Lithium ion battery silicon-tin composite negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrical conductivity, crushing, pulverization, and falling off of silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of plating solution: SnCl 2 75g / L, NaOH100g / L, sodium citrate 233g / L;

[0028] Electroless plating time: 5min

[0029] Chemical plating temperature: 50℃

[0030] Stirring conditions: 300 revolutions per minute / min

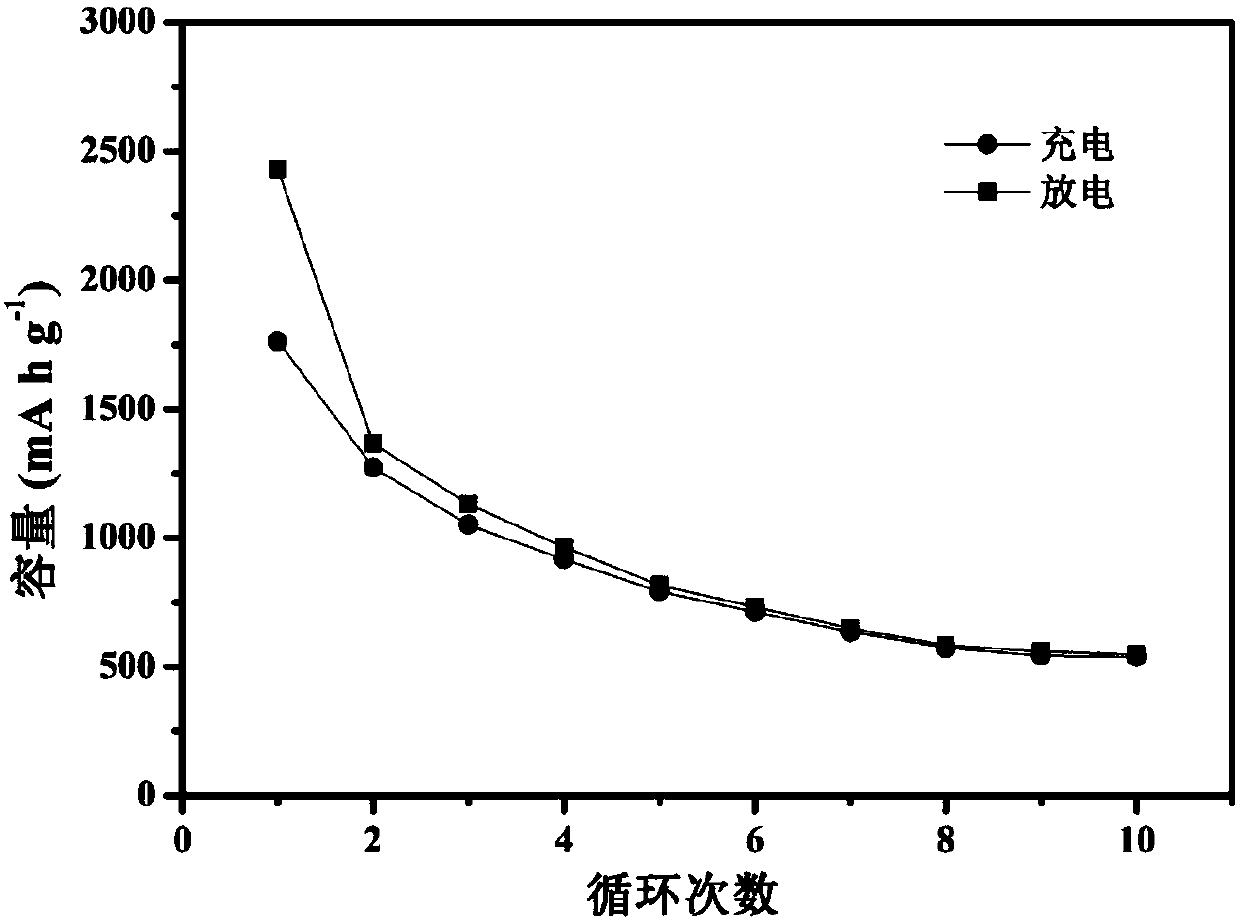

[0031] Post-processing: After the electroless plating product is cleaned and filtered with deionized water, it is dried in a blast oven to obtain a silicon-tin composite material with a silicon content of 73.9% and a tin content of 26.1%; this material is Negative electrode material, assembled button cell, conductive agent is acetylene black, binder is PVDF; silicon-tin active material, the mass ratio of conductive agent and binder is 70:15:15; charge and discharge current density is 100mA / g.

[0032] figure 1 SEM image of the silicon-tin composite material in Example 1 (scanning electron microscope model: Hitachi S-4800)

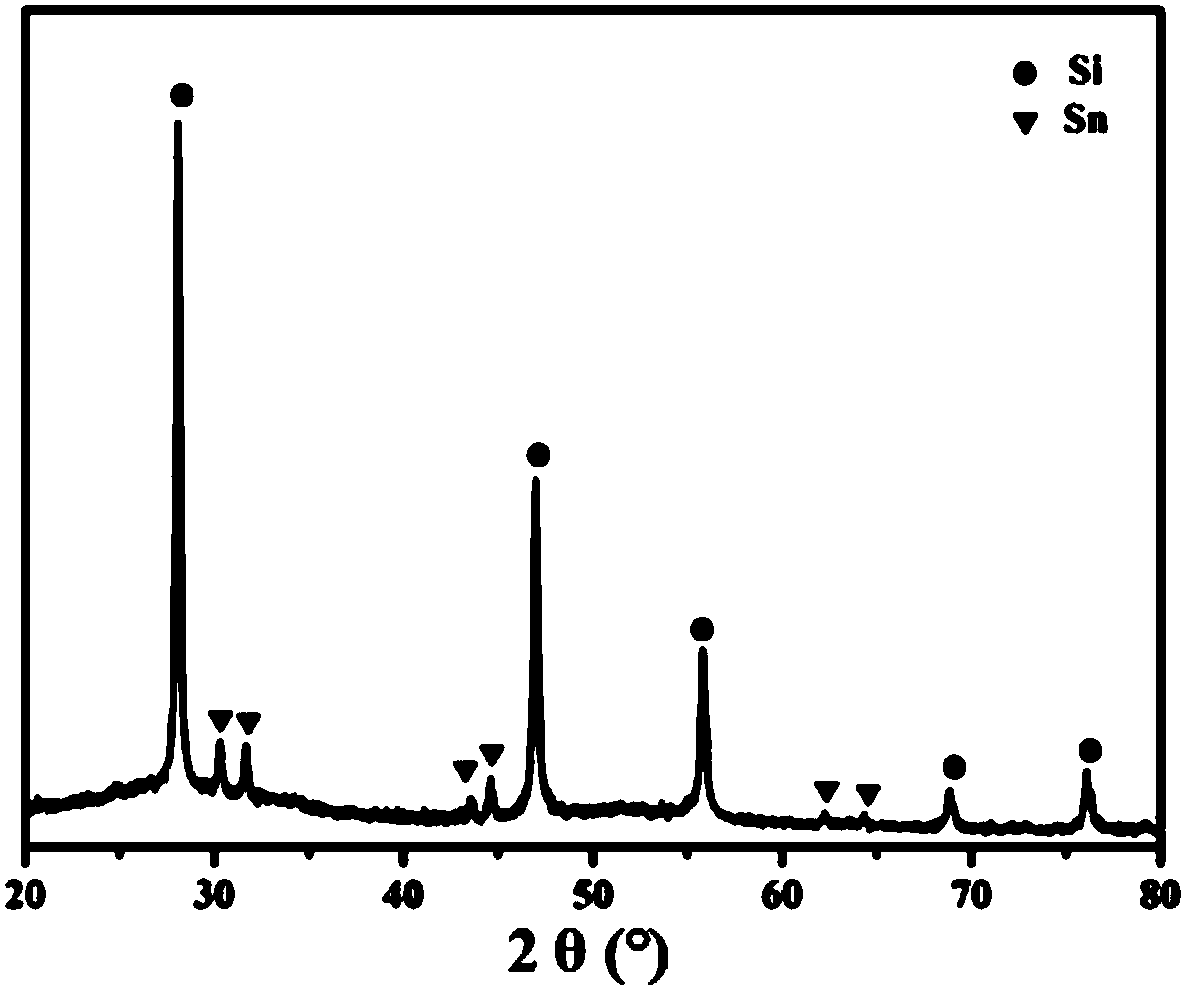

[0033] figure 2 For the XRD pattern of silicon in Example 1, it can be determined that Si and Sn are present in the material (X-ray d...

Embodiment 2

[0036] Preparation of plating solution: SnCl 2 70g / L, NaOH120g / L, sodium citrate 200g / L;

[0037] Electroless plating time: 8min

[0038] Chemical plating temperature: 80℃

[0039] Stirring conditions: 200 revolutions per minute / min

[0040] Post-processing: After cleaning and filtering the chemically plated product with deionized water, it is dried in a blast oven to obtain a silicon-tin composite material with a silicon content of 55% and a tin content of 45%; this material is Negative electrode material, assembled button cell, conductive agent is acetylene black, binder is PVDF; silicon-tin active material, the mass ratio of conductive agent and binder is 70:15:15; charge and discharge current density is 100mA / g.

[0041] Figure 4 SEM image of the silicon-tin composite material in Example 2 (scanning electron microscope model: Hitachi S-4800)

[0042] Figure 5 For the XRD pattern of silicon in Example 2, it can be determined that Si and Sn are present in the material (X-ray diffrac...

Embodiment 3

[0045] Preparation of plating solution: SnCl 2 75g / L, NaOH 110g / L, sodium citrate 220g / L;

[0046] Electroless plating time: 2min

[0047] Chemical plating temperature: 75℃

[0048] Post-processing: After the electroless plating product is cleaned and filtered with deionized water, it is dried in a blast oven to obtain a silicon-tin composite material with a silicon content of 52.6% and a tin content of 47.4%; this material is Negative electrode material, assembled button cell, conductive agent is acetylene black, binder is PVDF; silicon-tin active material, the mass ratio of conductive agent and binder is 70:15:15; charge and discharge current density is 100mA / g.

[0049] Figure 7 SEM image of the silicon-tin composite material in Example 3 (scanning electron microscope model: Hitachi S-4800)

[0050] Picture 8 For the XRD pattern of silicon in Example 3, it can be determined that Si and Sn are present in the material (X-ray diffractometer model: Rigaku D / MAX-2500)

[0051] Picture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com