Phase-separated silicon-tin composition as negative electrode material of lithium ion and battery and lithium-sulfur battery

A technology of negative electrode materials and composites, applied in the field of preparation of negative electrode materials, can solve problems such as shortening the effective cycle capacity of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

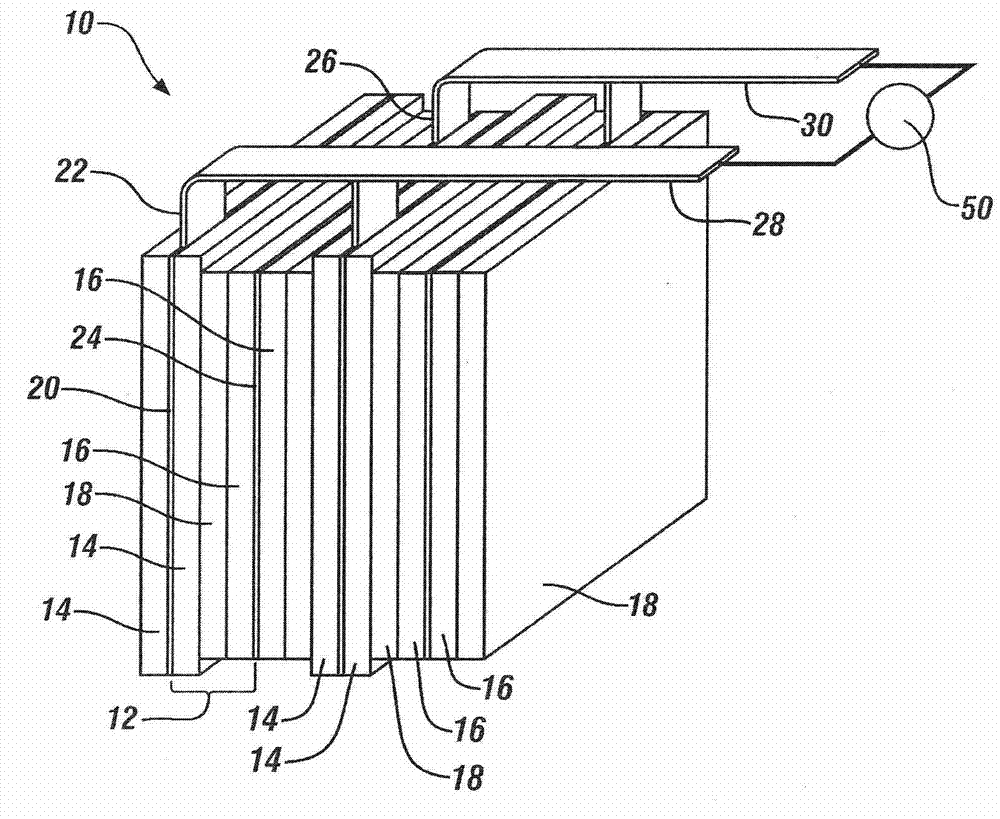

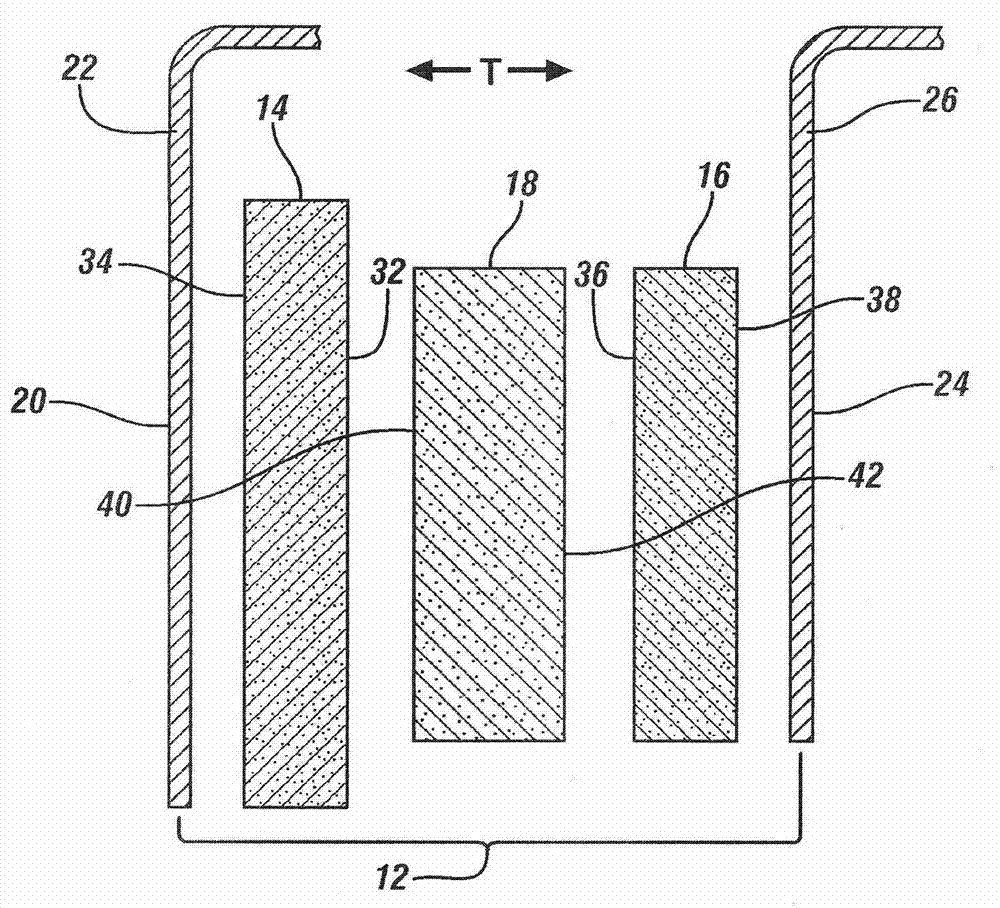

[0030] An exemplary and general description of lithium-ion battery 10 is described at figure 1 middle. The lithium-ion battery 10 shown here includes a plurality of thin rectangular electrochemical cells 12, each sandwiched by a metal current collector. The electrochemical cells 12 are stacked side by side in a modular configuration and, in this example, connected in parallel. Li-ion battery 10 may be formed from a plurality of similar electrochemical cells electrically connected in series or parallel to form a Li-ion battery exhibiting the desired voltage and current capabilities for a particular application. It should be understood that the lithium-ion battery 10 shown here is a schematic representation only. figure 1 The relative positions and physical interactions of the various components (i.e., electrodes and separators) that build up the electrochemical cell 12 are shown; the relative dimensions of the various components of the electrochemical cell are not meant to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com