Patents

Literature

57 results about "Silicon-tin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-tin or SiSn, is in general a term used for an alloy of the form Si₍₁₋ₓ₎Snₓ. The molecular ratio of tin in silicon can vary based on the fabrication methods or doping conditions. In general, SiSn is known to be intrinsically semiconducting, and even small amounts of Sn doping in silicon can also be used to create strain in the silicon lattice and alter the charge transport properties.

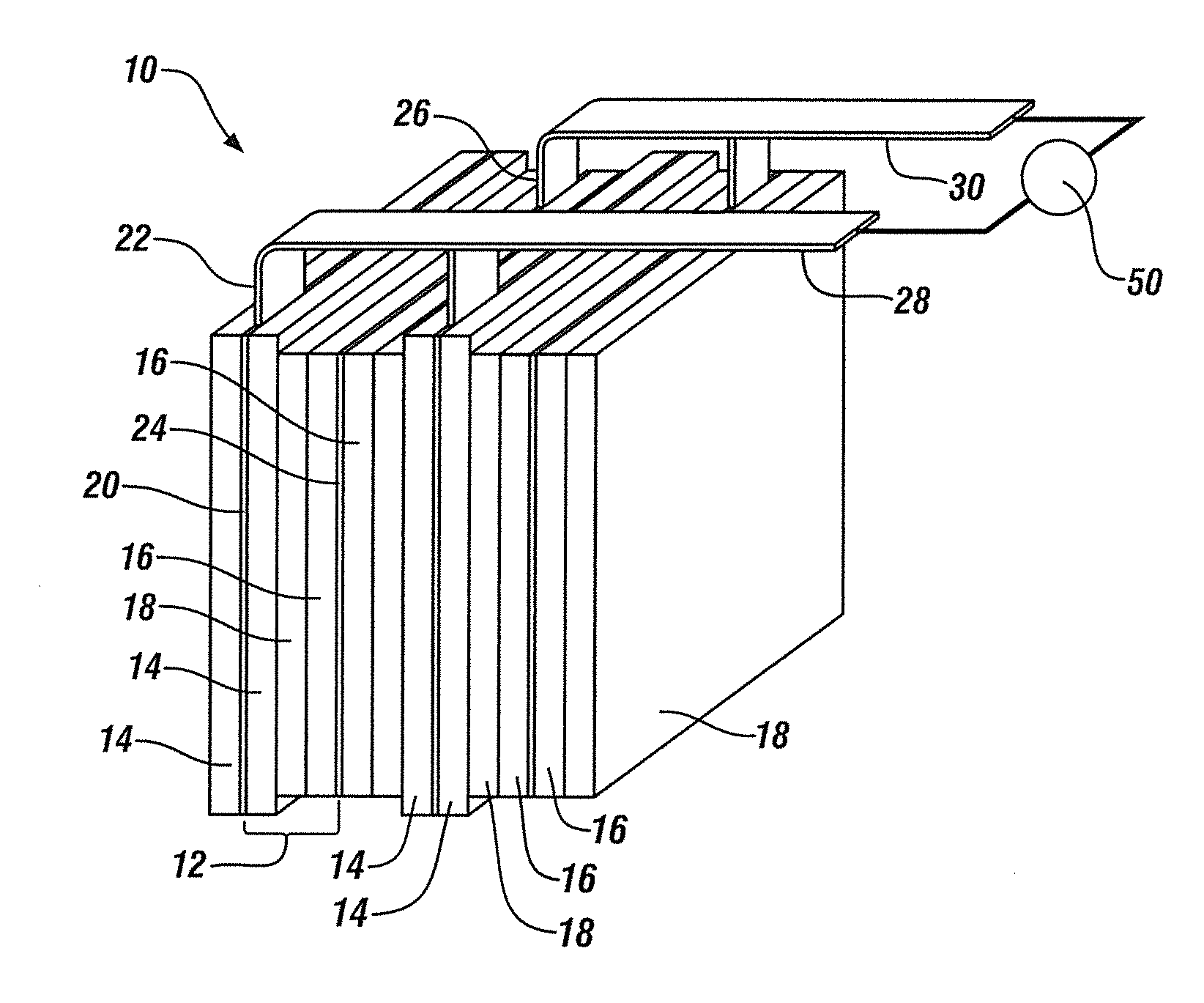

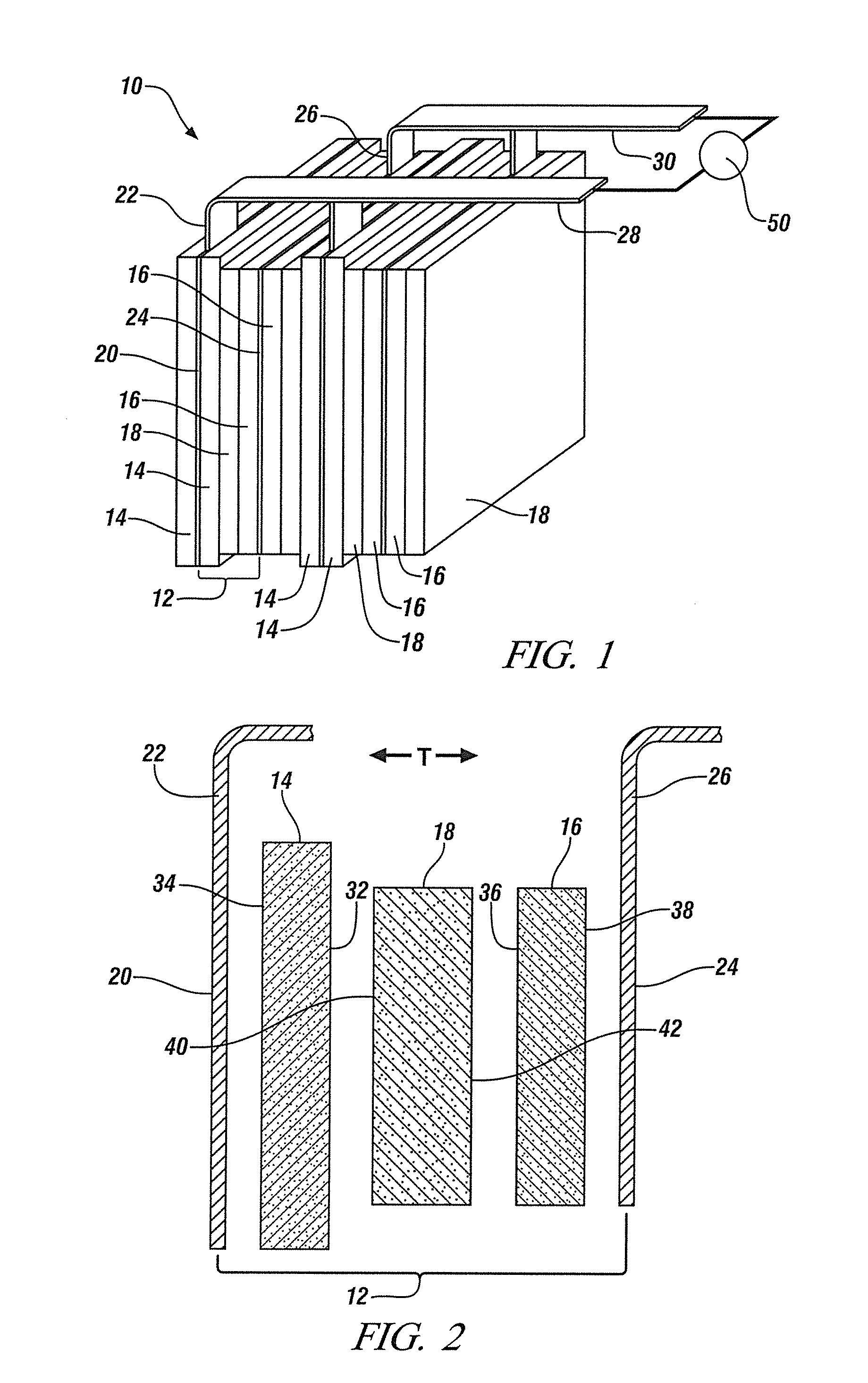

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

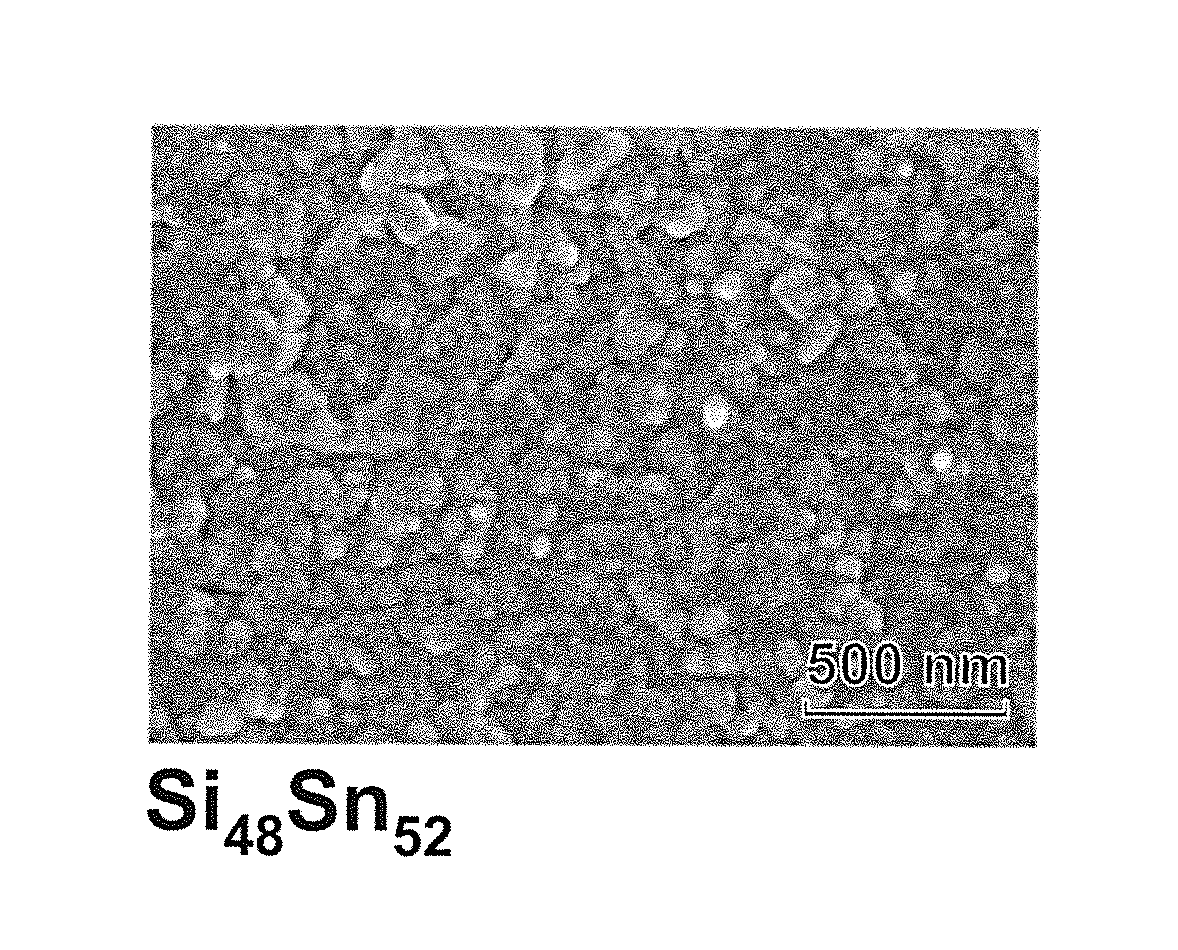

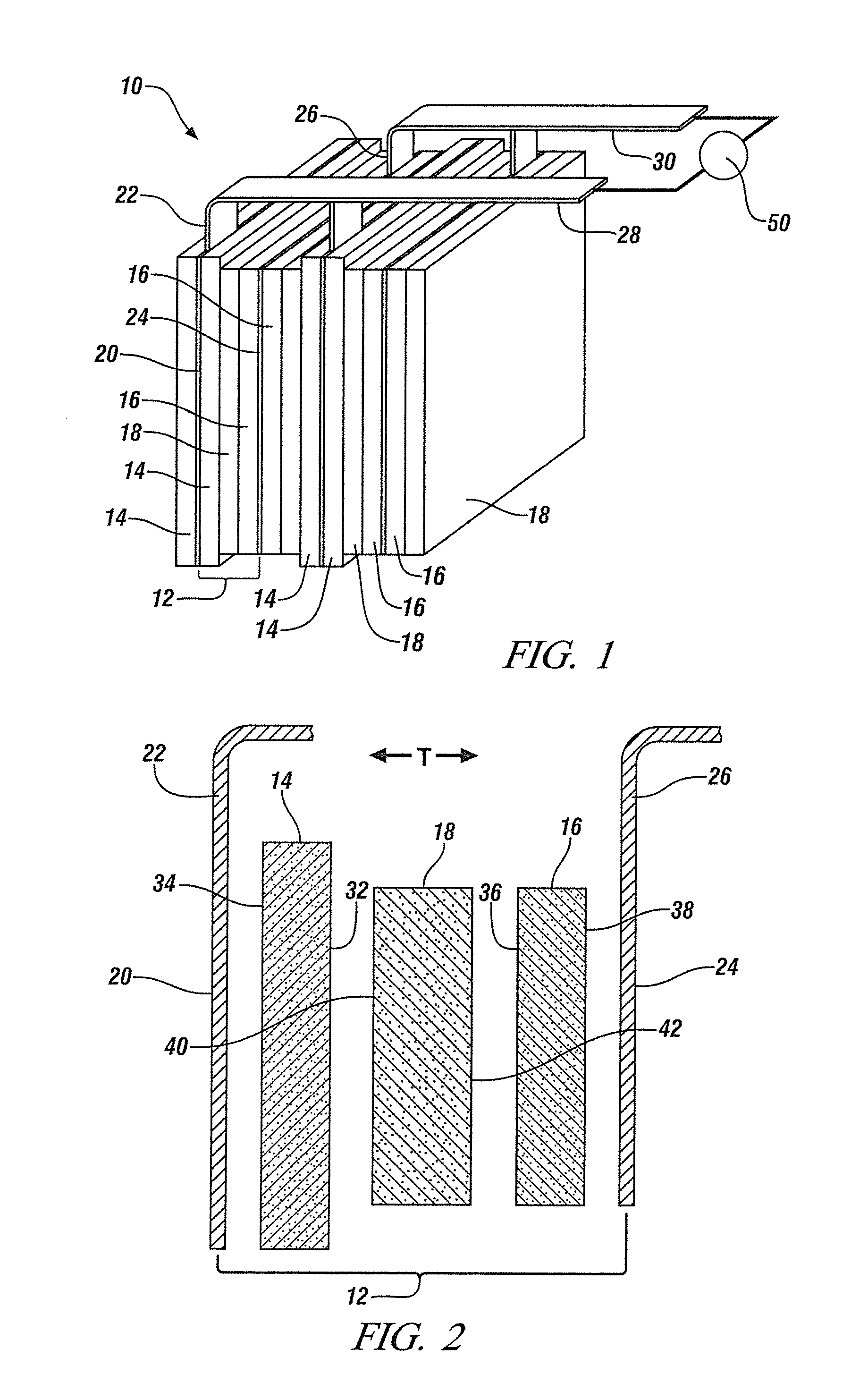

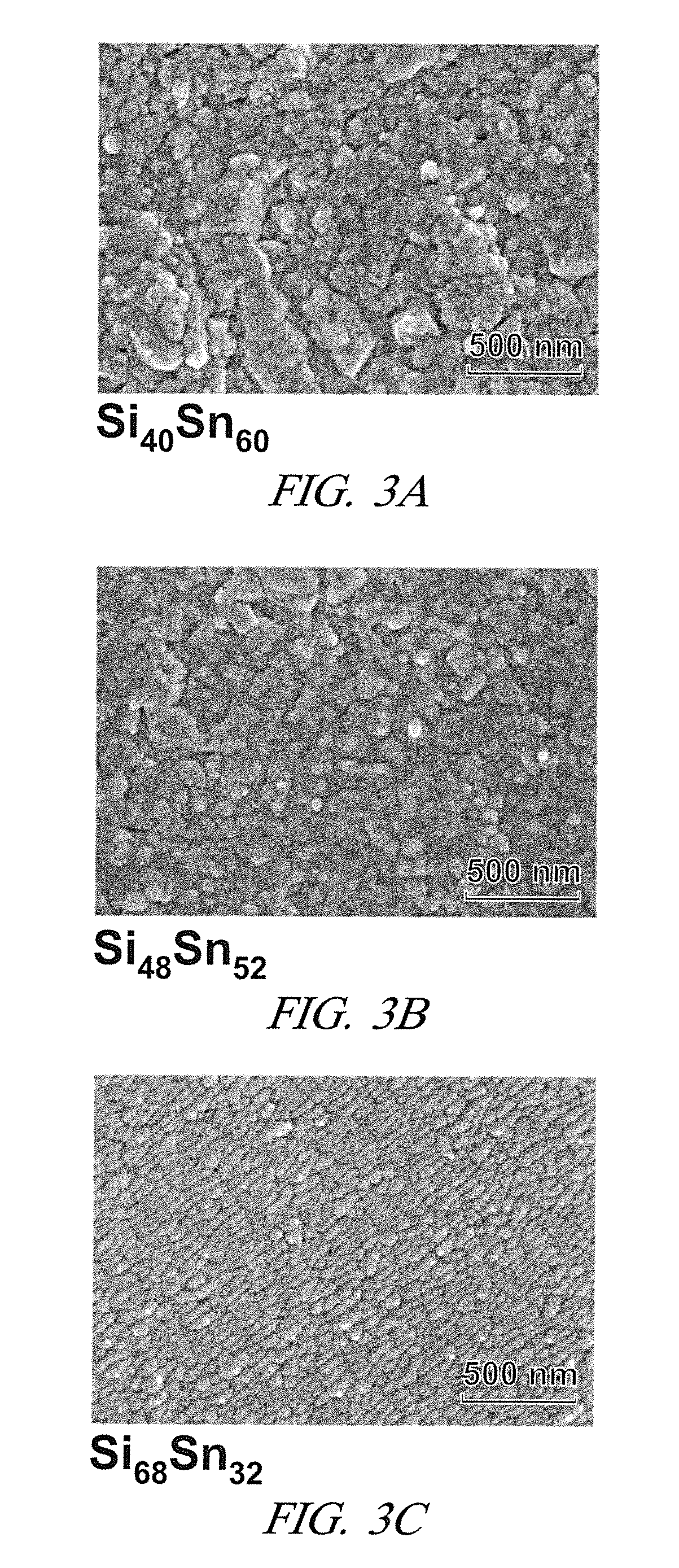

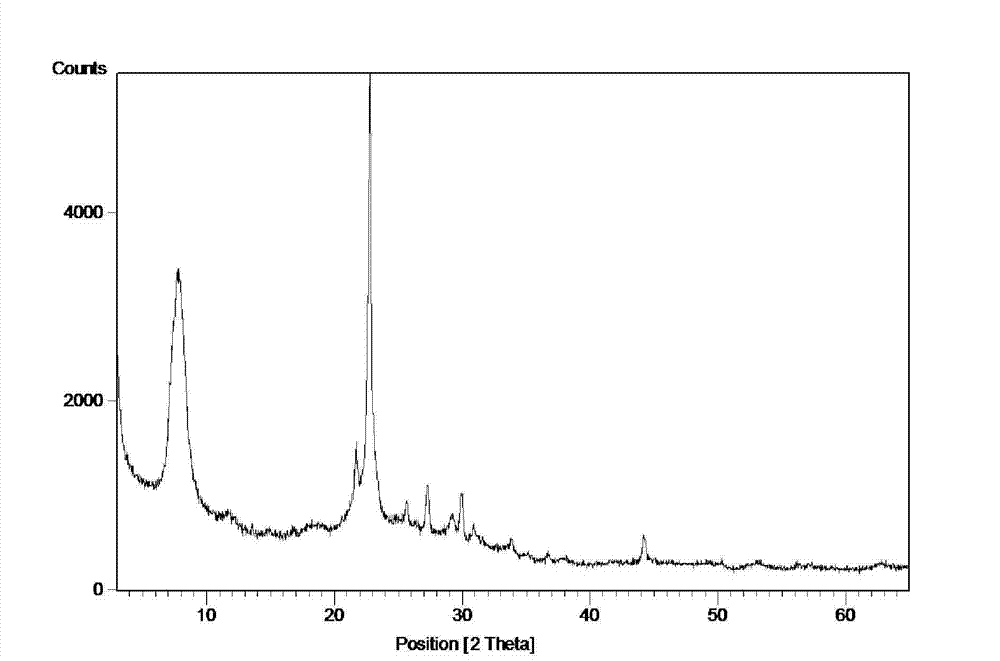

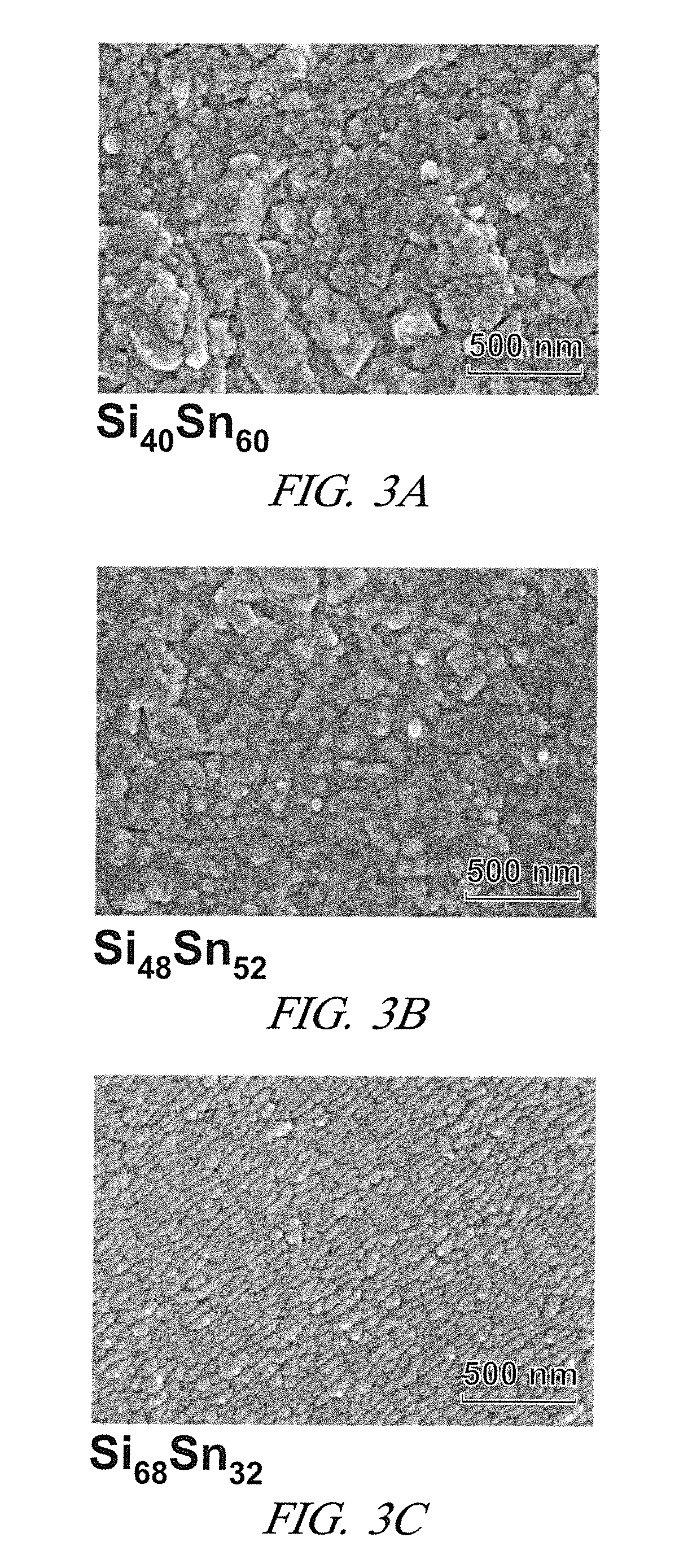

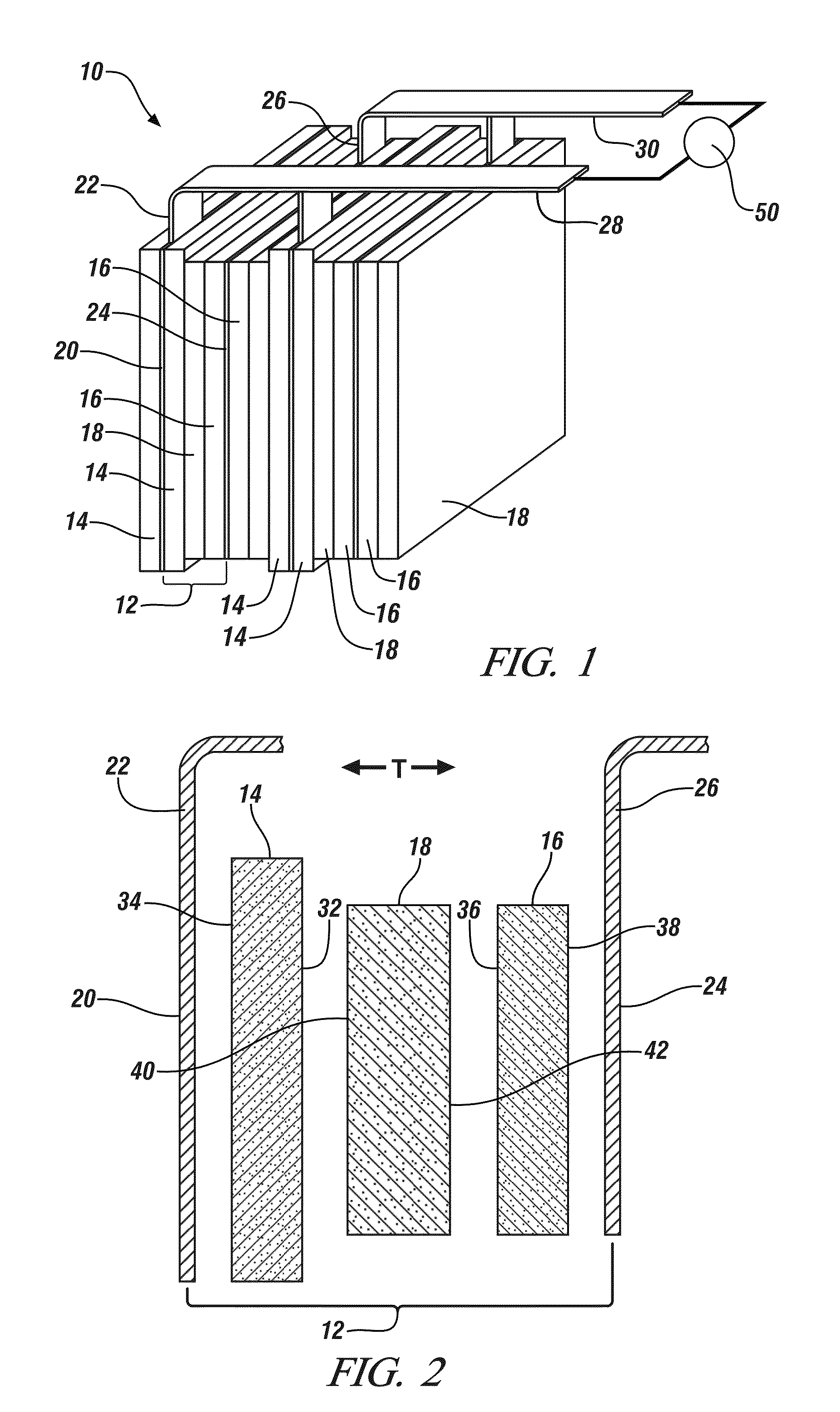

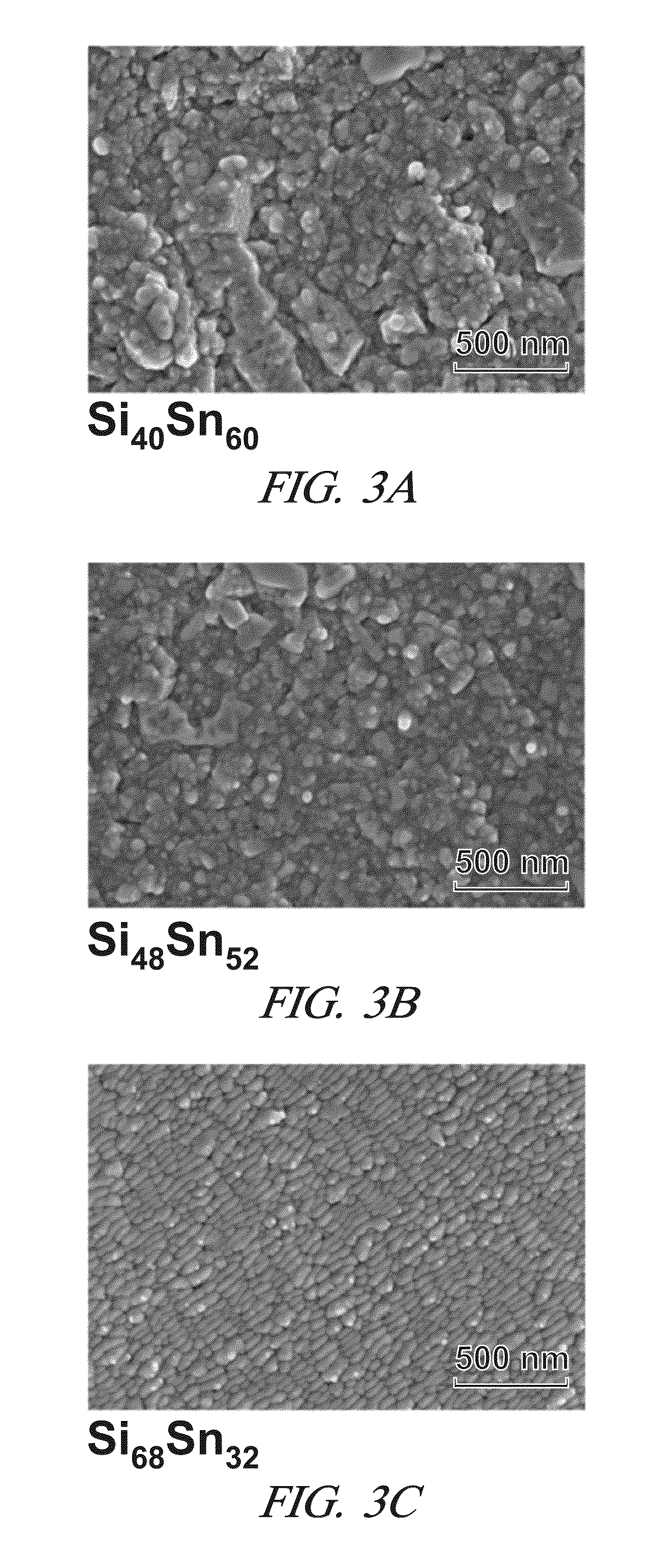

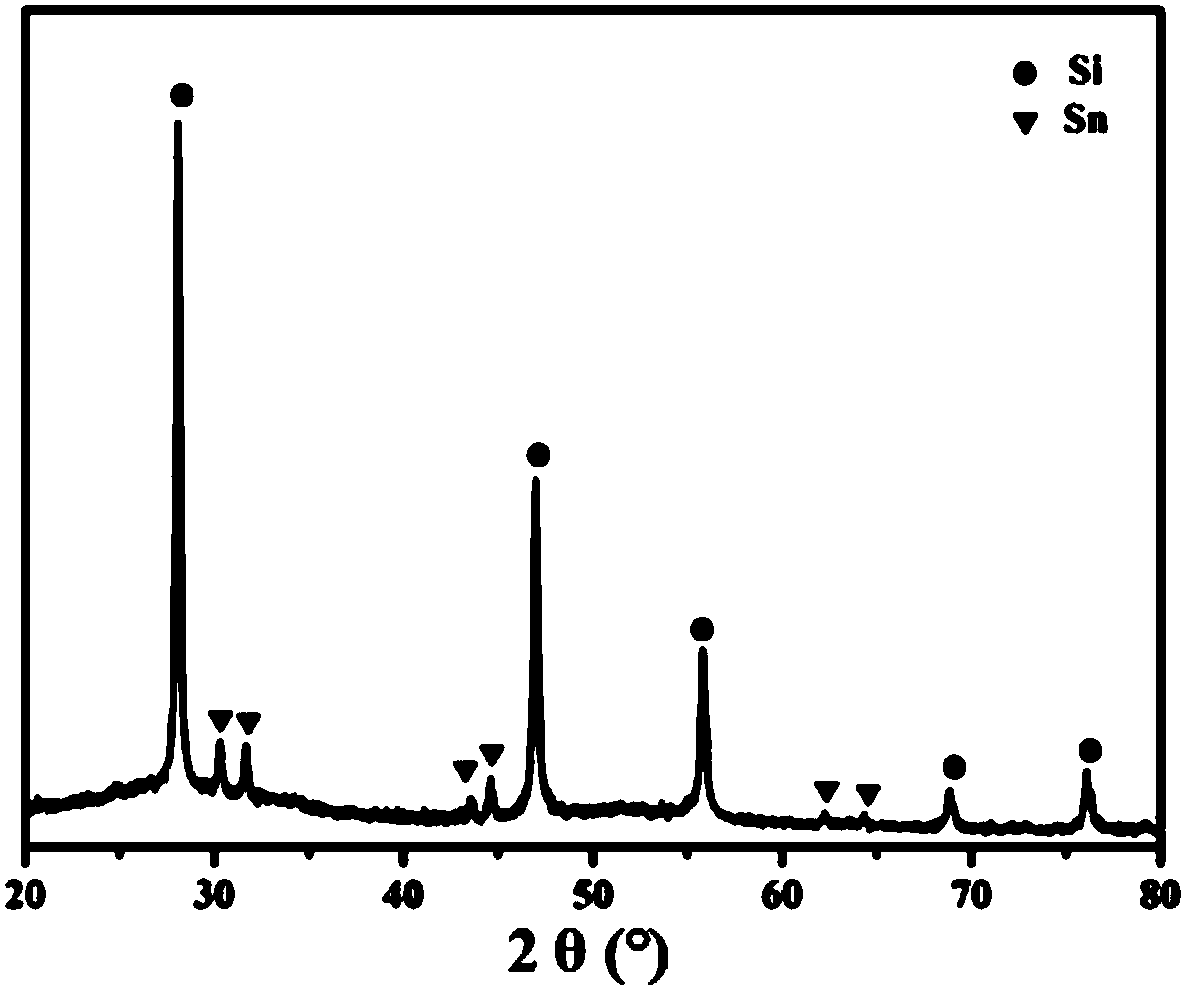

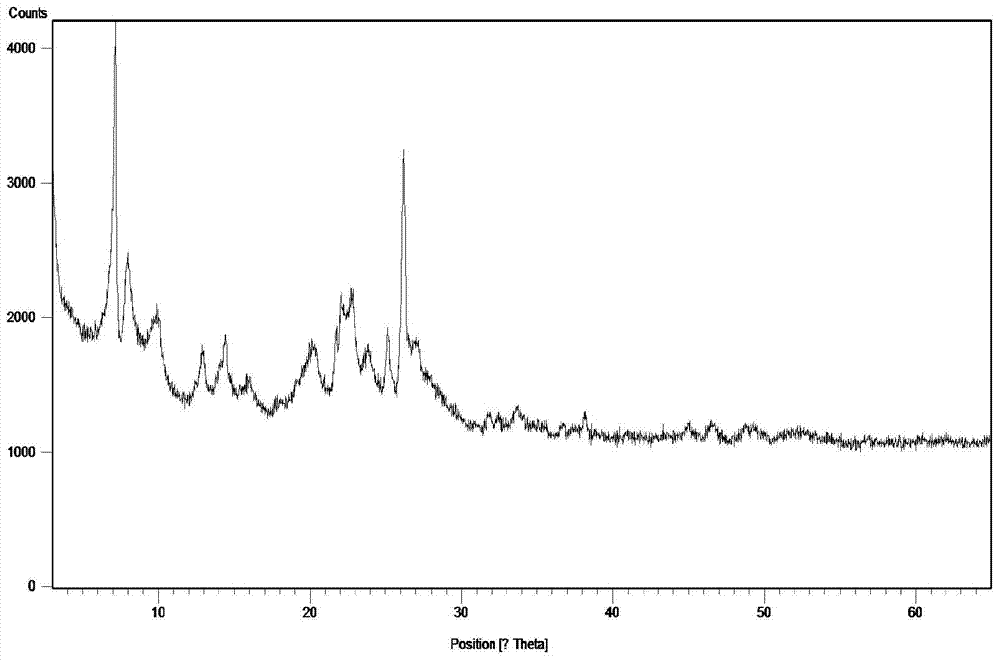

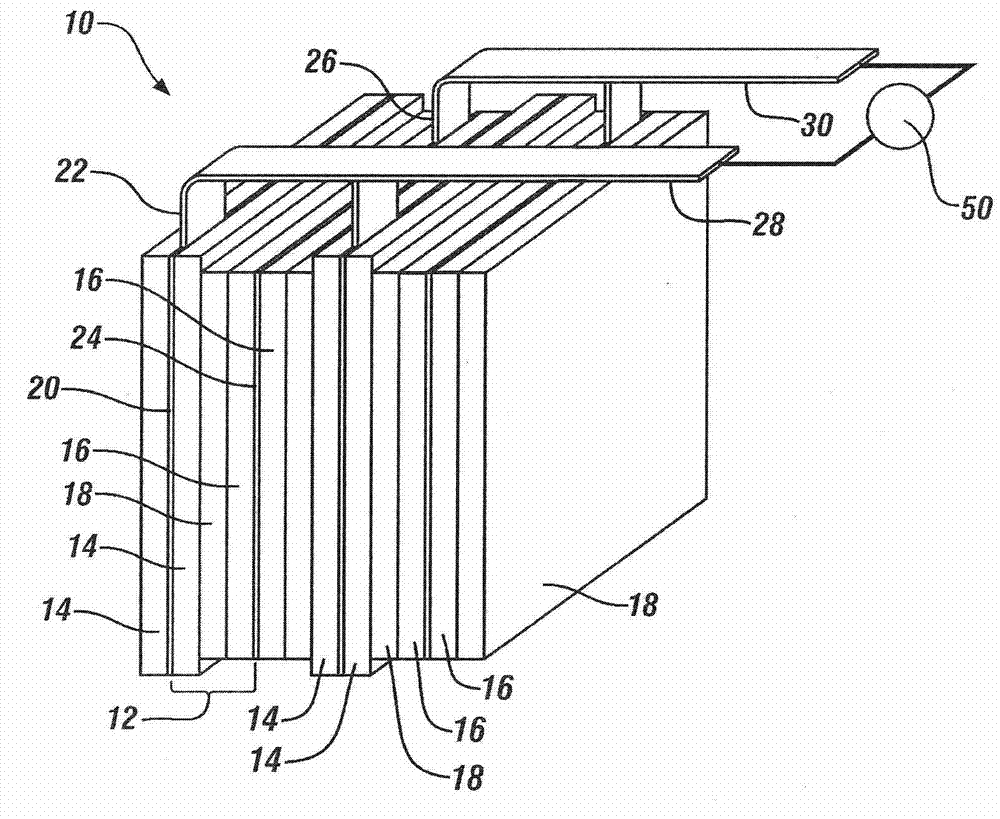

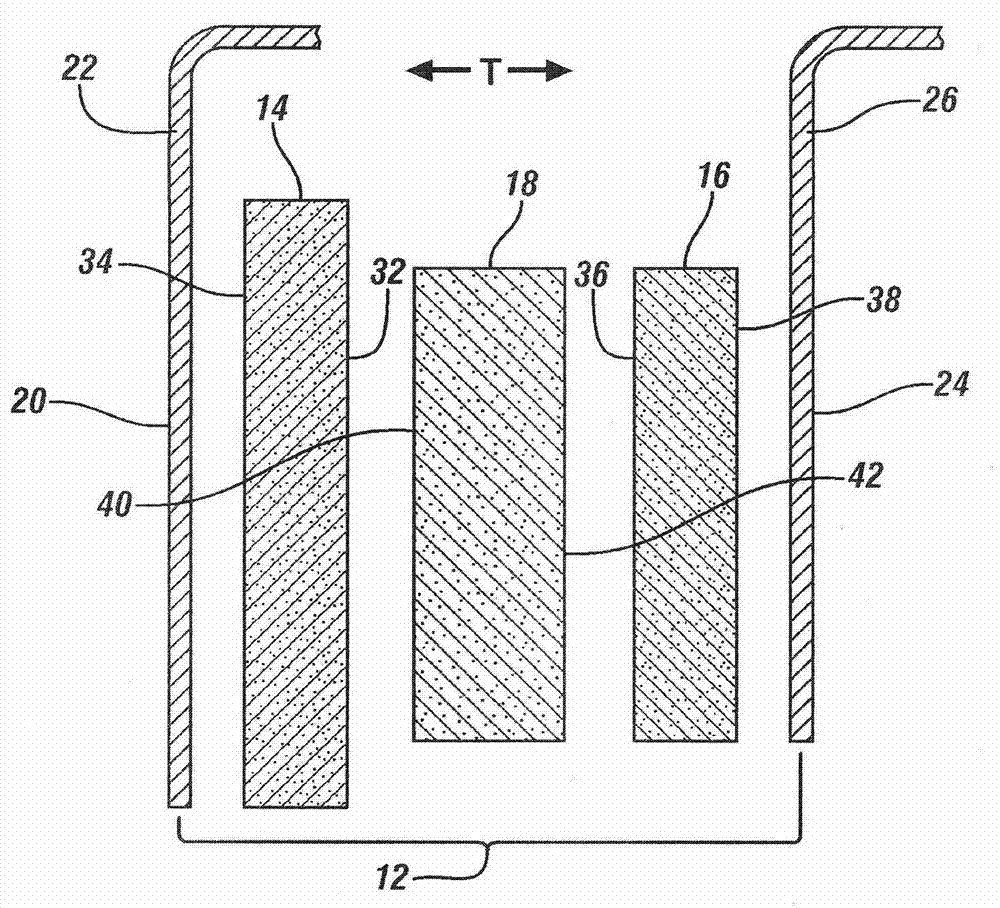

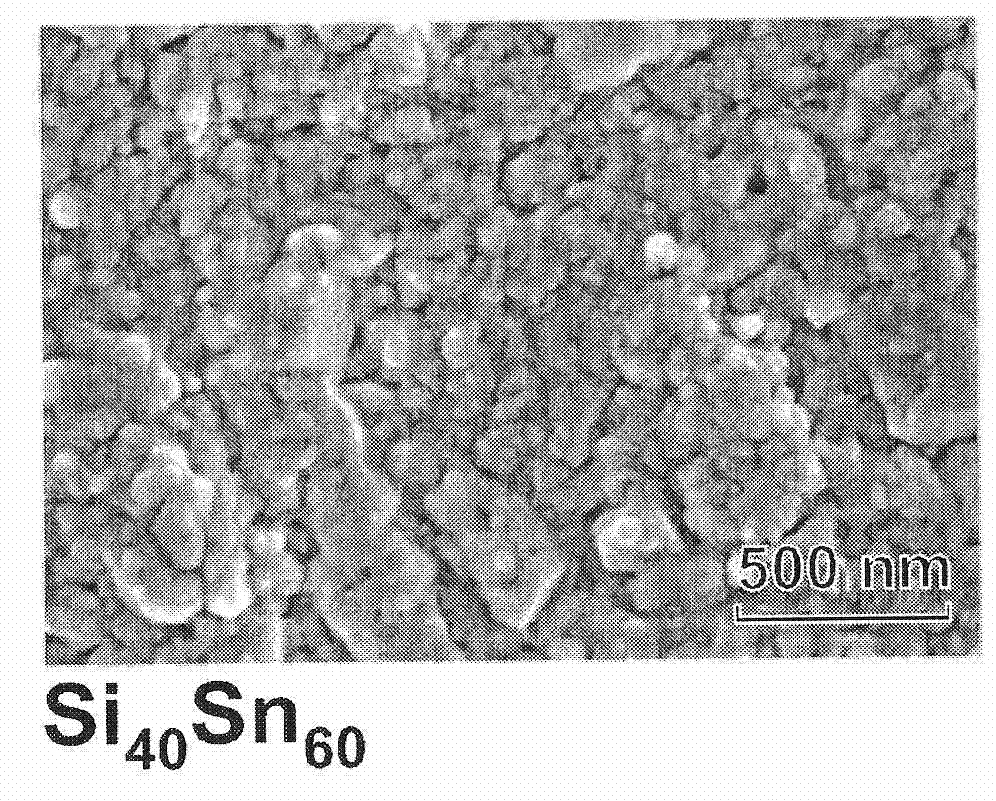

ActiveUS9142830B2Reduce stressMitigate the fracture of the larger composite particlesMaterial nanotechnologyConductive materialComposite electrodeAmorphous phase

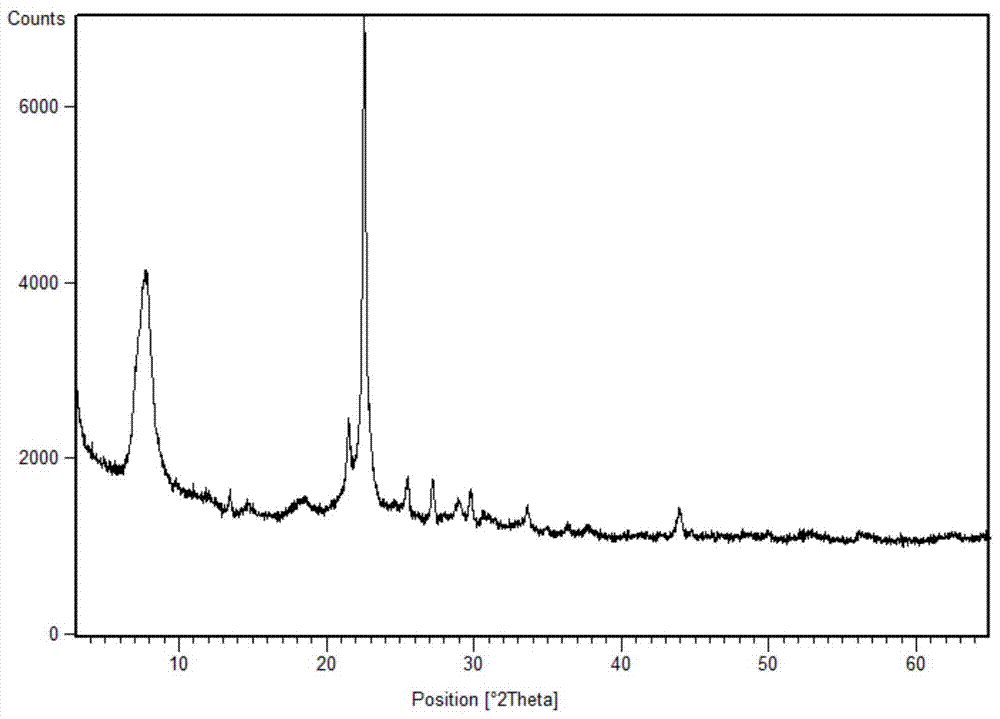

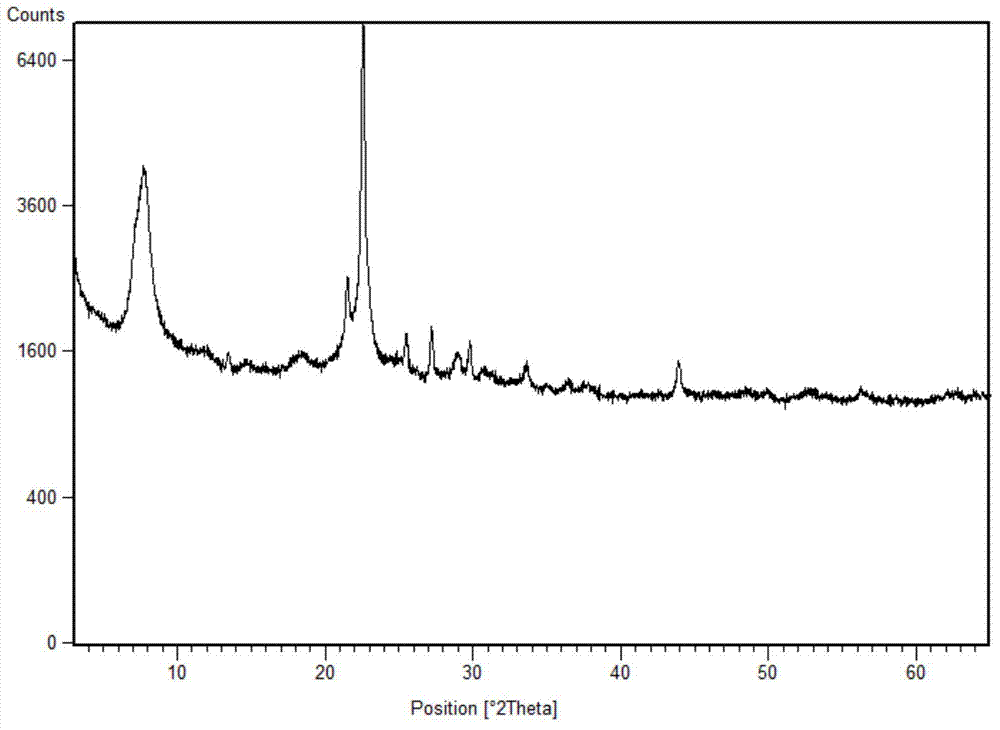

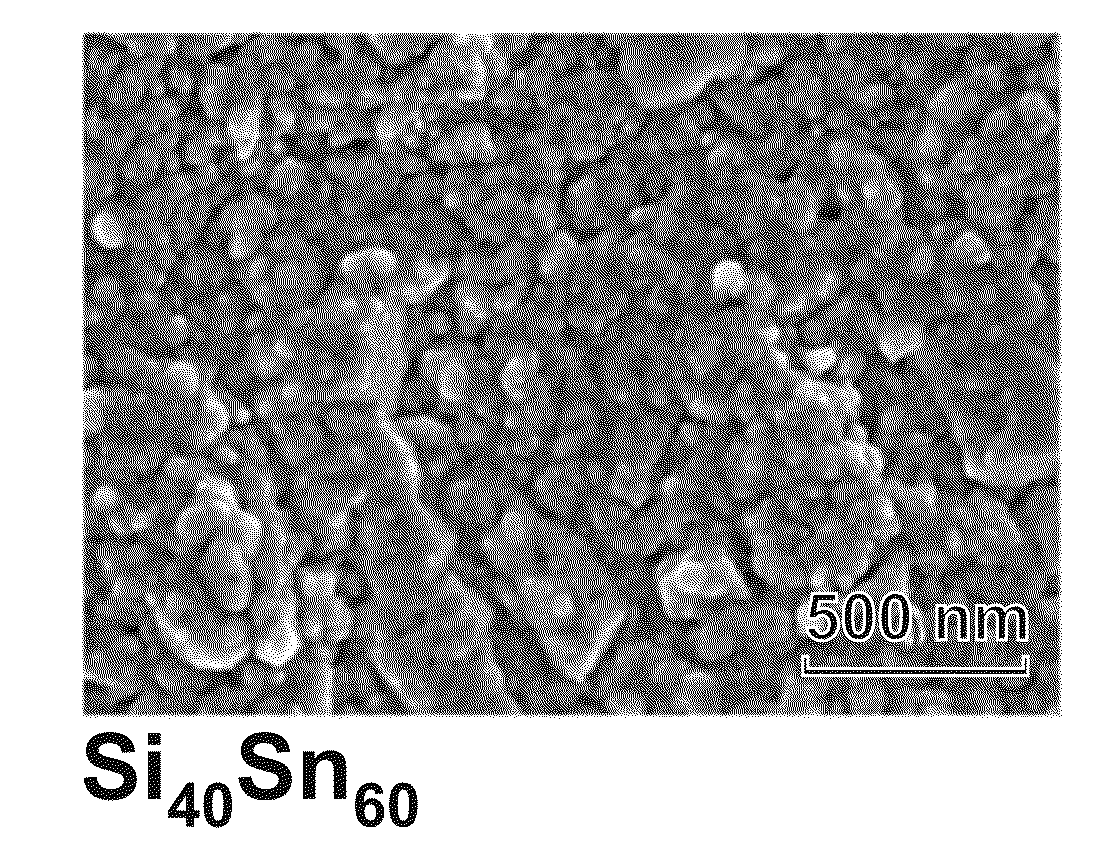

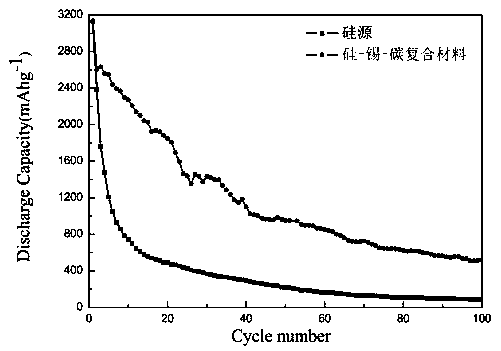

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

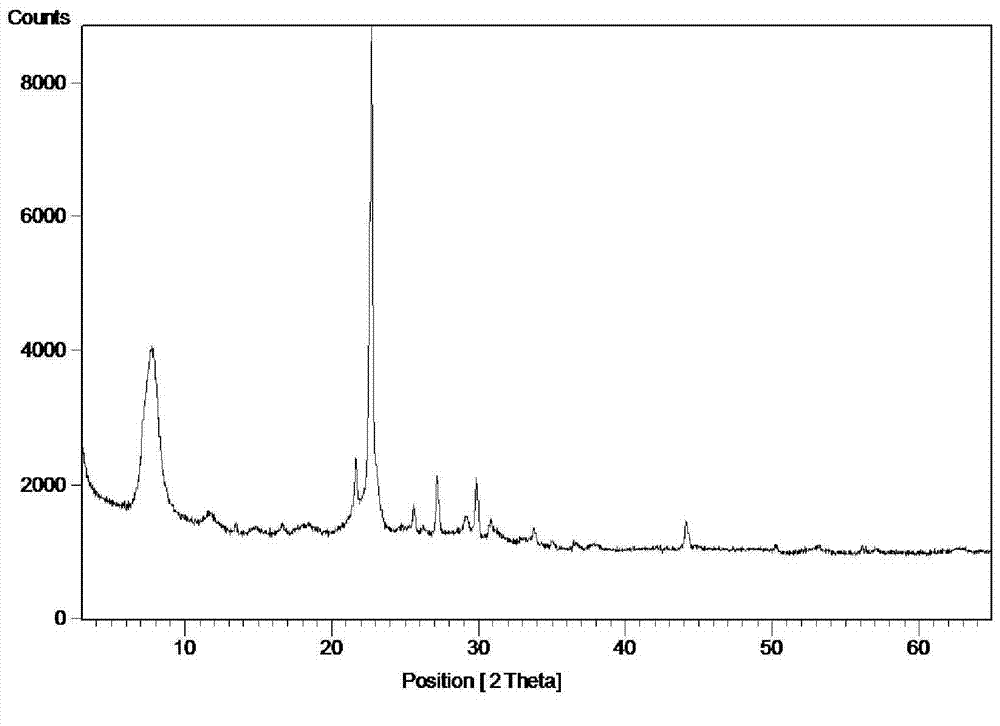

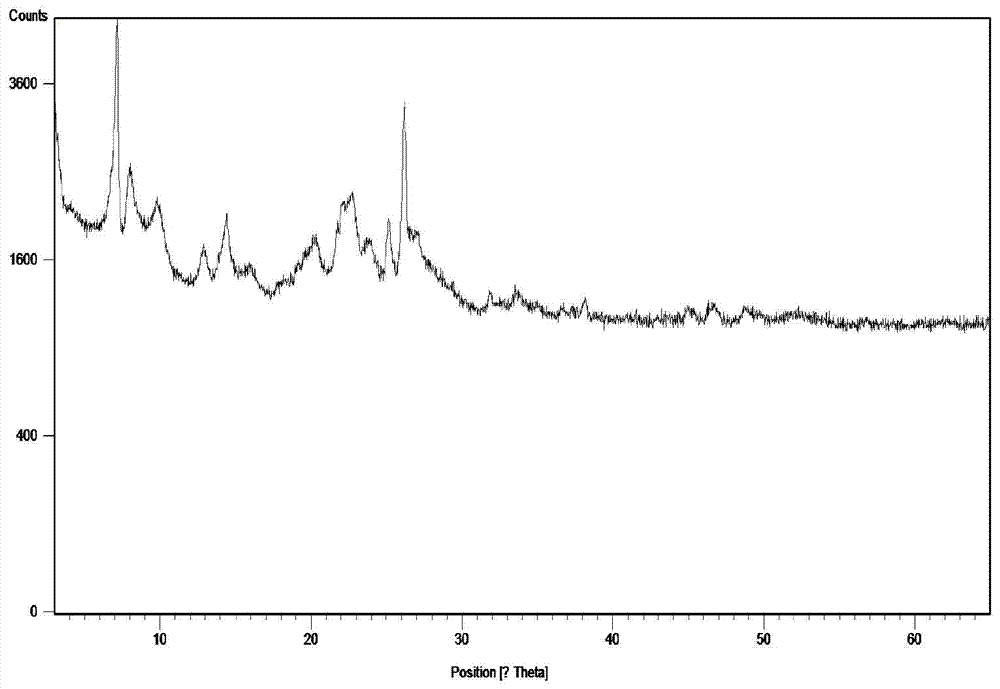

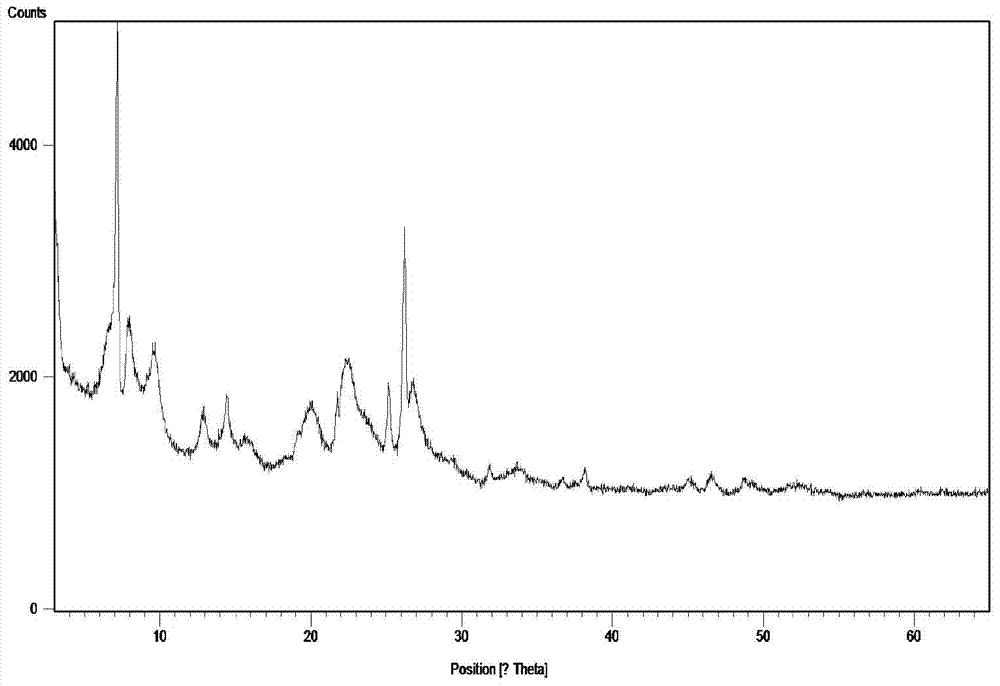

Tin-containing heteroatomic functional molecular sieve and synthesis and application thereof

ActiveCN104709920AFeatures BEA topologyCatalyst carriersMolecular sieve catalystsMolecular sieveSynthesis methods

The present invention discloses a tin-containing heteroatomic functional molecular sieve and a synthesis method thereof, the tin-containing heteroatomic functional molecular sieve has the characteristics of the BEA topologic structure, silicon-tin ratio (atomic ratio) is in the range of 80 to 1000, and the synthesis method of the tin-containing beta molecular sieve is a boric acid-assisted hydrothermal synthesis technology. A tin source, a silicon source, boric acid, a template agent, water and a crystal seed are evenly mixed according to a certain proportion and feeding method for crystallization for a certain time at a certain temperature, the Sn-beta heteroatomic functional molecular sieve can be obtained by separation, washing and drying, and a crystallization product can be directly used as a catalyst or catalyst carrier. The Sn-beta heteroatomic functional molecular sieve has good catalytic performance in the catalytic conversion of biomass and a plurality of fine chemical reaction processes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

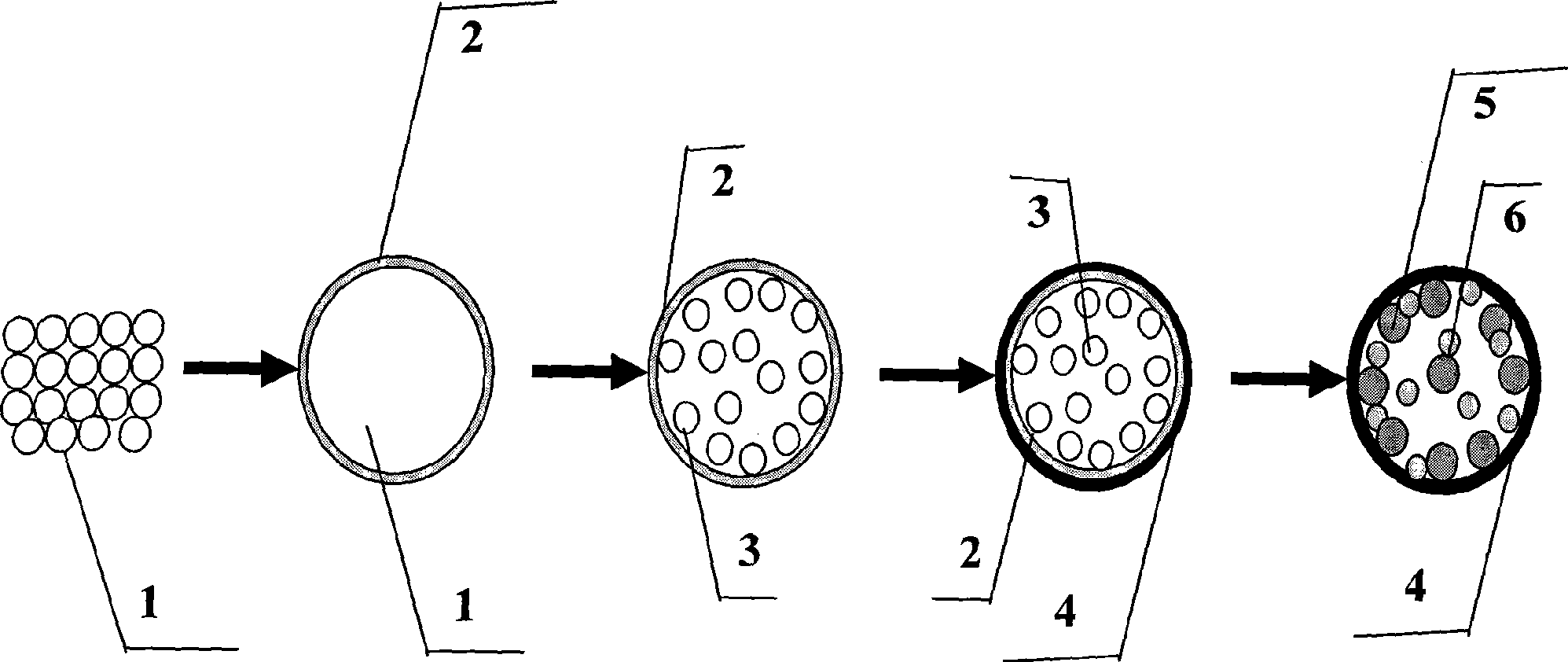

Method for preparing silicon stannum alloy cathode material of lithium ion battery

InactiveCN101510601ARaw materials are easy to getSimple processElectrode manufacturing processesAlloyRates reactions

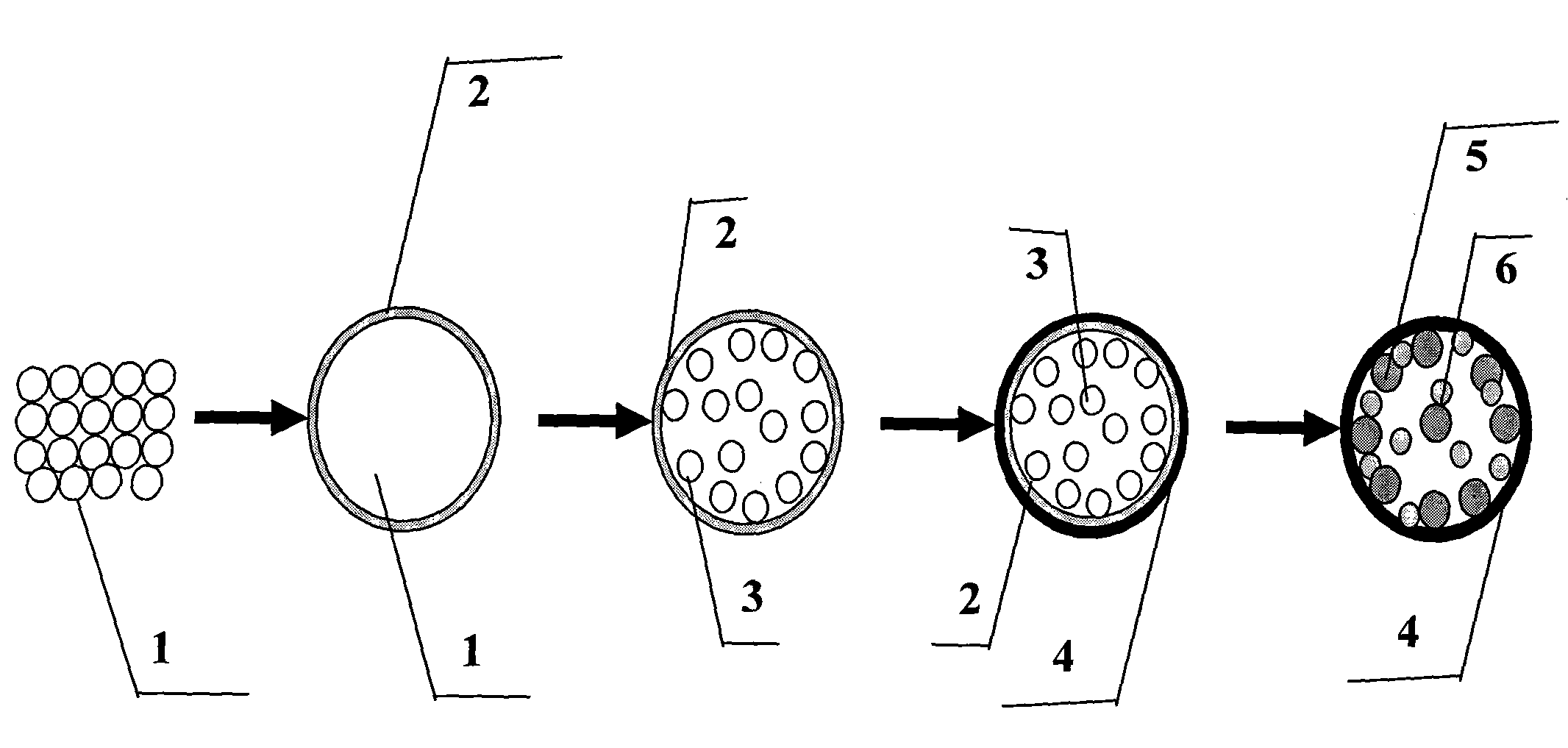

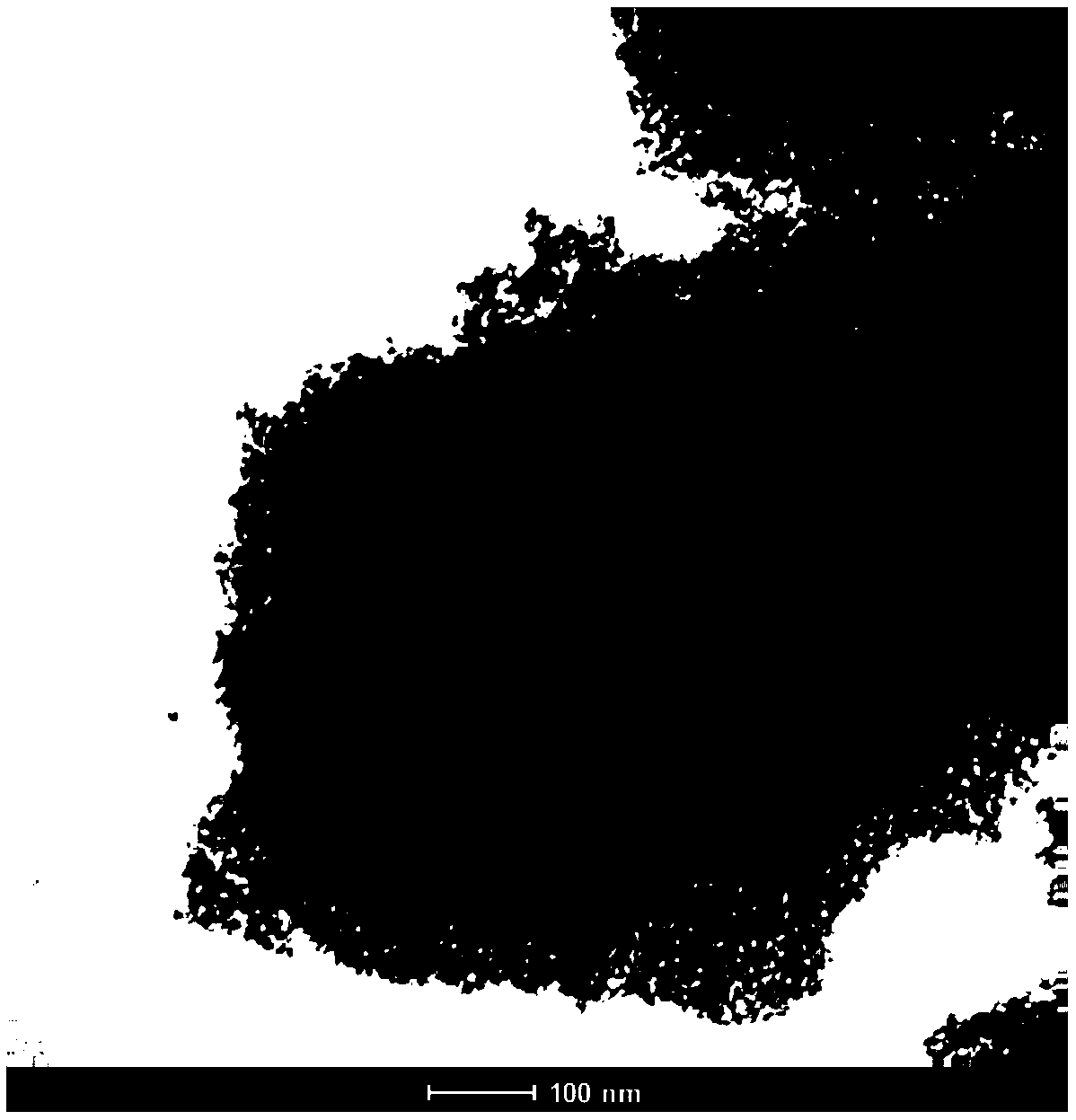

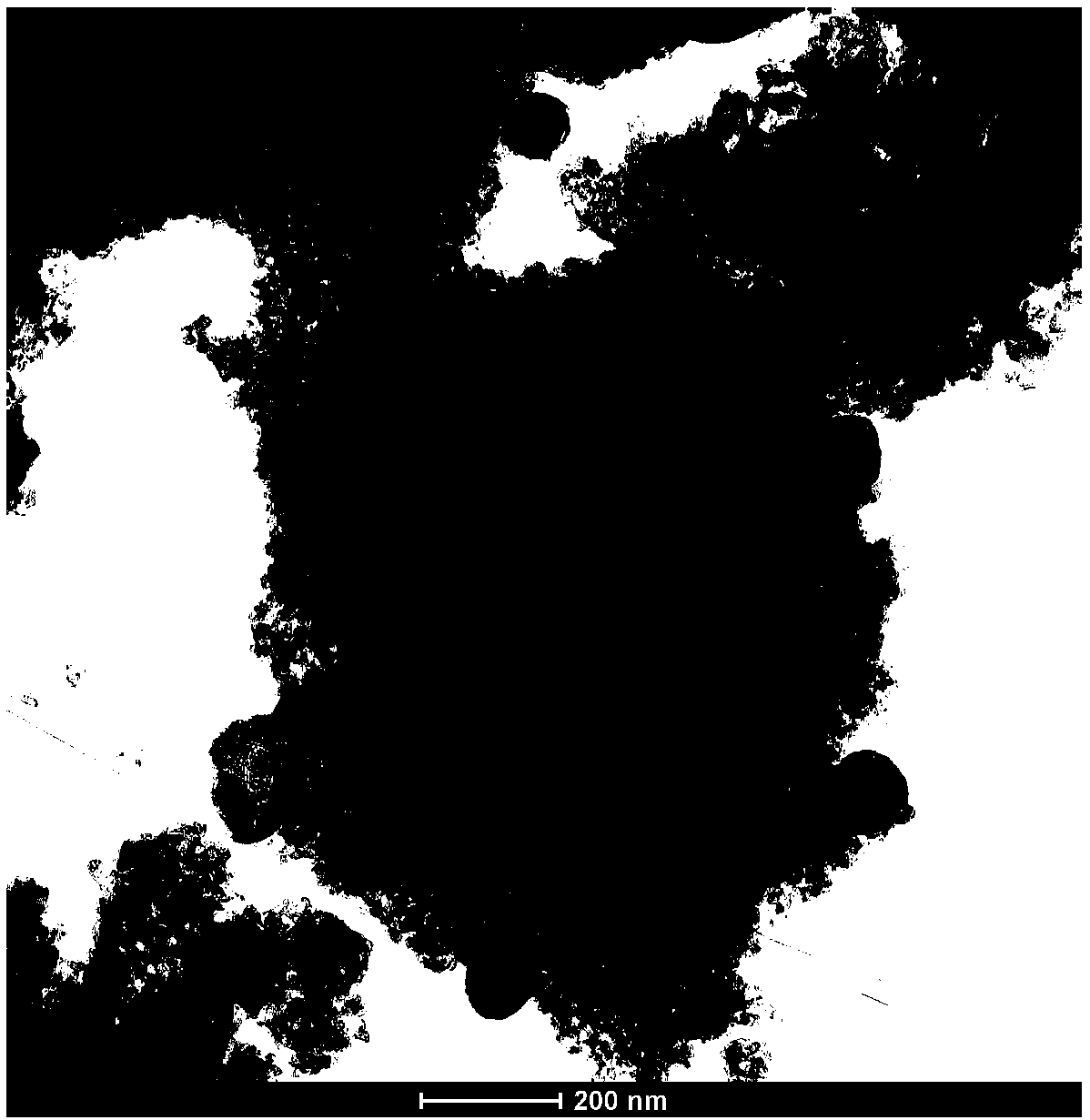

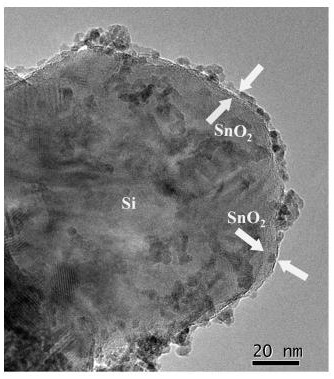

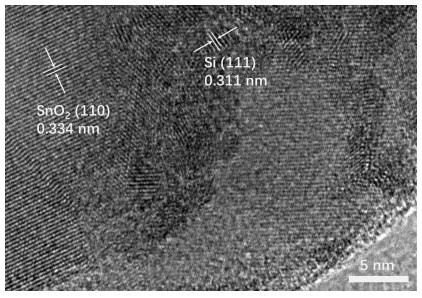

The invention discloses a preparation method for a silicon-tin alloy cathode material in a Li-ion battery. The preparation method comprises the following steps: an oxide ball of silicon is taken as a template, a silicide intermediate coated with tin oxides is prepared at first, and the silicide intermediate is coated with carbon, and then deoxidized to produce the cathode material of nanometer silicon-tin alloy. The preparation method has simple process and rich material sources. The high temperature reaction atmosphere adopted by the preparation method can shorten the reaction time and promote the reaction efficiency. And the material produced by the method has high actual capacity and excellent cycle performance. The preparation method is applicable to the industrialized production of the silicon-tin alloy of Li-ion battery cathode material.

Owner:广州鸿森材料有限公司

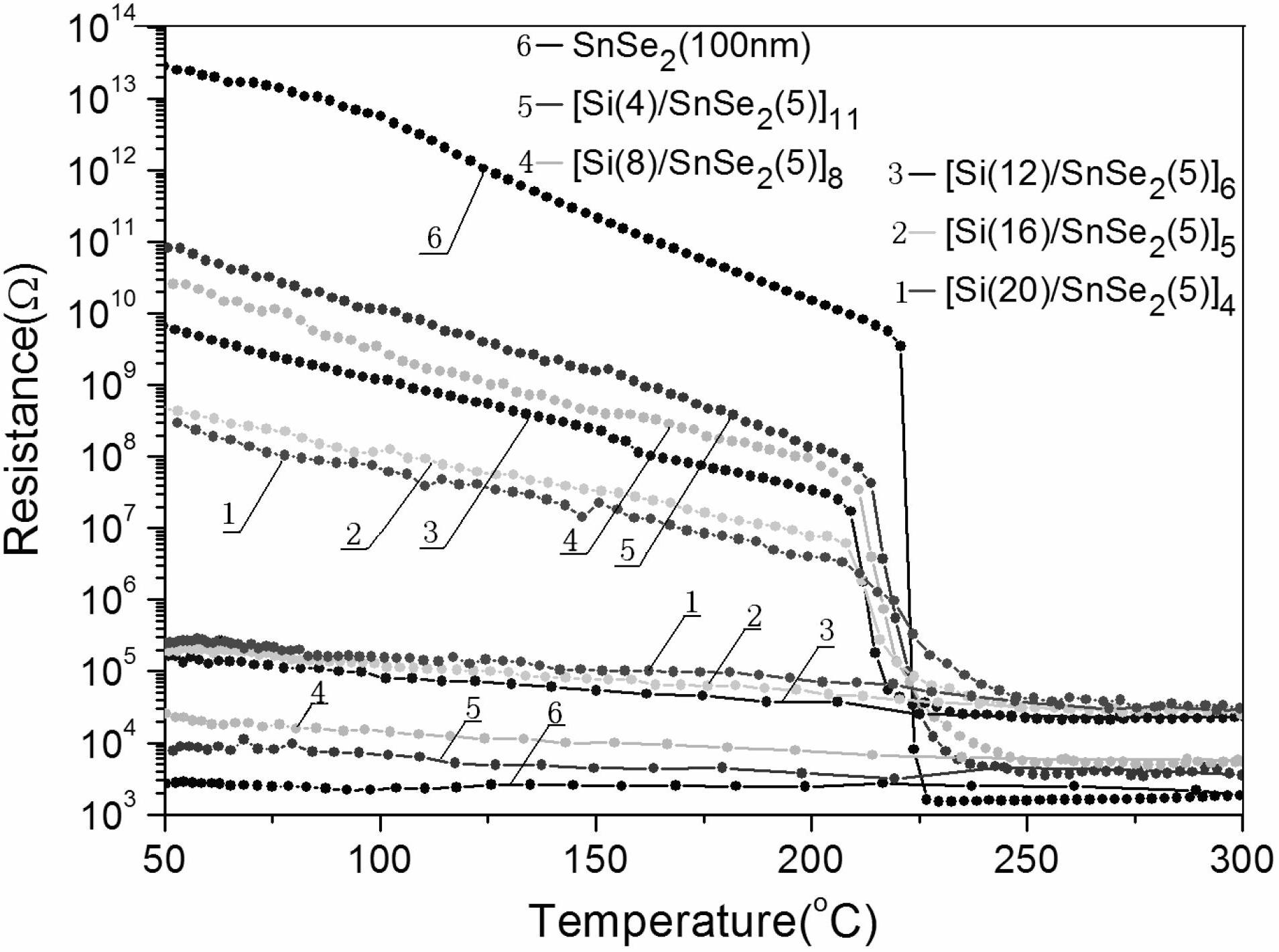

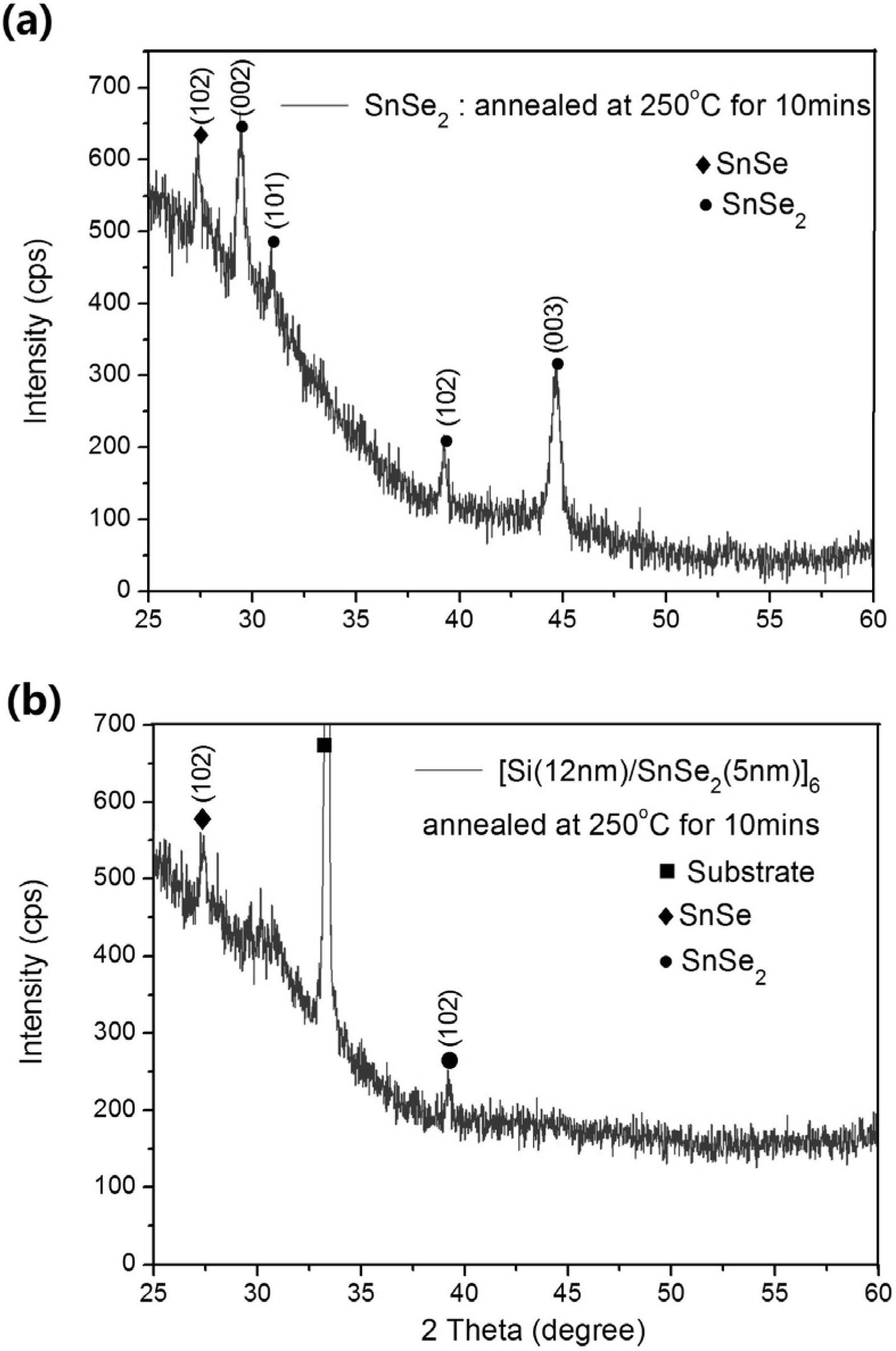

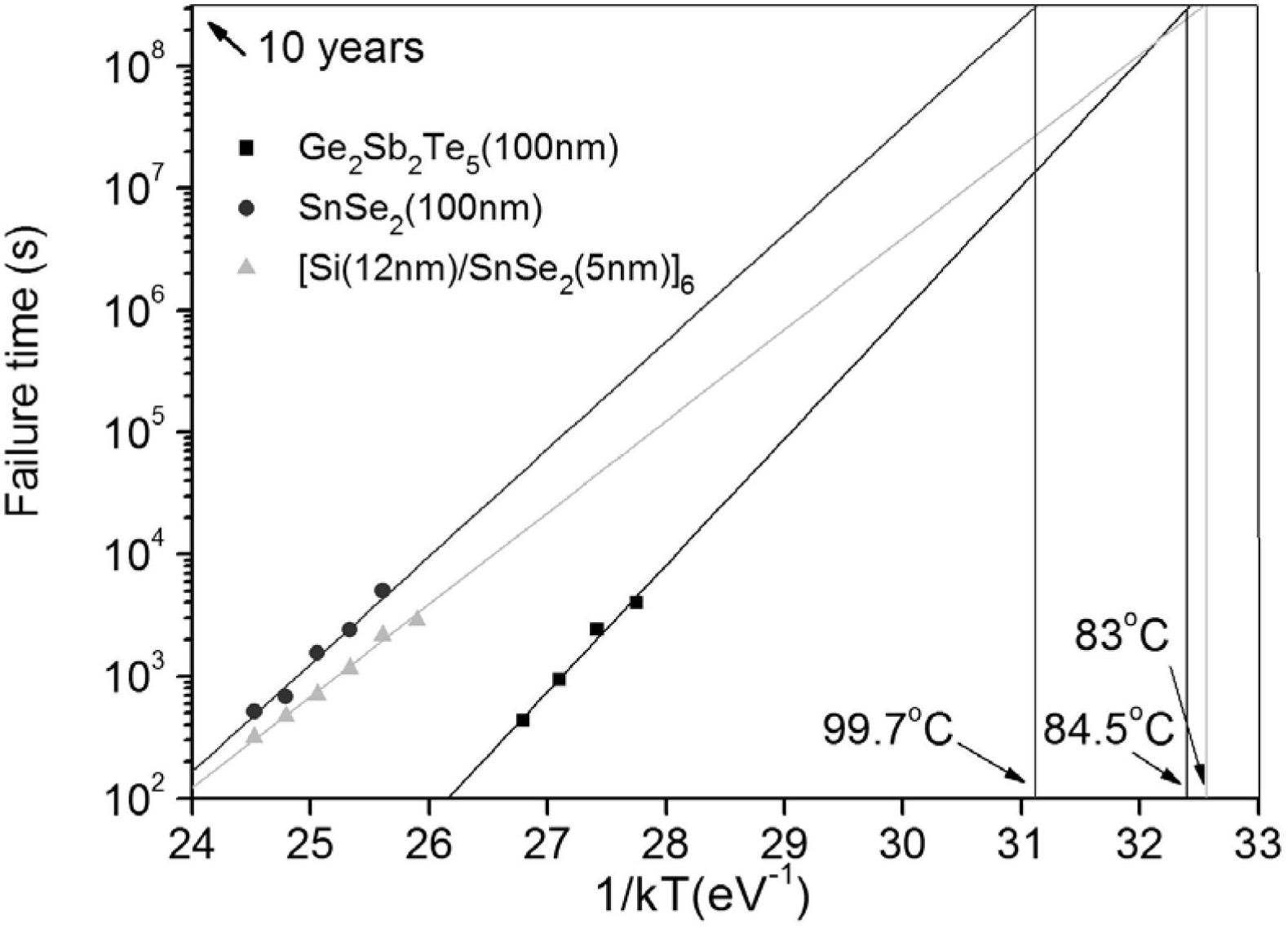

Silicon-tin selenide nano multilayer composite phase change thin film material for phase change memory

InactiveCN102683587ASolve the shortcomingsSolve problemsElectrical apparatusPhase-change memoryPower flow

Owner:TONGJI UNIV

Phase separated silicon-tin composite as negative electrode material for lithium-ion batteries

ActiveUS20130071736A1Reduces induced stressReduce stressMaterial nanotechnologyElectrode carriers/collectorsComposite electrodeAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery. This electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

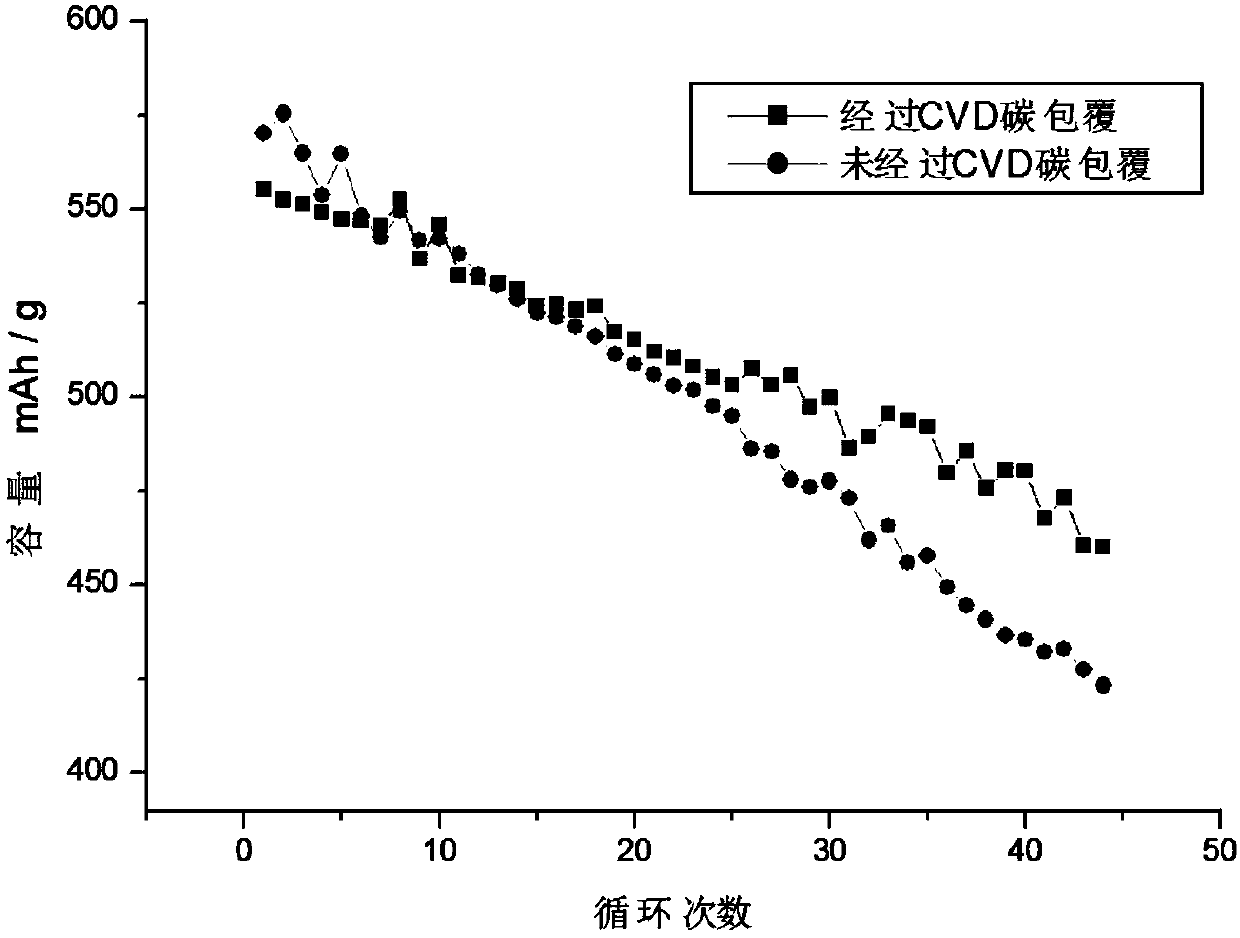

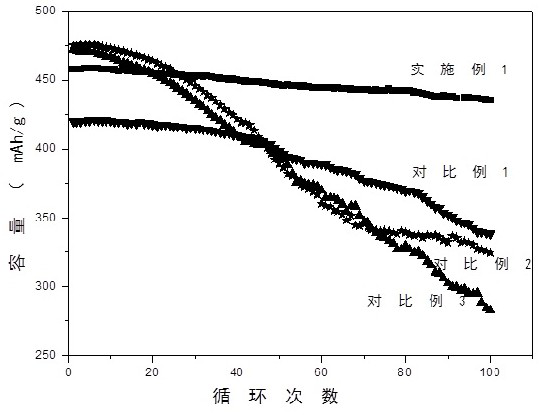

Preparation method of carbon coated silicon-tin composite negative electrode plate

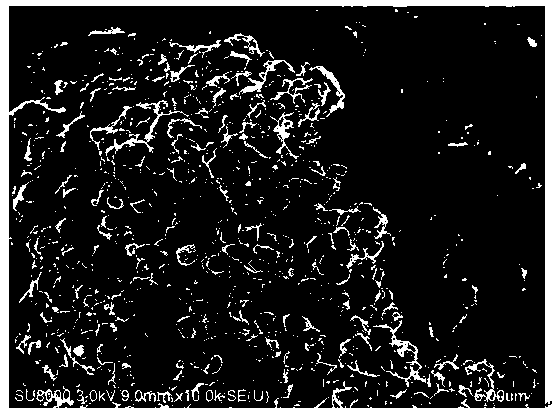

The invention discloses a preparation method of a carbon coated silicon-tin composite negative electrode plate. The preparation method includes the following steps: (1) carrying out mechanical high-energy ball milling of a silicon powder, a tin powder and an artificial graphite powder A to prepare a silicon-tin composite powder; (2) mixing the silicon-tin composite powder with an artificial graphite powder B, to prepare a silicon-tin composite powder matrix; (3) carrying out carbon coating on the silicon-tin composite powder matrix by a chemical vapor deposition method, to prepare a carbon coated silicon-tin composite material; (4) mixing the carbon coated silicon-tin composite material, a binder and a conductive agent, to prepare a carbon coated silicon-tin composite slurry; and (5) carrying out single-side coating of a copper foil with the carbon coated silicon-tin composite slurry, to prepare the carbon coated silicon-tin composite negative electrode plate. The carbon coated silicon-tin composite negative electrode plate has the characteristics of stable volume, high energy density, good electrical conductivity, stable circulation and long service life.

Owner:WANXIANG 123 CO LTD +1

Tin-containing molecular sieve with BEA topological structure and preparation and application thereof

The present invention discloses a tin-containing heteroatomic functional molecular sieve with a BEA topologic structure and a synthesis method thereof, the tin-containing heteroatomic functional molecular sieve has the characteristics of the BEA topologic structure, silicon-tin ratio (atomic ratio) of the Sn-beta heteroatomic functional molecular sieve is in the range of 10 to 1000, and the synthesis method of the tin-containing beta molecular sieve is an ionothermal secondary synthesis preparation method. A tin source, ionic liquid and a beta molecular sieve rich in Si-OH groups are evenly mixed according to a certain proportion and feeding method for crystallization for a certain time at a certain temperature, the Sn-beta heteroatomic functional molecular sieve can be obtained by separation, washing and drying, and a crystallization product can be directly used as a catalyst or catalyst carrier. The Sn-beta heteroatomic functional molecular sieve has good catalytic performance in the catalytic conversion of biomass and a plurality of fine chemical reaction processes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

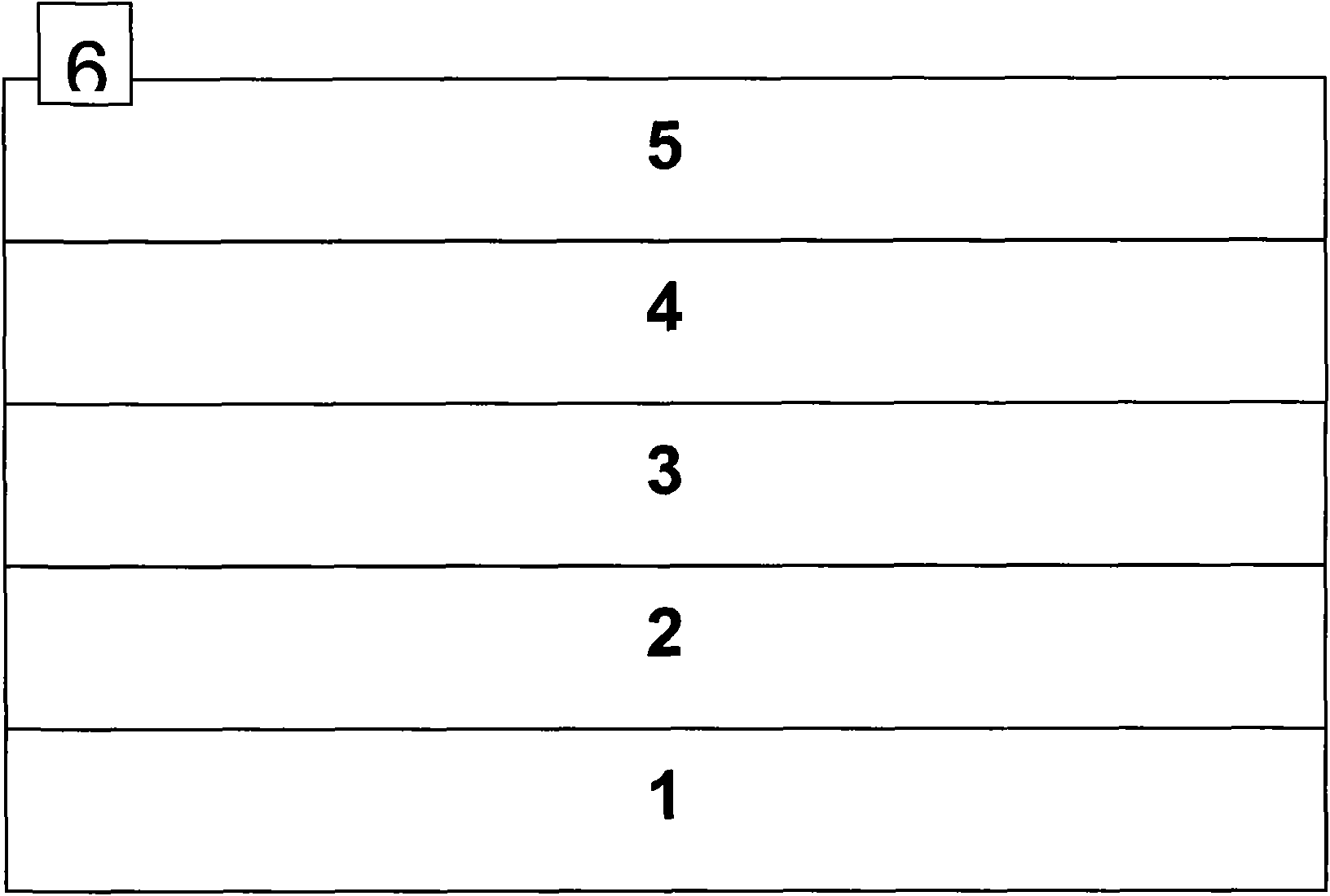

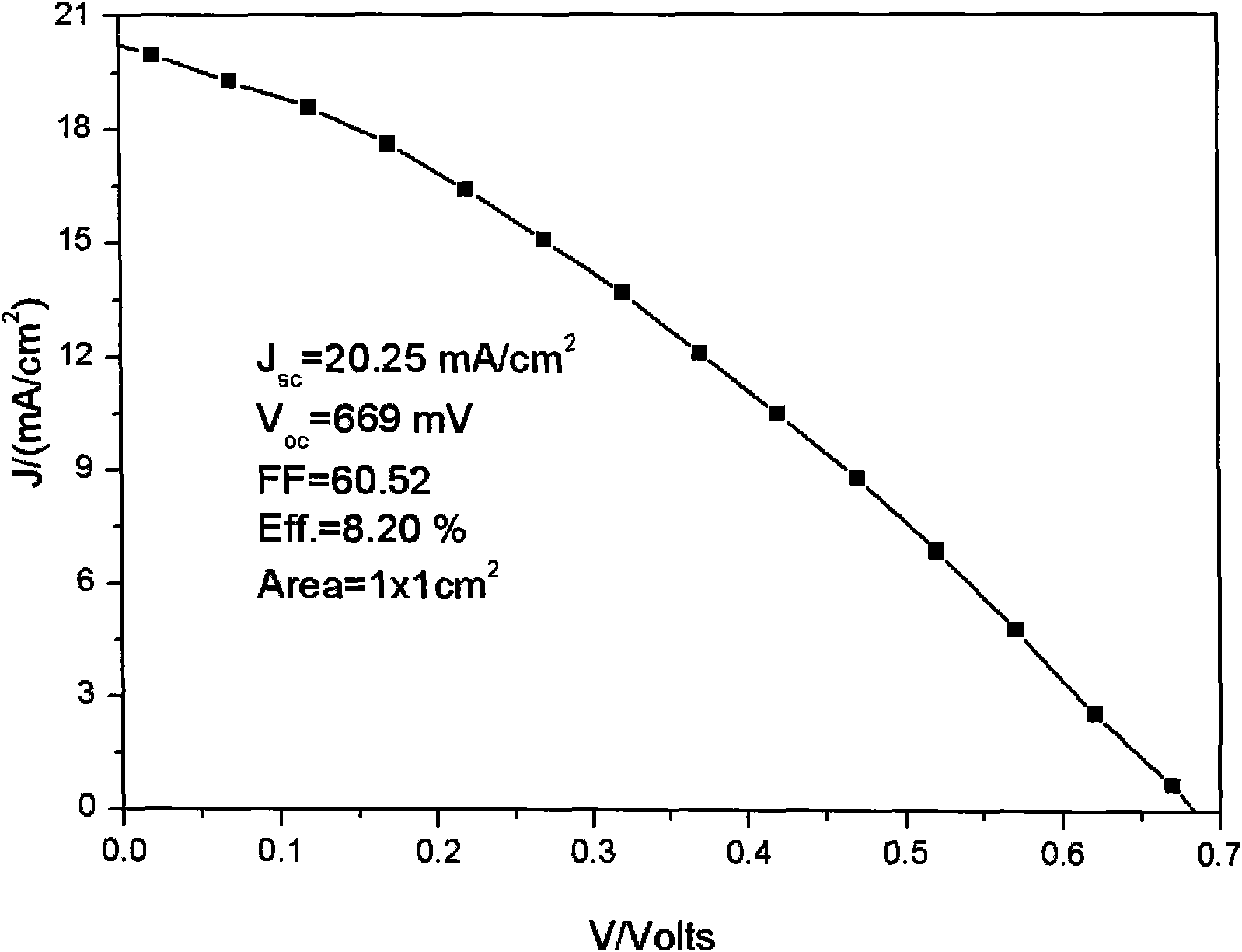

Film solar battery and manufacturing method thereof

ActiveCN101645469ASimple structureSimple processFinal product manufacturePhotovoltaic energy generationVulcanizationSulfur

The invention discloses a film solar battery and a manufacturing method thereof. The film solar battery sequentially comprises a glass substrate, a molybdenum-copper back electrode, a copper-silicon-tin-sulfur (CSTS) photoabsorption layer, a zinc sulfide (ZnS) buffer layer, a zinc aluminum oxide (ZAO) window layer and a nickel-aluminum top electrode, wherein, in the photoabsorption layer, a copper-silicon-tin-sulfur film of 0.5-5mu m is settled on the back electrode by adopting a sputtering vulcanization method. The invention avoids the use of rare noble metal and toxic elements and has the advantages of simple structure and manufacturing technique, high photoelectric conversion efficiency, favorable stability and the like.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

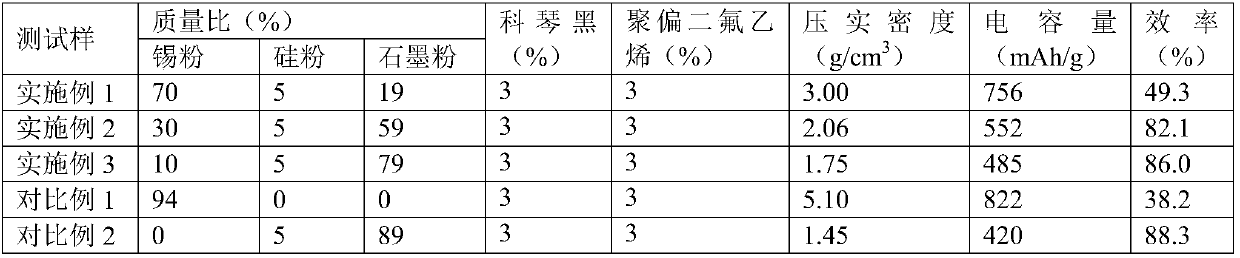

Carbon-silicon-tin compound negative electrode material and preparation method thereof

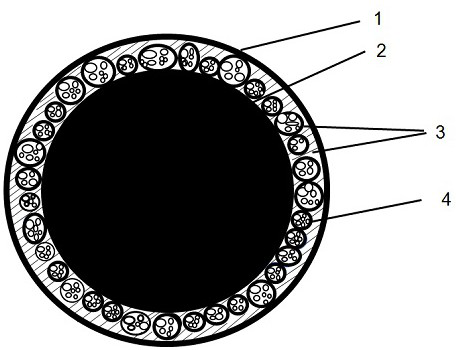

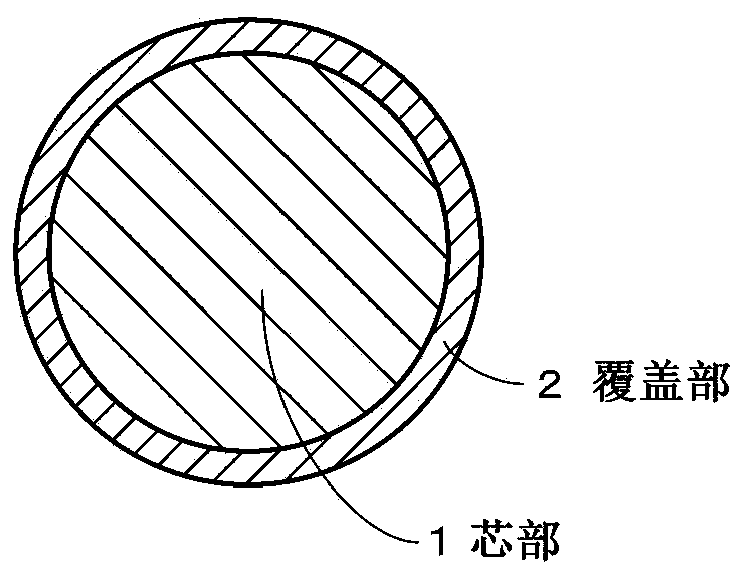

ActiveCN112635744AAvoid chalkingTake advantage of high-capacity featuresSilicaSecondary cellsCarbon coatingElectrode material

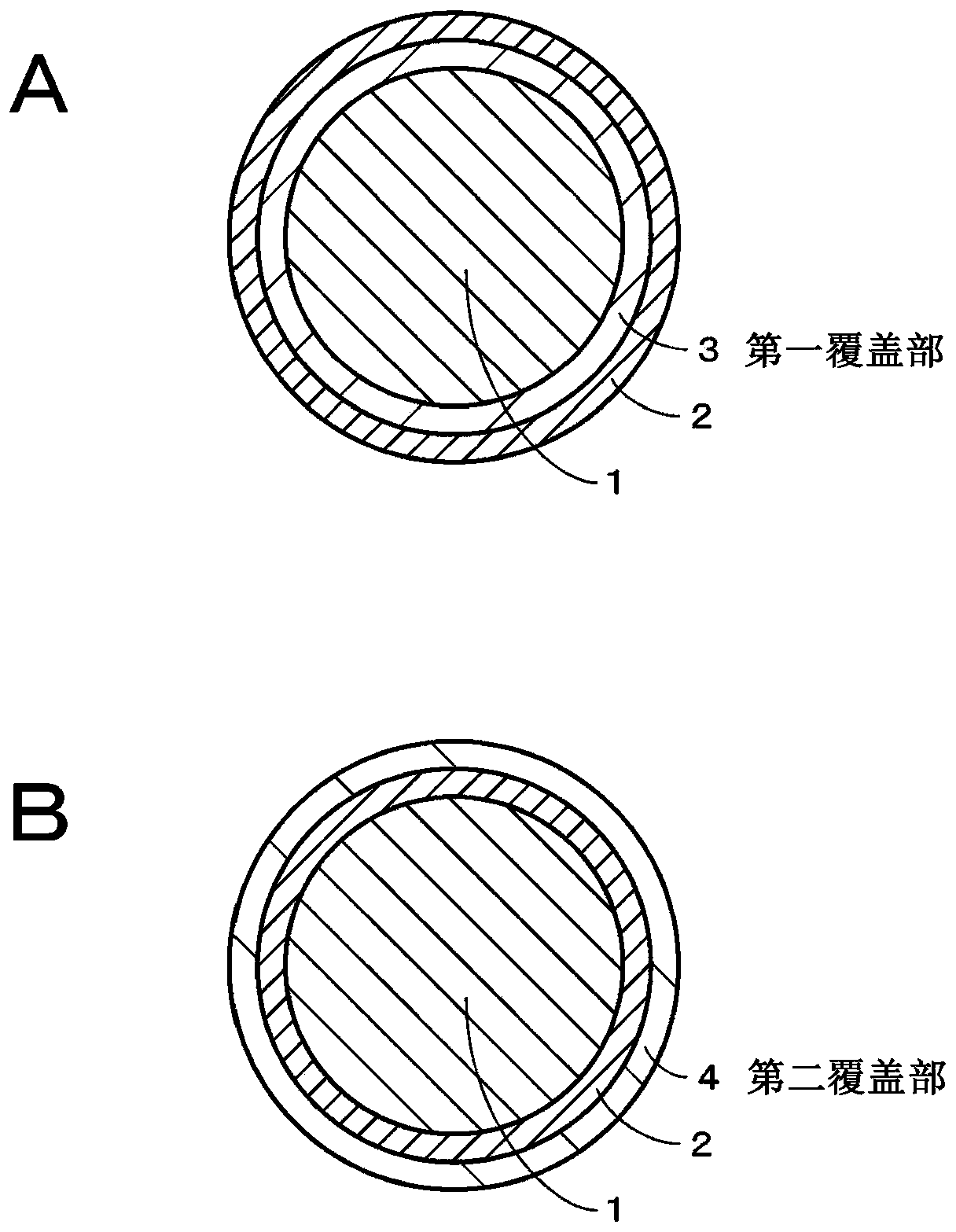

The invention discloses a carbon-silicon-tin compound negative electrode material. The carbon-silicon-tin compound negative electrode material comprises a carbon material particle matrix and a coating layer; the coating layer comprises a coating inner layer and a coating outer layer; the coating inner layer is a mixture of a silicon-tin composite material and amorphous carbon; the silicon-tin composite material is a silicon-based material of which the surface and holes are deposited with a nano tin material; the amorphous carbon coats the surface of the silicon-tin composite material and fills a gap between the carbon material particle matrix and the silicon-tin composite material; and the coating outer layer is a carbon coating layer. The invention further discloses a preparation method of the carbon-silicon-tin composite negative electrode material. The capacity of the carbon-silicon-tin composite negative electrode material prepared by the method is improved while the conductivity is improved, the volume expansion of the negative electrode material is effectively buffered, and the cycle performance is improved.

Owner:河南电池研究院有限公司

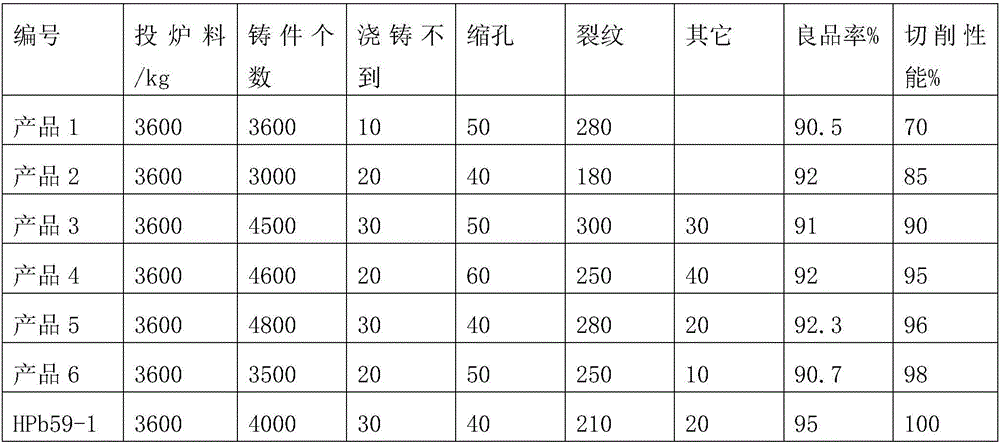

A kind of environment-friendly silicon-tin brass suitable for forging and its manufacturing method

The invention relates to an environment-friendly silicon tin brass suitable for forging. The environment-friendly silicon tin brass comprises the following components in percentages by weight: 66-72% of copper, 0.4-3.0% of silicon, 0.03-1.0% of tin, 0.001-0.1% of titanium, not more than 0.2% of lead and the balance of zinc and unavoidable impurities, wherein the total amount of the unavoidable impurities is not more 0.2%. A preparation method comprises the following steps of: firstly, preparing copper silicon and copper titanium intermediate alloys; then sequentially adding electrolytic copper, the copper silicon intermediate alloy, electrolytic zinc and a tin ingot into an induction electric furnace to smelt; adding the copper titanium intermediate alloy after all metals are melted; thenpouring a copper alloy ingot, wherein a copper alloy cast ingot is heated to 650-750 DEG C and thermally extruded; uniformly annealing an extruded semifinished product; and then carrying out acid washing, stretching, straightening and stress relief annealing to obtain a finished product. In the invention, lead is replaced with silicone to improve the cutting property and the forging property of the alloy, tin is used for improving the cutting property and the dezincification and corrosive resistances of the alloy, and the titanium is used for refining crystal grains. Comparative experiments show that the environment-friendly silicon tin brass suitable for forging has better forging property, cutting property and dezincification and corrosive resistances.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Environmentally-friendly fast cutting recasting copper alloy

The invention discloses an environmentally-friendly fast cutting recasting copper alloy and relates to the preparation technical field of the metal alloy materials. The copper alloy comprises the following components by weight percent: 57%-62% of Cu, 0.30%-1.0% of Al, 0.10%-0.5% of Fe, 0.01%-0.30% of P, 0.05%-0.20% of Pb, 0.05%-0.5% of Mg, 0.01%-0.06% of B, less than 0.50% of Ni, less than 0.50% of Si, less than 0.70% of Sn and the balance of Zn and inevitable impurities, wherein the total content of the impurities is less than 0.25%. The copper alloy selects aluminum, iron, nickel, silicon and tin elements to replace lead, thus the content of the lead element can be reduced, the damages to the environment and the human body can be reduced and the cost can be lowered; the smelting purity of the gravity cast ingot is good, the liquidity of the casting process is good, the thermal stress cracking resistance is high; the organization density is high, the grains are fine and uniform; and the cutting property is increased, the value of the polishing degree is good, the copper alloy has no welding stress crack and the corrosion resistance is increased.

Owner:苏州撼力合金股份有限公司

Phase separated silicon-tin composite as negative electrode material for lithium-ion and lithium sulfur batteries

ActiveUS20140106220A1Reduces induced stressNegates useMaterial nanotechnologyElectrode melt handlingLithium sulfurLithium-ion battery

A composite of silicon and tin is prepared as a negative electrode composition with increased lithium insertion capacity and durability for use with a metal current collector in cells of a lithium-ion battery or a lithium-sulfur battery. This negative electrode material is formed such that the silicon is present as a distinct amorphous phase in a matrix phase of crystalline tin. While the tin phase provides electron conductivity, both phases accommodate the insertion and extraction of lithium in the operation of the cell and both phases interact in minimizing mechanical damage to the material as the cell experiences repeated charge and discharge cycles. In general, roughly equal atomic proportions of the tin and silicon are used in forming the phase separated composite electrode material.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for preparing silicon stannum alloy cathode material of lithium ion battery

InactiveCN101510601BRaw materials are easy to getSimple processElectrode manufacturing processesElectrical batteryAlloy

The invention discloses a preparation method for a silicon-tin alloy cathode material in a Li-ion battery. The preparation method comprises the following steps: an oxide ball of silicon is taken as a template, a silicide intermediate coated with tin oxides is prepared at first, and the silicide intermediate is coated with carbon, and then deoxidized to produce the cathode material of nanometer silicon-tin alloy. The preparation method has simple process and rich material sources. The high temperature reaction atmosphere adopted by the preparation method can shorten the reaction time and promote the reaction efficiency. And the material produced by the method has high actual capacity and excellent cycle performance. The preparation method is applicable to the industrialized production of the silicon-tin alloy of Li-ion battery cathode material.

Owner:广州鸿森材料有限公司

Negative electrode active material, negative electrode, battery, battery pack, electronic device, electric vehicle, power storage device, and power system

PendingCN110121803AExcellent cycle characteristicsNegative electrodesLi-accumulatorsElectricity systemElectrical battery

Owner:MURATA MFG CO LTD

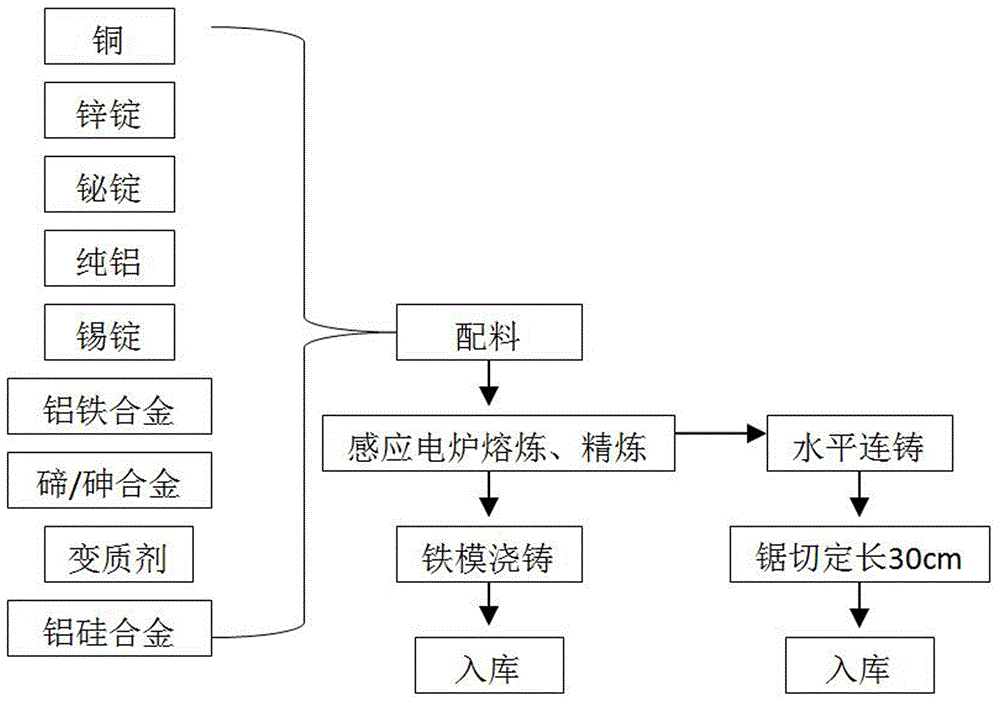

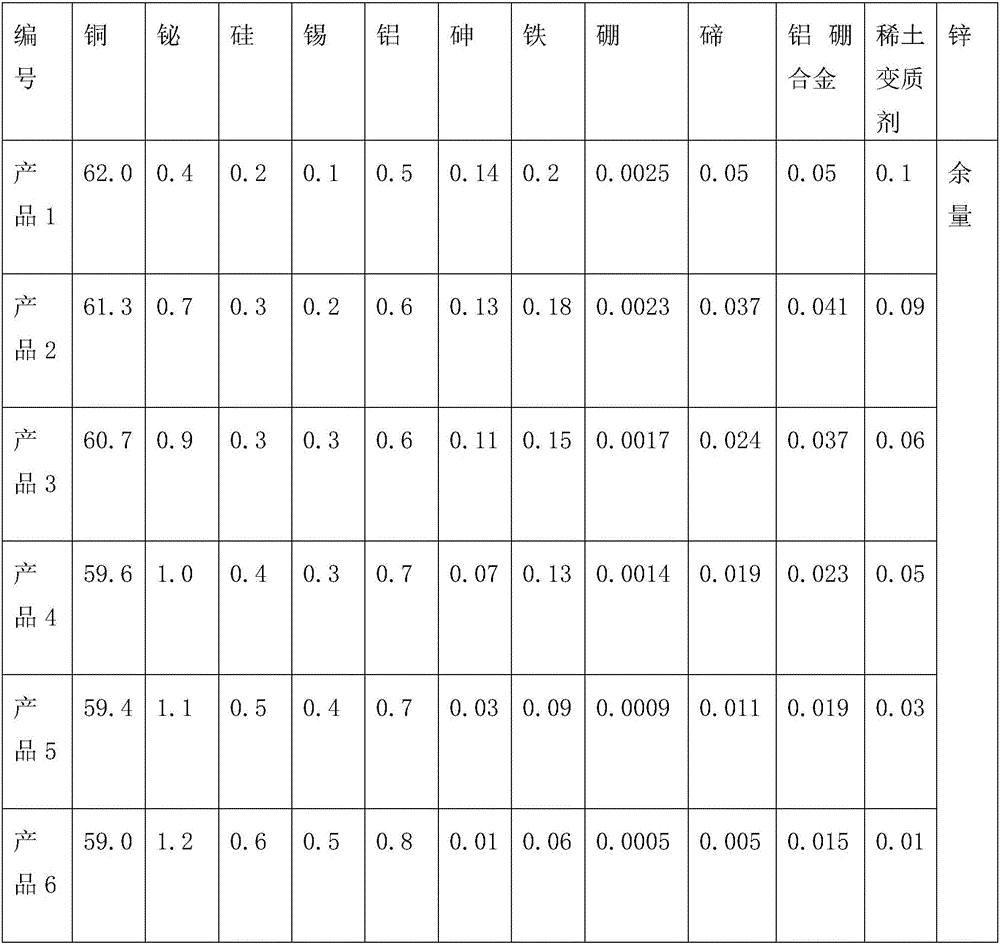

Free-cutting bismuth-silicon-tin brass remelting and polishing copper ingot and manufacturing method thereof

ActiveCN106756221AImprove mechanical propertiesChange the metallographic characteristicsRare earthMechanical property

The invention discloses a free-cutting bismuth-silicon-tin brass remelting and polishing copper ingot. The copper ingot comprises, by weight, 59.0-62.0% of copper, 0.4-1.2% of bismuth, 0.2-0.6% of silicon, 0.1-0.5% of tin, 0.5-0.8% of aluminum, 0.01-0.14% of arsenic, 0.06-0.2% of iron, 0.0005-0.0025% of boron, 0.005-0.05% of tellurium, no more than 0.10% of lead, no more than 0.20% of nickel, no more than 0.01% of cadmium, 0.025-0.15% of a modificator, and the balance zinc. The modificator is aluminum-boron alloy and a rare earth modificator. The metallographic structure characteristic of bismuth brass can be obviously changed, so that the mechanical property of the bismuth brass is effectively improved, and the problems that the mechanical property of the bismuth brass is low, and casting pieces are prone to cracking during casting forming and processing and use are effectively solved. The prepared free-cutting bismuth-silicon-tin brass remelting and polishing copper ingot is low in cost, environmentally friendly and healthy, and meets the lead-free upgrading and updating requirements of copper alloy materials of components, in contact with water, of water-heating bathroom facilities.

Owner:GUANGDONG WEIQIANG COPPER IND SCI & TECH CO LTD

Preparation method of molecular sieve for cyclohexane catalytic oxidation

InactiveCN108435232AEnsuring catalytic activityEnsuring catalytic selectivityMolecular sieve catalystsOrganic compound preparationMolecular sieveCatalytic oxidation

The invention relates to the technical field of chemical engineering, and in particular relates to a preparation method of a molecular sieve for cyclohexane catalytic oxidation. The preparation methodcomprises the following steps: (1) pretreating petroleum coke; (2) mixing a silicon source, a tin source, a structure guiding agent, a mineralizer and water according to a ratio, adding an alkaline substance, and conducting primary crystallization; (3) dispersing the silicon source into water, dropwise adding a precipitant to form amorphous sol, and carrying out secondary crystallization; (4) adding a binding agent, a binding assistant and water into the filter residue and the secondary crystallization product for kneading and forming, roasting the formed object, and then conducting crushingand sieving to obtain the molecular sieve. The composite molecular sieve is formed by the silicon-tin and petroleum coke carbonization, and the silicon in the silicon source is reduced by the carbon rich in the petroleum coke, and a pore structure is filled with silicon carbide with high hardness, meanwhile gas is released, and the pore structure is prevented from being reduced, so that the obtained molecular sieve has a relatively large specific surface area and the catalytic activity is improved.

Owner:ANHUI HAIDE PETROCHEM

Mesoporous silicon-tin composite electrode material and preparation method thereof, and application thereof

InactiveCN109585834AHigh reversible capacityImprove cycle stabilityCell electrodesSecondary cellsMesoporous silicaSilicon dioxide

The invention discloses a mesoporous silicon-tin composite electrode material and a preparation method thereof, and application thereof. The mesoporous silicon-tin composite electrode material has a pore structure of 5 to 40 nm, and the mass fraction of tin accounts for 5 to 20%. The preparation method comprises the steps of: preparing a mesoporous silicon by a magnesium thermal reaction of a mixture of magnesium powder and mesoporous silica; and preparing a mesoporous silicon-tin composite by employing a dipping hydrogen reduction method. The invention also provides the application of the mesoporous silicon-tin composite electrode material in the preparation of the lithium ion battery negative electrode. The mesoporous silicon-tin composite electrode material is high in reversible capacity, good in cycle stability and good in rate performance and can perform large-scale production.

Owner:包头市石墨烯材料研究院有限责任公司

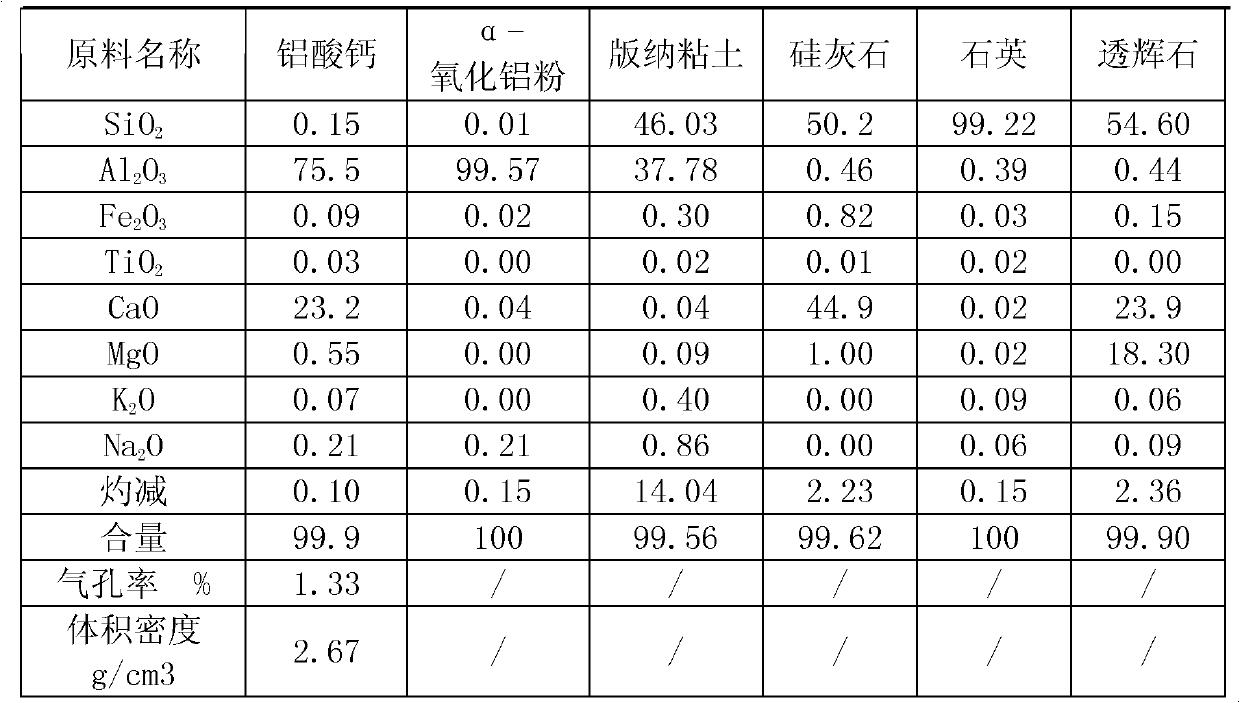

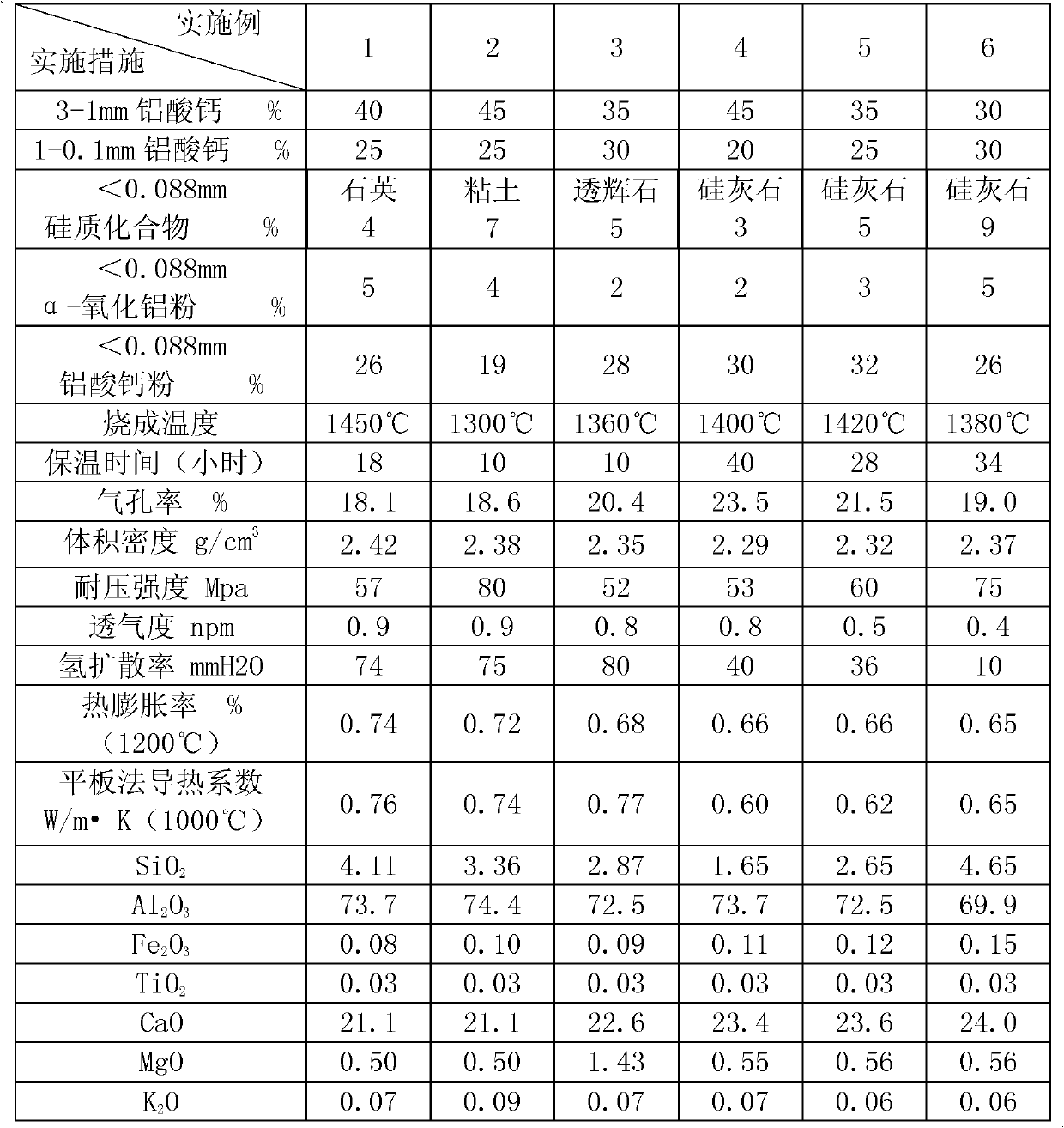

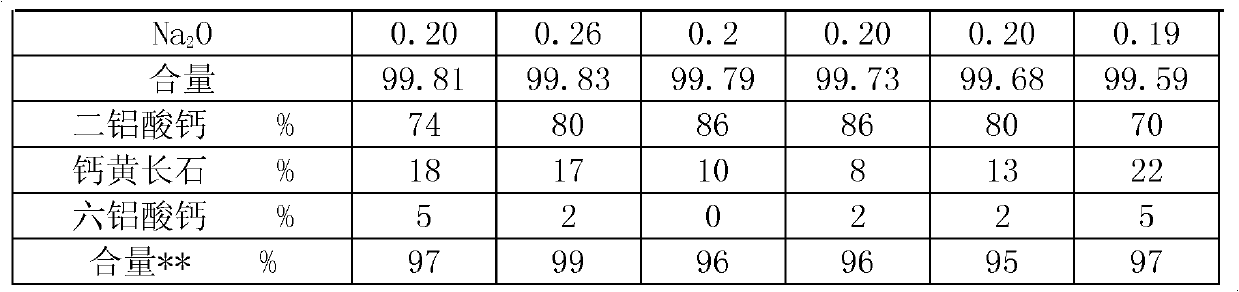

Preparation method for isostatic pressure calcium-aluminum-silicon tin bath bottom brick

Disclosed are a tin bath bottom brick and a method for preparing the same, the tin bath bottom brick consisting, in weight percent, of: Al2O3 66%-80%, CaO 17%-28%, SiO2 1.5%-5%, and the balance being common mineral impurities. The method comprises: formulating, isostatic pressing and firing at a high temperature, the weight percentages for the formulation being 30%-45% of calcium aluminate coarse particles with a particle size of 3-1 mm, 20%-35% of calcium aluminate medium particles with a particle size of 1-0.1 mm, and 25-40% of fine binding powder with a particle size less than 0.088 mm. The product has a good corrosion resistance to alkali metal oxides, a low thermal expansion, a low thermal conductivity and a low hydrogen diffusion rate.

Owner:ZIBO GT INDAL CERAMICS

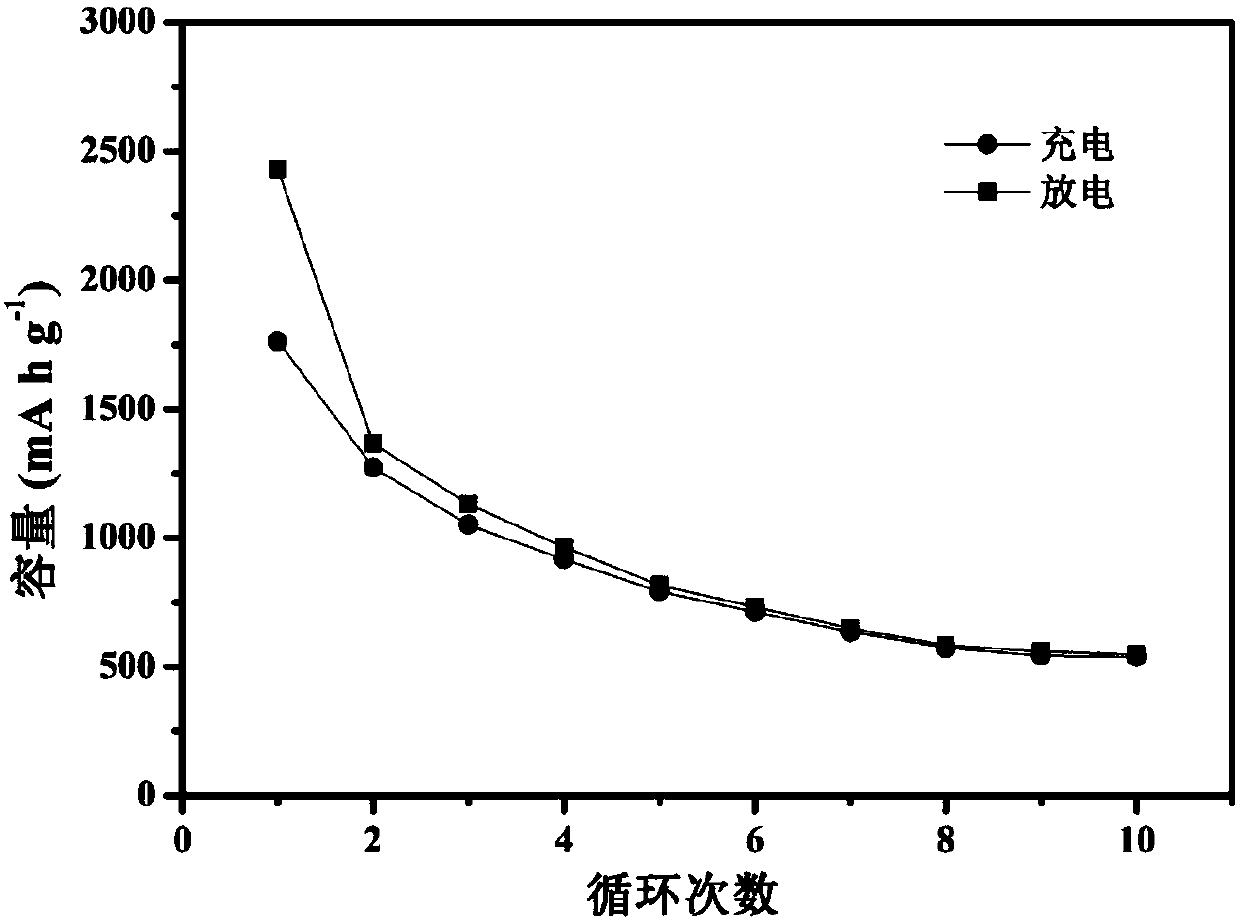

Lithium ion battery silicon-tin composite negative electrode material and preparation method thereof

InactiveCN107845804AImprove electrochemical performanceHigh specific capacityCell electrodesSecondary cellsChemical platingTin plating

The invention discloses a lithium ion battery silicon-tin composite negative electrode material and a preparation method thereof, wherein the lithium ion battery silicon-tin composite negative electrode material comprises a micro-scale silicon material and tin uniformly and chemically plated on the surface of the silicon material, the weight content of the element silicon is 20-75%, the weight content of the element tin is 25-80%, the micro-scale silicon material is placed in a chemical plating solution and is continuously stirred so as to uniformly disperse the micro-scale silicon material inthe chemical plating solution during the chemical plating, the chemical plating temperature is 50-80 DEGC, and the chemical plating time is 2-10 min. According to the present invention, the sensitization activation is not required during the chemical plating so as to reduce the cost and simplify the process; the silicon negative electrode material is modified through the chemical tin plating so as to improve the capacity and the electrochemical performance; and the prepared lithium ion battery silicon-tin composite negative electrode material has advantages of high specific capacity and stable cycle performance, and can remain above 500 mAh / g after 10 cycles.

Owner:TIANJIN UNIV

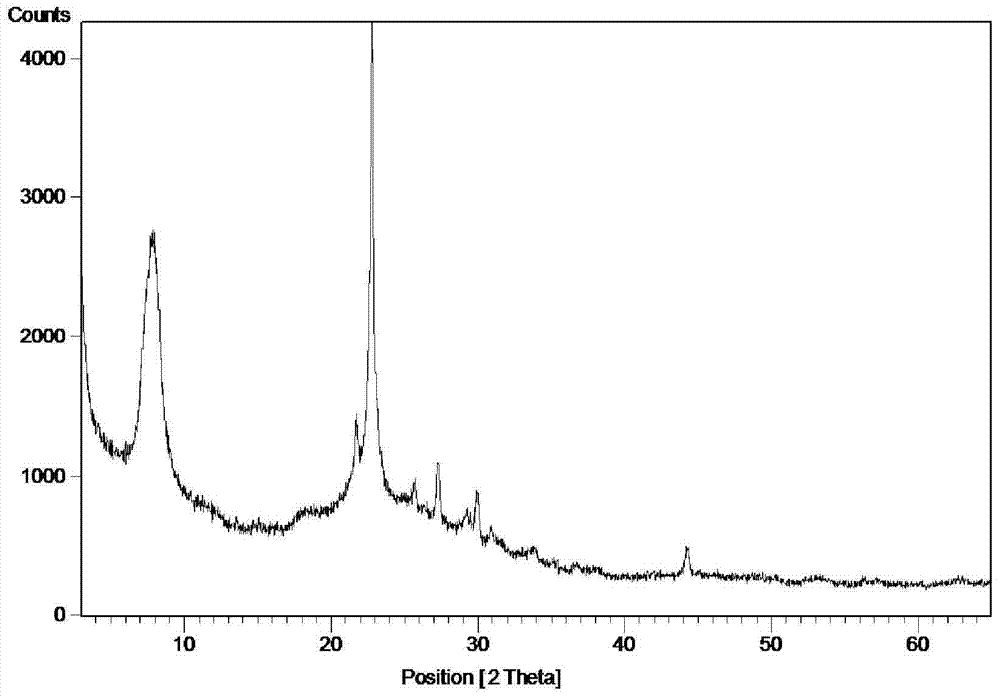

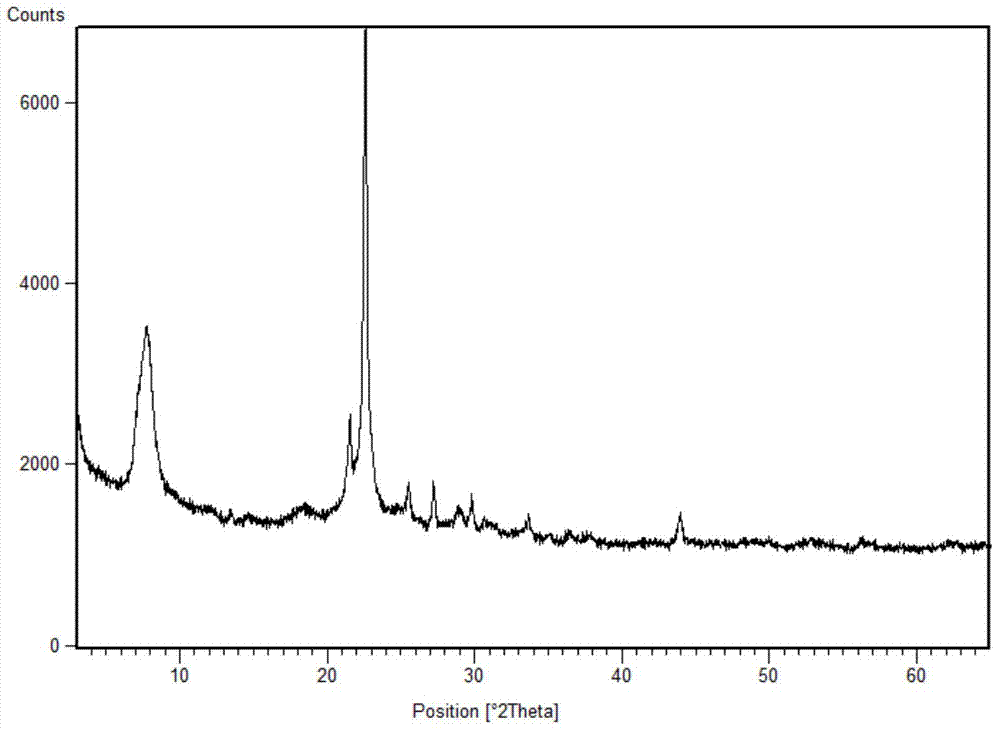

Tin-containing molecular sieve with MWW topological structure and preparation and application thereof

ActiveCN104709919AReduce stress riskWide liquid rangeCatalyst carriersMolecular sieve catalystsMolecular sieveSynthesis methods

The present invention discloses a tin-containing heteroatomic functional molecular sieve with a MWW topologic structure and a synthesis method thereof, the silicon-tin ratio (atomic ratio) of the Sn-MWW heteroatomic functional molecular sieve is in the range of 10 to 1000, and the synthesis method of the tin-containing MWW molecular sieve is an ionothermal secondary synthesis preparation method. A tin source, ionic liquid and a MWW molecular sieve rich in Si-OH groups are evenly mixed according to a certain proportion and feeding method for crystallization for a certain time at a certain temperature, the Sn-MWW heteroatomic functional molecular sieve can be obtained by separation, washing and drying, and a crystallization product can be directly used as a catalyst or catalyst carrier. The Sn-MWW heteroatomic functional molecular sieve has good catalytic performance in the catalytic conversion of biomass and a plurality of fine chemical reaction processes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Phase-separated silicon-tin composition as negative electrode material of lithium ion and battery and lithium-sulfur battery

InactiveCN104716308ANon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium–sulfur batteryAmorphous phase

A composite of silicon and tin is prepared as a negative electrode composition having an increased capacity to lithium intercalation and durability for use with a metal current collector in cells of a lithium ion battery or a lithium-sulfur battery. This negative electrode material is formed so that the silicon is present in an amorphous phase alone in a matrix phase of crystalline tin. While the tin phase provides electrical conductivity, both phases are involved in the uptake and extraction of lithium during use of the cell and the two phases act together in minimizing mechanical damage to the material when the cell undergoes repeated charging and discharging cycles. Generally, approximately equal atomic ratios of tin and silicon may be used in the formation of phase-separated composition electrode materials.

Owner:GM GLOBAL TECH OPERATIONS LLC

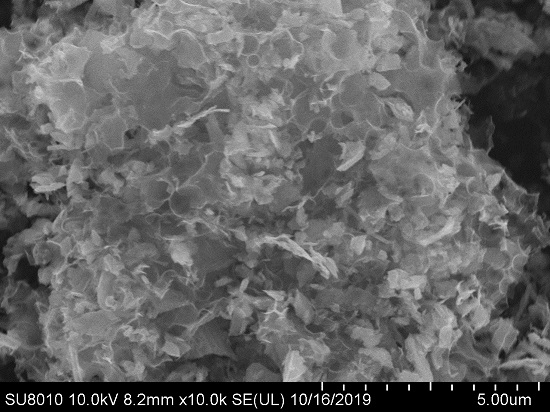

Preparation method of silicon-tin-carbon composite material

InactiveCN110233255ASimple preparation processWell mixedNegative electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a preparation method of a silicon-tin-carbon composite material. The method comprises the steps of: parts by weight, taking 3-5 parts of a silicon source, performing centrifugal cleaning of the silicon source with hydrofluoric acid, sulfuric acid, ethyl alcohol and ultrapure water, performing drying to obtain a product A; parts by weight, uniformly mixing a product A, 0.3-1parts of tin powder and 0.02-0.07 parts of a carbon source, and performing tabletting to obtain a product B; performing calcining of the product B in an atmosphere furnace, taking out the product B for cooling, and grinding the product B to powder to obtain a product C; dissolving 5-8 parts of the carbon source into pure water to obtain a product D; pouring the product C into the product D for uniform stirring to obtain a product E; putting the product E into a hydrothermal reaction kettle for reaction to obtain a product F; and uniformly mixing the product F, and performing tabletting to obtain a product G; and performing calcining of the product G in the atmosphere furnace, taking out the product G for cooling, and grinding the product G into powder to obtain a finished product. The preparation method of a silicon-tin-carbon composite material is simple in process, good in contact of tin powder and silicon powder and uniform in the carbon coating at the outer surface of the silicon-tin alloy, the tin layer is uniformly distributed between the silicon and the carbon, and the product is good in performance; and moreover, the production cost is low.

Owner:GUIZHOU UNIV

Simple preparation method of silicon-tin-graphite alloy

InactiveCN108807869AHigh initial charge and discharge capacityImprove first-time efficiencyCell electrodesSecondary cellsTube furnaceAlloy

The invention discloses a simple preparation method of a silicon-tin-graphite alloy. The preparation method comprises the following steps: (1) uniformly mixing silicon powder and tin powder: adding 4to 8g of silicon powder and 3 to 5g of tin powder to a ball mill to be dispersed, introducing argon for protection, performing ball-milling for 15 to 25H, controlling the grinding rate to be 300 to 500rpm; then adding 1 to 3g of PVA and 0.3 to 0.7g of graphite to a ball-milling tank of the ball mill, carrying out ball milling for 8 to 12H in air, and controlling the grinding rate to be 300 to 500rpm; keeping the weight ratio of a grinding ball to a mixture at 10: 1; (2) performing a material annealing process: putting the mixture in a tube furnace to be calcined, calcining for 120 to 180min inargon atmosphere at the temperature of 600 to 800 DEG C and controlling the heating rate to be 2 to 4 DEG C / min, then cooling with the furnace. By adopting the method disclosed by the invention, thesilicon powder and the tin powder are firstly mixed uniformly, and then the annealing process is performed to obtain a highly stable silicon-tin-graphite alloy, the process is simple, and the first charge and discharge capacity is high, and the first-time efficiency is also high, and use demands are met, therefore, the simple preparation method of the silicon-tin-graphite alloy is worthy of beingpopularized and used.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

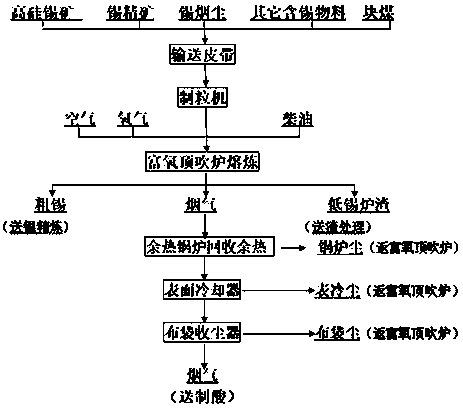

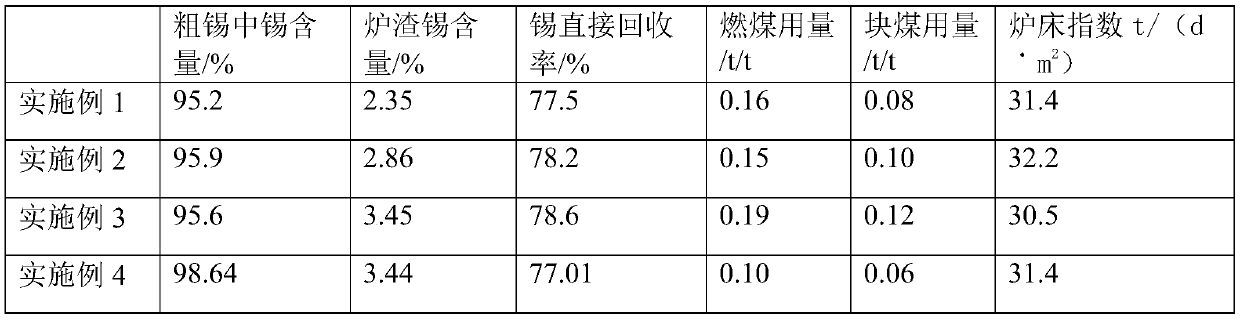

Method for treating high-silicon tin ore by use of oxygen-rich top blowing furnace

ActiveCN111088437ASolve the technical problem that the melting point is too high to be industrializedFilling the gap in direct tin smelting technologySlagCassiterite

The invention relates to a method for treating high-silicon tin ore by use of an oxygen-rich top blowing furnace and belongs to the technical field of smelting of high-silicon tin ore. The method comprises six steps: raw material mixing, granulation, low-temperature smelting, high-temperature smelting, three-time crude tin discharging for three times and one-time slag discharging. Industrial production of the high-silicon tin ore in the top blowing furnace is realized through material mixing, process selection, process condition control and the like; the silicon content of the tin smelting oreis increased to 1%-10%, the direct recovery rate of tin reaches 77% or above, the furnace hearth index reaches 30 t / (dm<2>) or above, and the technology bottleneck of difficulty in industrializationof the high-silicon tin ore is effectively solved.

Owner:YUNNAN TIN

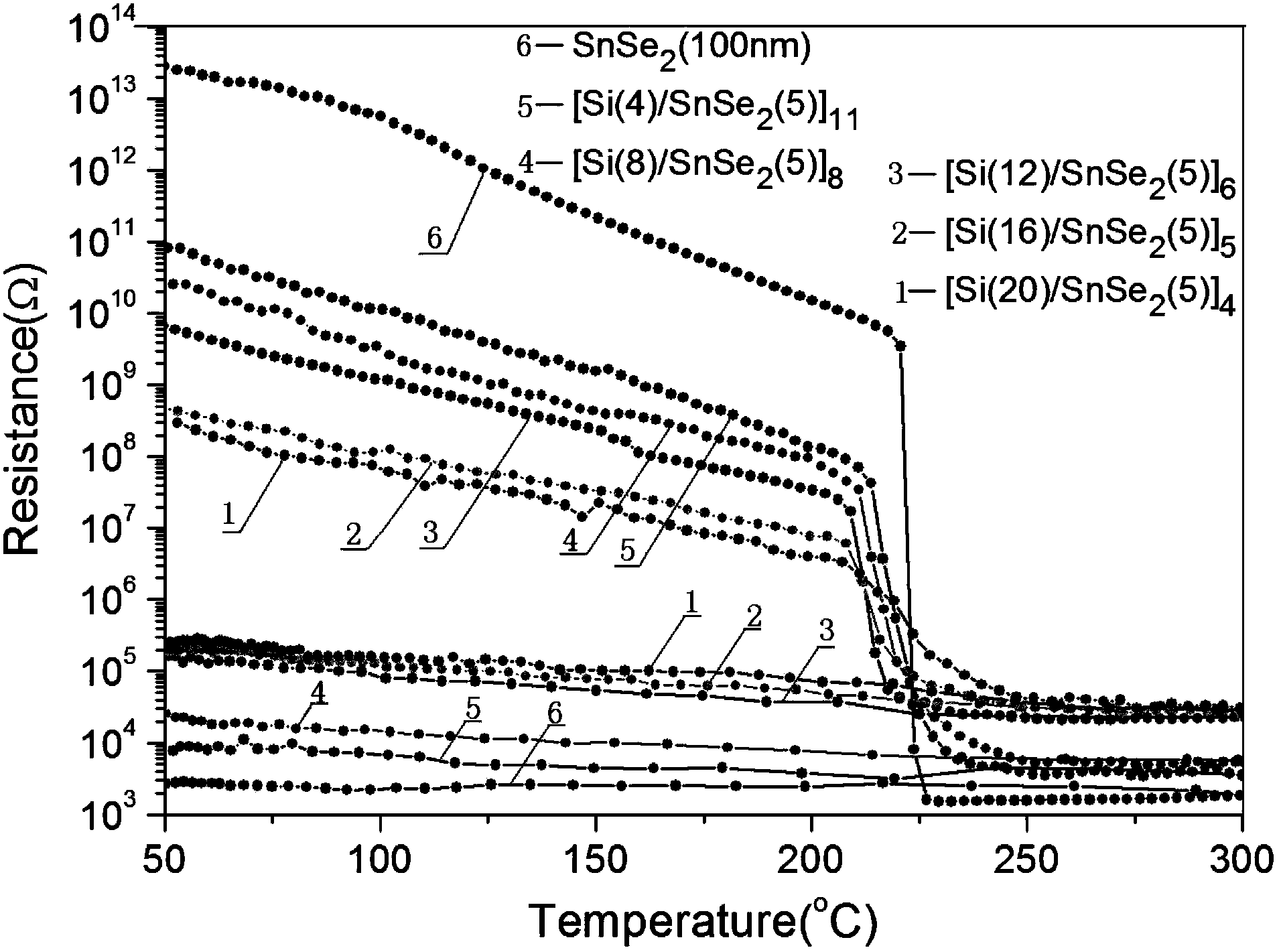

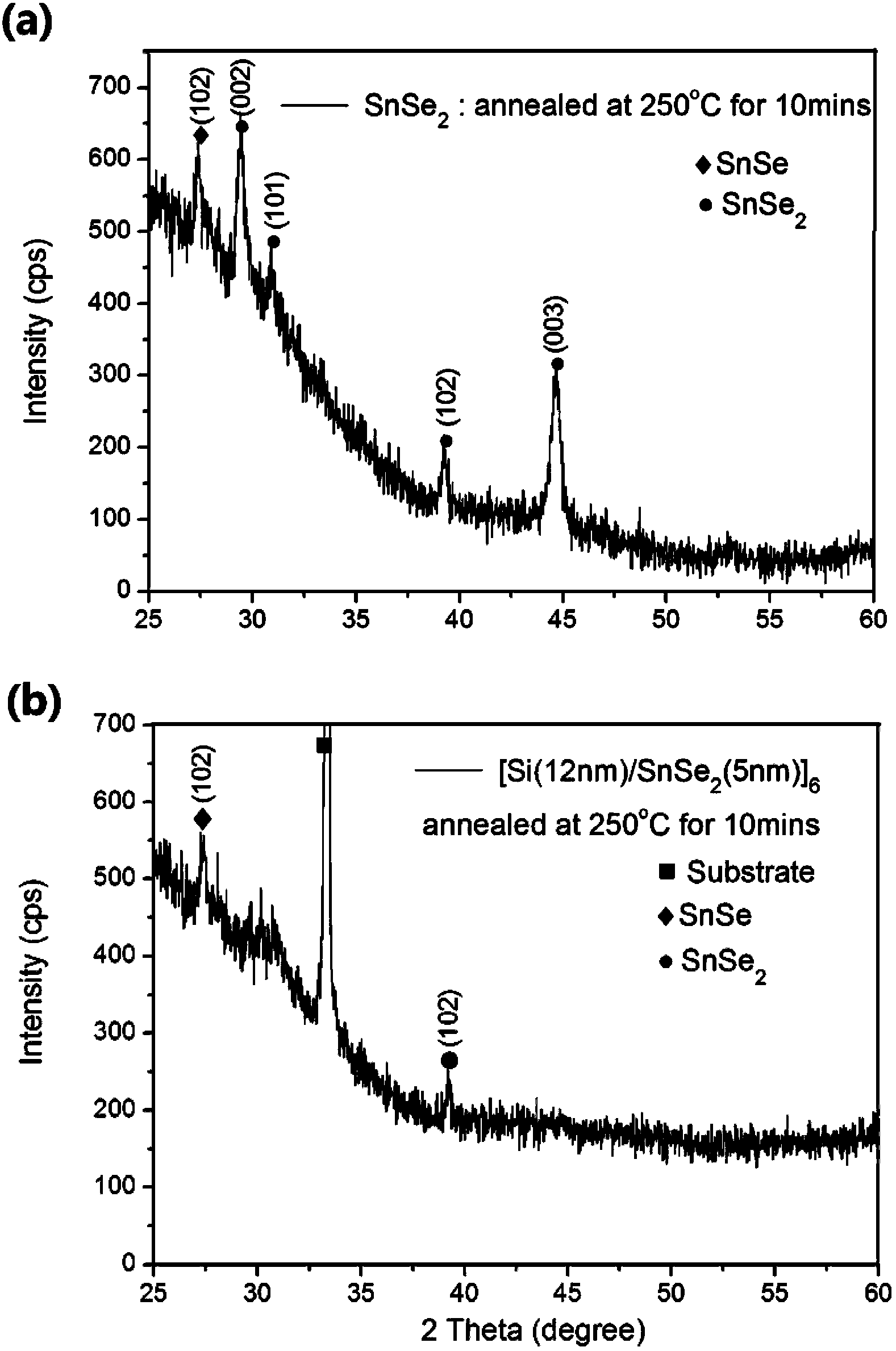

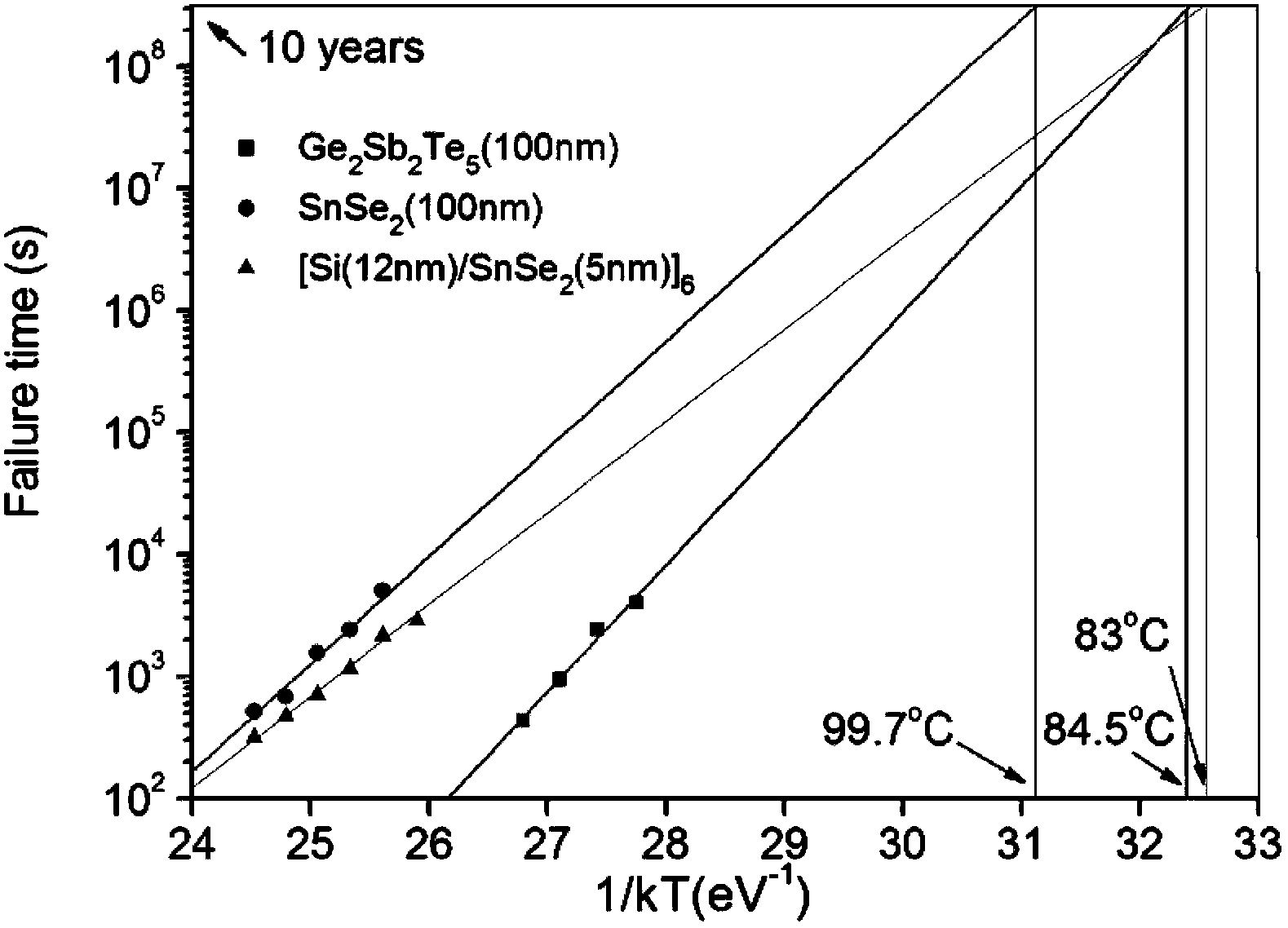

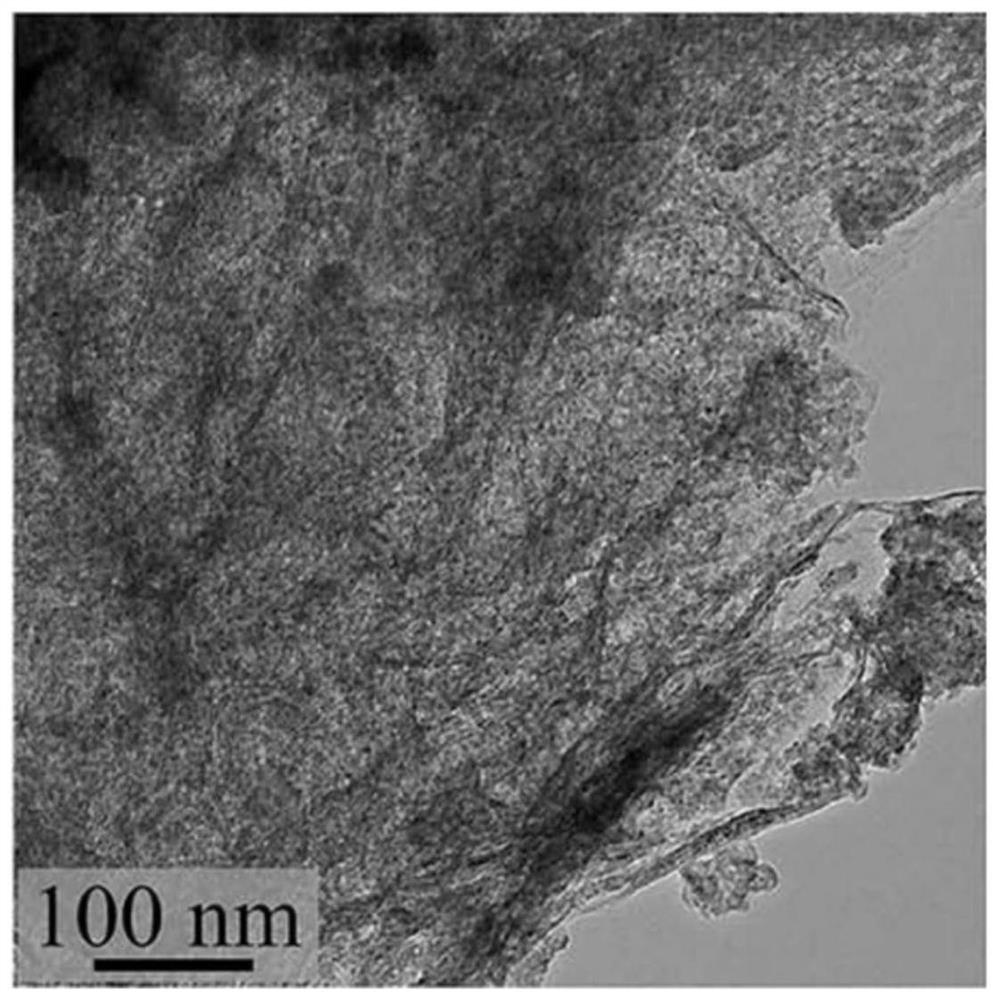

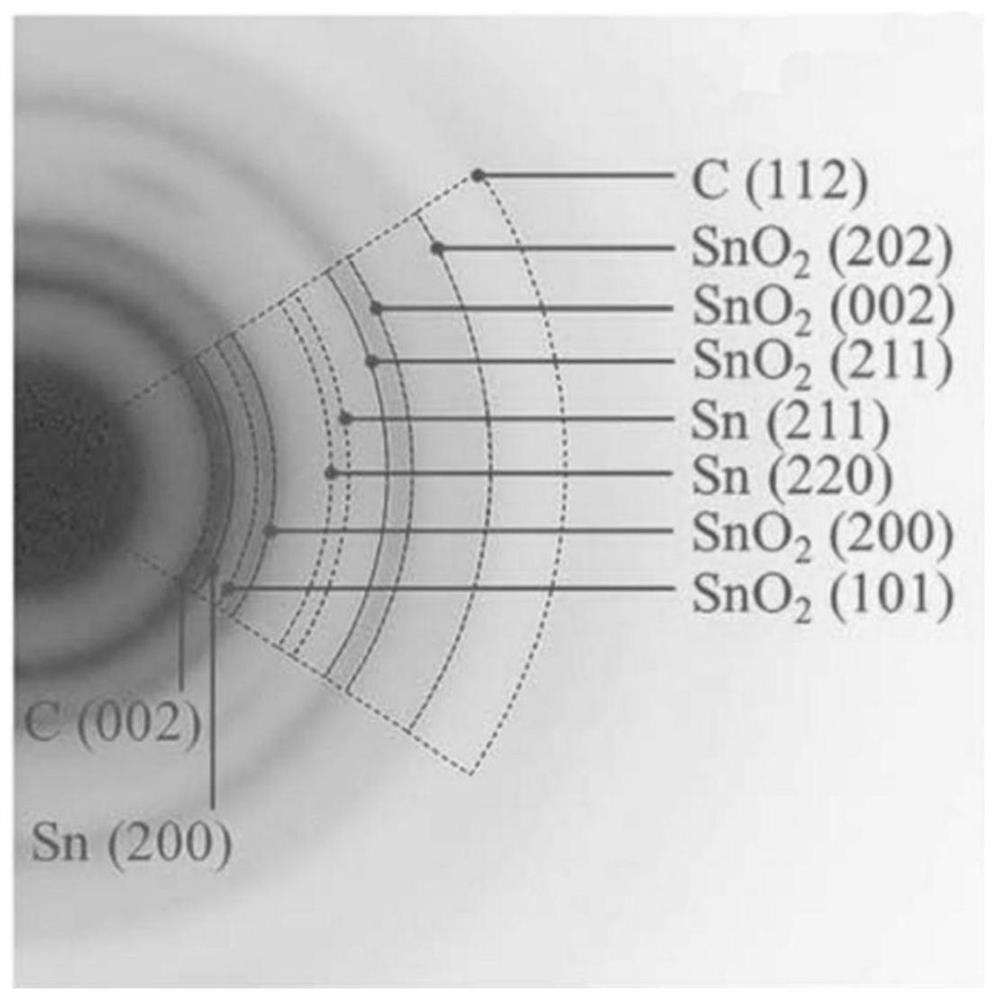

Silicon-tin selenide nano multilayer composite phase change thin film material for phase change memory

InactiveCN102683587BImprove data retentionHigh crystalline resistanceElectrical apparatusPhase-change memoryTotal thickness

The invention relates to a Si / SnSe2 selenide nano multilayer composite phase change thin film material for a phase change memory with low operation current. A multilayer film structure is formed by alternatively arraying a single-layer Si thin film and a single-layer SnSe2 thin film in the Si / SnSe2 selenide nano multilayer composite phase change thin film material; the thickness of the single-layer Si thin film is 3-40 nm and the thickness of the single-layer SnSe2 thin film is 4-10 nm; and the total thickness of the Si / SnSe2 selenide nano multilayer composite phase change thin film material is 75-210 nm. The phase change memory based on the Si / SnSe2 selenide nano multilayer composite phase change thin film material disclosed by the invention has the advantage of extremely low operation current; and meanwhile, the keeping capability of data is stronger and the Si / SnSe2 selenide nano multilayer composite phase change thin film material can be used for the phase change memory with low operation current.

Owner:TONGJI UNIV

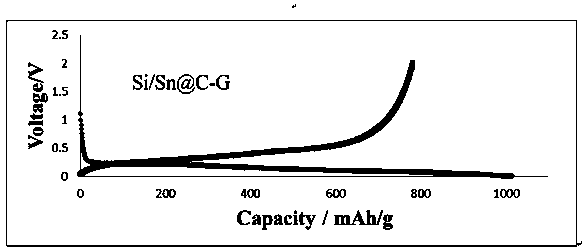

Preparation method and application of graphene-based composite electrode material

InactiveCN113540430AImprove Capacitive PerformanceGood dispersionNegative electrodesSecondary cellsDoped grapheneComposite electrode

The invention discloses a preparation method and application of a graphene-based composite electrode material. The preparation method comprises the following steps: firstly, adding SiO2 into graphene, and carrying out ultrasonic dispersion to obtain a SiO2 / graphene-based composite material; then adding the mixture into an organic solvent containing divalent tin salt for ultrasonic dispersion, and finally adding a reducing agent for ultrasonic dispersion, wherein on one hand, the reducing agent can reduce the graphene oxide and can also react with the divalent tin salt and the organic solvent to generate a Sn simple substance, the silicon / tin doped graphene-based composite material is obtained, the doped substances have very high theoretical specific capacity, and the capacity performance of the composite material can be remarkably improved. The doped substance is uniformly dispersed on the graphene with a large specific surface area through ultrasound, the material is helped to form a stable and uniform SEI film in the battery cycle process, so that the cycle stability is improved; meanwhile, the graphene can effectively inhibit the volume expansion effect of the metal substance.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

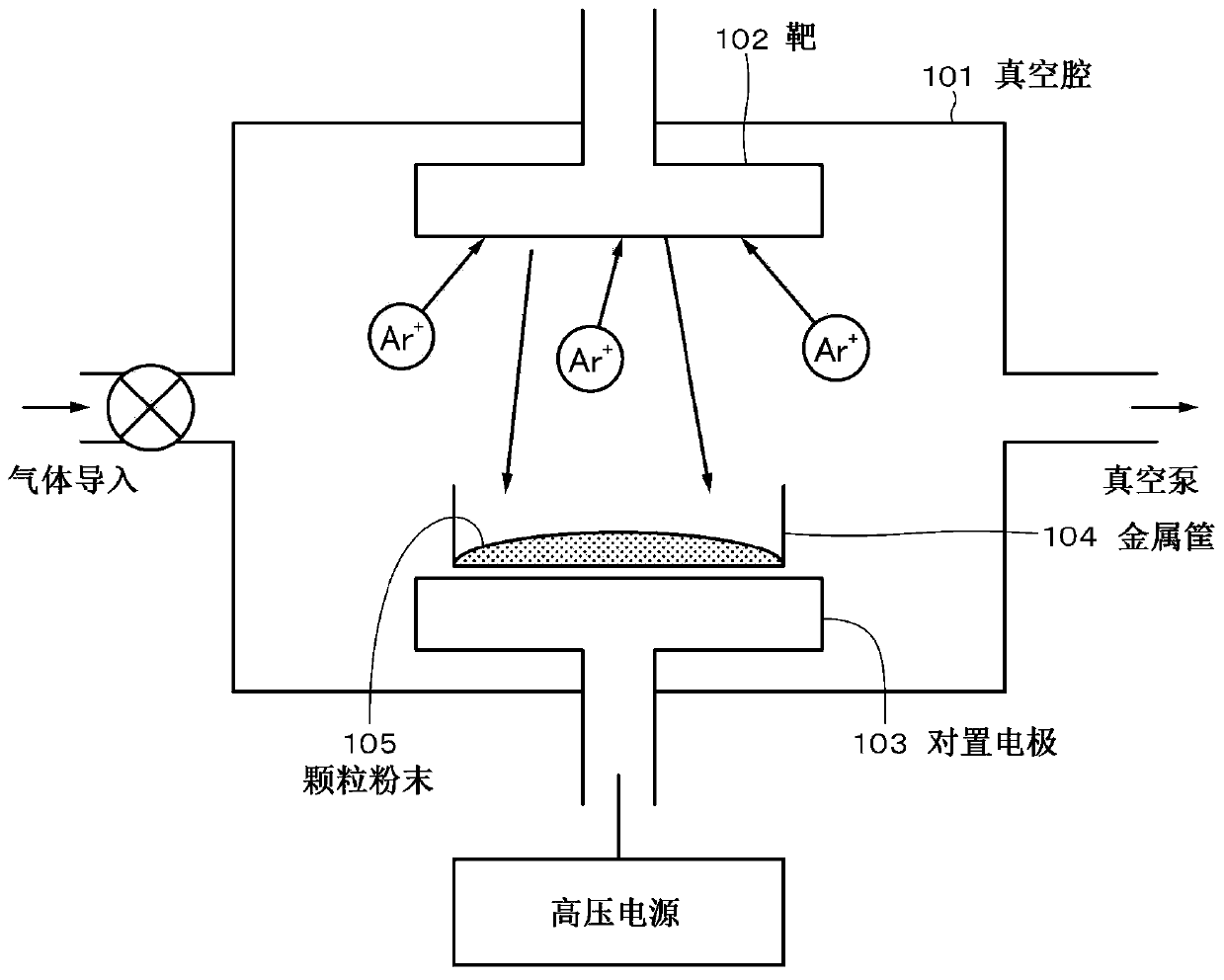

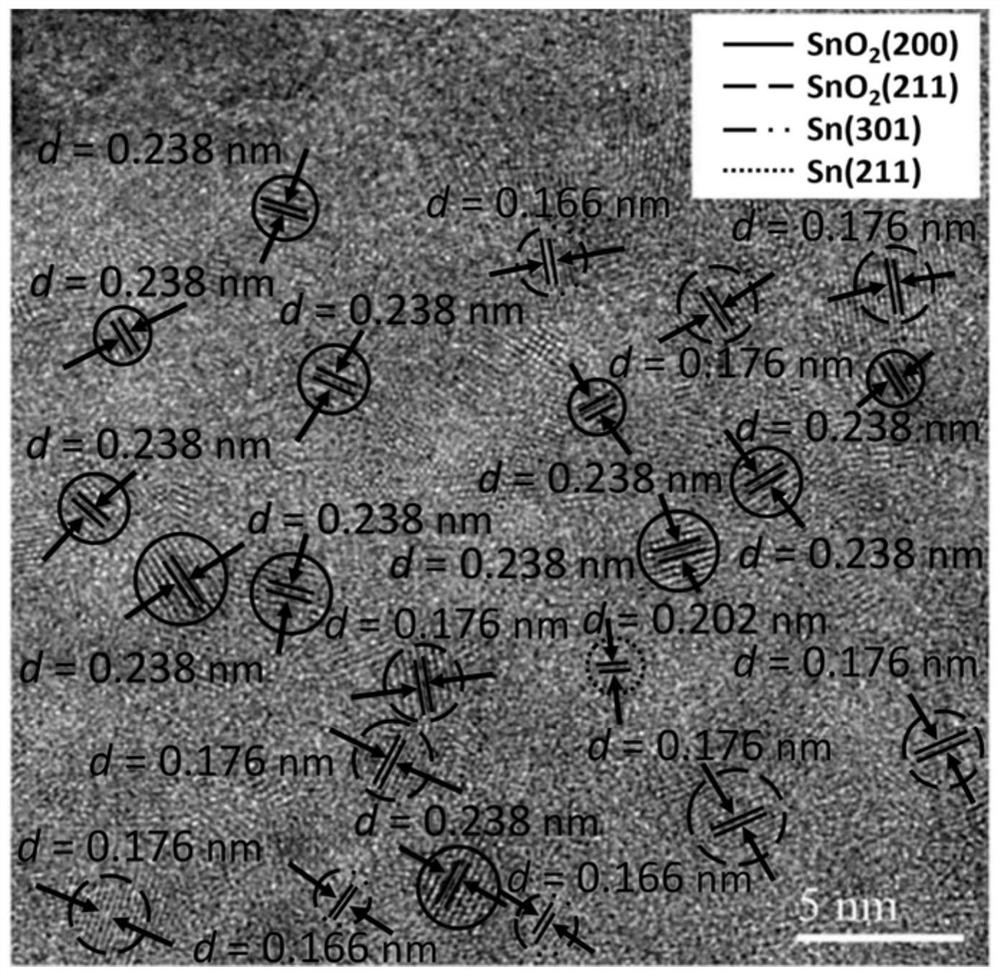

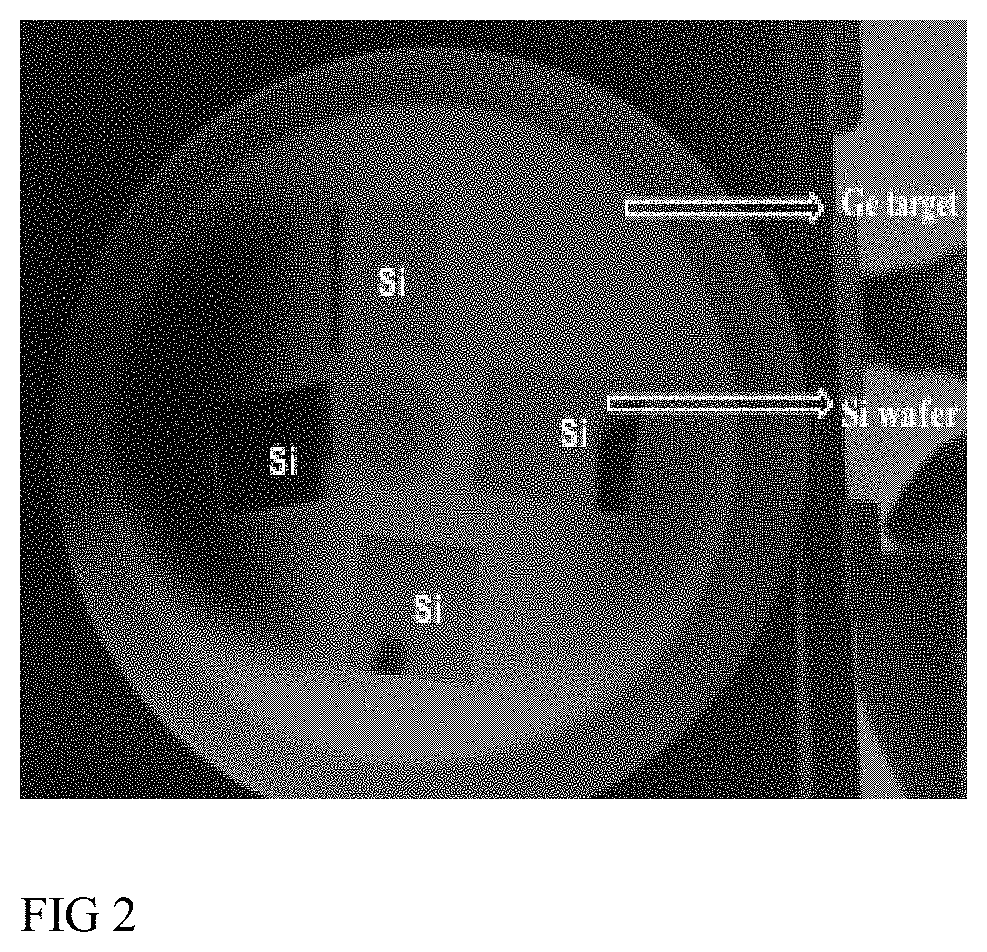

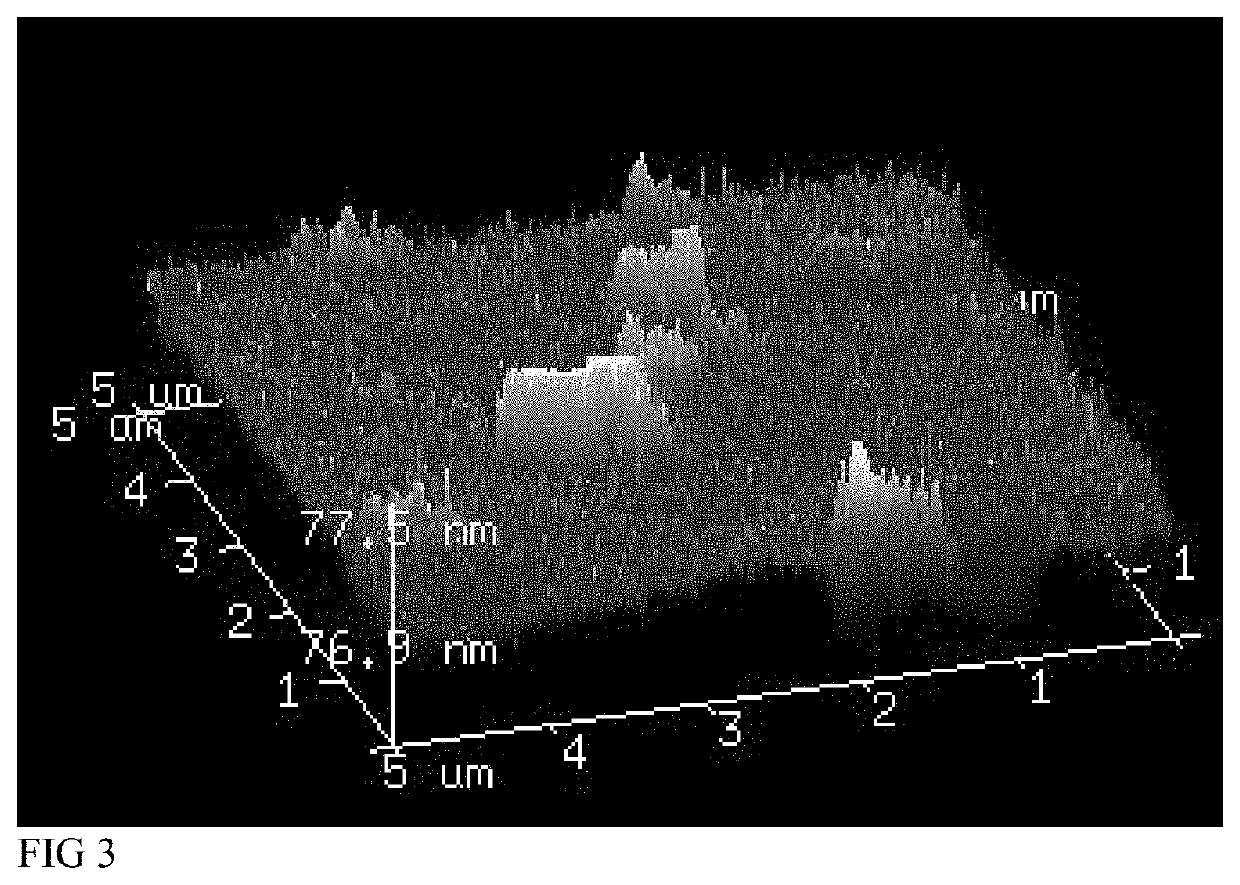

Germanium Silicon Tin Oxide Thin Films for Uncooled Infrared Detection

ActiveUS20190391019A1High TCR valueReduce noise valuePyrometry using electric radation detectorsSemiconductor devicesRefractive indexSilicon oxide

Microbolometer is a class of infrared detector whose resistance changes when the temperature changes. In this work, we deposited and characterized Germanium Silicon Oxide thin films mixed with Sn (Ge—Si—Sn—O) for uncooled infrared detection. Ge—Si—Sn—O were deposited by co-sputtering of Sn and Ge—Si targets in the Ar+O environment using a radio frequency sputtering system. Optical characterization shows that the absorption in Ge—Si—Sn—O was most sensitive in the wavelength ranges between 2.5-3.7 μm. The transmission data was further used to determine the optical energy band gap (0.22 eV) of the thin-film using Tauc's equation. We also found the variations of absorption coefficient (6592305.87 m−1-11615736.95 m−1), refractive index (2.5-4.0), and the extinction coefficient (2.31-5.73) for the wavelength ranges between 2.5-5.5 μm. The thin film's resistivity measured by the four point probe was found to be 142.55 Ω-cm and TCR was in the range of −4.9-−3.1 (% / k) in the temperature range 289-325 k.

Owner:RANA MUKTI +2

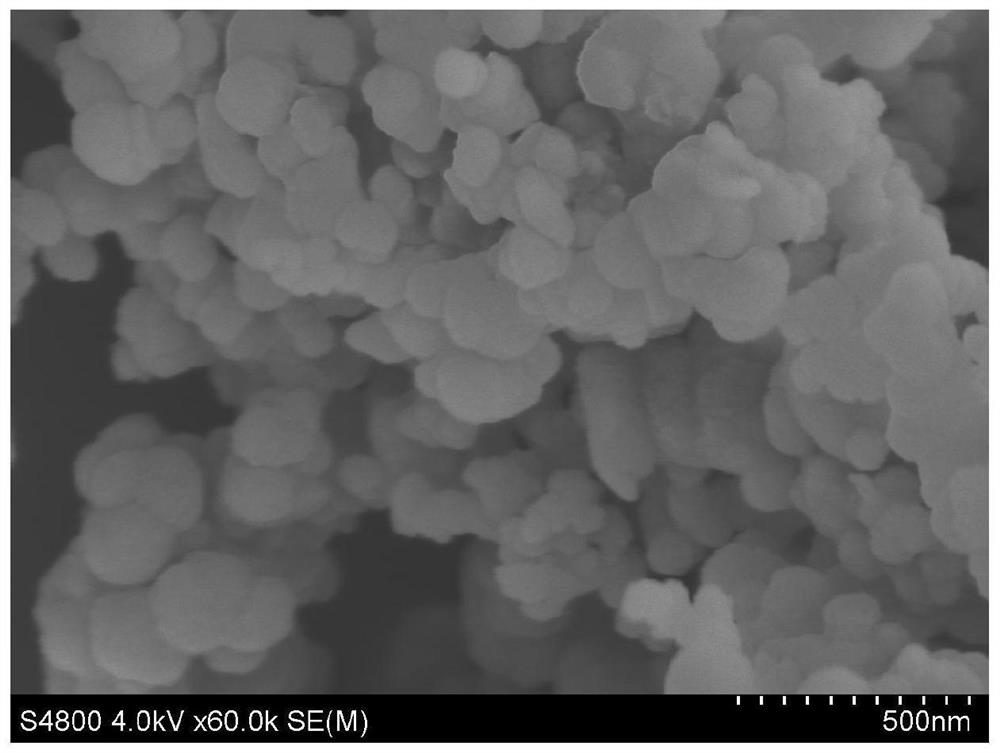

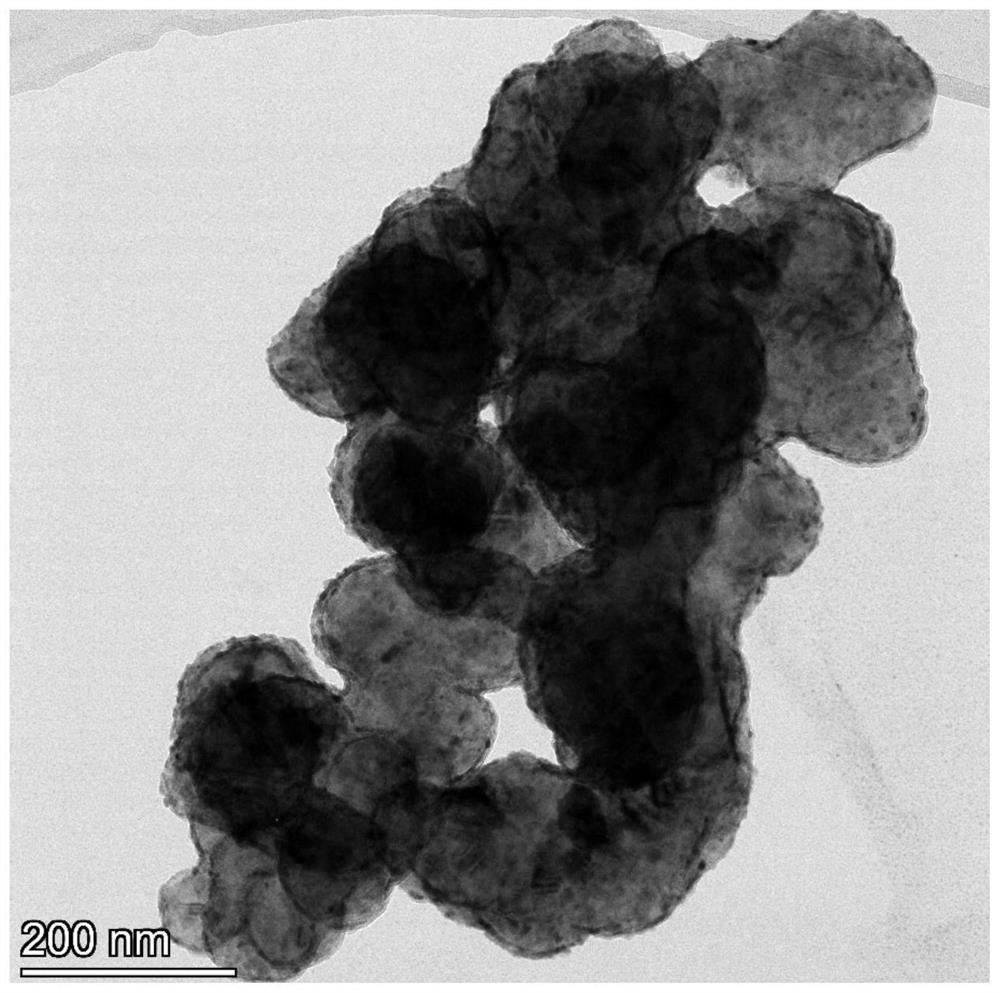

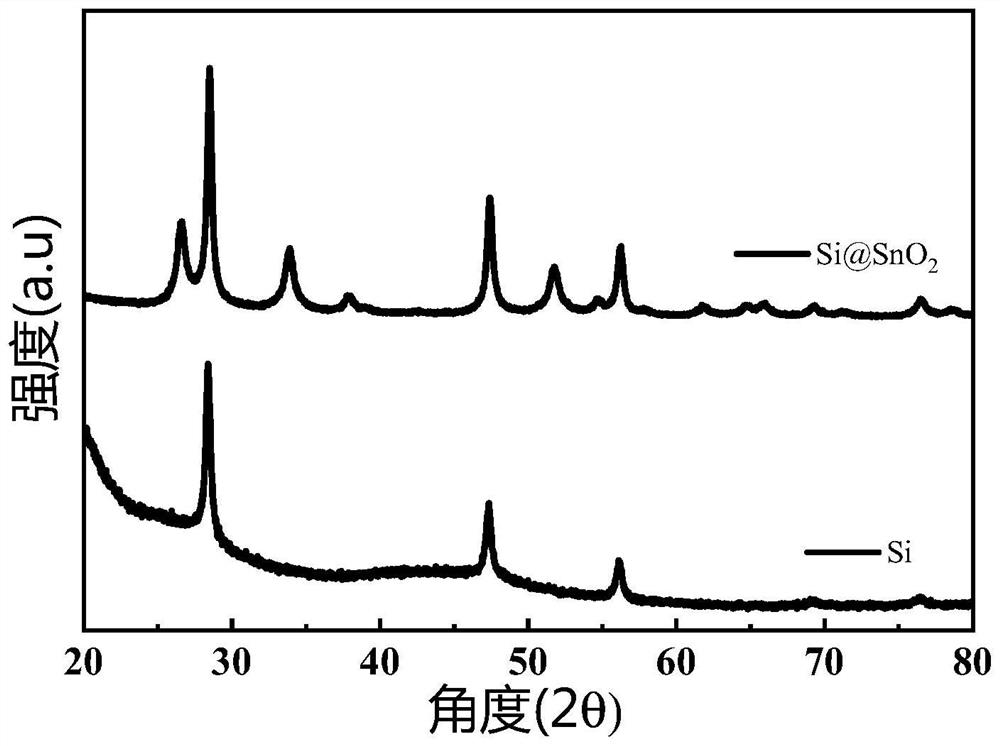

Silicon-tin nano material as well as preparation method and application thereof

InactiveCN114843479AEfficient manufacturingGood repeatabilityMaterial nanotechnologyCell electrodesConductive materialsSilicon particle

The invention provides a silicon-tin nano material as well as a preparation method and application thereof. Comprising silicon particles and tin dioxide particles loaded on the surfaces of the silicon particles, the silicon particles comprise nano silicon and / or micron silicon; and the particle size of the silicon-tin nano material is 1-2 microns. The silicon serves as an inner core, the stannic oxide serves as a coating layer, the stannic oxide is a good conductive material, the specific capacity of the stannic oxide is as high as 782mAh / g, the lithium insertion potential is low, and lithium dendrites are not easy to form when the stannic oxide participates in an electrode reaction. In the cycle process of a battery, tin dioxide on the surface reacts with lithium in a system to become LixSn, and a formed lithium tin interface can better maintain the structural stability, reduce side reactions and reduce the thickness of an SEI film, so that the cycle performance of the composite material is effectively improved. And batch production can be realized, and industrial application is facilitated. Compared with pure silicon, the lithium ion battery prepared from the negative electrode material obtained by the method has excellent electrochemical properties such as high first efficiency, high specific capacity, good cycle performance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Silicon-tin dioxide chain-shaped and dendritic core-shell structure lithium ion battery negative electrode material and preparation method thereof

ActiveCN112599755ALower requirementImprove electrochemical performanceMaterial nanotechnologyCell electrodesNano siliconBattery cell

The invention belongs to the technical field of lithium ion battery negative electrode materials, and particularly relates to a silicon-tin dioxide chain-shaped and dendritic core-shell structure lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: ultrasonically dispersing nano silicon powder in an ethanol aqueoussolution, adding a certain amount of tin tetrachloride pentahydrate for reaction compounding, standing, carrying out suction filtration, washing and drying to obtain the silicon tin dioxide chain-likeand dendritic core-shell structured negative electrode material. Finally, the material is prepared into a negative pole piece, the negative pole piece is placed in a button cell, and the constant-current charge-discharge specific capacity of the button cell is detected. When the material is tested by using a Land test system at normal temperature and normal pressure, the initial coulombic efficiency of a sample with the most excellent performance of the material can reach 83.0%, and the specific capacity can still reach 1900mAh / g or above after 200 circles of charging and discharging. The material has the characteristics of rich raw materials, simplicity in operation, low cost and environmental friendliness, and the prepared silicon tin dioxide composite material has excellent performance.

Owner:FUZHOU UNIV

Silicon-tin-graphene compound electrode material as well as preparation method and application thereof

ActiveCN110931746AImprove conductivityImprove ductilityCell electrodesSecondary cellsGraphene flakeGraphite

The invention discloses a silicon-tin-graphene compound electrode material which comprises silicon particles, tin particles and a graphene sheet layer. The silicon particles and the tin particles areloaded on the graphene sheet layer at the same time, the particle size of the silicon particles is 20-60 nm, the particle size of the tin particles is 50-100 nm, and tin accounts for 5%-50% of the mass fraction of silicon-tin. The invention also discloses a preparation method of the compound electrode material and an application of the compound electrode material in a lithium ion battery negativeelectrode. The silicon-tin particles are modified on the surface of a redox graphene sheet layer, and the tin particles are next to the silicon particles, so that the effective support is provided forthe shrinkage and expansion of the silicon particles in the lithium intercalation and deintercalation process, the pulverization of the silicon particles is inhibited, and the cycling stability of the silicon-based electrode is improved. Even if the silicon particles are broken, the tin particles can provide the electric contact for silicon on the surface of the silicon, so that the conductivityis improved. The silicon-tin-graphene compound electrode material provided by the invention is high in energy density, high in reversible capacity, good in cycling stability and excellent in conductivity.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com