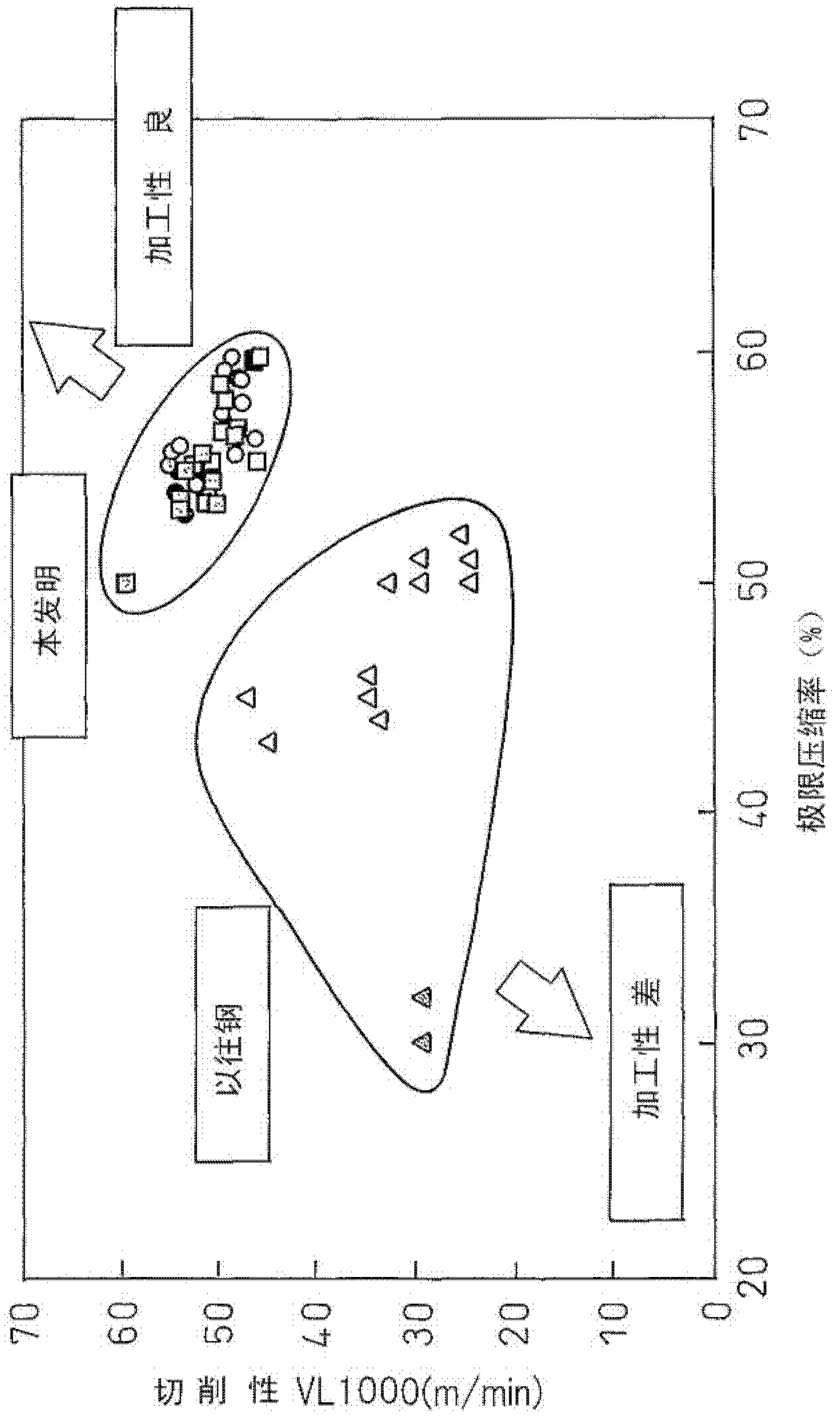

Steel for case hardening which has excellent cold workability and machinability and which exhibits excellent fatigue characteristics after carburizing and quenching, and process for production of same

A technology of carburizing and quenching and cold workability, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of increased manufacturing costs, achieve extended life, excellent processability, and suppress the coarseness of grains effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

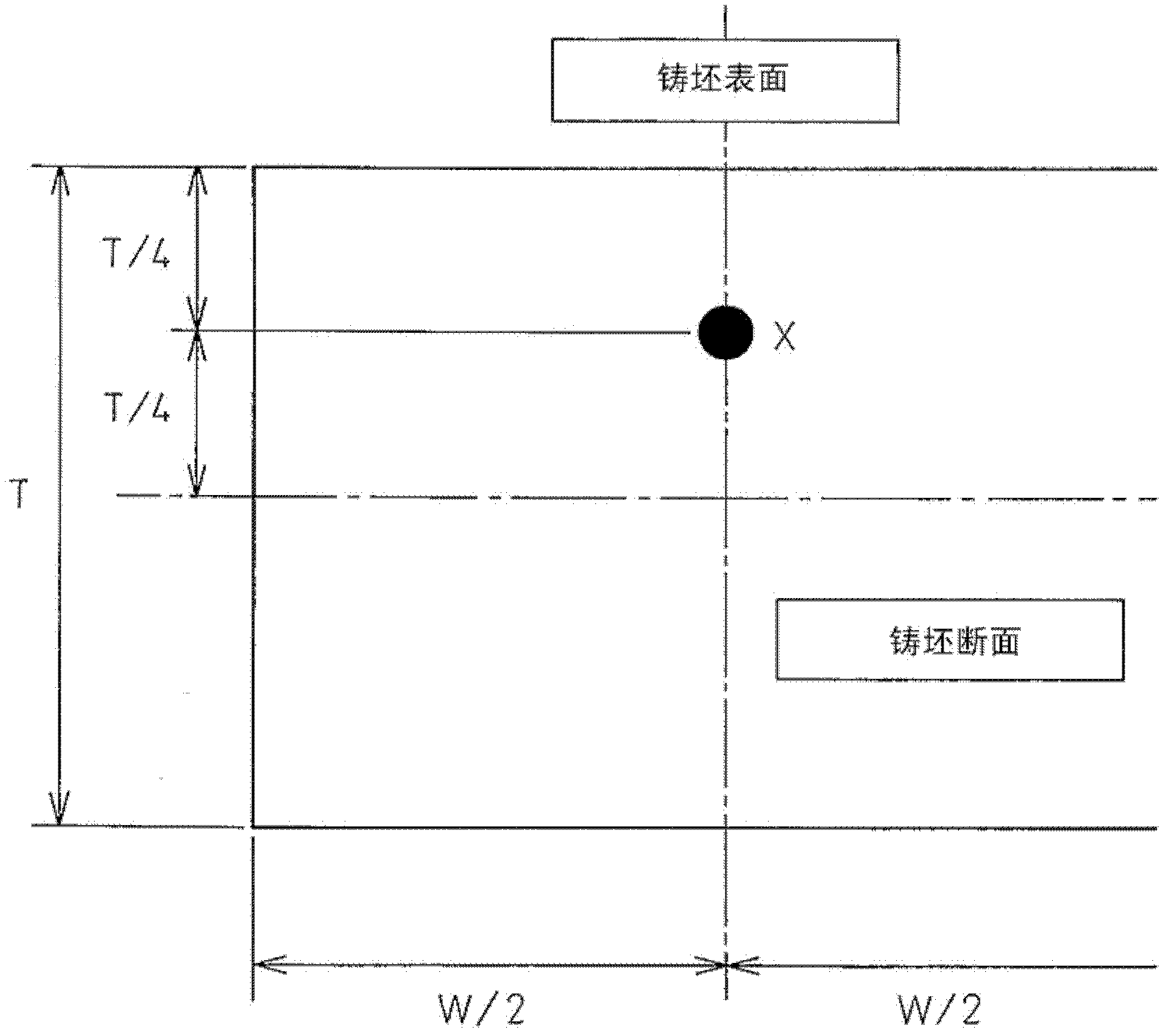

[0165] Steels having the compositions shown in Tables 1 to 3 were smelted and cast at a solidification cooling rate of 10 to 11° C. / min. The blank columns of the components in Tables 1 to 3 indicate that they are not intentionally added, and the underlines indicate that they are outside the scope of the present invention.

[0166] The solidification cooling rate is adjusted based on data obtained by sorting out the relationship between the cooling conditions and the solidification cooling rate when casting slabs of various sizes in advance. The solidification cooling rate of a part of the slab was confirmed to be in the range of 10 to 11° C. / min from the secondary dendrite arm spacing. Part of the slab is subjected to slab rolling as needed.

[0167]

[0168]

[0169]

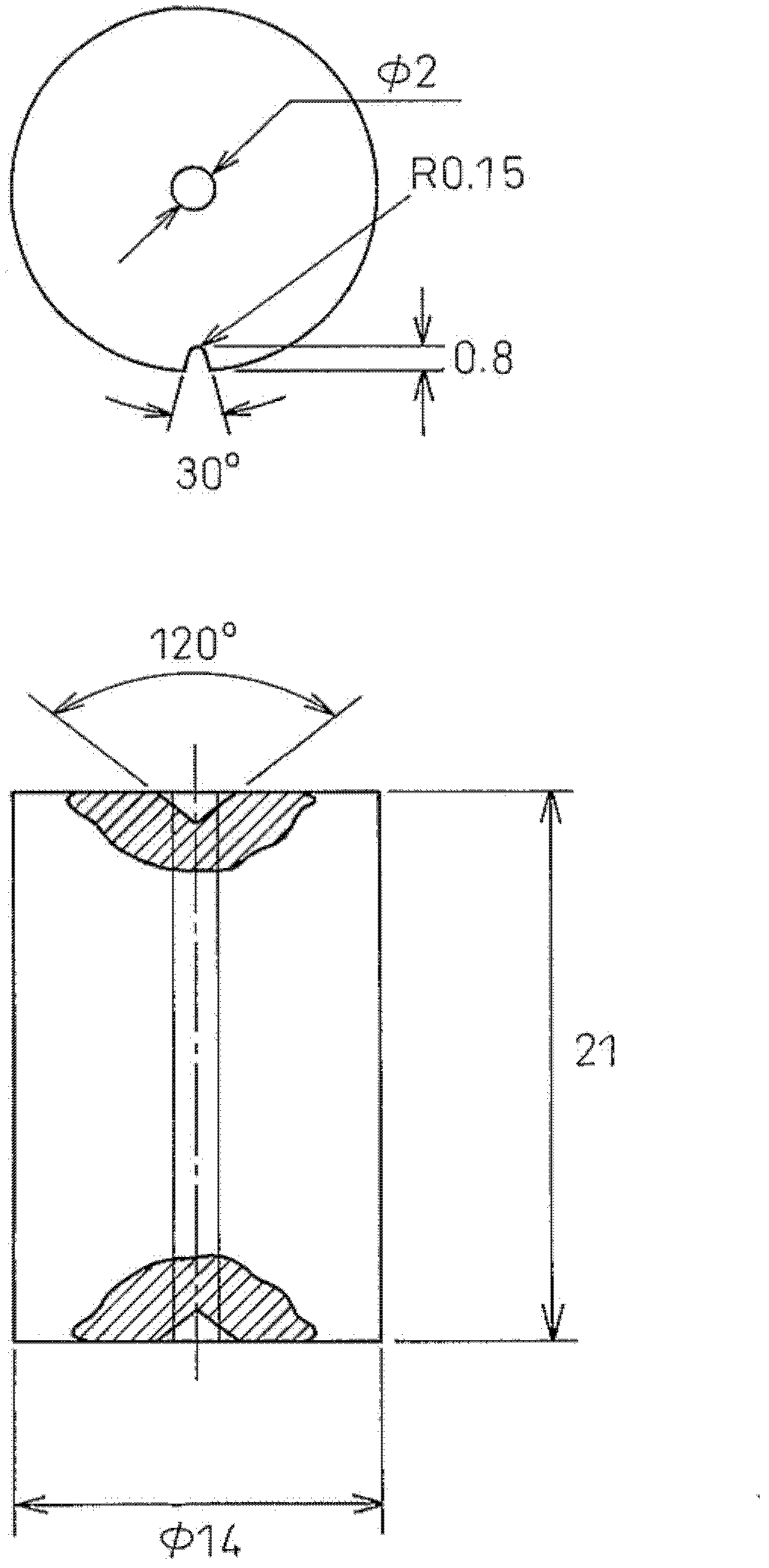

[0170] Then hot working is carried out to manufacture bar steel with a diameter of 24-30mm. The microscopic observation of the bar steel was carried out, and the measurement of the bainite fraction was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com