Lithium-yttrium co-doped high-performance sodium ion battery positive electrode material and preparation method thereof

A technology of sodium ion battery and positive electrode material, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve the problem of irreversibility of anion redox reaction, achieve high energy density and structural stability, good electrochemical reversibility, The effect of high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

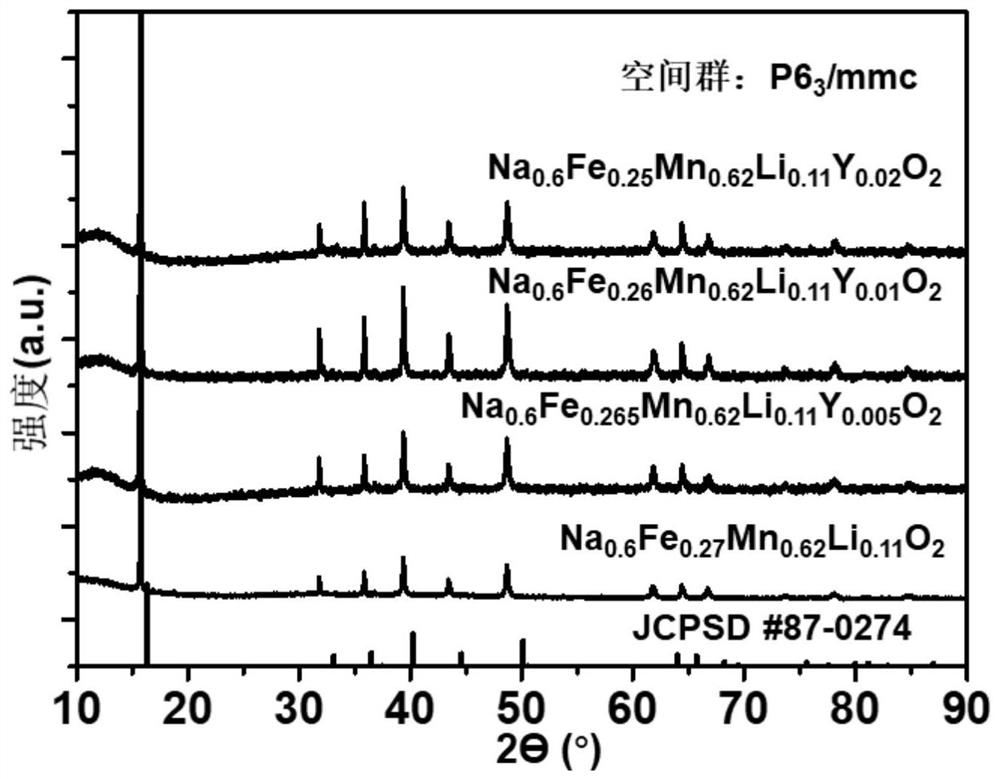

[0030] This embodiment provides a lithium-yttrium co-doped layered oxide material whose general chemical formula is Na x Fe a mn b Li c Y d o 2 , wherein the range of the mole percentage of each element in the material is 0.6≤x≤0.7, 0.075<a≤0.27, 0.62≤b≤0.75, 0.11≤c≤0.175, 0<d≤0.1, where a, b, c , the relationship of d satisfies a+b+c+d=1, and the entire chemical formula should maintain electrical neutrality.

[0031] Further, the preparation steps of the lithium-yttrium co-doped layered oxide material are:

[0032] Step 1, Na 2 CO 3 , Fe 2 o 3 , MnO 2 , Li 2 CO 3 and Y 2 o 3 Mixing according to the stoichiometric ratio, adding an appropriate amount of solvent, wherein the solvent is ethanol, to obtain a mixture;

[0033] Step 2, transferring the mixture to an agate ball mill jar, and placing the agate ball mill jar on a planetary ball mill for wet ball milling for 5 hours;

[0034] Step 3, drying the mixture obtained after ball milling to obtain a precursor; ...

Embodiment 2

[0039] Sodium carbonate, manganese dioxide, iron oxide, lithium carbonate and yttrium oxide are used as precursors, mixed according to the ratio of Na:Fe:Mn:Li:Y of 0.6:0.26:0.62:0.11:0.01, dissolved in 10mL NMP to obtain a mixed solution, and then transfer the mixed solution to a ball mill tank for ball milling. The ball milling speed is 600rpm, and the ball milling time is 4h. Precalcined at 450°C for 4h, then calcined at 950°C for 18h, the heating and cooling rate was 5°C / min, and the lithium-yttrium co-doped layered positive electrode material Na 0.6 Fe 0.26 mn 0.62 Li 0.11 Y 0.01 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com