MethyIsuIfino benzaldehyde preparation method

A technology for p-methylsulfonyl and methylsulfonyl toluene is applied in the field of chemical oxidation to prepare p-methylsulfonyl benzaldehyde and p-methylsulfonyl benzaldehyde, and can solve problems such as environmental pollution, equipment corrosion, difficulty in product separation and purification, and the like , to achieve the effect of reducing costs and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Main process equipment: stirred tank reactor, flat electrochemical reactor, sedimentation solid-liquid separator, melting equipment, preheating equipment, washing equipment, drying equipment, etc.

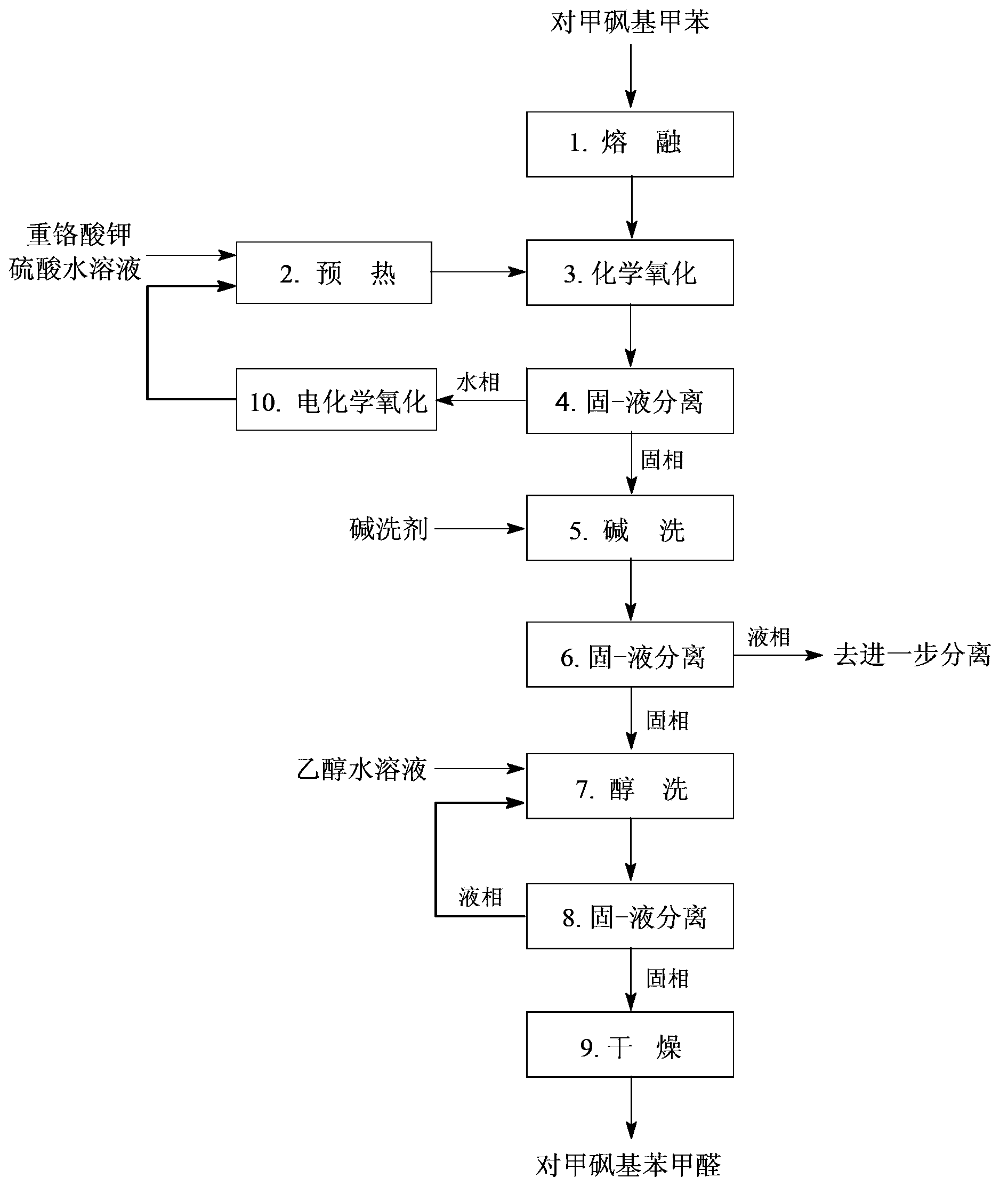

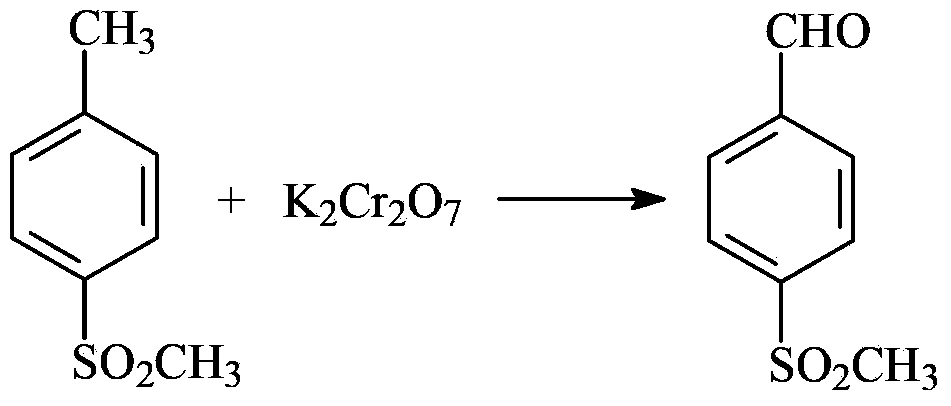

[0052] Such as figure 1 As shown, a method for preparing p-methylsulfonyl benzaldehyde is a process method for preparing p-methylsulfonyl benzaldehyde through selective oxidation of p-methylsulfonyl toluene as a raw material, and the method steps are as follows:

[0053] (1) Melting: In a stirred tank, heat the p-methylsulfonyl toluene to 90° C. to melt the p-methylsulfonyl toluene in a solid state at room temperature into a liquid material;

[0054] (2) Preheating: Add sulfuric acid aqueous solution and oxidant potassium dichromate into the stirred tank, and heat to 90°C. The concentration of potassium dichromate in the system is 0.5 mol / L, and the concentration of sulfuric acid is 0.1 mol / L. The system is in a liquid state when the material is mixed with the raw material p-methy...

Embodiment 2

[0064] Main process equipment: static mixing reactor, three-dimensional electrochemical reactor, filter solid-liquid separator, melting equipment, preheating equipment, washing equipment, drying equipment, etc.

[0065] The method steps are as follows:

[0066] (1) Melting: In the falling film melting equipment, heat the p-methylsulfonyl toluene to 150°C, and melt the p-methylsulfonyl toluene in a solid state at room temperature into a liquid material;

[0067] (2) Preheating: Add sulfuric acid aqueous solution and oxidant potassium dichromate to the stirred tank, and heat to 120°C. The concentration of potassium dichromate in the system is 3.0 mol / L, and the concentration of sulfuric acid is 8.0 mol / L. The system is in a liquid state when the material is mixed with the raw material p-methylsulfonyl toluene by heating up;

[0068] (3) Chemical oxidation: In a static mixing reactor, add the preheated sulfuric acid aqueous solution of potassium dichromate in the previous step to the mol...

Embodiment 3

[0077] Main process equipment: static mixing reactor, flat electrochemical reactor, centrifugal solid-liquid separator, melting equipment, preheating equipment, washing equipment, drying equipment, etc.

[0078] The method steps are as follows:

[0079] (1) Melting: In a stirred tank, heat the p-methylsulfonyl toluene to 120° C. to melt the p-methylsulfonyl toluene in a solid state at room temperature into a liquid material;

[0080] (2) Preheating: In the stirred tank, add sulfuric acid aqueous solution and oxidant potassium dichromate, heat to 100℃, the concentration of potassium dichromate in the system is 2.0mol / L, and the concentration of sulfuric acid is 4.0mol / L, The system is in a liquid state when the material is mixed with the raw material p-methylsulfonyl toluene by heating up;

[0081] (3) Chemical oxidation: In a static mixing reactor, add the preheated sulfuric acid aqueous solution of potassium dichromate in the previous step to the molten reaction raw material p-methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com