Method for performing hydrophilic modification on surface of polyvinylidene fluoride microporous membrane

A technology of polyvinylidene fluoride and microporous membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of uncertain hydrophilization effect and short retention time, and improve hydrophilicity , low cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

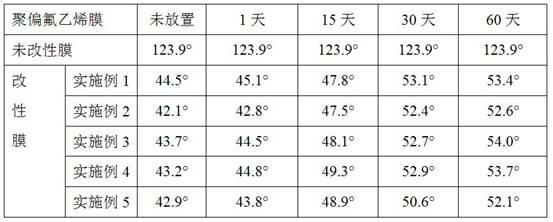

Examples

Embodiment 1

[0021] (1) Wash the polyvinylidene fluoride microporous filter membrane with deionized water for 10 times, then soak it in 70% ethanol solution for 24 hours, and then immerse it in deionized water;

[0022] (2) The polyvinylidene fluoride film that above-mentioned process has been immersed in adding phase transfer catalyst is in the alkali / oxidant solution of tetrabutylammonium bromide, reacts 40min at 50 DEG C, wherein, alkali is potassium hydroxide, weight Percentage concentration is 20%; Oxidant is potassium permanganate, and weight percent concentration is 3%, and the concentration of tetrabutylammonium bromide is 3000mg / l;

[0023] (3) Soak the above-mentioned treated polyvinylidene fluoride film in sodium bisulfite containing sulfuric acid to remove potassium permanganate and potassium hydroxide on the surface, wash it with deionized water for 10 times, and dry it. The volume percent concentration of sodium bisulfite is 1%, and the weight percent concentration of sodium ...

Embodiment 2

[0026] (1) Wash the polyvinylidene fluoride microporous filter membrane with deionized water for 10 times, then soak it in 70% ethanol solution for 24 hours, and then immerse it in deionized water;

[0027] (2) The polyvinylidene fluoride film that above-mentioned processing is immersed in adding phase-transfer catalyst is in the alkali / oxidant solution of tetrabutylammonium bromide, reacts 60min at 60 DEG C, wherein, alkali is potassium hydroxide, weight The percentage concentration is 30%; Oxidant is potassium permanganate, and the weight percentage concentration is 2%, and the concentration of tetrabutylammonium bromide is 5000mg / l;

[0028] (3) Soak the above-mentioned treated polyvinylidene fluoride film in sodium bisulfite containing sulfuric acid to remove potassium permanganate and potassium hydroxide on the surface, wash it with deionized water for 10 times, and dry it. The volume percent concentration of sodium bisulfite is 2%, and the weight percent concentration of...

Embodiment 3

[0031] (1) Wash the polyvinylidene fluoride microporous filter membrane with deionized water for 10 times, then soak it in 70% ethanol solution for 24 hours, and then immerse it in deionized water;

[0032] (2) The polyvinylidene fluoride film that above-mentioned process has been immersed in adding phase transfer catalyst is in the alkali / oxidant solution of tetrabutyl ammonium bromide, reacts 50min at 40 DEG C, wherein, alkali is potassium hydroxide, weight Percentage concentration is 40%; Oxidant is potassium permanganate, and weight percent concentration is 3%, and the concentration of tetrabutylammonium bromide is 4000mg / l;

[0033] (3) Soak the above-mentioned treated polyvinylidene fluoride film in sodium bisulfite containing sulfuric acid to remove potassium permanganate and potassium hydroxide on the surface, wash it with deionized water for 10 times, and dry it. The volume percent concentration of sodium bisulfite is 2.5%, and the weight percent concentration of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com