Lithium battery current collector and preparing method thereof

A current collector and lithium battery technology, which is applied in the direction of battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problem of expansion and separation of active materials and current collectors, the impact of cycle life battery safety performance, and poor application of electrode materials, etc. Problems, to achieve the effect of high power characteristics, strong adhesion, and strong force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

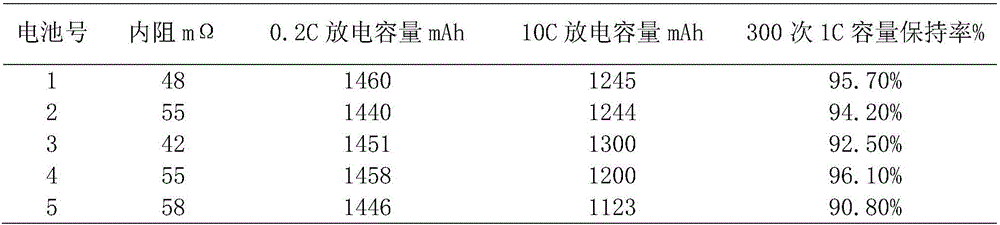

Examples

preparation example Construction

[0025] Correspondingly, the embodiment of the present invention also provides a preparation method of a lithium battery current collector, comprising the following steps:

[0026] S01. Disperse the coating powder and the binder in a solvent to form an inert buffer slurry, wherein the coating powder includes at least one of metal nitride and metal carbide;

[0027] S02. Coating the inert buffer slurry on at least one surface of the current collector foil to form a coating of the inert buffer slurry;

[0028] S03. Drying treatment.

[0029] Specifically, in the above step S01, in the embodiment of the present invention, the coating powder and the binder are the coating powder and the binder mentioned in the lithium battery current collector, wherein the coating powder includes At least one of metal nitride and metal carbide. Preferably, the solvent is water, a mixed solvent of water and ethanol or N-methylpyrrolidone. The coating powder and the binder are dispersed in a solve...

Embodiment 1

[0037] Weigh 8 g of TiN powder with a particle size of 50 nm and add it to 500 g of nitrogen methyl pyrrolidone for 8 hours, then ultrasonically disperse for 10 minutes, and the ultrasonic frequency is 15KHz; weigh 1.5 g of polyvinylidene fluoride and add it to 1000 g of nitrogen methyl pyrrolidone. The mixer mixed evenly, then added 508g of TiN slurry after ultrasonic dispersion, stirred and mixed evenly, added 1500g of nitrogen methyl pyrrolidone to adjust the viscosity of the slurry, and the viscosity was controlled to 1000mPa.s; the slurry was uniformly coated by a transfer coater On the surface of aluminum foil, and dried in a blast drying oven to obtain a conductive coating with a single-sided coating thickness of 3 μm.

[0038] The peel strength of the current collector prepared above was measured by a peel strength tester to be 0.45N, and the resistivity of the pole piece was measured by a four-point probe method to be 2.362×10 -6 ohm.cm.

Embodiment 2

[0040] Weigh 8 g of TiN powder with a particle size of 1 μm and add it to 500 g of nitrogen methyl pyrrolidone for 8 hours, then ultrasonically disperse for 10 minutes, and the ultrasonic frequency is 15KHz; weigh 1.5 g of polyvinylidene fluoride and add it to 1000 g of nitrogen methyl pyrrolidone. The mixer mixed evenly, then added 508g of TiN slurry after ultrasonic dispersion, stirred and mixed evenly, added 1500g of nitrogen methyl pyrrolidone to adjust the viscosity of the slurry, and the viscosity was controlled to 1000mPa.s; the slurry was uniformly coated by a transfer coater On the surface of aluminum foil, and dried in a blast drying oven to obtain a conductive coating with a single-sided coating thickness of 3 μm.

[0041] The peel strength of the current collector prepared above was measured by a peel strength tester to be 0.26N, and the resistivity of the pole piece was measured by a four-point probe method to be 5.362×10 -6 ohm.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com