Manganiferous lead-free forgeable easy-cutting brass and preparation method thereof

A free-cutting and brass technology, applied in the field of lead-free free-cutting brass alloy and its preparation, can solve the problems of easy cracking on the surface, poor forging performance of lead-free free-cutting brass, etc. Hazardous, easy recovery and recycling, effect of good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

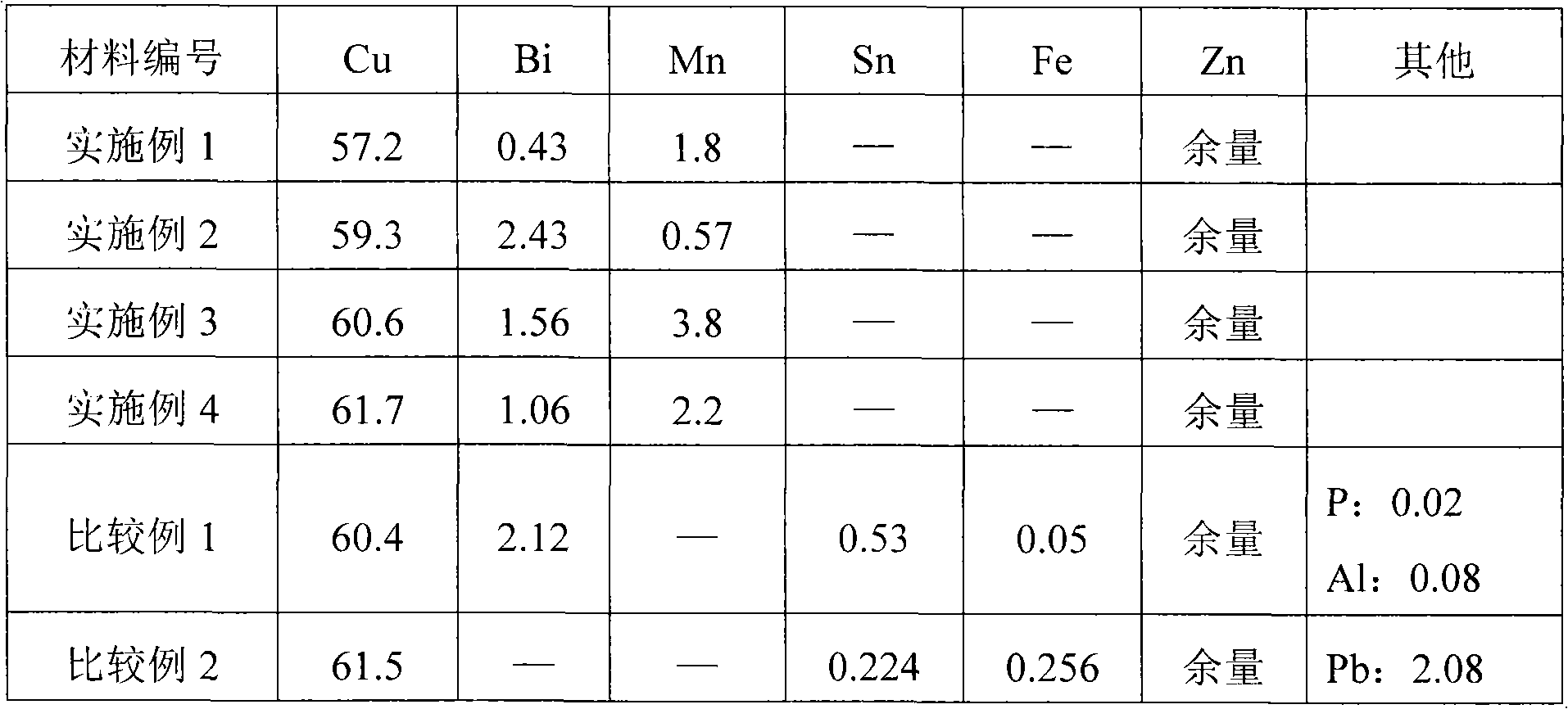

Examples

preparation example Construction

[0029] A method for preparing manganese-containing lead-free forgeable free-cutting brass, the specific process is as follows:

[0030] First, a copper-bismuth master alloy is prepared. The preparation method of the copper-bismuth master alloy is as follows: the proportion of bismuth is 30wt%, and the balance is copper and unavoidable impurities, and copper and bismuth are melted in a vacuum melting furnace with a vacuum degree of less than 1Pa in the range of 1080-1100°C. Cast a round ingot of copper-bismuth master alloy at 1030-1050°C, and break the ingot into blocks for later use.

[0031] The preparation method of the brass alloy is as follows: 57-62wt% copper, 0.3-2.5wt% bismuth, 0.5-4.0wt% manganese, the balance is zinc and unavoidable impurities, and the total amount of impurities is not more than 0.2wt%. Add electrolytic copper, electrolytic manganese, copper-bismuth intermediate alloy, and electrolytic zinc into the induction furnace in sequence; the melting temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com