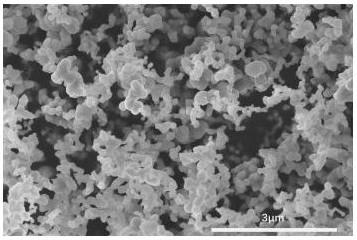

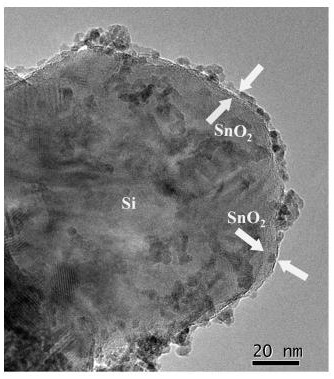

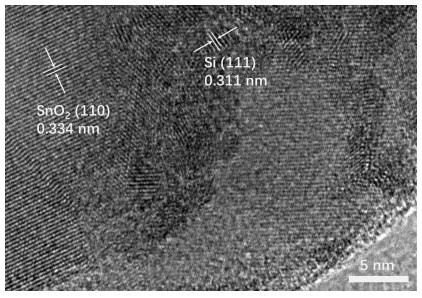

Silicon-tin dioxide chain-shaped and dendritic core-shell structure lithium ion battery negative electrode material and preparation method thereof

A lithium-ion battery, core-shell structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of cycle performance decline, electrode capacity decline, easy powdering and cracking, etc., to achieve stable discharge specific capacity and operation. Simple, easy-to-use ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 0.21g of nano-silicon powder into 200ml of ethanol aqueous solution, including 180ml of deionized water and 20ml of absolute ethanol, and perform ultrasonication at 60Hz for 15 minutes to obtain a uniformly dispersed nano-silicon solution. 0.12 g of tin tetrachloride pentahydrate was dissolved in the solution, and stirred under magnetic force in an oil bath at 75° C., reacted for 24 hours, and then stood overnight to obtain an aqueous solution of a silicon tin dioxide core-shell structure negative electrode material. It was subjected to suction filtration, alternately washed with absolute ethanol and deionized water for 3-5 times, and finally vacuum-dried at 80° C. for 12 hours to obtain a silicon tin dioxide core-shell structure negative electrode material (active material). The active material, conductive agent (carbon black) and binder (sodium alginate) were weighed and mixed uniformly at a mass ratio of 7:1:2, and 2.0 mL of deionized water was added to make a slu...

Embodiment 2

[0024] Add 0.34g of nano-silicon powder into 200ml of ethanol aqueous solution, including 80ml of deionized water and 20ml of absolute ethanol, and perform ultrasonication at 60Hz for 15 minutes to obtain a uniformly dispersed nano-silicon solution. 0.66g of tin tetrachloride pentahydrate was dissolved in the solution, and stirred under magnetic force in an oil bath at 60°C, reacted for 24 hours, and then stood overnight to obtain an aqueous solution of a silicon tin dioxide core-shell structure negative electrode material. It was subjected to suction filtration, alternately washed with absolute ethanol and deionized water for 3-5 times, and finally vacuum-dried at 80° C. for 12 hours to obtain a silicon tin dioxide core-shell structure negative electrode material (active material). The active material, conductive agent (carbon black) and binder (sodium alginate) were weighed and mixed uniformly at a mass ratio of 7:1:2, and 2.0 mL of deionized water was added to make a slurry,...

Embodiment 3

[0026] Add 0.58g of nano-silicon powder into 200ml of ethanol aqueous solution, including 180ml of deionized water and 20ml of absolute ethanol, and perform ultrasonication at 60Hz for 15 minutes to obtain a uniformly dispersed nano-silicon solution. 0.078g of tin tetrachloride pentahydrate was dissolved in the solution, and stirred under magnetic force in an oil bath at 75°C, reacted for 24 hours, and then stood overnight to obtain an aqueous solution of silicon tin dioxide core-shell structure negative electrode material. It was subjected to suction filtration, alternately washed with absolute ethanol and deionized water for 3-5 times, and finally vacuum-dried at 80° C. for 12 hours to obtain a silicon tin dioxide core-shell structure negative electrode material (active material). The active material, conductive agent (carbon black) and binder (sodium alginate) were weighed and mixed uniformly at a mass ratio of 7:1:2, and 2.0 mL of deionized water was added to make a slurry,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com