Washing impurity-removing technology of crude nitrochlorobenzene products after chlorobenzene thermal insulation nitration

A technology for crude nitrochlorobenzene and adiabatic nitration, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., and can solve the problems of wastewater containing organic matter and sulfate, difficult biochemical conversion, and large primary water consumption. , to achieve the effect of facilitating large-scale industrialization, less energy consumption, and reducing the amount of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The main process equipment is: mixing scrubber and liquid-liquid separator, etc.

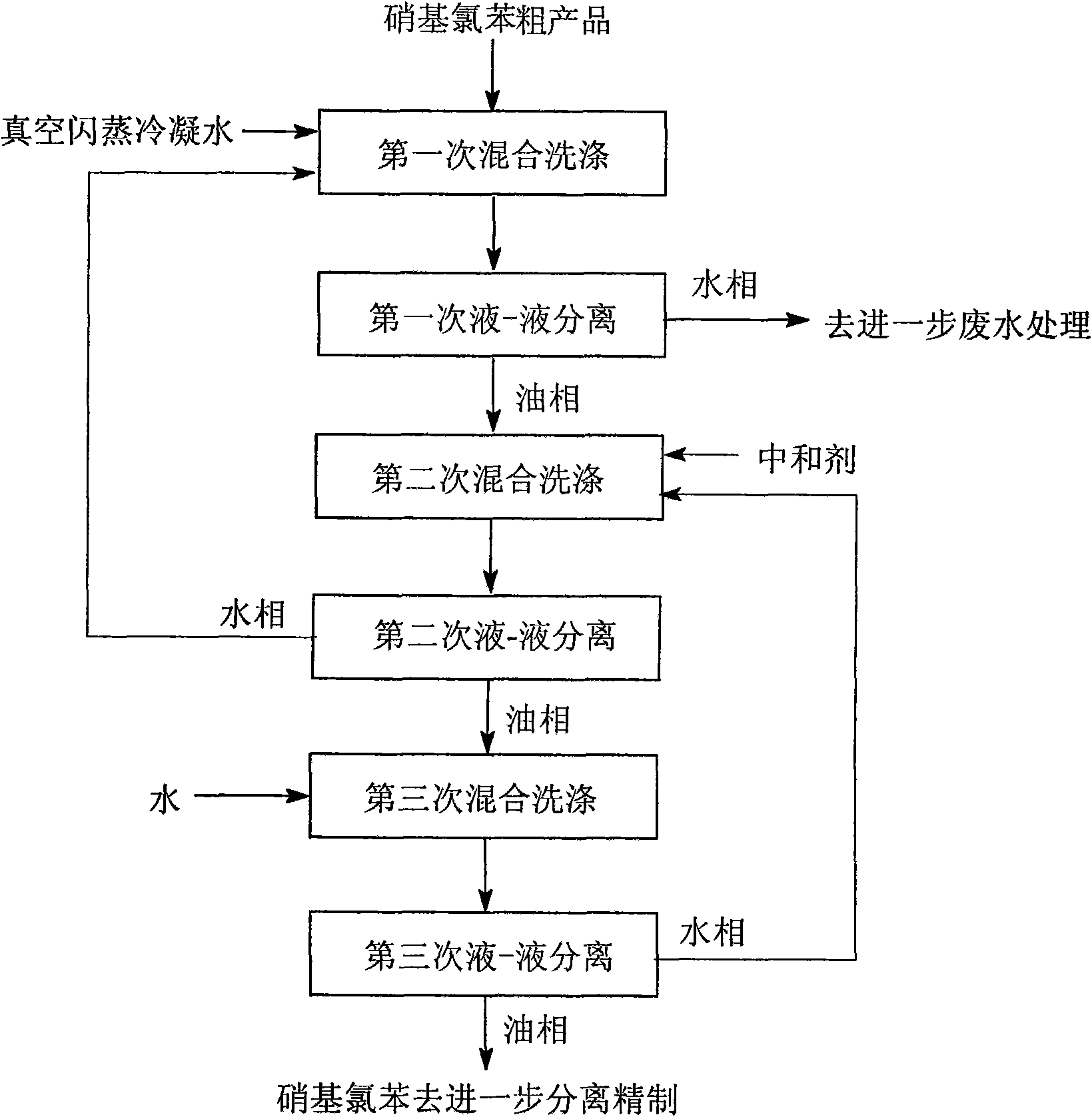

[0025] like figure 1 Shown, a kind of washing impurity-removing process of nitrochlorobenzene crude product after adiabatic nitration reaction of chlorobenzene, described process step is as follows:

[0026] (1) Mixed washing for the first time: In the static mixing scrubber, the nitrochlorobenzene crude product obtained by decompression flash evaporation and oil-water separation of the material after the adiabatic nitration reaction of chlorobenzene is condensed with the condensate obtained by decompression flash evaporation. The water and the aqueous phase material obtained in the second liquid-liquid separation process are mixed and washed, the volume ratio of the washing water used in the mixed washing to the crude nitrochlorobenzene is 10:1, and the operating temperature of the mixed washing is 80 ° C. Sulfuric acid and a small amount of organic matter entrained in the chlorobenzene...

Embodiment 2

[0033] The main process equipment is: mixing scrubber and liquid-liquid separator, etc.

[0034] like figure 1 Shown, a kind of washing impurity-removing process of nitrochlorobenzene crude product after adiabatic nitration reaction of chlorobenzene, described process step is as follows:

[0035] (1) Mixed washing for the first time: In the tank-type stirring mixed washing equipment, the operating temperature of the mixed washing is 40°C, and the nitrochloride obtained by decompression flash evaporation and oil-water separation of the material after the adiabatic nitration reaction of chlorobenzene The benzene crude product is mixed with the condensed water obtained by decompression flash evaporation and the aqueous phase material obtained in the second liquid-liquid separation process, and the volume ratio of the washing water used for the mixed washing to the nitrochlorobenzene crude product is 1:1. Sulfuric acid and a small amount of organic matter entrained in the crude n...

Embodiment 3

[0042] The main process equipment is: mixing scrubber and liquid-liquid separator, etc.

[0043] like figure 1 Shown, a kind of washing impurity-removing process of nitrochlorobenzene crude product after adiabatic nitration reaction of chlorobenzene, described process step is as follows:

[0044] (1) The first mixed washing: In the tubular mixed washing machine, the operating temperature of the mixed washing is 60 ° C, and the nitrochlorobenzene obtained by decompression flash evaporation and oil-water separation of the material after the adiabatic nitration reaction of chlorobenzene The condensed water obtained by the crude product and decompression flash evaporation and the aqueous phase material obtained in the second liquid-liquid separation process are mixed and washed, and the volume ratio of the washing water used for the mixed washing and the crude product of nitrochlorobenzene is 1: 1. Sulfuric acid and a small amount of organic matter entrained in the nitrochloroben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com