Silicon-tin-graphene compound electrode material as well as preparation method and application thereof

An electrode material and composite technology, which is applied in the field of silicon-tin-graphene composite electrode material and its preparation, can solve the problems such as the cycle stability and electrical conductivity of silicon carbon negative electrode material need to be further improved, so as to improve the cycle stability. , The effect of inhibiting powdering and accelerating transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

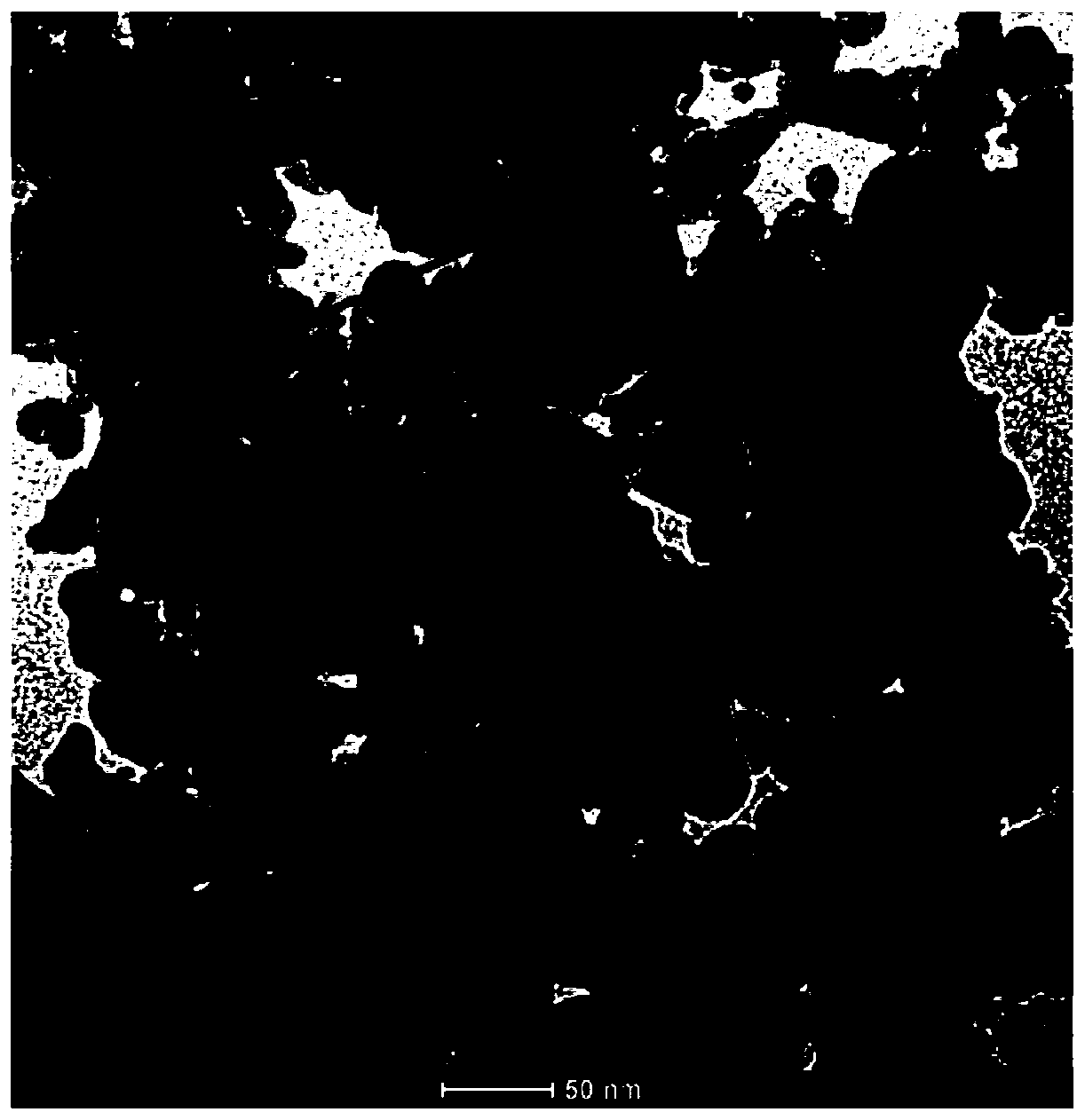

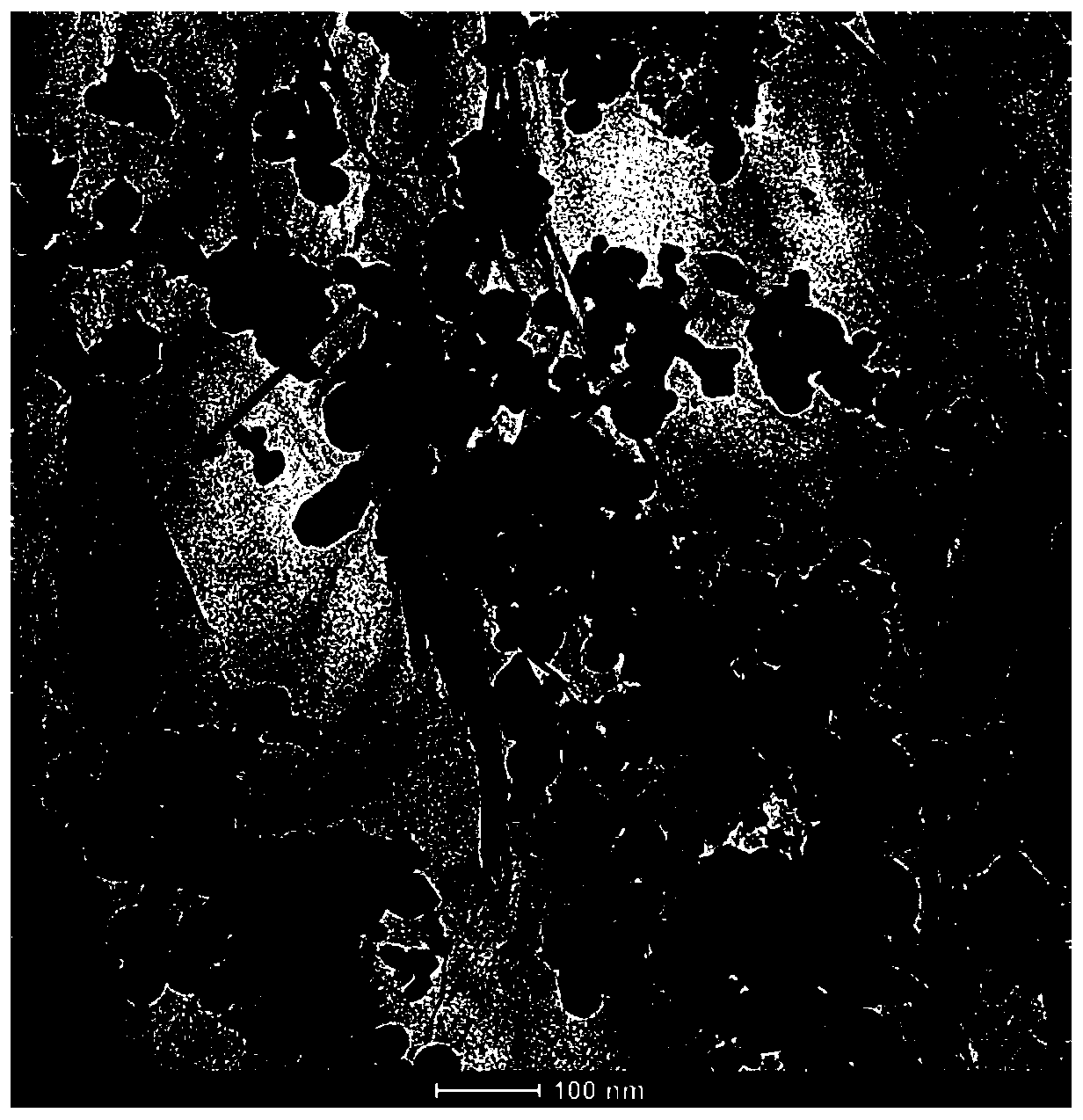

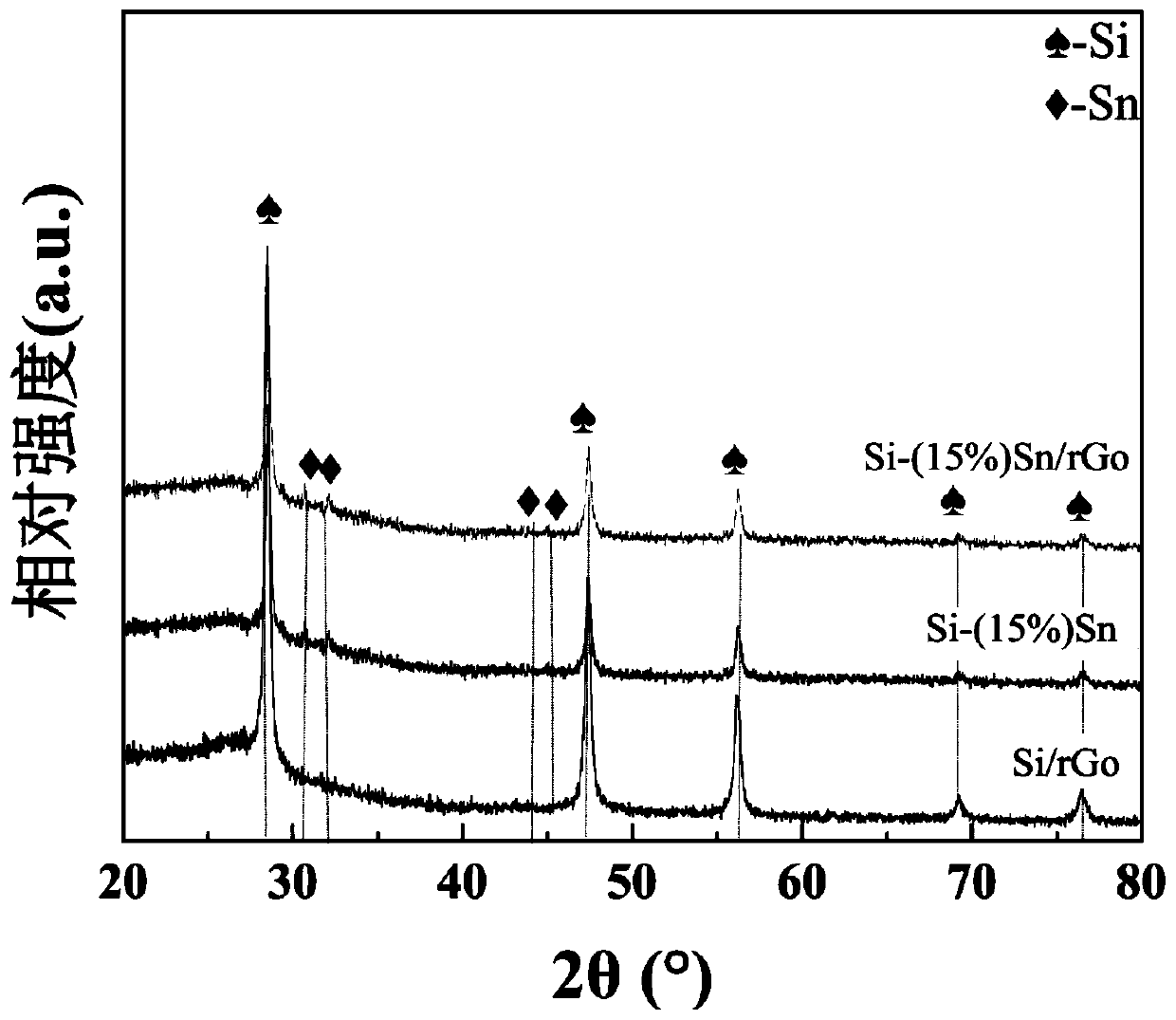

[0028] 1. Preparation of silicon-tin-graphene (Si-Sn / rGO) composite electrode material

[0029] (1) Weigh 0.1275g of commercial nano-silicon particles, and add them to SnCl with concentrations of 0.015mol / L, 0.032mol / L, and 0.077mol / L 4 In the solution, the volume of the solution is 6mL. After ultrasonication for 60min, it is vacuum-dried at 80°C for 10h; the obtained dried sample is placed in a tubular calciner for high-temperature heat treatment, and the temperature is raised to 350°C at a rate of 5°C / min, and kept for 1h. During the hydrogenation reduction process, 20 sccm of H was introduced into the whole process. 2 And the Ar mixed gas of 40sccm, finally cool to room temperature with furnace, obtain silicon-tin (Si-Sn) compound;

[0030] (2) Weigh 2.149g of commercial polydiallyldimethylammonium chloride solution, 0.363g of trishydroxymethylaminomethane, and 0.173g of sodium chloride, and add them to 150mL of deionized water to configure polydiallyldimethylammonium chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com