Nickel-maleate-grafted polypropylene ionomer as well as preparation method and application thereof

A technology of grafting polypropylene and nickel maleate, which is applied in the field of nickel maleate grafted polypropylene ionomer and its preparation, can solve the problems of not fully utilizing the comprehensive properties of the ionomer, and achieve improved strength and mold The effect of improving the amount, improving compatibility, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

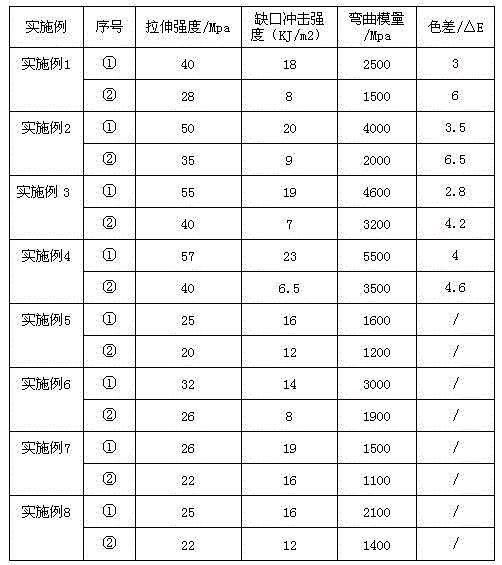

Embodiment 1

[0043] Weigh 90 parts of homopolypropylene, 0.5 part of cumene peroxide, 10 parts of nickel maleate, 0.1 part of antioxidant 1010, and 0.1 part of styrene according to the weight ratio, put them into a high-speed mixer, and seal After putting the lid on, turn on the mixer, adjust the rotating speed to be 1000rpm and stir for 5 minutes, then put the evenly stirred mixture into the twin-screw extruder, melt and extrude it, and after water cooling, cut it into particles with a length of 3mm by a pelletizer to obtain Nickel maleate grafted polypropylene ionomer. Among them, the processing temperature of the extruder is 180°C, 195°C, 200°C, 200°C, 205°C from the feeding port to the die port in sequence, the main engine speed is 60rpm, and the vacuum degree is 0.3MPa.

[0044] ?Weigh 0.1 part of the above-mentioned nickel maleate grafted polypropylene ionomer, 90 parts of polypropylene, 10 parts of alkali-free chopped glass fiber 305K, and 2 parts of antioxidant 1010 according to th...

Embodiment 2

[0047] Weigh 95 parts of homopolypropylene, 0.1 part of cumene peroxide, and 5 parts of nickel maleate by weight; 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, and 0.3 part of styrene , put it into a high-speed mixer, close the upper cover, turn on the mixer, adjust the speed to 1000rpm and stir for 5 minutes, then put the evenly stirred mixture into the twin-screw extruder, melt and extrude, and after water cooling, cut into pellets Particles with a length of 1 mm were grown to obtain a nickel maleate grafted polypropylene ionomer. Among them, the processing temperature of the extruder is 180°C, 195°C, 200°C, 200°C, 205°C from the feeding port to the die port in sequence, the main engine speed is 70rpm, and the vacuum degree is 0.3MPa.

[0048] ?Weigh 1 part of the above-mentioned nickel maleate grafted polypropylene ionomer, 80 parts of polypropylene, 20 parts of alkali-free chopped glass fiber 305K, and 2 parts of antioxidant 1010 according to the weight ratio....

Embodiment 3

[0051] Weigh 100 parts of homopolypropylene, 0.3 part of cumene peroxide, 0.2 part of diisononanoyl peroxide, 10 parts of nickel maleate by weight; 0.1 part of antioxidant 1010, and 0.1 part of antioxidant 168 is 0.2 parts, styrene is 0.3 parts, put it into a high-speed mixer, close the lid, turn on the mixer, adjust the rotation speed to 1000rpm and stir for 5 minutes, then put the evenly stirred mixture into the twin-screw extruder, and melt and extrude , After water cooling, cut into particles with a length of 2mm by a pelletizer to obtain a nickel maleate grafted polypropylene ionomer. Among them, the processing temperature of the extruder is 180°C, 195°C, 200°C, 200°C, 205°C from the feeding port to the die port in sequence, the main engine speed is 80rpm, and the vacuum degree is 0.3MPa.

[0052] ?Weigh 5 parts of nickel maleate grafted polypropylene ionomer prepared above, 70 parts of polypropylene, 30 parts of alkali-free chopped glass fiber 305K, 2 parts of antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com