A method for making anode material Li3V2(PO4)3 of lithium ion battery

A lithium ion battery, lithium vanadium phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of restricting the large-scale industrialization of lithium vanadium phosphate, poor charging and discharging performance of synthetic materials, and harsh control conditions, etc. Achieve the effect of reducing synthesis cost, short synthesis cycle and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

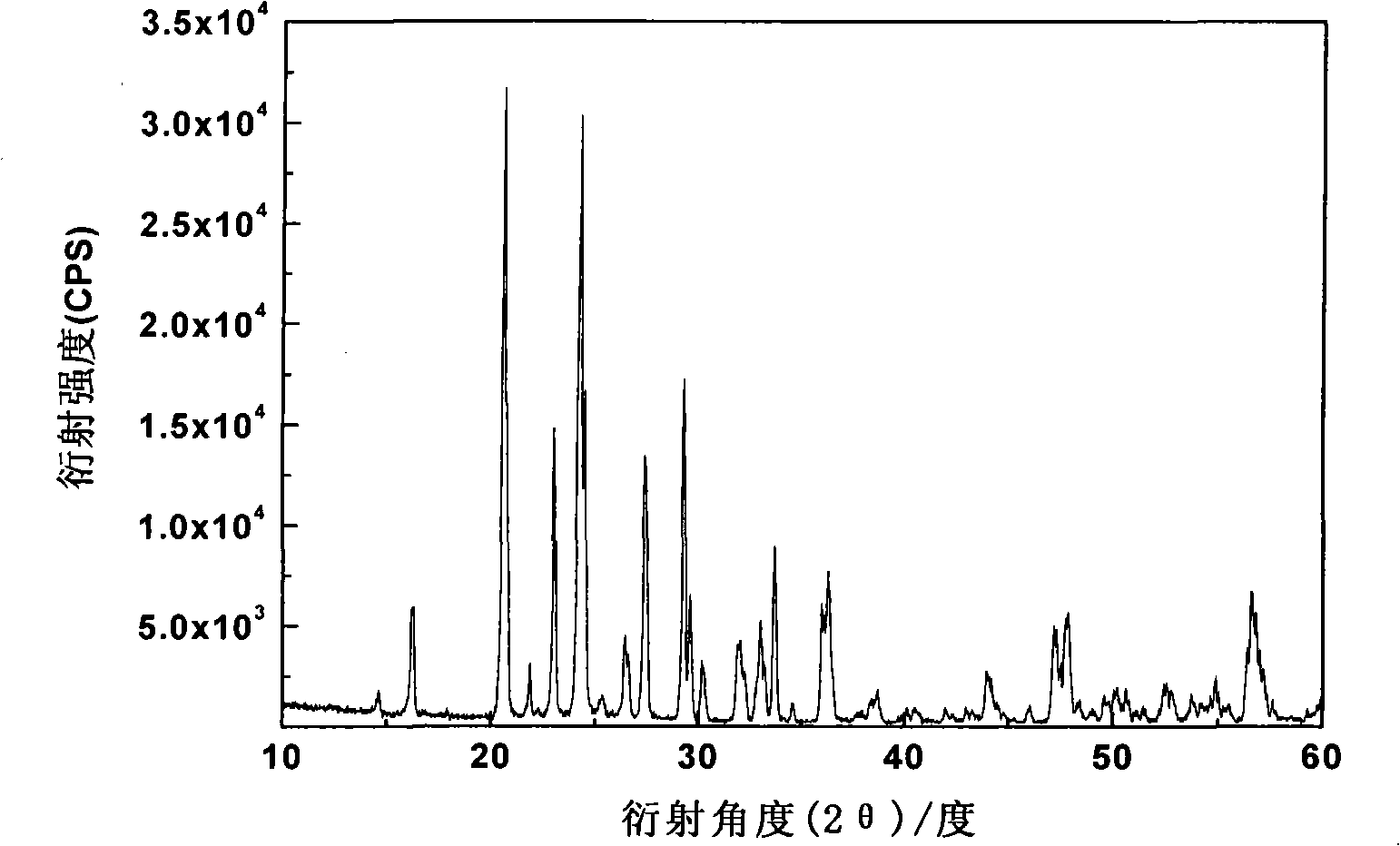

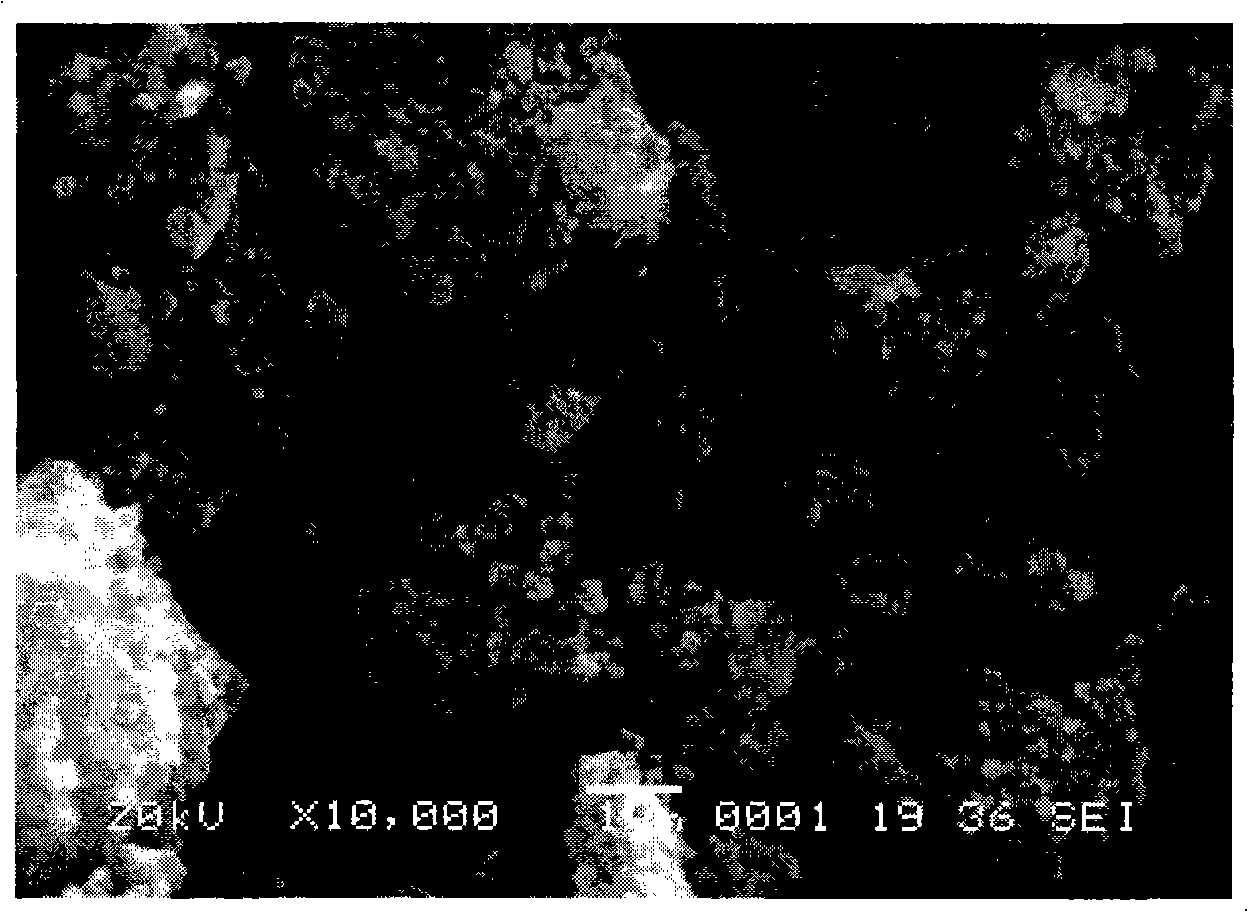

[0018] Use vanadium pentoxide, lithium carbonate, ammonium dihydrogen phosphate and malic acid as raw materials, mix uniformly in a molar ratio of 1:1.5:3:1, and mechanically activate for 0.5 hours; The temperature was kept at 500°C, 560°C, 650°C and 700°C for 12 hours respectively. The obtained material is analyzed by X-ray diffraction as a monoclinic crystal, which is Li 3 V 2 (PO 4 ) 3 Structure. The particle size of the product obtained by SEM is 100-200 nm. The resulting products were assembled into button batteries to measure their charge-discharge specific capacity and cycle performance, and they were charged and discharged at a rate of 0.1C. Their initial discharge capacity and discharge capacity after 50 cycles are shown in Table 1.

[0019] Experimental condition and result of table 1 embodiment 1

[0020]

Embodiment 2

[0022] Using vanadium dioxide, lithium formate, triammonium phosphate and mandelic acid as raw materials, mix them uniformly in a molar ratio of 2:3:3:3, and activate them mechanically for 20 hours; then put them into a tube furnace, and under a hydrogen atmosphere, The temperature was kept at 650°C for 2h, 5h, 8h, and 20 hours, respectively. The obtained material is analyzed by X-ray diffraction as a monoclinic crystal, which is Li 3 V 2 (PO 4 ) 3 Structure. The particle size of the product obtained by SEM is 100-200 nm. The obtained product was assembled into a button battery to measure its charge-discharge specific capacity and cycle performance, and the charge-discharge was carried out at a rate of 0.1C. Their initial discharge capacity and discharge capacity after 50 cycles are shown in the table

[0023] Experimental condition and result of table 2 embodiment 2

[0024]

Embodiment 3

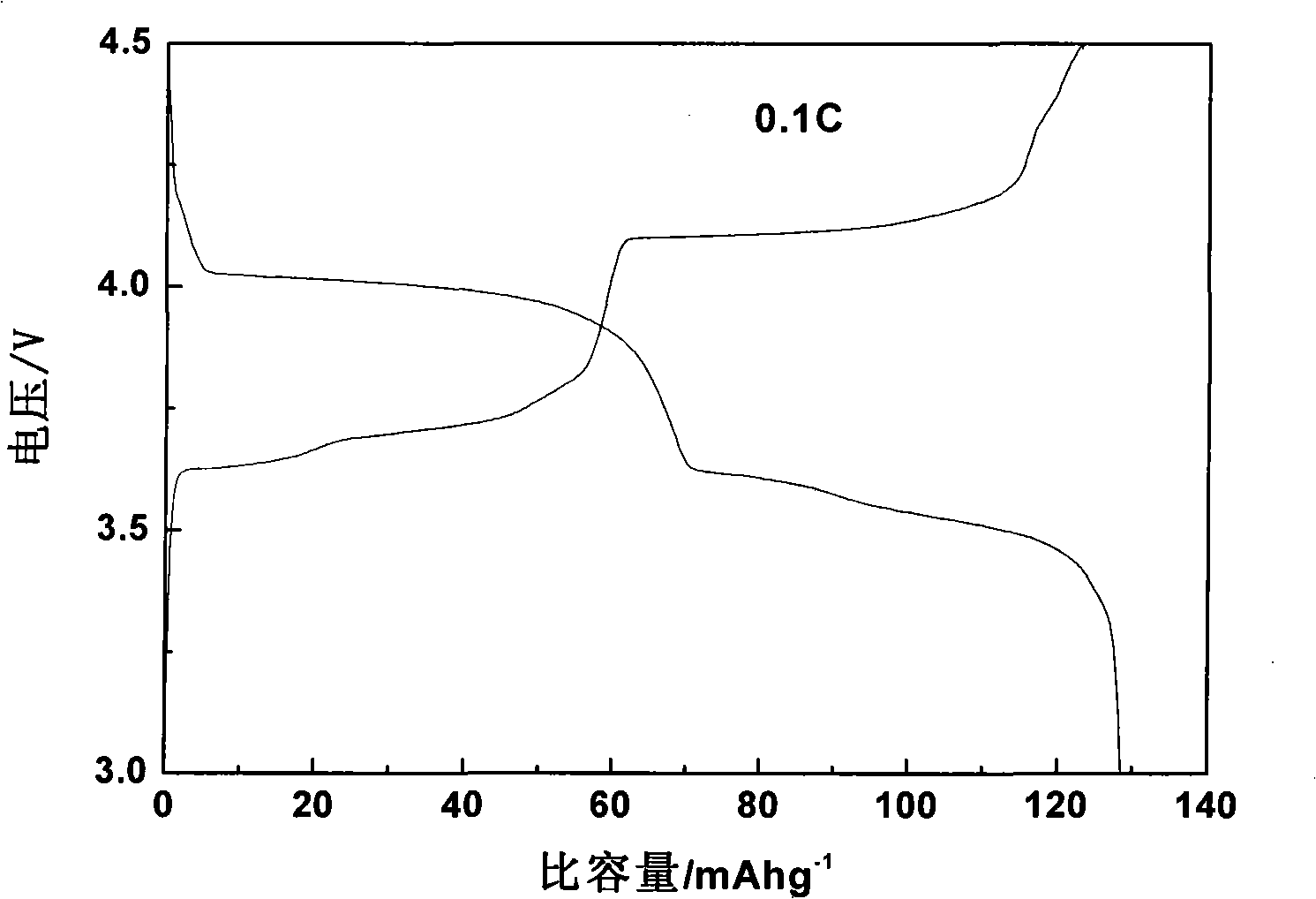

[0026] Using ammonium metavanadate, lithium oxide, diammonium hydrogen phosphate, and oxalic acid as raw materials, mix them uniformly in a molar ratio of 2:1.5:3:4, and mechanically activate them for 8 hours; , the temperature was kept at 550°C for 15 hours. The obtained material is analyzed by X-ray diffraction as a monoclinic crystal, which is Li 3 V 2 (PO 4 ) 3 Structure. The obtained product was assembled into a button battery to measure its charge-discharge specific capacity and cycle performance, and the charge-discharge was carried out at a rate of 0.1C, and the initial discharge capacity was 131.5mAh·g -1 , the discharge capacity after 50 cycles is 130mAh·g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com