Positive pole plate of lithium-sulfur cell and manufacturing method thereof

A cathode electrode, lithium-sulfur battery technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of cathode active material elemental sulfur or polysulfide loss, poor adhesion, etc. The effect of stability and cycle stability, strong adhesion and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At room temperature, fully swell the gelatin in water, and then dissolve it in a water bath at 60° C. to prepare an aqueous gelatin solution with a concentration of 3% by mass, and set aside.

[0030] Preparation of the positive electrode sheet: mix 7 parts by mass of sublimed sulfur and 2 parts of acetylene black in proportion, grind them evenly, then add a binder solution containing 1 part of gelatin solid, grind to make the binder solution and the active material Fully and evenly mixed with acetylene black to make a positive electrode material slurry, coated on an aluminum foil current collector, and vacuum-dried for 10 hours to obtain a positive electrode active material, a conductive agent and a gelatin binder with mass percentages of 70%, 20%, and 10% % positive pole piece.

[0031] The pole piece prepared above is used as the positive pole, Li is the negative pole, the diaphragm is made of polypropylene film, and the electrolyte is 1mol / L LiClO 4Solution, the so...

Embodiment 2

[0033] At room temperature, fully swell the gelatin in water, and then dissolve it in a water bath at 60° C. to prepare a 2% gelatin aqueous solution for later use.

[0034] Preparation of the positive electrode sheet: mix 6 parts by mass of sublimed sulfur and 3 parts of acetylene black in proportion, grind them evenly, then add a binder solution containing 1 part of gelatin solid, grind to make the binder solution and the active substance Fully and evenly mixed with acetylene black to make a positive electrode material slurry, coated on an aluminum foil current collector, and vacuum-dried for 10 hours to obtain a positive electrode active material, a conductive agent and a gelatin binder with mass percentages of 60%, 30%, 10% % positive pole piece.

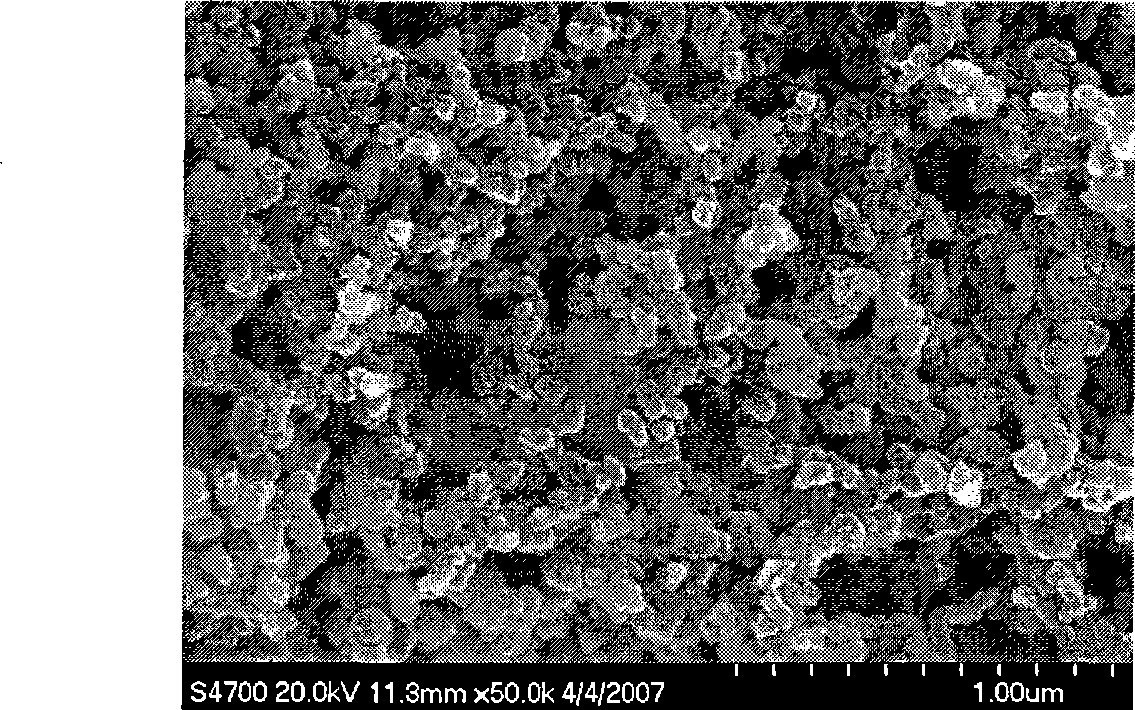

[0035] Because the gelatin binder used has good dispersibility for the conductive agent, the components of the pole piece are uniformly dispersed without obvious agglomeration, such as figure 1 shown. Thus, the discharge perfo...

Embodiment 3

[0038] At room temperature, fully swell the gelatin in water, and then dissolve it in a water bath at 60° C. to prepare a 4% gelatin aqueous solution for later use.

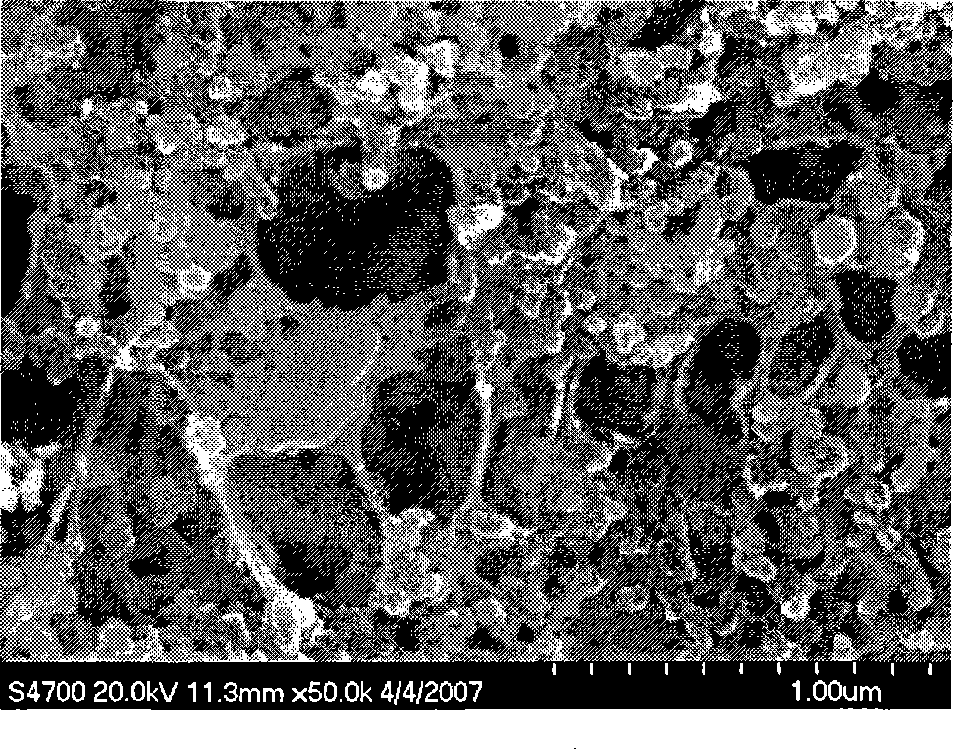

[0039] Preparation of positive electrode material: Mix 7 parts by mass of sublimed sulfur and 2 parts of acetylene black in proportion, grind them evenly, then add a binder solution containing 1 part of gelatin solid, and grind until a uniformly dispersed positive electrode material slurry is formed , and coated on the aluminum foil current collector, frozen at -40 ° C for 4 hours to form an ice crystal structure, and then vacuum-dried for 12 hours to obtain a positive active material, a conductive agent and a gelatin binder with a mass percentage of 70%, 20%, 10% positive pole pieces with microporous structure.

[0040] The pole piece prepared above is used as the positive pole, Li is the negative pole, the diaphragm is made of polypropylene film, and the electrolyte is 1mol / L LiClO 4 Solution, the solvent is D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com