Porous polymer electrolyte supporting membrane material, preparation method thereof and application thereof

A porous polymer and electrolyte technology, applied in circuits, secondary batteries, electrical components, etc., can solve the problems of restricting the commercialization process of lithium-sulfur batteries, low utilization rate of positive active materials, low battery safety, etc. Solubility, operation and environmental requirements are not harsh, and the effect of wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 10% by mass percentage of polyacrylonitrile (PAN) / polymethyl methacrylate (PMMA) (the mass ratio of the two is 8:2,) powder dissolved in 90% by mass of N-N dimethylformamide ( DMF), vigorously stirred at 60 °C for 24 h to obtain a homogeneous polymer solution. Under the action of a 15kV high-voltage DC power supply, the polymer solution is sprayed out in the form of a jet at the end of the capillary of the syringe. The distance between the end of the capillary and the collector is 15cm. Reticular fibers; the electrospun reticular fibers obtained above were vacuum-dried at 80° C. to obtain a porous polymer electrolyte support membrane material: the average fiber diameter was 200 nm, and the porosity was 80%.

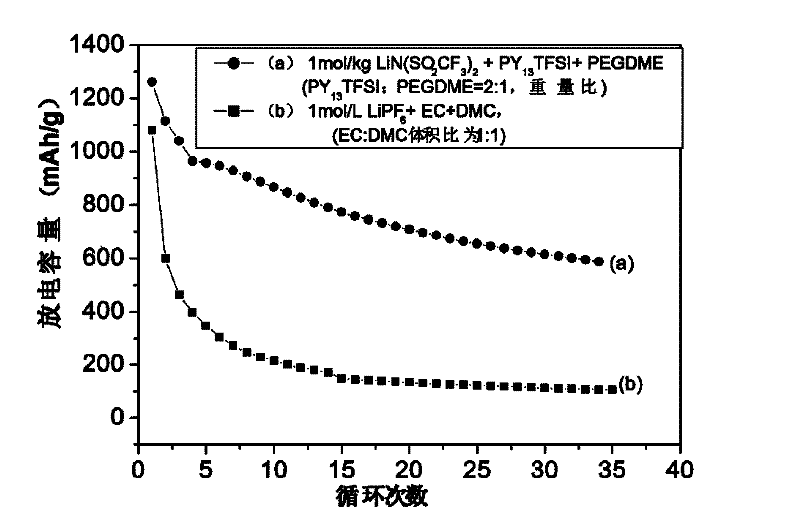

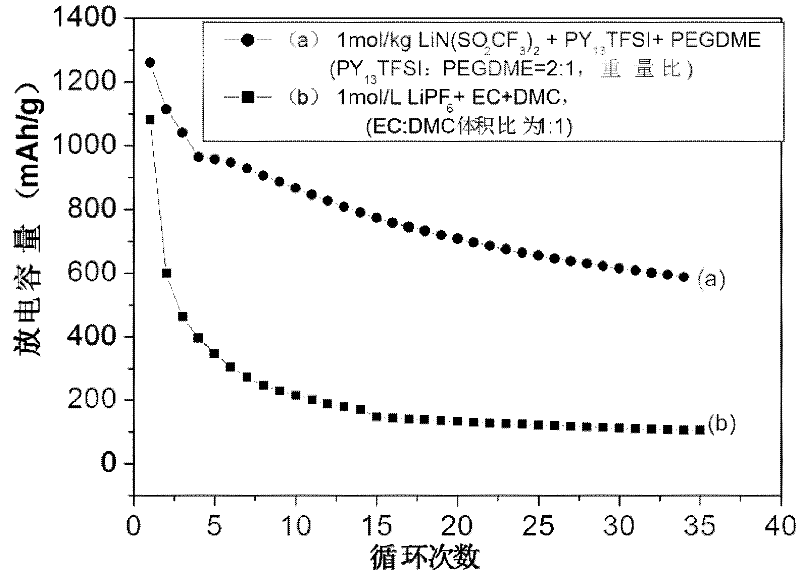

[0036] 2.87g LiN(SO 2 CF 3 ) 2 , 6.66g PY 13 TFSI and 3.34g PEGDME prepared 1mol / kg LiN(SO 2 CF 3 ) 2 +PY 13 TFSI+PEGDME (PY 13 TFSI:PEGDME=2:1, weight ratio) electrolyte. In a glove box filled with argon, the porous polymer electrolyte support membrane m...

Embodiment 2

[0041] Dissolve 8 mass percent polyacrylonitrile (PAN) / polyvinyl acetate (PVAc) (6:4, mass ratio) powder in 92 mass percent tetrahydrofuran (THF), and stir vigorously at 60°C 24h to obtain a homogeneous polymer solution. The solution is under the action of a 10kV high-voltage direct current power supply, and the polymer solution is sprayed out in the form of a jet at the end of the capillary of the syringe. The distance between the end of the capillary and the collector is 10 cm. Vacuum drying at ℃ to obtain a porous polymer electrolyte supporting membrane material: the average fiber diameter is 400nm, and the porosity is 70%.

[0042] 0.3g LiPF 6 , 9g PP 13 0.2mol / kg LiPF prepared by TFSI and 1g TEGDME 6 +PP 13 TFSI+TEGDME (PP 13 TFSI:TEGDME=9:1, weight ratio) electrolyte. In a glove box full of argon, the porous polymer electrolyte support membrane material obtained above was immersed in 0.2mol / kg LiPF 6 +PP 13 TFSI+TEGDME (PP 13 TFSI:TEGDME=9:1, weight ratio) in th...

Embodiment 3

[0044] Dissolve 8 mass percent polyacrylonitrile (PAN) / L-polylactic acid (PLLA) (7:3, mass ratio) powder in 92 mass percent dimethyl sulfoxide (DMSO) at 60°C Stir vigorously for 24 h to obtain a homogeneous polymer solution. Under the action of a 20kV high-voltage direct current power supply, the polymer solution sprays out in the form of a jet at the end of the capillary of the syringe, and the distance between the end of the capillary and the collector is 20 cm. Vacuum drying at ℃ to obtain a porous polymer electrolyte supporting membrane material: the average fiber diameter is 300nm, and the porosity is 75%.

[0045] 3.44g LiN(SO 2 CF 3 ) 2 , 5g PP 14 TFSI and 5g DOL prepared 1.2mol / kg LiN(SO 2 CF 3 ) 2 +PP 14 TFSI+DOL(PP 14 TFSI:DOL=1:1, weight ratio) electrolyte. In a glove box filled with argon, the porous polymer electrolyte support membrane material obtained above was immersed in 1.2mol / kg LiN(SO 2 CF 3 ) 2 +PP 14 TFSI+DOL(PP 14 TFSI:DOL=1:1, weight rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com