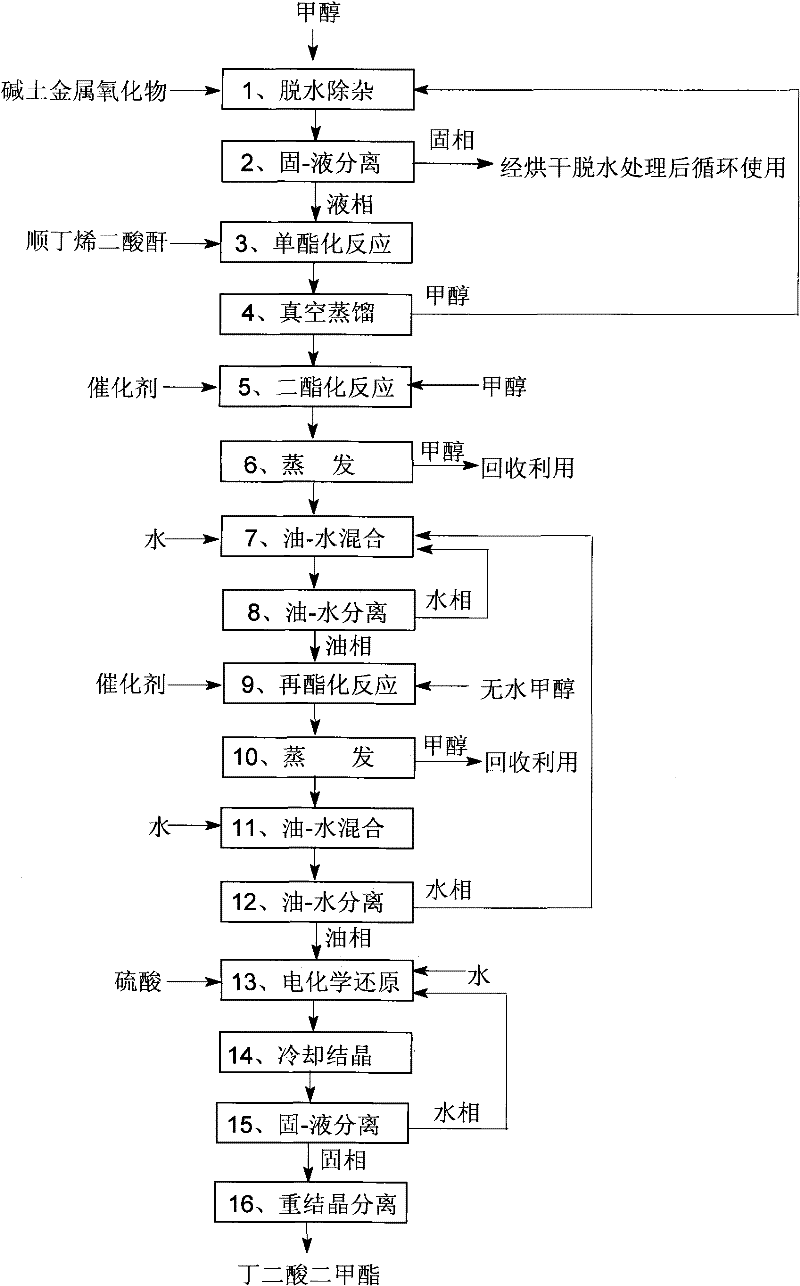

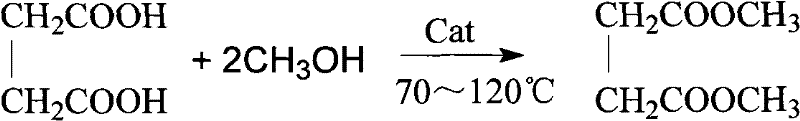

Method for preparing dimethyl succinate

ActiveCN101824627AThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

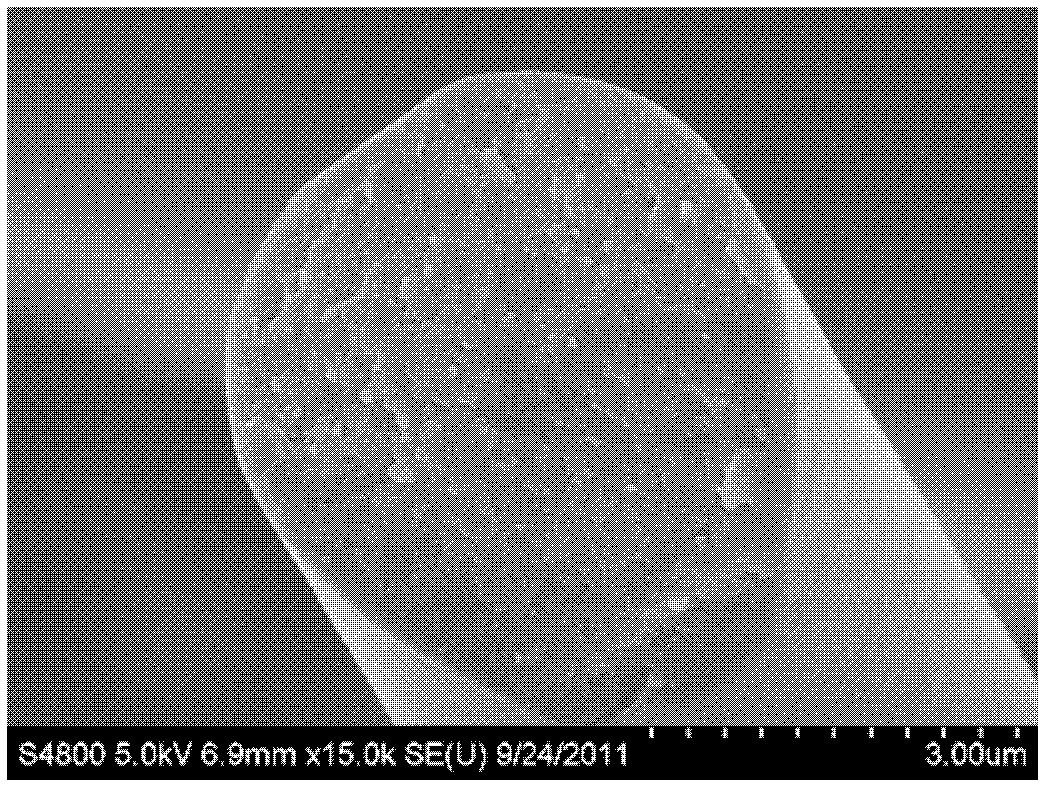

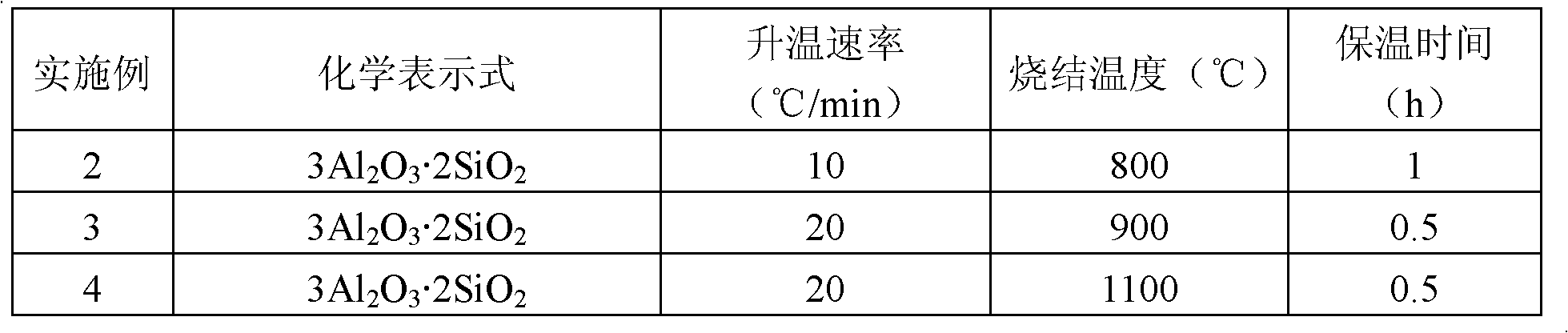

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

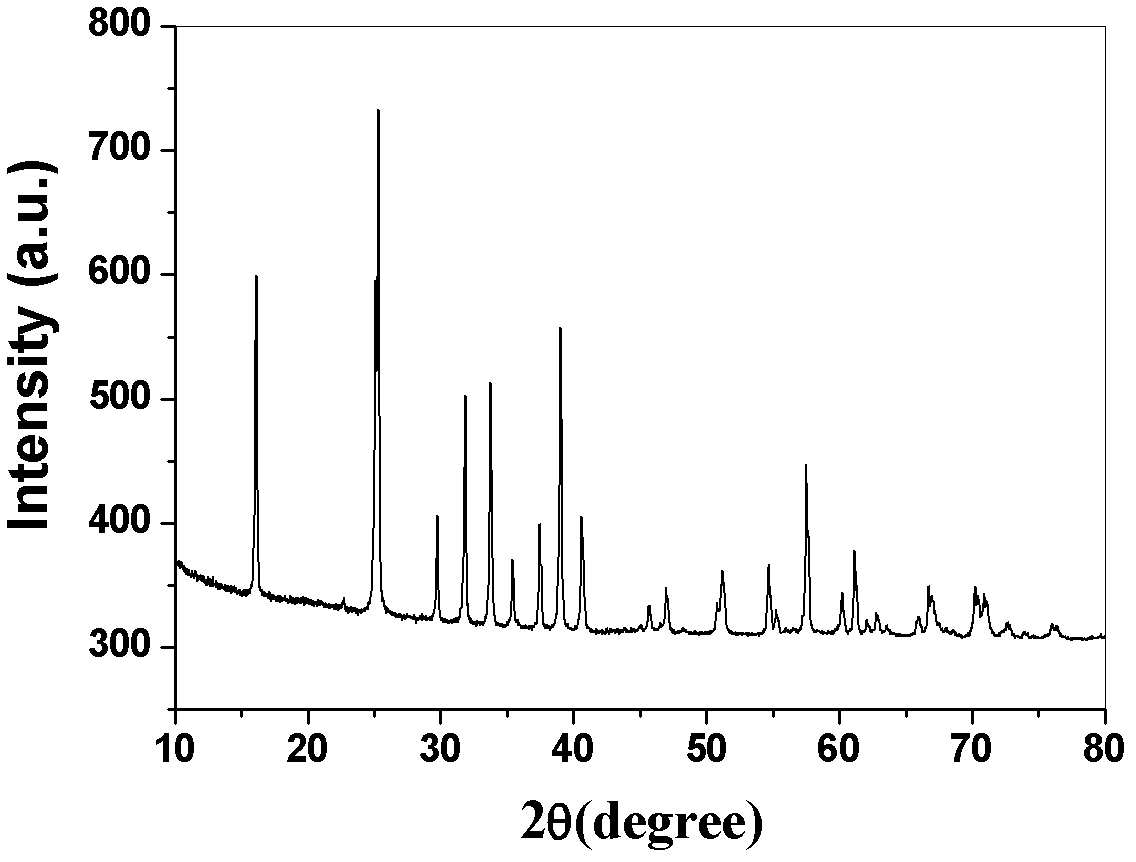

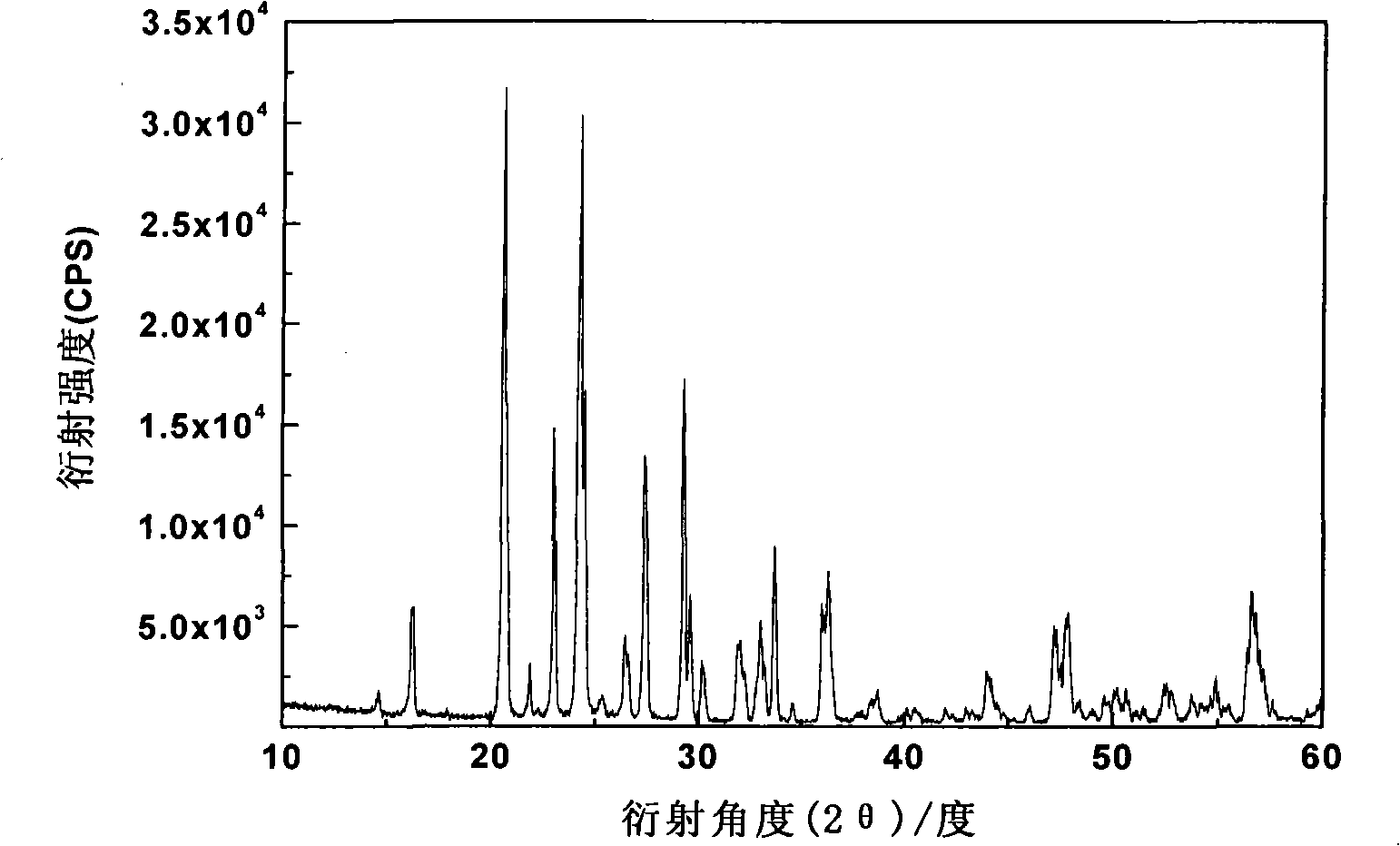

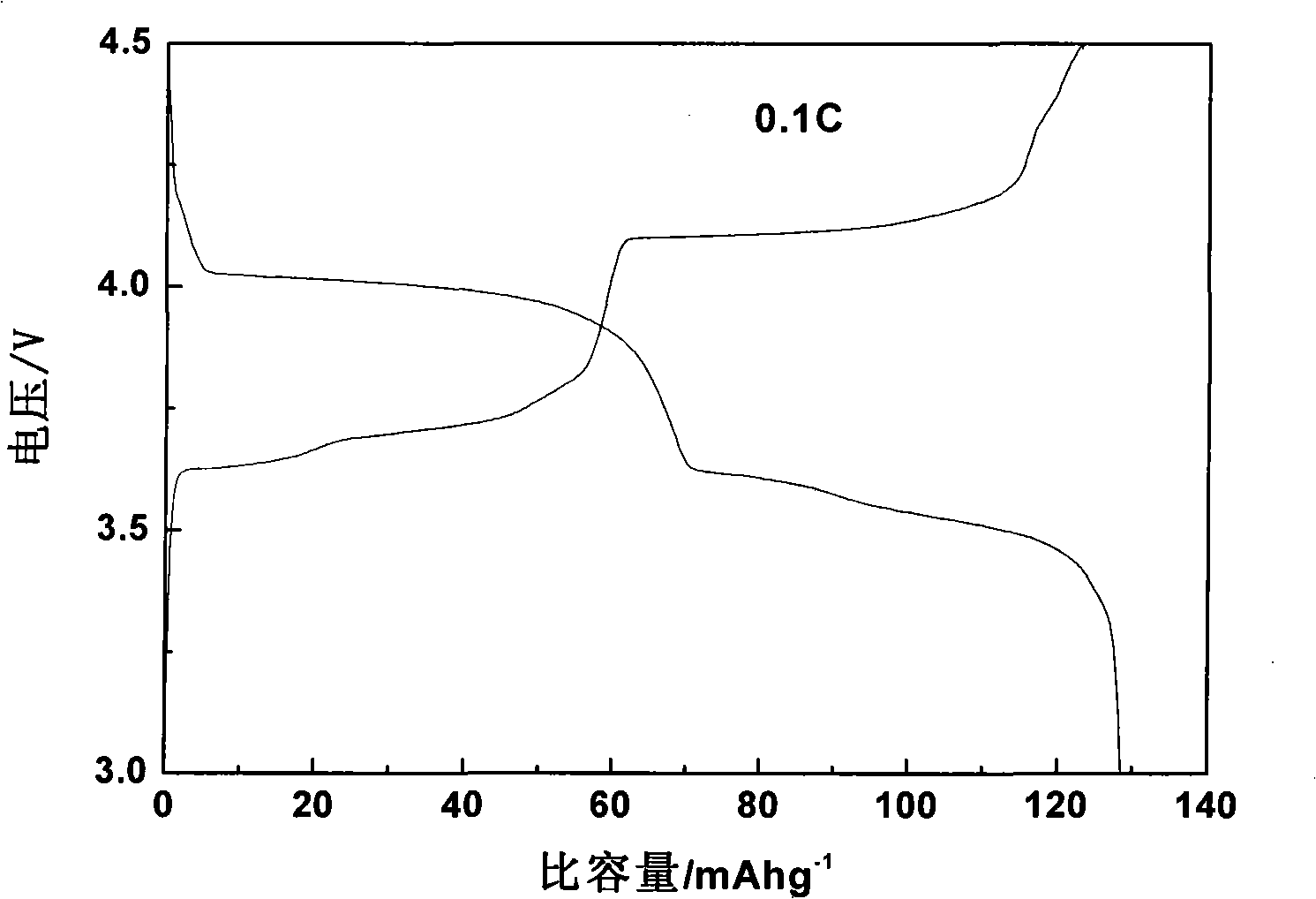

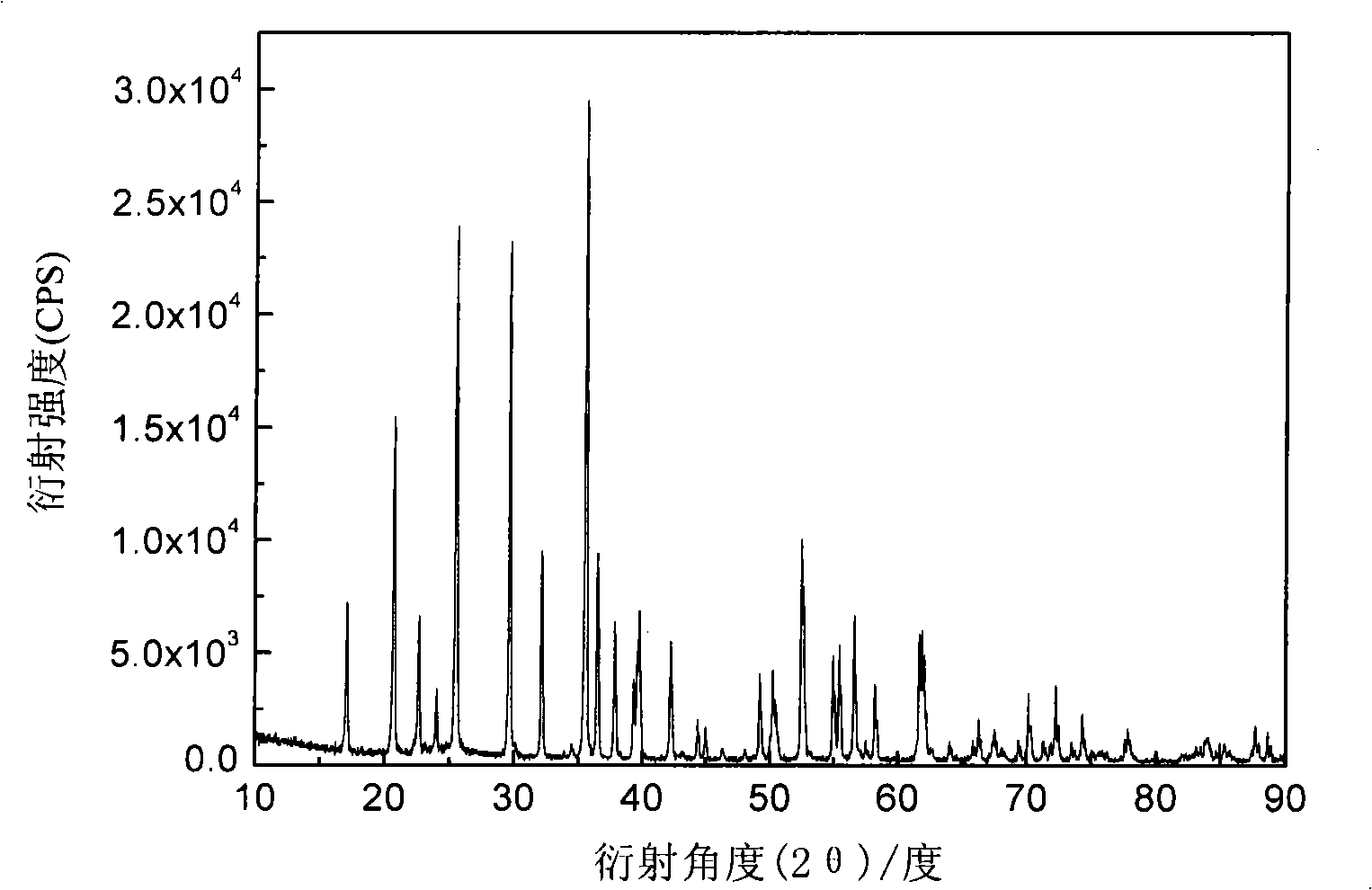

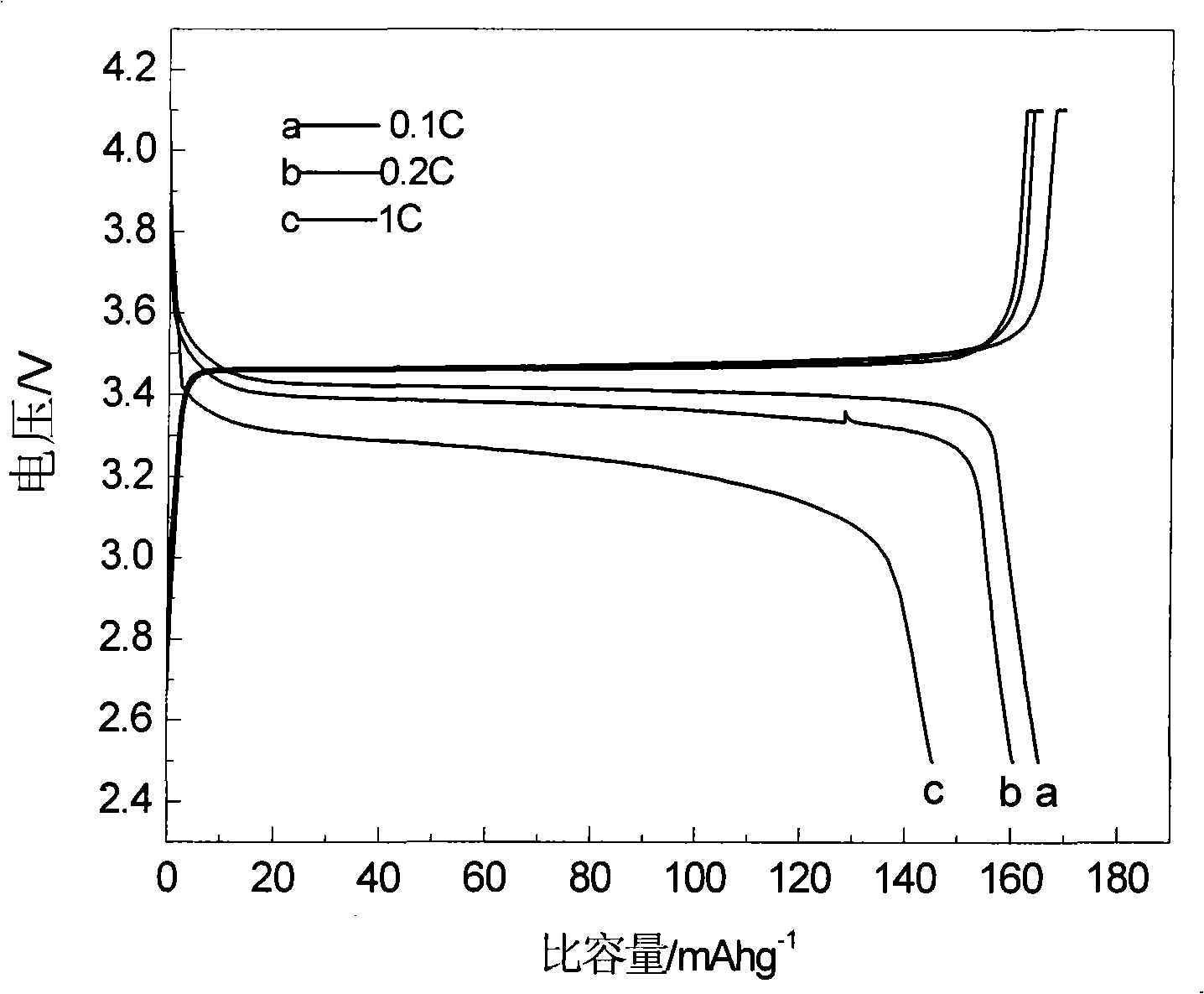

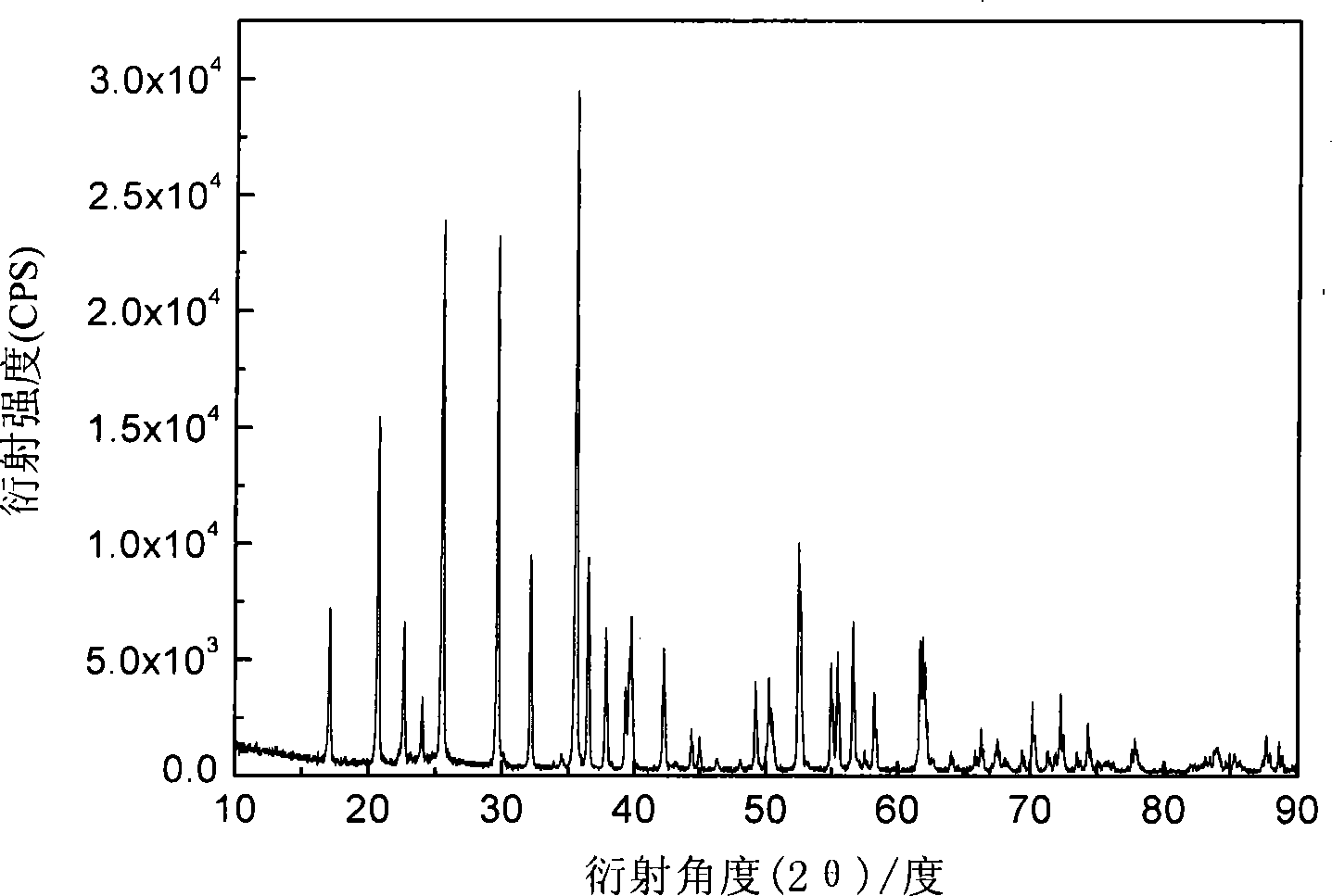

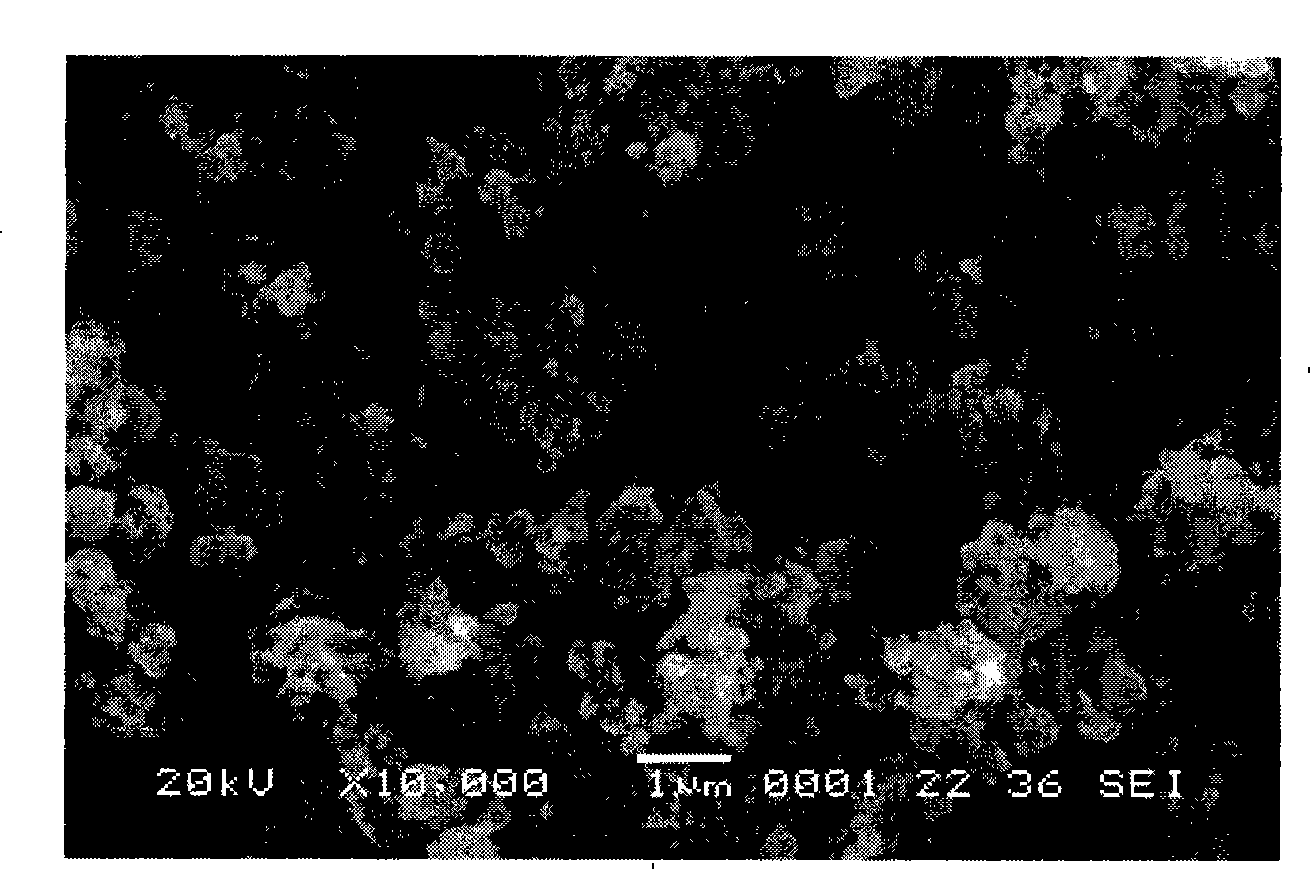

A method for making anode material Li3V2(PO4)3 of lithium ion battery

InactiveCN101262060ASmall particlesUniform particle size distributionElectrode manufacturing processesLithium compoundsAluminium-ion batterySodium-ion battery

The invention discloses a preparation method of lithium vanadium phosphate, a material for positive electrode of lithium ion battery. The preparation method of the invention comprises the steps that: high-valent vanadium compound, phosphorus compound and lithium compound are taken as raw materials and mixed according to molar ratio of contained vanadium, phosphorus and lithium is 2:3:3; the mixture is evenly mixed under room temperature and is added with a reducing agent, then mechanical activation is carried out; the molar ratio of the reducing agent and iron compound is controlled within 1:1-10:1; after 0.5-20 hours of activation and under normal temperature and pressure, the reducing agent is adopted to reduce high-valent vanadium compound so as to produce fine particles of amorphous Li3V2(PO4)3 which is then sent into non oxidizing atmosphere to be heated to 500-700 DEG C and calcined for 2-20 hours under constant temperature; then the crystalline state lithium vanadium phosphate powder is obtained. The preparation method of lithium vanadium phosphate adopts the low-temperature method to process the amorphous lithium vanadium phosphate so as to prepare the lithium vanadium phosphate with excellent performance, which greatly reduces energy consumption and cost. The lithium vanadium phosphate prepared by the preparation method of lithium vanadium phosphate has excellent charge / discharge performance.

Owner:CENT SOUTH UNIV

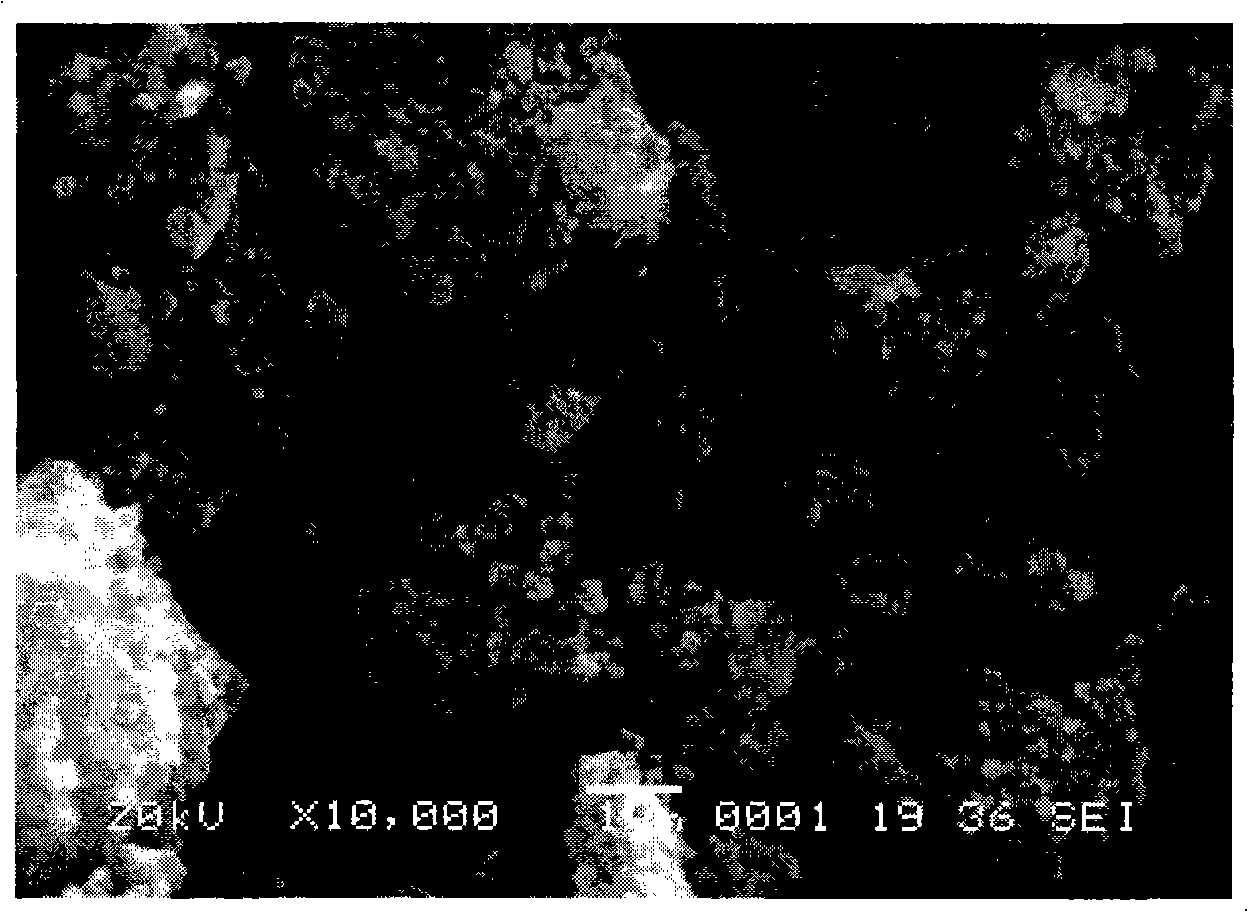

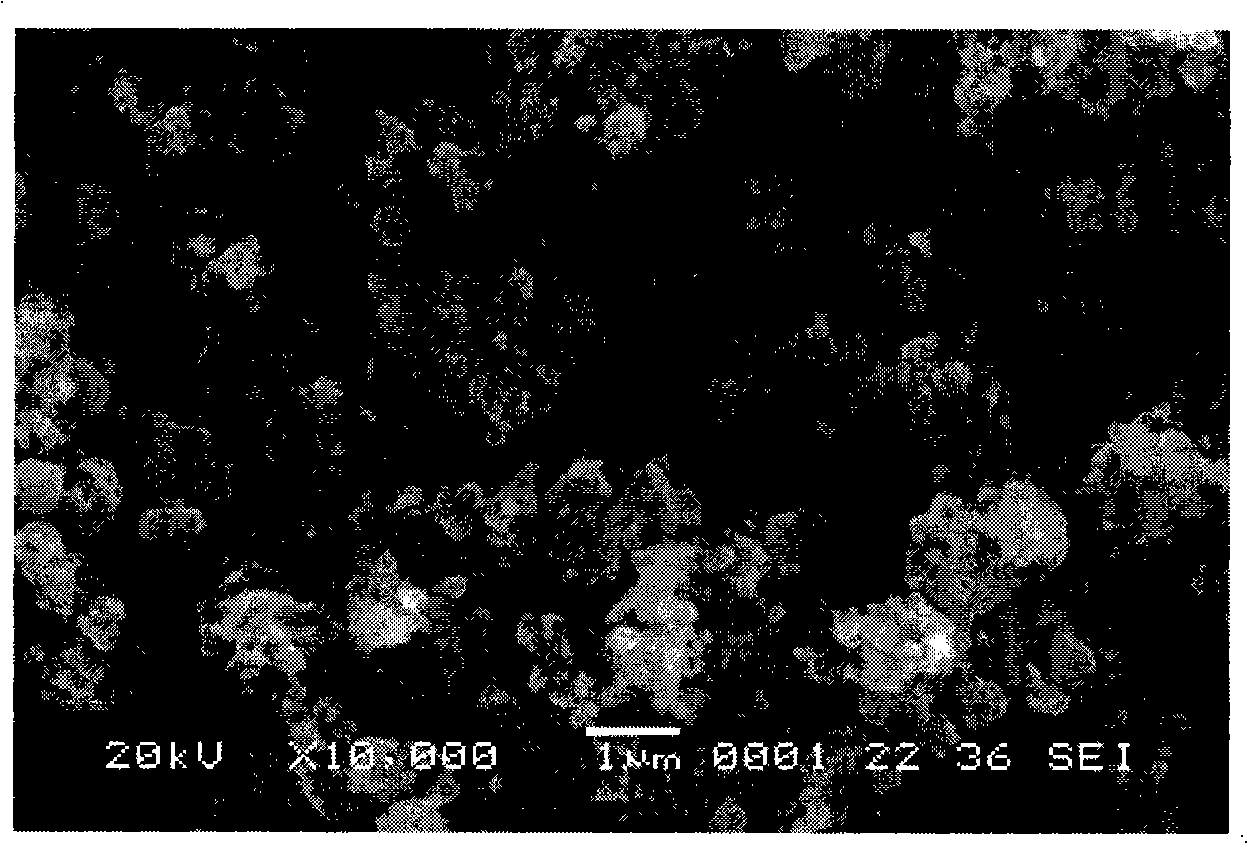

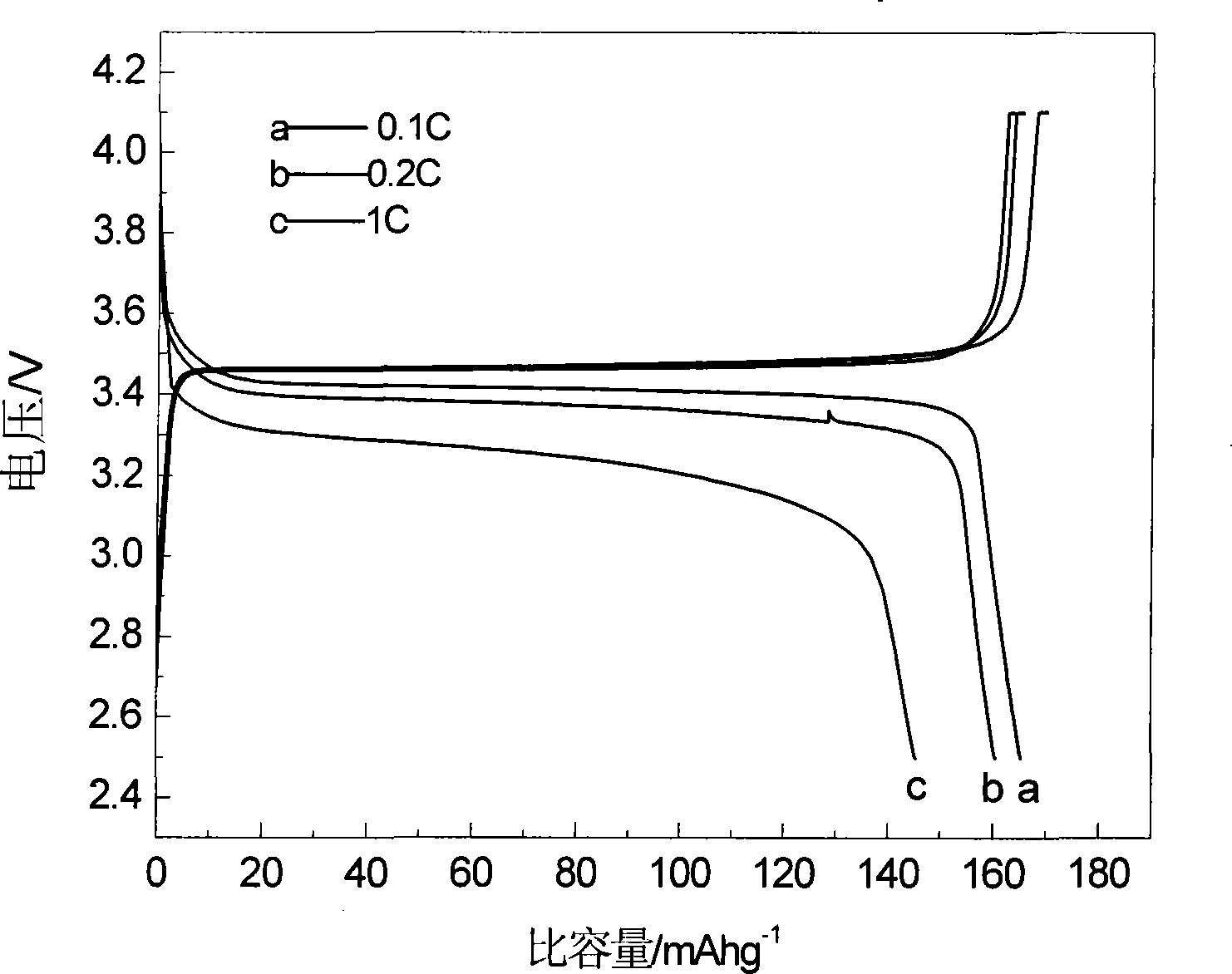

A method for making anode material LiFePO4 of lithium ion battery

InactiveCN101262059ALow costReduce energy consumptionElectrode manufacturing processesLithium compoundsLithium compoundLithium electrode

The invention discloses a preparation method of lithium iron phosphate, a material for positive electrode of lithium ion battery. The preparation method comprises the steps that: ferric iron compound, phosphorus compound and lithium compound are taken as raw materials and mixed according to molar ratio of the contained iron, phosphorus and lithium 1:1:1; the obtained mixture is evenly mixed under room temperature, and then mechanical activation is carried out; after 0.5-20 hours of activation, a reducing agent is added with the molar ratio of the reducing agent and the iron compound is 1:1-1:6; under normal temperature and pressure, the ferric iron is reduced by the reducing agent, so as to produce fine particles of LiFePO4 which is then sent into non oxidizing gas to be heated to 300-700 DEG C and calcined for 2-20 hours under constant temperature; finally, the lithium iron phosphate is obtained. The preparation method of lithium iron phosphate adopts low-temperature method to process the amorphous lithium iron phosphate so as to produce the lithium iron phosphate with excellent performance, which greatly reduces energy consumption and cost.

Owner:CENT SOUTH UNIV

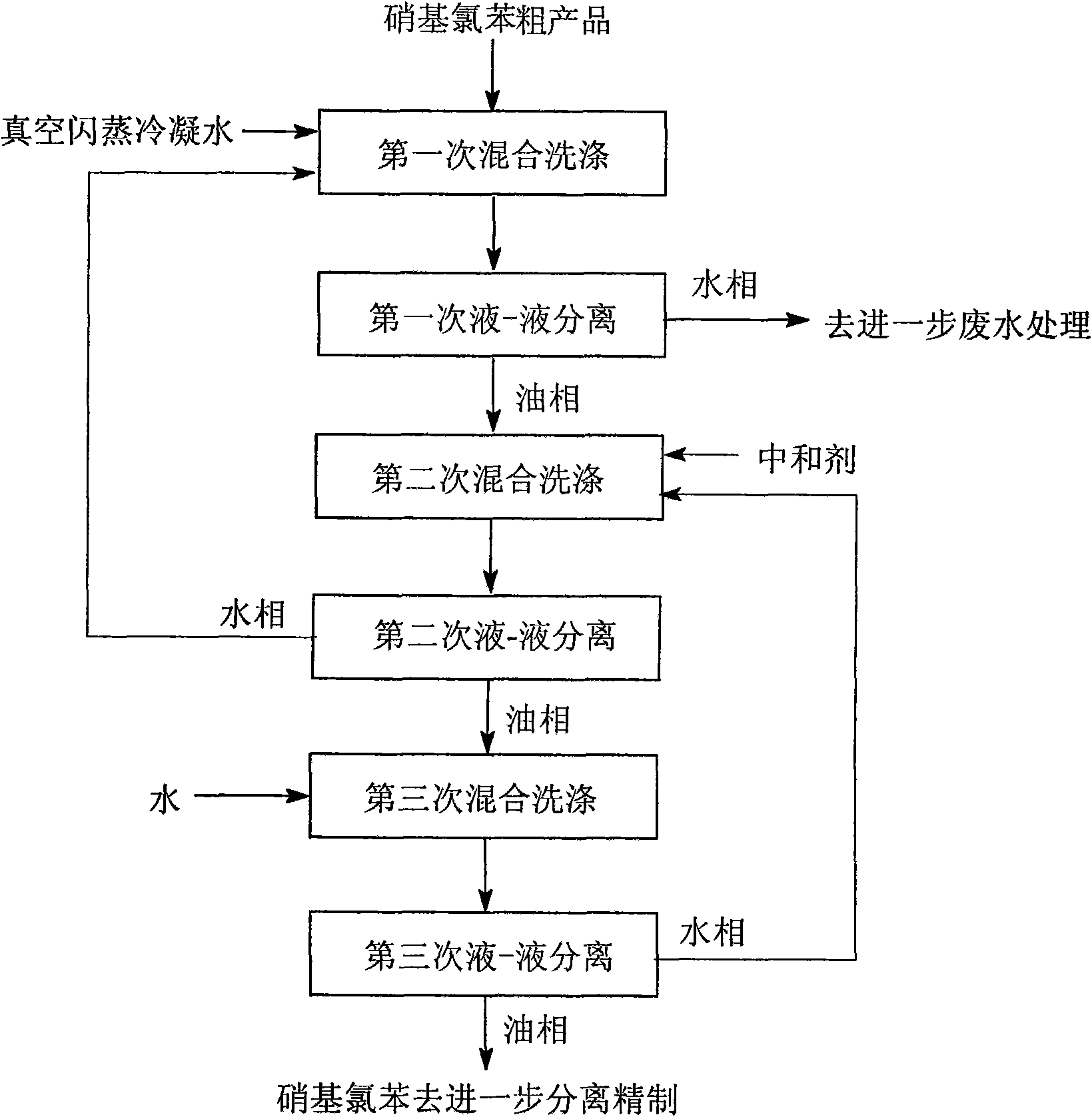

Washing impurity-removing technology of crude nitrochlorobenzene products after chlorobenzene thermal insulation nitration

InactiveCN101607911AHigh yieldReduce processingOrganic chemistryOrganic compound preparationThermal insulationNitration

The invention discloses a washing impurity-removing technology of crude nitrochlorobenzene products after a chlorobenzene thermal insulation nitration, comprising the following steps: (1) mixed washing of the crude nitrochlorobenzene products with condensation water obtained by vacuum flashing and water-phase materials obtained by secondary liquid-liquid separation is conducted; (2) wastewater in the water-phase materials is removed, and oil-phase materials enter the next step; (3) mixed washing of the oil-phase materials, the water-phase materials obtained by liquid-liquid separation of the third time and a neutralizer is conducted; (4) the water phase materials are used as primary mixed washing water, and the oil-phase materials enter the next step; (5) mixed washing of the oil-phase materials and water is conducted; and (6) the water-phase materials are used as secondary mixed washing water, and the oil-phase materials are separated and refined. The washing impurity-removing technology has the advantages of simpleness, easy operation, less energy consumption, washing water conservation, wastewater reduction, recyclable auxiliary products, saved cost and convenient realization of large-scale industrialization.

Owner:YANGZHOU UNIV

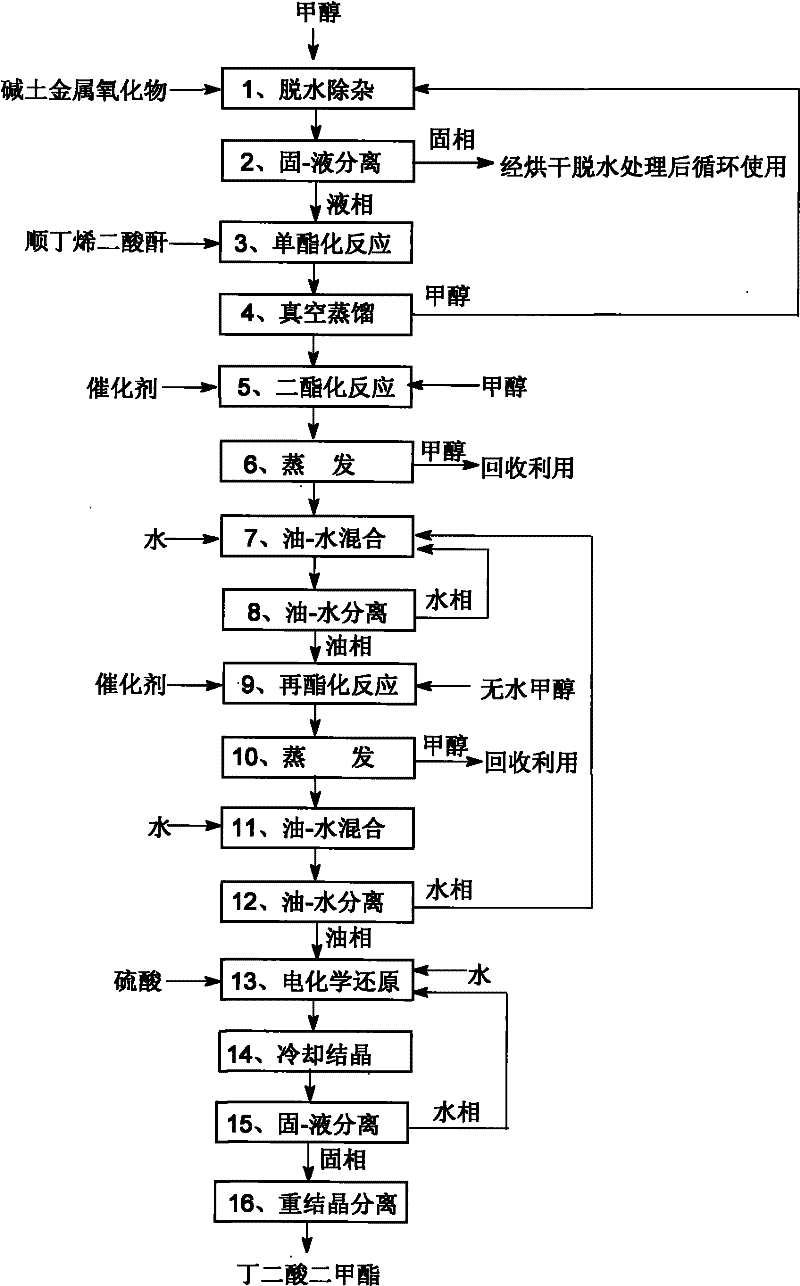

Method for preparing dimethyl maleate

ActiveCN101823962AThorough responseReduce generationOrganic compound preparationCarboxylic acid esters preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl maleate, which comprises the following steps of : (1) dehydration and impurity removal: methanol is mixed with alkaline-earth metal oxide to be dehydrated and removed impurity; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) two-esterification reaction: acid catalyst and methanol are added in the material after the vacuum distillation in the previous step; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-esterification reaction; (10) evaporation; (11) mixing of oil and water; (12) separation of oil and water; (13) impurity removal and dehydration; (14) separation of solid and liquid: liquid-phase material enters the next step; (15) rectification separation: the product dimethyl maleate is obtained. The method is simple and has reasonable process, low preparation cost, high product purity and good product quality.

Owner:河北彩客新材料科技股份有限公司

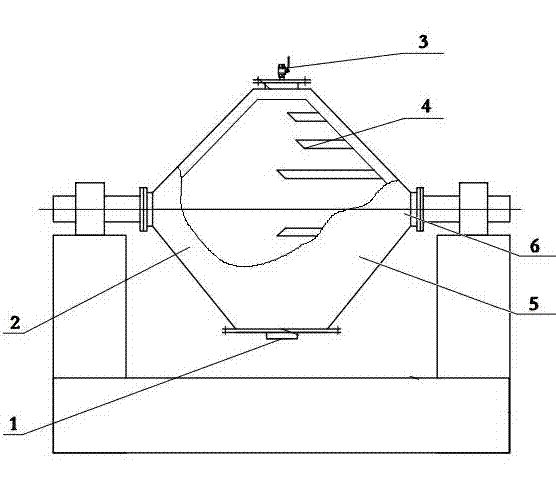

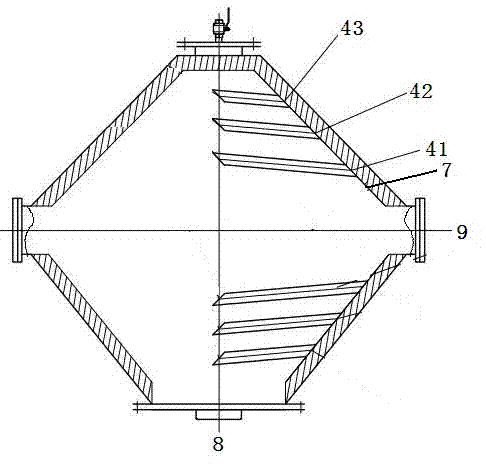

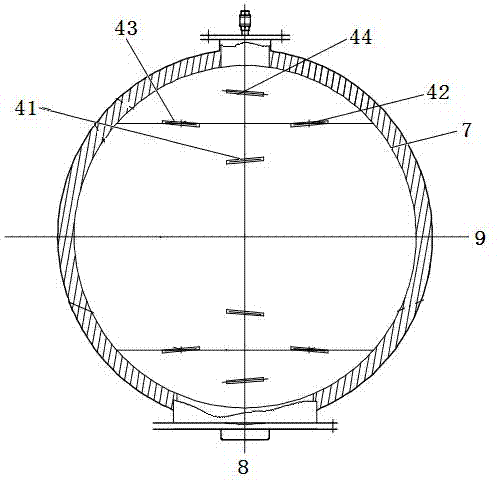

Nano silicon dioxide stirring modification method and device thereof

InactiveCN102755871AWell mixedAdequate responseChemical/physical/physico-chemical moving reactorsHigh probabilityEngineering

The invention discloses a nano silicon dioxide stirring modification method and a device thereof, which comprise a kettle body and an operation method thereof, and are characterized in that closed cones with conical structures are adopted at the two ends of the kettle body, wherein the inner wall of the kettle body is provided with flow guide baffles. The nano silicon dioxide stirring modification method and the device thereof have the beneficial effects that the kettle body has a double-cone structure, power for flowing all materials can be provided, a mixing process from centralization to decentralization and from decentralization to centralization can also be finished, eight oblique flow guide baffles are arranged in the kettle body, so that the material which flows in the kettle at a high speed flows in a given direction, and thus, the material can be uniformly mixed and fully reacted. The materials with high probability of being adhered to walls and forming stirring dead angles such as powder and filter cakes in the production field of the nano silicon dioxide can be equivalently effectively modified. The stirring mode is unique, complex stirring shape and high-speed operation are not required, the technical difficulty is low, the equipment machining cost and the operation cost are low, and large-scale industrialization is easy to realize.

Owner:XIUSHAN LONFEE NEW MATERIAL

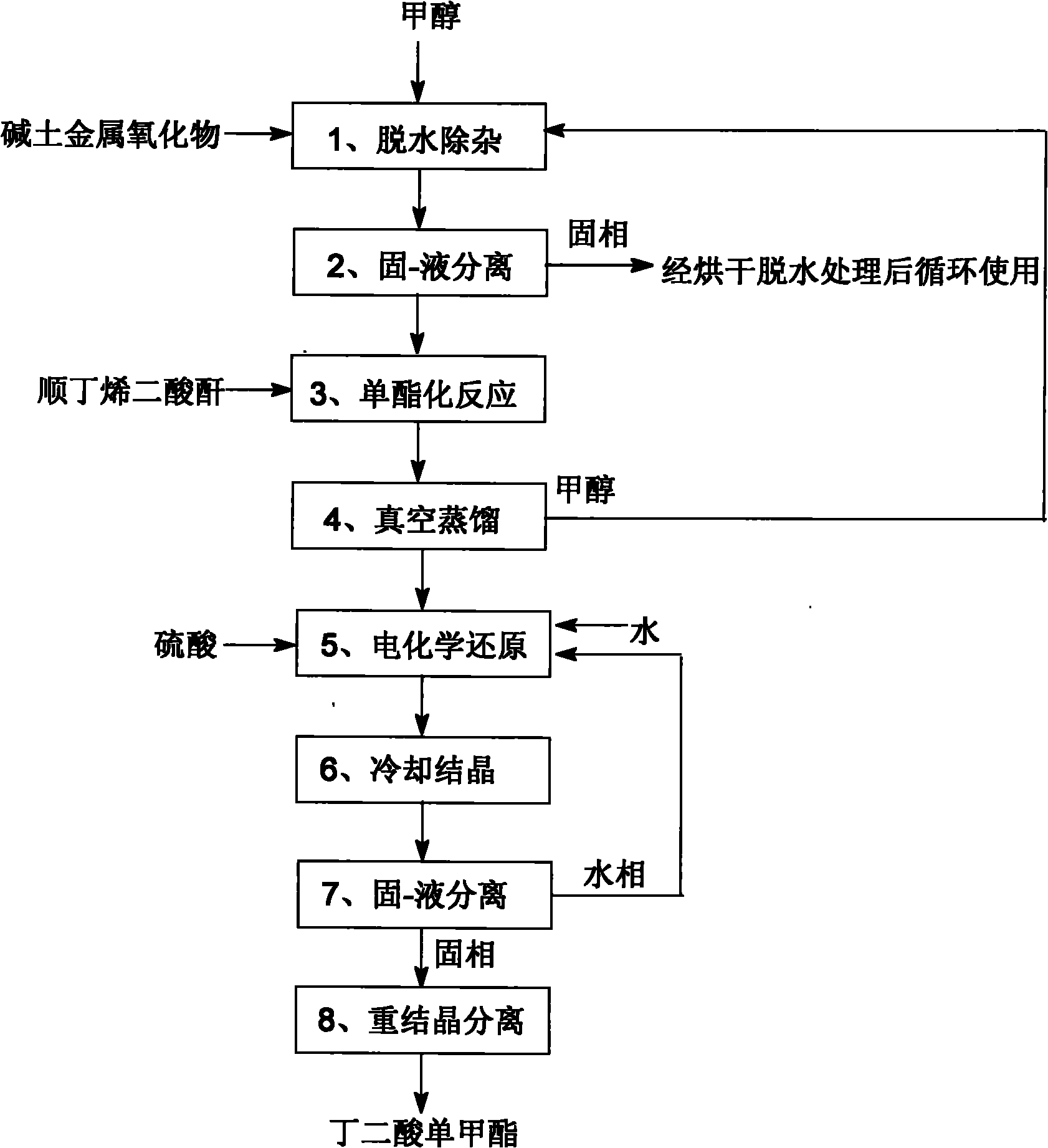

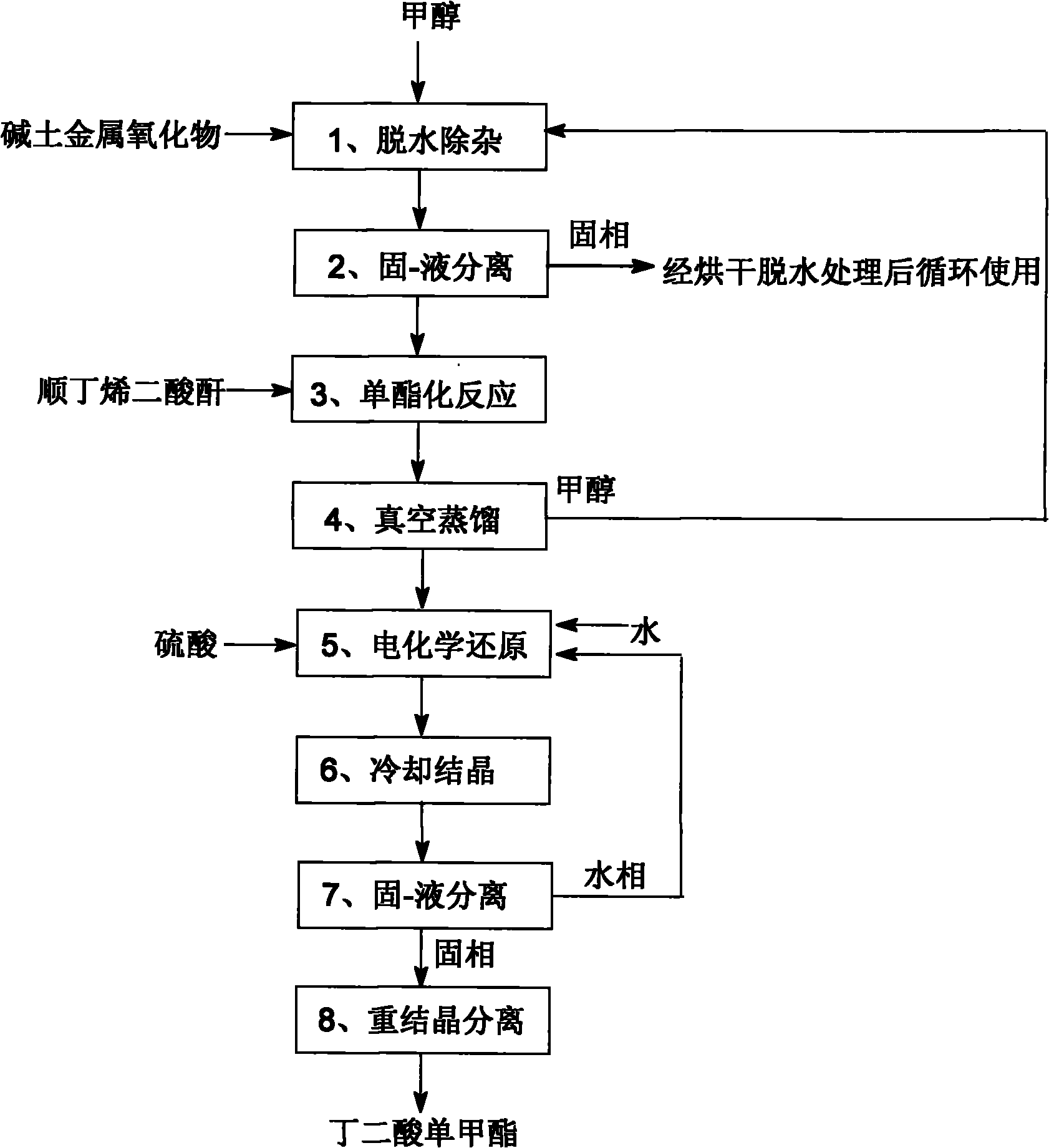

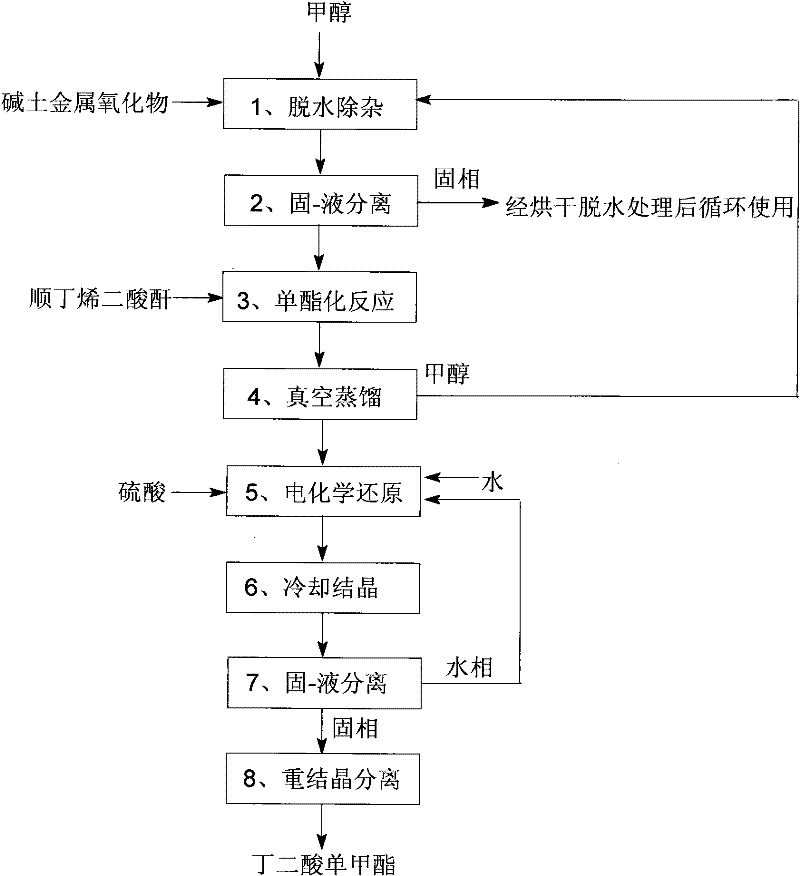

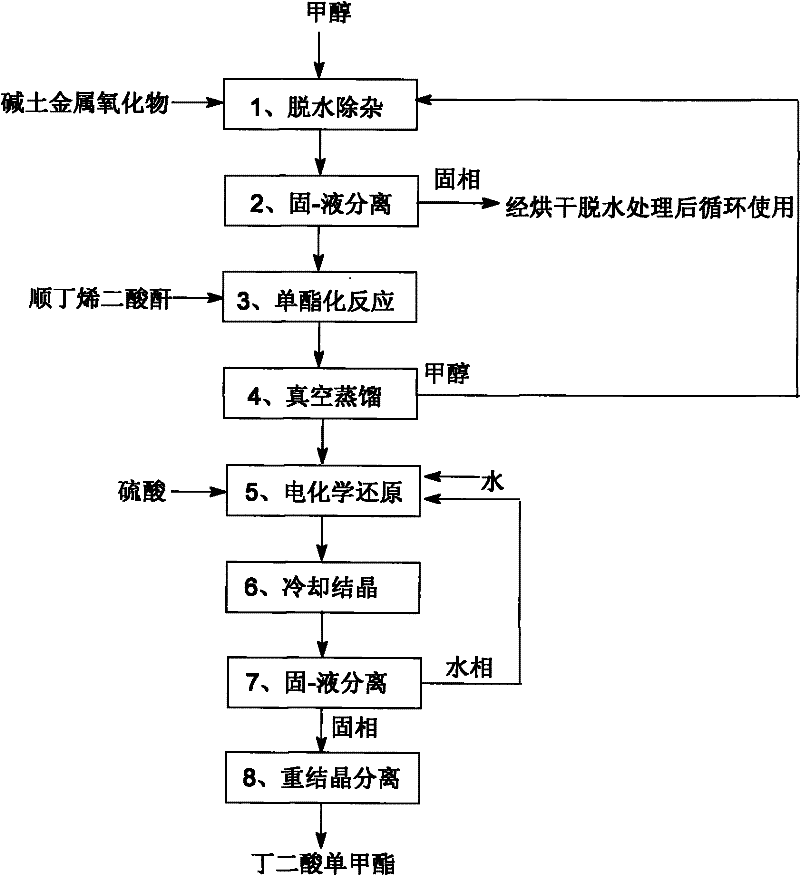

Method for preparing monomethyl succinate

InactiveCN101831662AStrong equipment applicabilityFlexible operationElectrolysis componentsElectrolytic organic productionSolid phasesMaleic anhydride

The invention relates to a method for preparing monomethyl succinate. The monomethyl succinate is prepared by using maleic anhydride and methyl alcohol as raw materials. The method comprises the steps of: 1, dehydrating and removing impurities: adding the methyl alcohol into a dehydrating and impurity-removing device, adding alkali-earth oxides for dehydrating and removing impurities; 2, carrying out solid-liquid separation: ensuring that liquid-phase materials enter the next step; 3, carrying out hemisuccination: adding the maleic anhydride into the liquid phase materials obtained by the step 2; 4, carrying out vacuum distillation: ensuring that the materials subjected to the methyl alcohol removal enter the next step; 5, carrying out electrochemistry reduction: carrying out electrochemistry hydrogenation reduction reaction on a monomethyl cis-butenedioic acid product, water and sulfuric acid; 6, cooling and crystallizing; 7, carrying out solid-liquid separation: ensuring that solid phase materials enter the next step; and 8, carrying out recrystallization separation to obtain the product of the monomethyl succinate. The invention has simple preparation method, reasonable process, low preparation cost, high product purity, good product quality, high yield and convenient implementation for mass industrialization.

Owner:淮安苏瑞精细化工有限公司

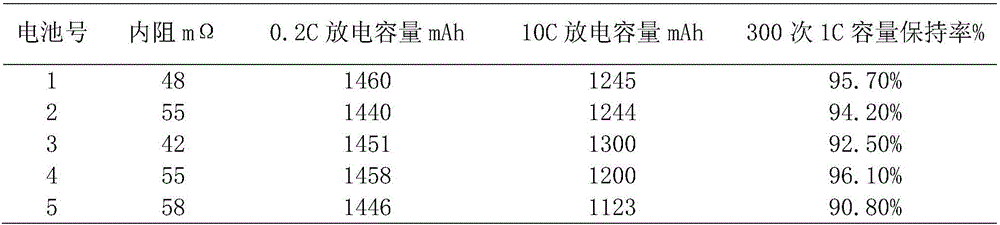

Lithium battery current collector and preparing method thereof

InactiveCN105826569ALower internal resistanceImprove power characteristicsElectrode carriers/collectorsCarbideSolvent

The invention belongs to the field of lithium batteries, and provides a lithium battery current collector and a preparing method thereof. The lithium battery current collector comprises current collector foil and inert buffer layers applied to at least one surface of the current collector foil. Each inert buffer layer comprises coating powder and a binder, wherein the coating powder comprises at least one of metal nitride and metal carbide. The preparing method comprises the steps of dispersing the coating powder and the binder in a solvent to form inert buffer size, applying the inert buffer size to at least one surface of the current collector foil to form an inert buffer size coating, and conducting drying treatment.

Owner:INST OF NEW ENERGY SHENZHEN +1

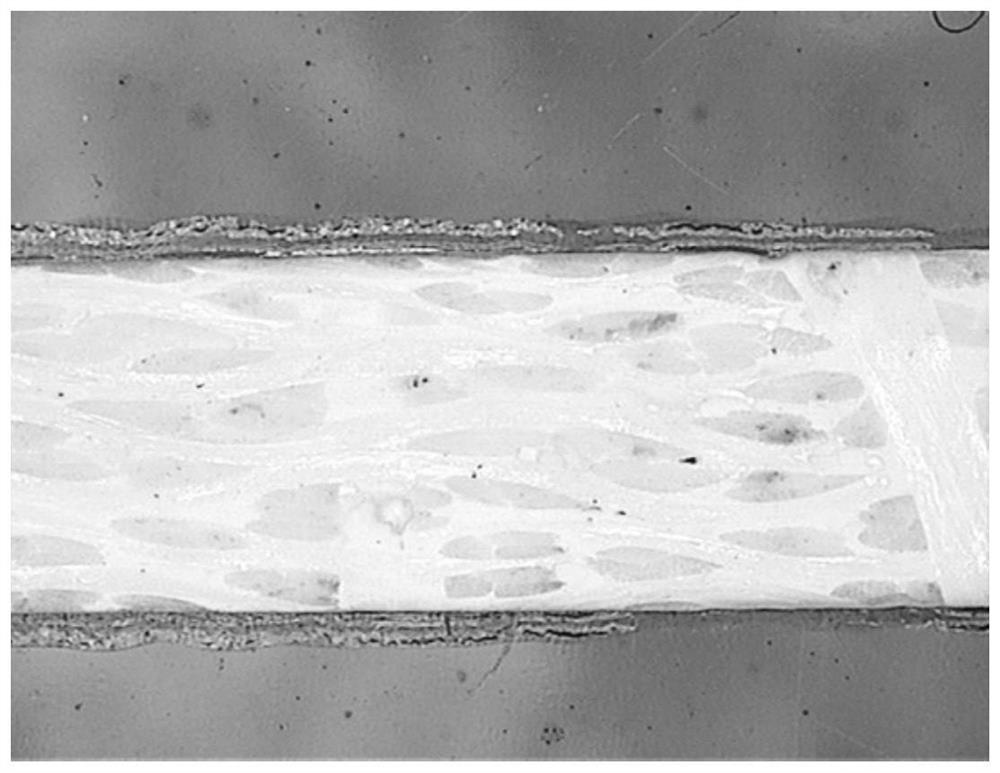

Three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on aqueous slurry impregnation process and preparation method of three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material

PendingCN112851386AOvercoming the problem of easy failure without fiber reinforcementGuaranteed deflectionOxide compositeAlumina composite

The invention relates to the technical field of continuous fiber reinforced ceramic matrix composite materials, and particularly discloses a three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on an aqueous slurry impregnation process, and the porosity of the composite material is 20-30%. A reinforced phase of the composite material is a continuous aluminum oxide fiber woven part, the woven part is in a fiber cloth sewing, two-dimensional and half or three-dimensional weaving mode, the mass content of alumina in alumina fibers is not lower than 70%, and the volume fraction of the fibers in the composite material is 40-45%. The aluminum oxide matrix of the composite material is prepared through the processes of multiple times of dipping, drying and sintering of water-based aluminum oxide powder slurry with high solid content and low viscosity, the solid content of the water-based aluminum oxide powder slurry is 30-40 vol%, the viscosity of the slurry is 5-30 mPas, the pH is 3-4.5, and the Zeta potential is 60-70 mV. The invention also provides a preparation method of the composite material. The reinforced fibers are arranged between the layers of the composite material, so that the integrity is good. The preparation method disclosed by the invention is simple in process, low in cost, good in environmental protection property and easy to realize large-scale industrialization.

Owner:NAT UNIV OF DEFENSE TECH

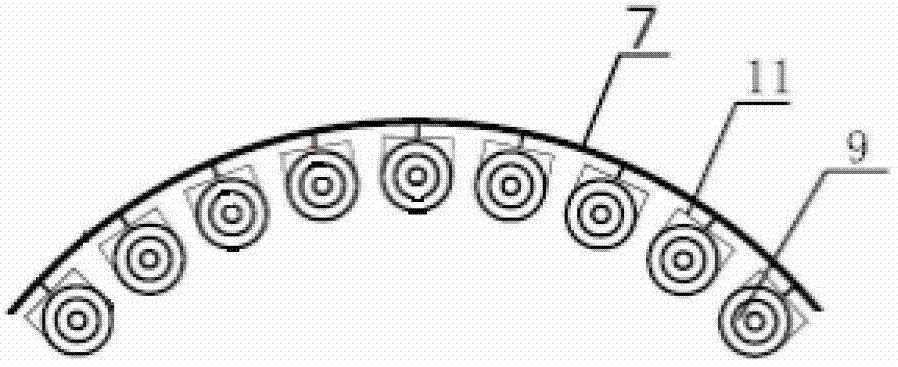

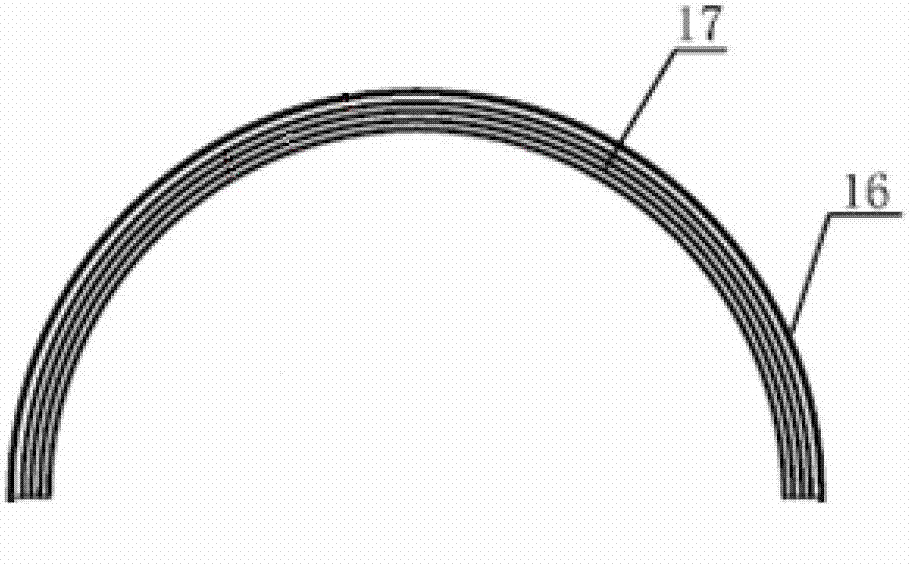

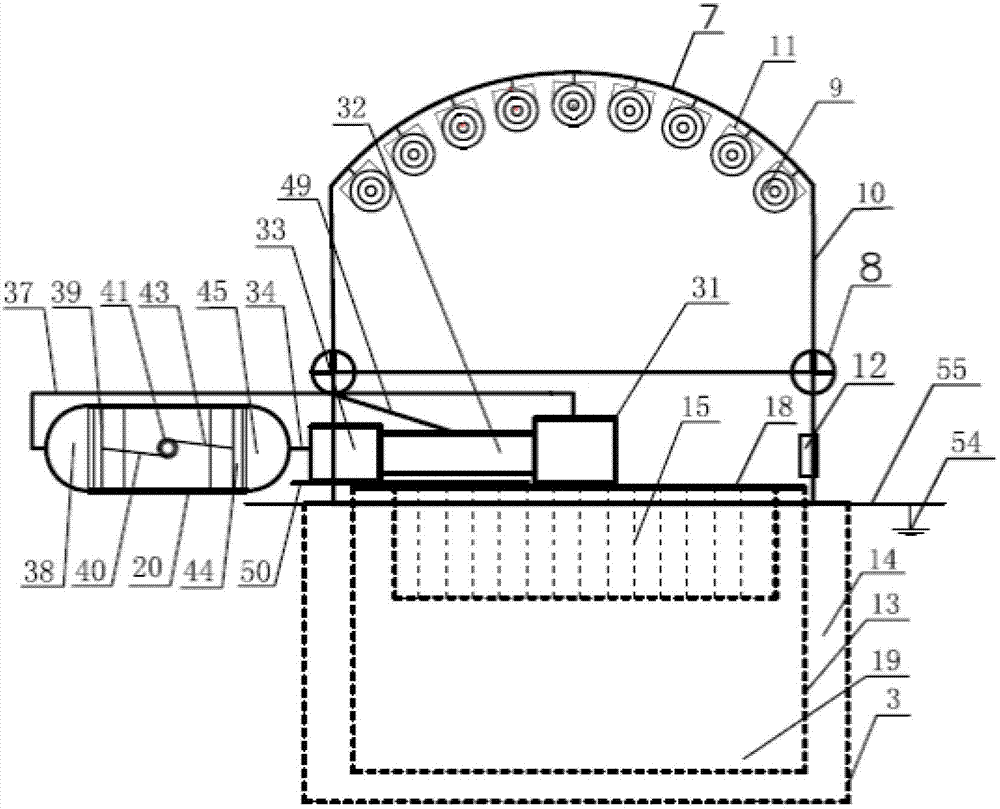

Dome type focusing heat accumulator and dome type solar thermoelectric system

ActiveCN103115441ASimple structureLow costSolar heating energyFrom solar energyExternal combustion engineEngineering

The invention discloses a dome type focusing heat accumulator which comprises a paraboloid-shaped dome. The paraboloid-shaped dome is composed of multiple Fresnel lenses, and an opening of the dome faces the ground. In addition, the invention discloses a dome type solar thermoelectric system which comprises the dome type focusing heat accumulator, an external combustion engine and a power generator. A heater of the external combustion engine is arranged with in a focal point range of the dome, and the external combustion engine is connected with the power generator and used for driving the power generator to generate power. The dome type focusing heat accumulator and the dome type solar thermoelectric system have the advantages of simple structure and low cost.

Owner:毛建华

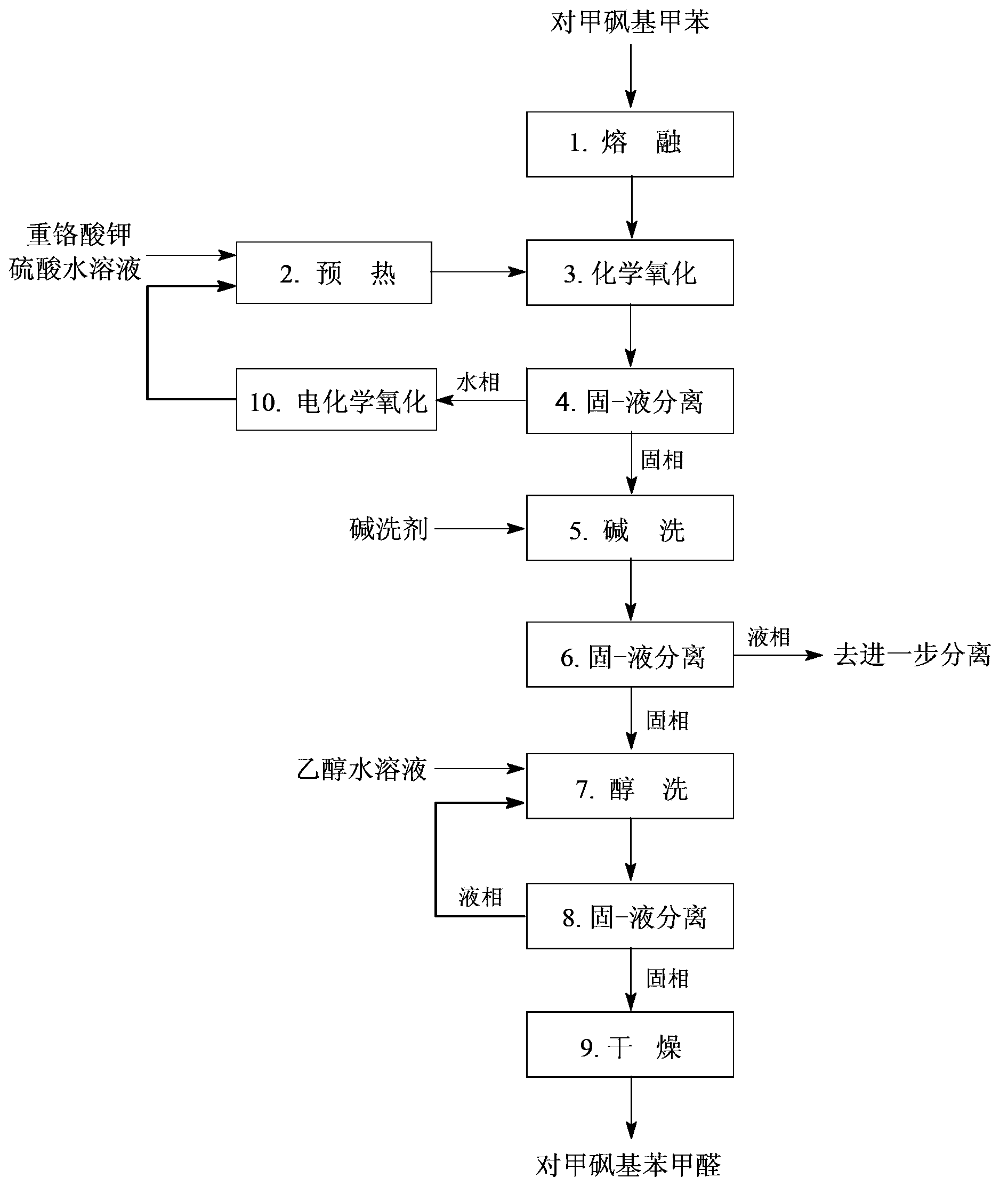

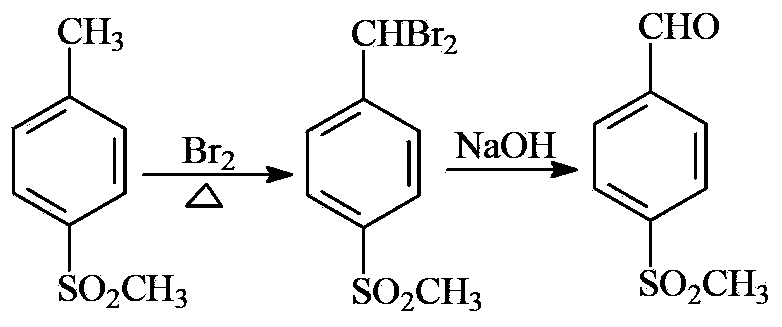

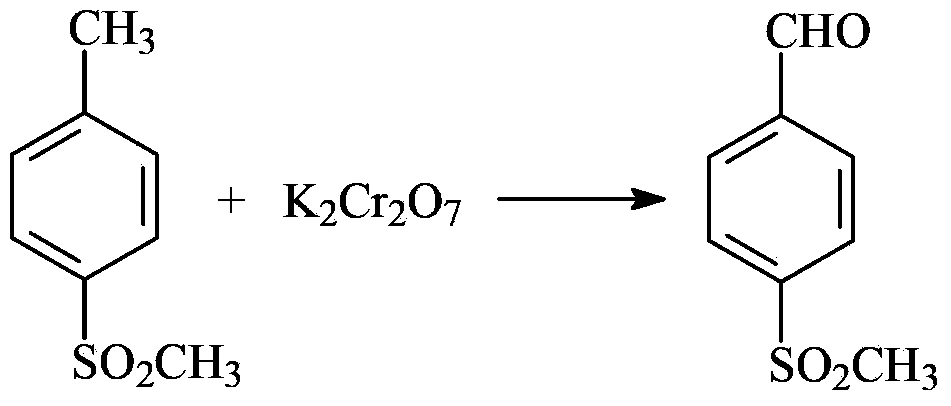

MethyIsuIfino benzaldehyde preparation method

ActiveCN103360287AAchieve recyclingReduce pollutionOrganic chemistryOrganic compound preparationAlcoholBenzaldehyde

The invention relates to a methyIsuIfino benzaldehyde preparation method mainly comprising the steps of: (1) smelting; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) alkali washing; (6) solid-liquid separation; (7) alcohol washing; (8) solid-liquid separation; (9) drying; and (10) electrochemical oxidation. The process provided by the invention is reasonable, the preparation method is simple, production cost is low, product purity is high, and the process is safe. The method is suitable for realizing large-scale industrialization. The process is a clean production process of methyIsuIfino benzaldehyde preparation. The process satisfies the requirement of green chemical engineering development.

Owner:YANGZHOU UNIV

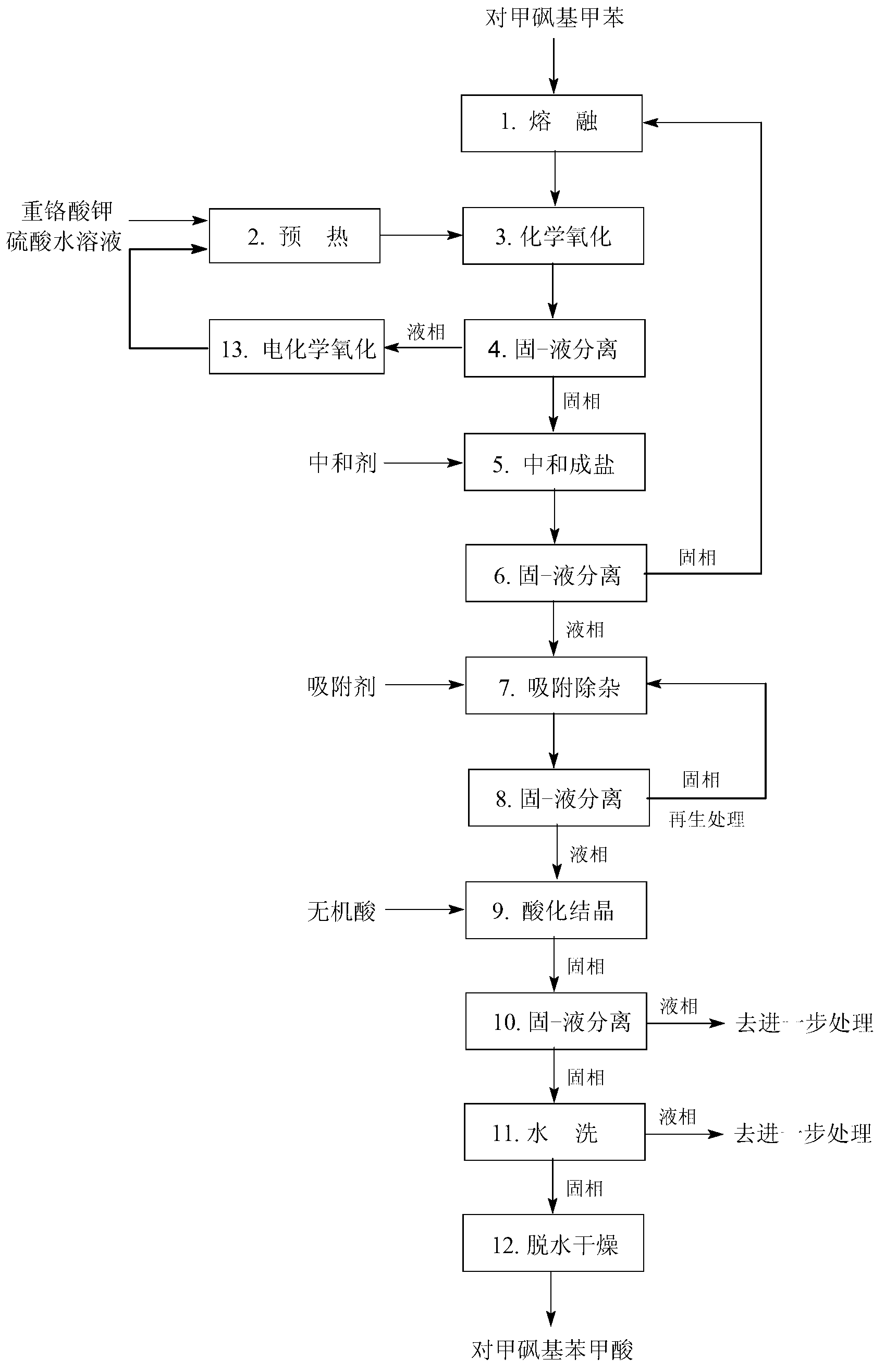

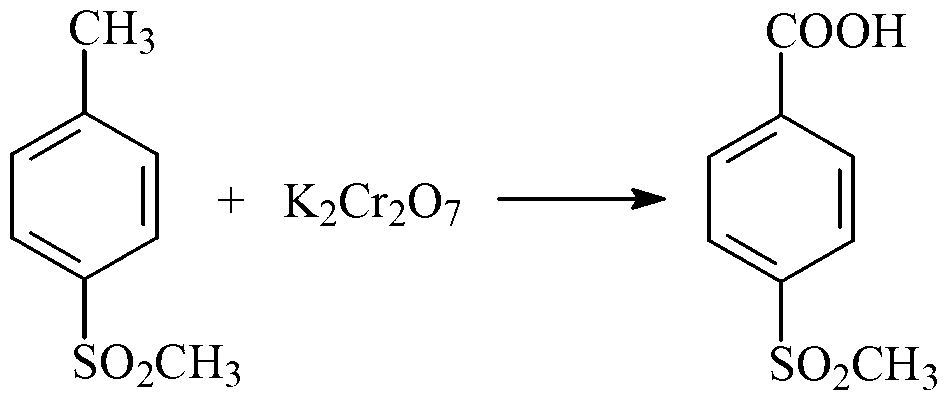

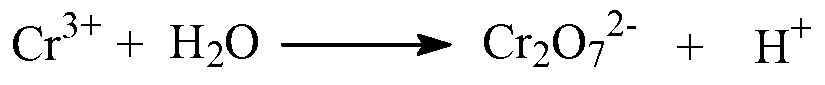

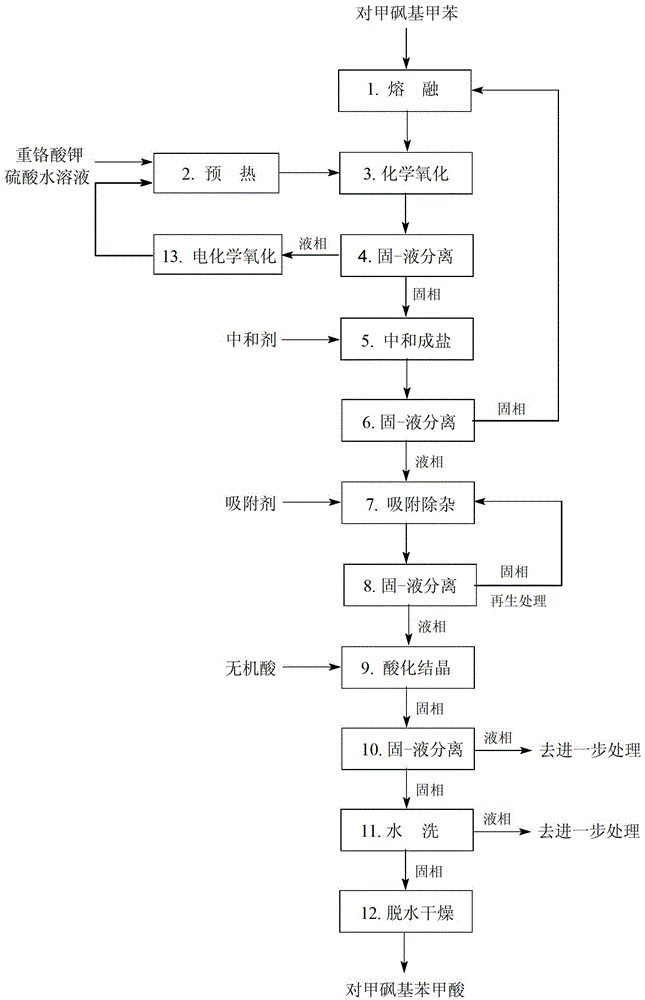

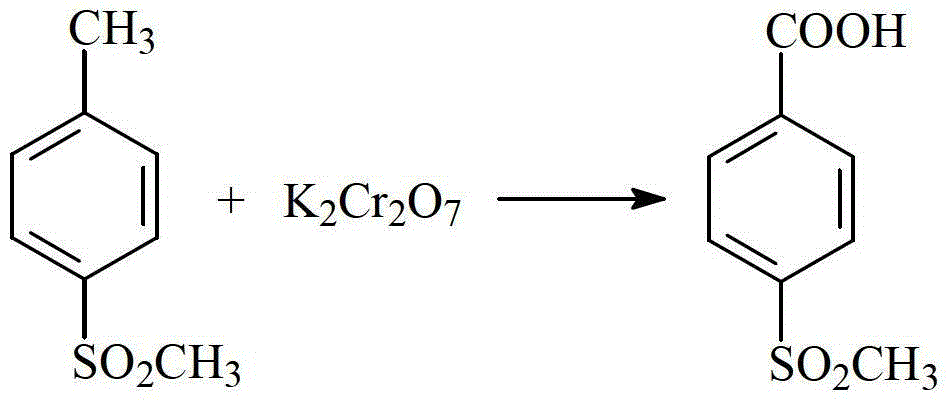

Preparation method of p-methylsulfonylbenzoic acid

InactiveCN103319383AAchieve recyclingReduce pollutionOrganic chemistryOrganic compound preparationImpurityCleaner production

The invention relates to a preparation method of p-methylsulfonylbenzoic acid. The method provided by the invention mainly comprises the following steps: (1) fusing; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) neutralization for salt formation; (6) solid-liquid separation; (7) adsorption for removal of impurities; (8) solid-liquid separation; (9) acidification and crystallization; (10) solid-liquid separation; (11) washing; (12) dewatering and drying for obtaining a product p-methylsulfonylbenzoic acid; and (13) electrochemical oxidation. The preparation method provided by the invention is simple, has advantages of reasonable technology, low production cost, high product purity and safe process, is convenient to realize large-scale industrialization, and is a clean production technology which is used for preparing p-methylsulfonylbenzoic acid and accords with green chemical development requirements.

Owner:扬州德耀电气有限公司

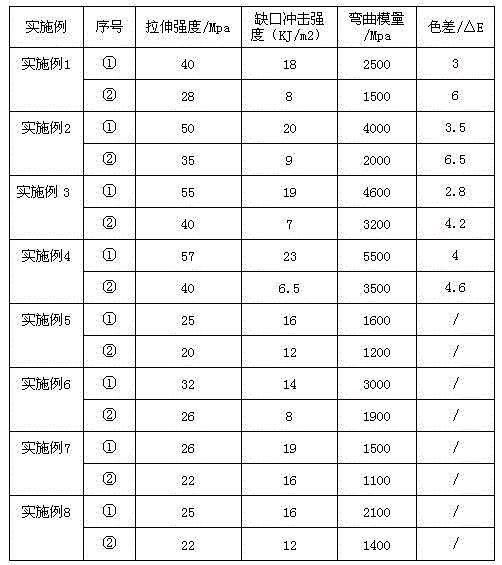

Nickel-maleate-grafted polypropylene ionomer as well as preparation method and application thereof

ActiveCN104418980AThe preparation process is simple and controllableImprove compatibilityPolypropyleneWeather resistance

The invention discloses a nickel-maleate-grafted polypropylene ionomer as well as a preparation method and an application thereof. The nickel-maleate-grafted polypropylene ionomer is prepared by adding and melting polypropylene, an initiator, nickel maleate, an antioxidant and a grafted additive in parts by weight in an extruder. The preparation method of the ionomer is simple and free of secondary pollution, and the ionomer has multiple functions of nucleation and compatibilization; in glass fiber reinforced system, the compatibility of the glass fiber and a matrix can be increased and meanwhile, the weather resistance of the system can be improved; and in a filling system, the compatibility of the powder and a matrix can be increased and meanwhile, the strength and modulus of the material can also be improved. By modifying glass fiber reinforced polypropylene or inorganic filler polypropylene with the ionomer, the flexural modulus, tensile strength and notch impact strength of a composite material can be improved and the weather resistance of the material can be increased by virtue of the chelated metal ions.

Owner:HEFEI GENIUS NEW MATERIALS

A method for making anode material LiFePO4 of lithium ion battery

InactiveCN101262059BLow costEasy to oxidizeElectrode manufacturing processesLithium compoundsAluminium-ion batterySodium-ion battery

Owner:CENT SOUTH UNIV

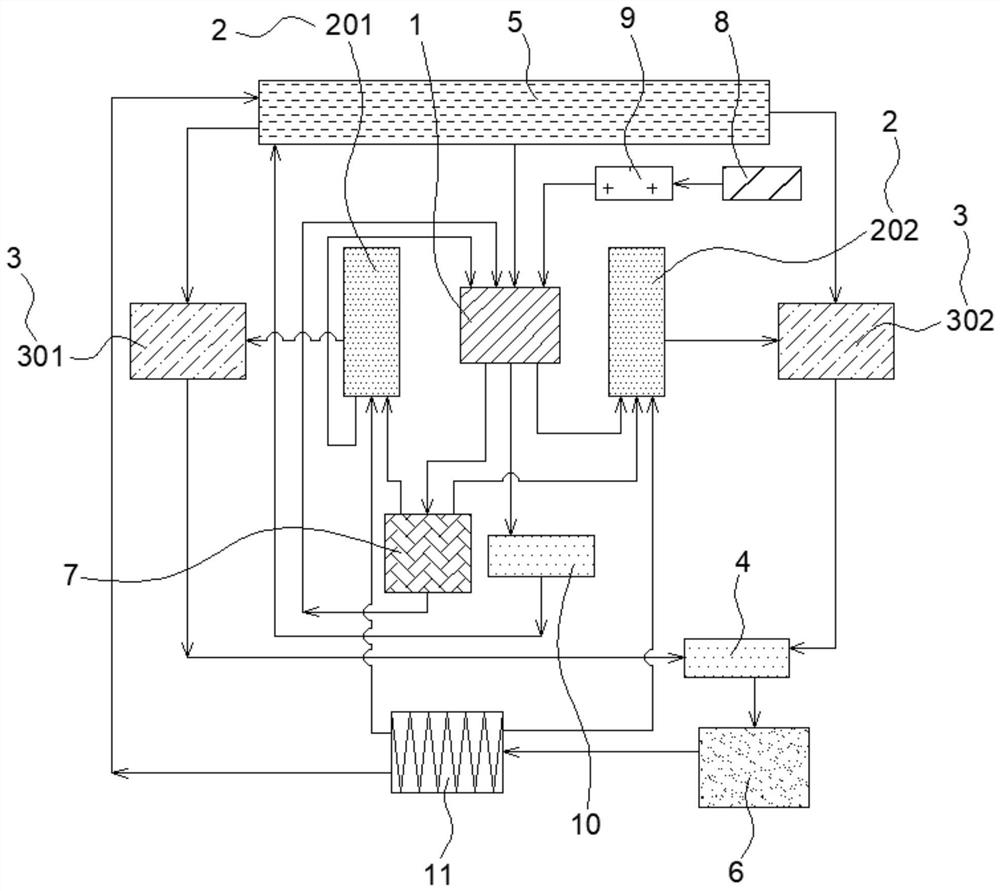

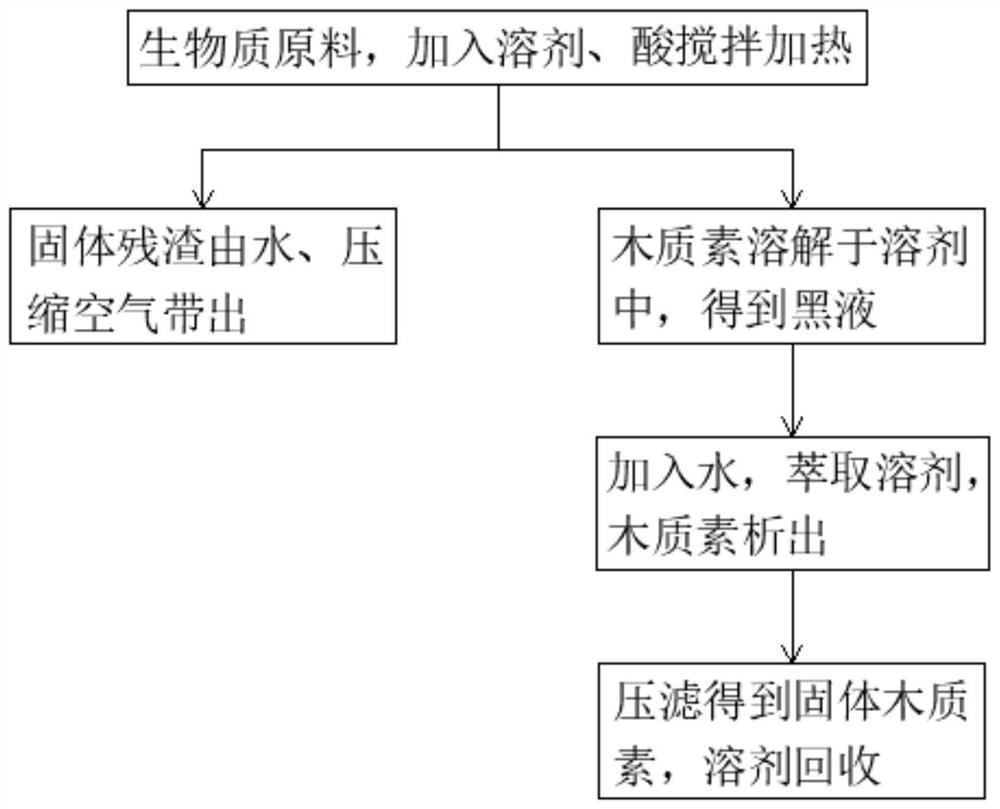

Lignin separation system and method thereof

ActiveCN114029022AImprove separation efficiencyImprove dissolution efficiencyChemical/physical/physico-chemical stationary reactorsFiltration circuitsSolventFilter press

The invention discloses a lignin separation system and method. The lignin separation system comprises a reaction kettle, solvent tanks, lignin separation tanks, a first filter press, a water tank and a solvent / water tank. After the biomass raw material in the reaction kettle and the solvent and the acid from one of the solvent tanks are jointly stirred and heated to be decomposed, most lignin is dissolved in the solvent and then sucked into the other solvent tank; after the solvent in the initial solvent tank is completely sucked, the solvent is reversely sucked from the other solvent tank to pass through the reaction kettle to enter the initial solvent tank, and suchsuction is carried out repeatedly and circularlyfor multiple times until the lignin is basically dissolved; then liquid in the two solvent tanks is introduced into the two lignin separation tanks,and meanwhile, water is introduced into the two lignin separation tanks from the water tank, the lignin is separated out and separated from the solvent and enter the first filter press together with the liquid; and the solid which is extruded and separated out is the lignin, and the solvent and water are introduced into the solvent / water tank. The method is simple and feasible in process route, simple in equipment and high in lignin separation efficiency.

Owner:合肥智慧环境研究院 +1

Preparation method of p-methylsulfonylbenzoic acid

InactiveCN103319383BReasonable workmanshipEasy to prepareOrganic chemistryOrganic compound preparationImpurityCleaner production

The invention relates to a preparation method of p-methylsulfonylbenzoic acid. The method provided by the invention mainly comprises the following steps: (1) fusing; (2) preheating; (3) chemical oxidation; (4) solid-liquid separation; (5) neutralization for salt formation; (6) solid-liquid separation; (7) adsorption for removal of impurities; (8) solid-liquid separation; (9) acidification and crystallization; (10) solid-liquid separation; (11) washing; (12) dewatering and drying for obtaining a product p-methylsulfonylbenzoic acid; and (13) electrochemical oxidation. The preparation method provided by the invention is simple, has advantages of reasonable technology, low production cost, high product purity and safe process, is convenient to realize large-scale industrialization, and is a clean production technology which is used for preparing p-methylsulfonylbenzoic acid and accords with green chemical development requirements.

Owner:扬州德耀电气有限公司

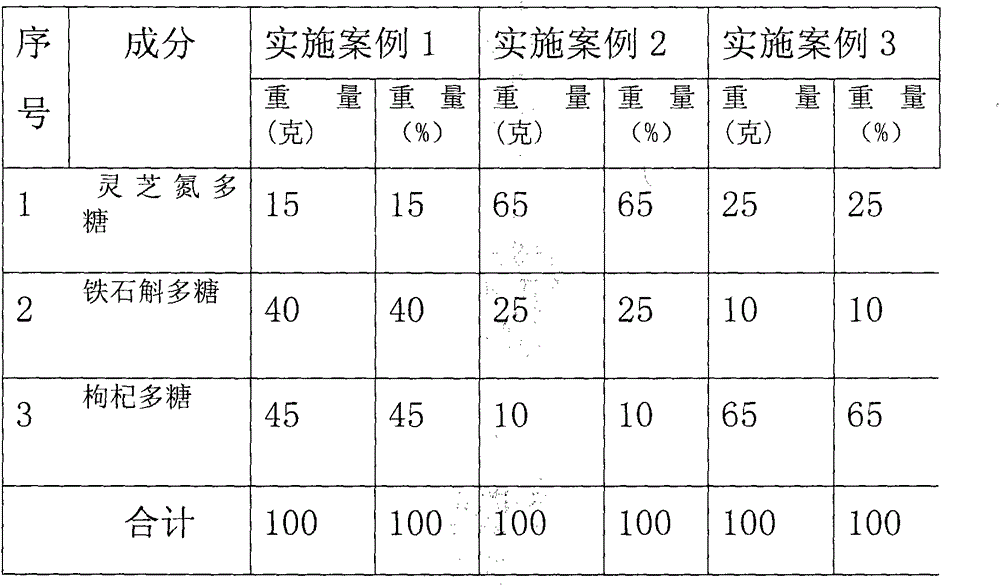

Glossy ganoderma dendrobium candidum polysaccharide and preparation technology thereof

InactiveCN104522462ANo side effectsControl changesFermentationFood preparationLycium chinenseDrinking wine

The invention discloses glossy ganoderma dendrobium candidum polysaccharide and a preparation technology thereof. The glossy ganoderma dendrobium candidum polysaccharide consists of the following components in percentage by weight: 15-65% of glossy ganoderma nitrogen polysaccharide, 10-40% of dendrobium candidum polysaccharide and 10-65% of Chinese wolfberry polysaccharide. The glossy ganoderma dendrobium candidum polysaccharide is prepared through the following steps of culturing, filtering, refining, drying, crushing, compounding and filling. The glossy ganoderma dendrobium candidum polysaccharide belongs to health-care food with curative effects, is suitable for recuperating the heart and the lung, has favorable recuperating and health-care effects on the inflammation of the liver, the restraint of pulmonary tuberculosis, hyperthyreosis and pharyngitis, adjusts immunity, has the efficacies of inflammation resistance, virus resistance, oxidation resistance, radiation resistance, ageing resistance and the like, and is suitable for crowds smoking cigarettes and drinking wines.

Owner:唐山宇慈生物科技有限公司

Method for preparing dimethyl succinate

ActiveCN101824627BThorough responseLow production costElectrolysis componentsOrganic compound preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl succinate, which comprises the following steps that: (1) dehydration and decontamination: methanol and alkali-earth metal oxide are mixed, dehydrated and decontaminated; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in the liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) 2-esterification reaction; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-eesterification; (10) evaporation; (11) mixing of oil and water; (12)separation of oil and water; (13) electrochemical reduction: hydrogen is introduced to reduce dimethyl maleate to dimethyl succinate; (14) cooling and crystallization; (15) separation of solid and liquid: solid material enters the next step; (6) re-crystallization and separation: the product dimethyl succinate is obtained. The method is simple, and has reasonable process, low preparation cost, high product purity and good quality.

Owner:RUNTAI CHEM CO LTD

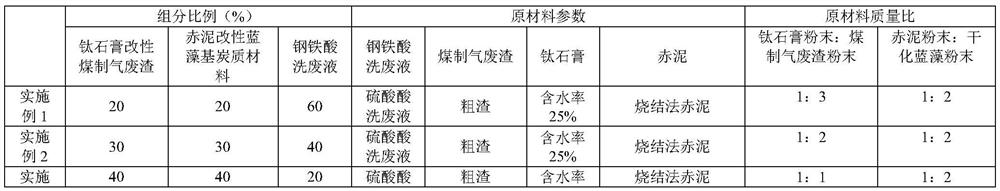

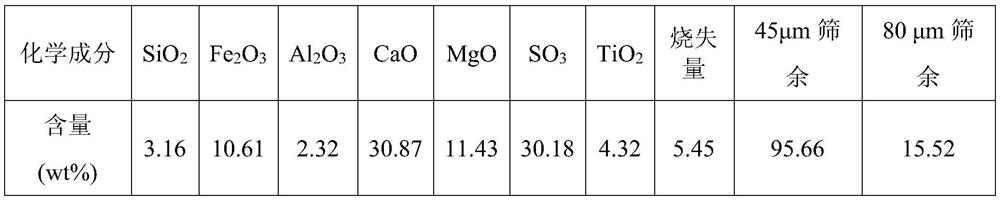

Novel repairing agent for heavy metal and organic matter combined polluted soil

ActiveCN112760098AImprove repair efficiencyImprove soil physical and chemical propertiesCalcareous fertilisersOrganic fertilisersEnvironmental chemistryGreen algae

The invention discloses a novel repairing agent for heavy metal and organic matter combined polluted soil. The repairing agent comprises the following components in percentage by mass: 20-40% of titanium gypsum modified coal gas waste residue; 20-40% of a red mud modified blue-green algae-based carbon material; and 20-60% of steel pickling waste liquid. The main components of the repairing agent are industrial and biological wastes, the material source is wide, the repairing agent is environment-friendly, heavy metal and organic pollutants can be synchronously and efficiently treated, the leaching toxicity of soil pollutants is remarkably reduced, pollution treatment with wastes is realized, and the environmental safety of polluted soil is improved; and meanwhile, physical and chemical properties of soil can be improved, and economic and environmental benefits are remarkable.

Owner:江苏省环境工程技术有限公司

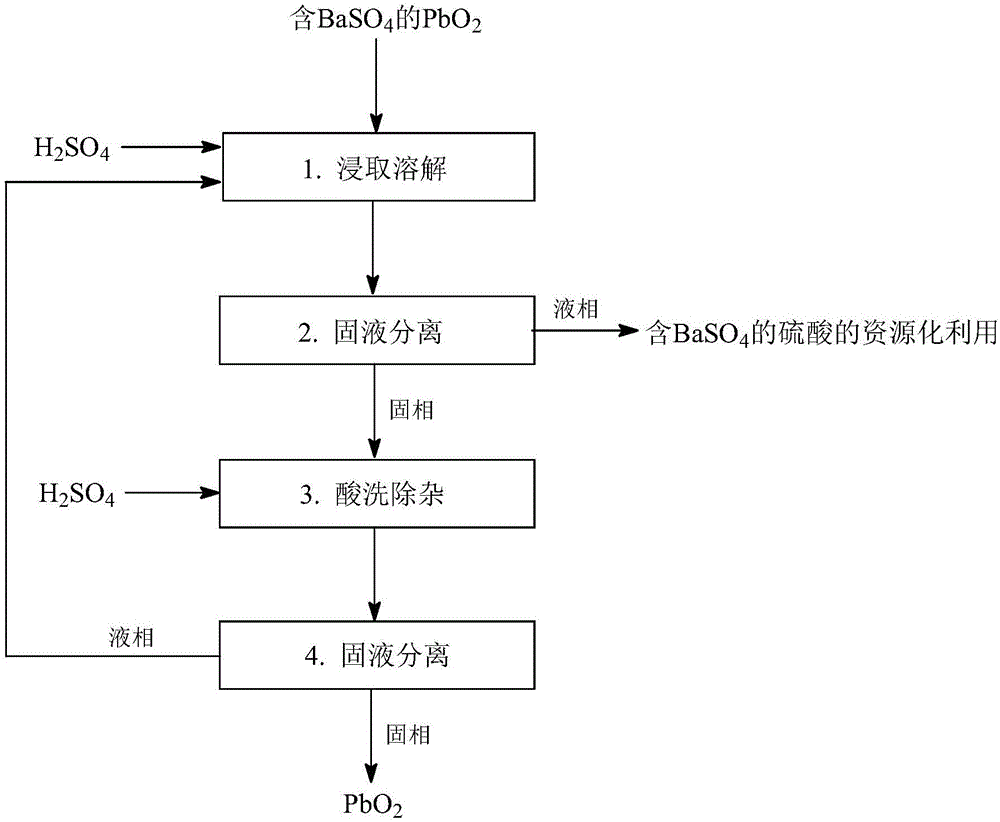

Method for removing barium sulfate impurity from lead dioxide

The invention relates to a method for removing barium sulfate impurity from lead dioxide. The method comprises the following steps: taking lead dioxide containing barium sulfate as the raw material, taking concentrated sulfuric acid as the leaching agent and washing agent, dissolving barium sulfate in lead dioxide into concentrated sulfuric acid at first, then carrying out solid-liquid separation, washing the solids by acid to further remove barium sulfate; and finally carrying out solid-liquid separation to obtain lead dioxide and a sulfuric acid solution containing barium sulfate. The lead oxide without barium sulfate can be directly used as the raw material to prepare active substances of electrode of lead battery, the sulfuric acid containing barium sulfate can be further separated to remove the impurity, and the wastes are converted into valuable resources. The method has the advantages of environment-friendliness, simple technology, low energy consumption, safe and reliable process, and easiness for realizing massive industrial production.

Owner:YANGZHOU UNIV

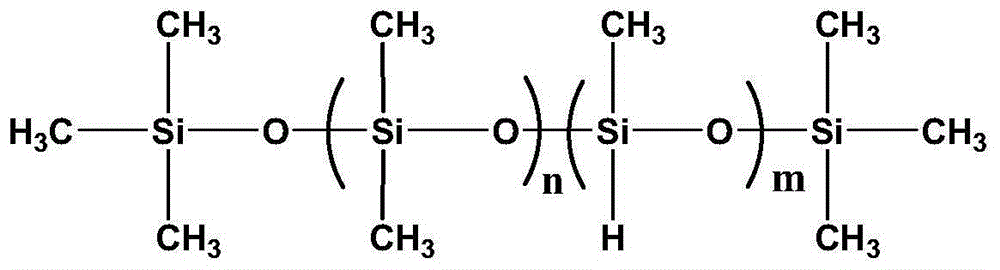

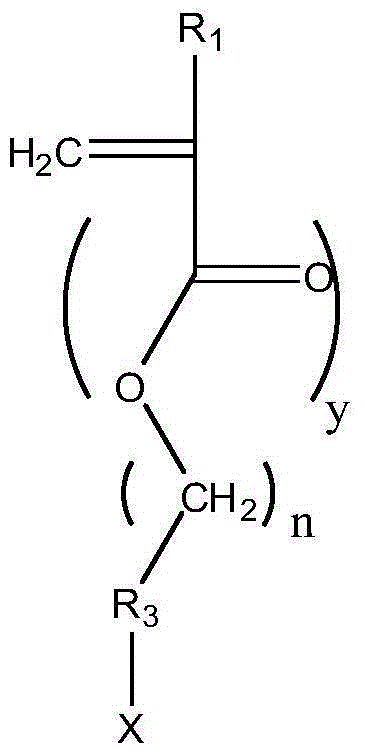

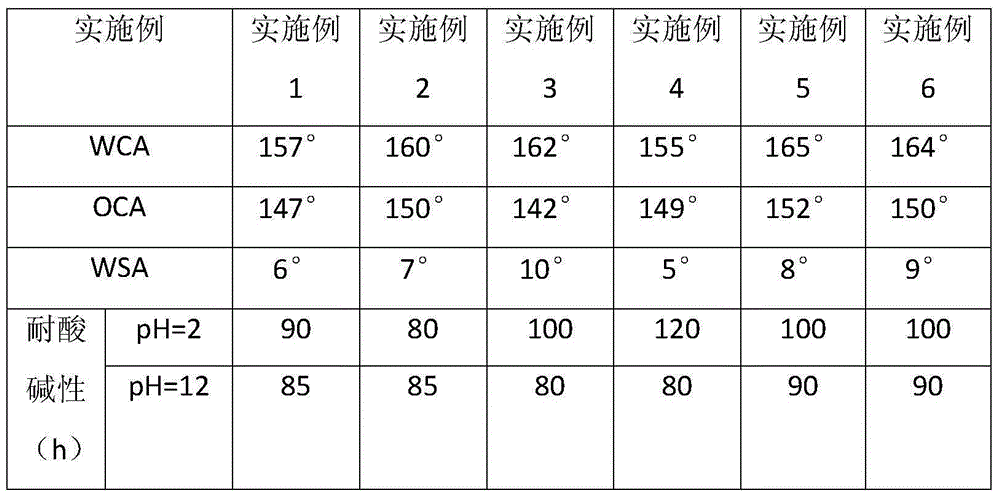

A kind of cross-linkable fluorosilicone resin and its preparation and application in super amphiphobic materials

The invention discloses cross-linkable fluorosilicon resin as well as a preparation and an application thereof in a super-amphiphobic material. A chemical grafting method is used for grafting a fluorine-containing polymer and a hydrophilic substance onto silicon-containing epoxy resin, and meanwhile partial epoxy groups are remained. According to the method, an epoxy component, a fluorine-containing component and the hydrophilic substance can be flexibly regulated according to demands. The preparation method is simple, convenient to operate, low in cost and easily subjected to large-scale industrialization. The fluorosilicon resin disclosed by the invention has very wide application field and can be prepared into the aqueous super-amphiphobic material. The fluorine-containing substance is firmly adhered on the surface of a base material in a polymer form, so that a constructed super-amphiphobic coating has good durability, and then satisfies the growing demands of modern dopes and surface treatment field, can be widely applied to production and life aspects such as outer layer protection of military equipment, water-resistance and corrosion-resistance of outer layers of oil pipelines, sanitary tools, windscreens, wood and buildings.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for preparing monomethyl succinate

InactiveCN101831662BFully transformedReduce generationElectrolysis componentsElectrolytic organic productionCis-Butenedioic AcidElectrochemistry

The invention relates to a method for preparing monomethyl succinate. The monomethyl succinate is prepared by using maleic anhydride and methyl alcohol as raw materials. The method comprises the steps of: 1, dehydrating and removing impurities: adding the methyl alcohol into a dehydrating and impurity-removing device, adding alkali-earth oxides for dehydrating and removing impurities; 2, carryingout solid-liquid separation: ensuring that liquid-phase materials enter the next step; 3, carrying out hemisuccination: adding the maleic anhydride into the liquid phase materials obtained by the step 2; 4, carrying out vacuum distillation: ensuring that the materials subjected to the methyl alcohol removal enter the next step; 5, carrying out electrochemistry reduction: carrying out electrochemistry hydrogenation reduction reaction on a monomethyl cis-butenedioic acid product, water and sulfuric acid; 6, cooling and crystallizing; 7, carrying out solid-liquid separation: ensuring that solid phase materials enter the next step; and 8, carrying out recrystallization separation to obtain the product of the monomethyl succinate. The invention has simple preparation method, reasonable process, low preparation cost, high product purity, good product quality, high yield and convenient implementation for mass industrialization.

Owner:淮安苏瑞精细化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com