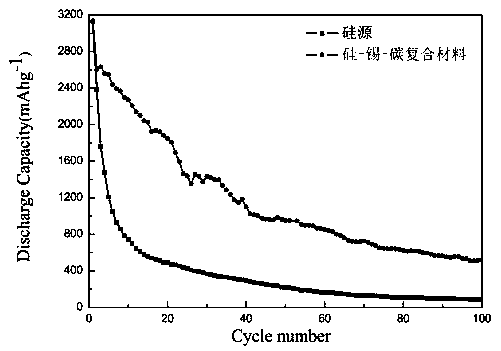

Preparation method of silicon-tin-carbon composite material

A carbon composite material and silicon source technology, which is applied to active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of difficult preparation and complex preparation process, and achieve high-quality product performance, simple preparation process and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. A preparation method of silicon-tin-carbon composite material, the preparation method is as follows:

[0035] (a) Take 3 kg of monocrystalline silicon powder with a particle diameter of 3 μm, wash it sequentially with hydrofluoric acid, sulfuric acid, ethanol and ultrapure water, and dry it in a vacuum drying oven at 90 ° C for 7 hours to obtain product A;

[0036] (b) Mix product A, 0.3kg tin powder and 0.02kg glucose evenly, and use a tablet machine to press at 10Mpa for 2 minutes to make a tablet to obtain product B;

[0037] (c) Put product B into an atmosphere furnace for calcination, specifically heat it to 200°C and keep it warm for 0.5 hours. During the process, the atmosphere furnace is fed with nitrogen, and the air flow rate is 10ml / min. Take it out and cool it, and then grind it into a particle with a particle size of 1 μm. Powder, product C;

[0038] (d) Dissolve 5kg of glucose in pure water to form a 1mol / L solution to obtain product D;

[00...

Embodiment 2

[0043] Example 2. A preparation method of silicon-tin-carbon composite material, the preparation method is as follows:

[0044] (a) Take 4kg of polysilicon powder with a particle diameter of 9 μm, wash it with hydrofluoric acid, sulfuric acid, ethanol and ultrapure water in sequence, and dry it in a vacuum drying oven at 100°C for 8 hours to obtain product A;

[0045] (b) Mix product A, 6.5kg of tin powder and 0.045kg of cornstarch evenly, press with a tablet machine at 10-20Mpa for 3.5min to form a tablet, and obtain product B;

[0046] (c) Put product B into an atmosphere furnace for calcination, specifically heat it to 375°C and keep it warm for 1.75 hours. During the process, the atmosphere furnace is fed with nitrogen, and the air flow rate is 55ml / min. Take it out and cool it, and then grind it to a particle size of 4.5μm powder, get product C;

[0047] (d) Dissolve 6.5kg of cornstarch in pure water to form a 2.5mol / L solution to obtain product D;

[0048] (e) Pour pr...

Embodiment 3

[0052] Example 3. A preparation method of silicon-tin-carbon composite material, the preparation method is as follows:

[0053] (a) Take 5 kg of porous silicon powder with a particle diameter of 15 μm, successively wash it with hydrofluoric acid, sulfuric acid, ethanol and ultrapure water, and dry it in a vacuum drying oven at 110 ° C for 9 hours to obtain product A;

[0054] (b) Mix product A, 1kg of tin powder and 0.07kg of sodium alginate evenly, and use a tablet machine to press at 20Mpa for 5 minutes to make a tablet to obtain product B;

[0055] (c) Put product B into an atmosphere furnace for calcination, specifically heat it to 550°C and keep it warm for 3 hours. During the process, the atmosphere furnace is fed with nitrogen, and the air flow rate is 100ml / min. Take it out and cool it, and then grind it into a particle with a particle size of 10μm. Powder, product C;

[0056] (d) Dissolve 8kg of sodium alginate in pure water to form a 5mol / L solution to obtain produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com