Preparation method and application of graphene-based composite electrode material

A graphene-based, composite electrode technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve problems such as attenuation, electrode damage capacity, cycle stability and electrical conductivity to be further improved, and achieve low cost and improved Capacity performance, the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

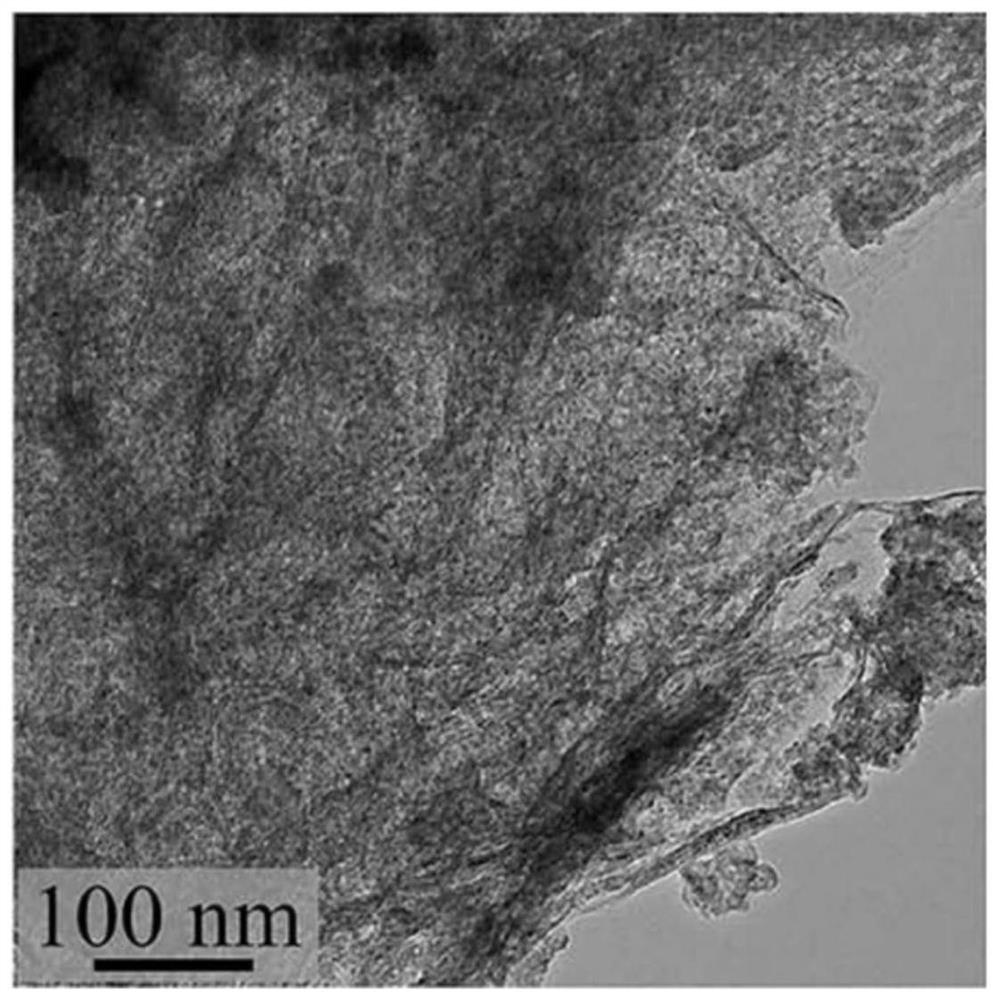

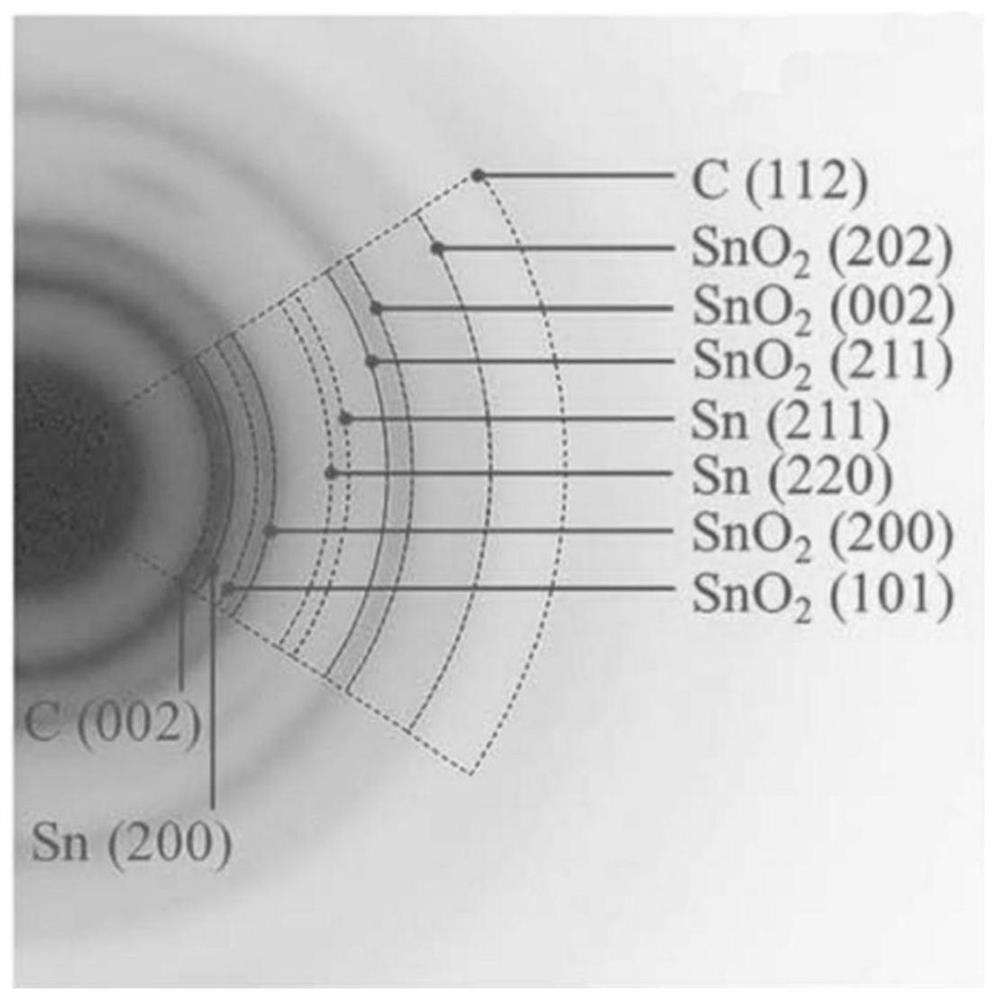

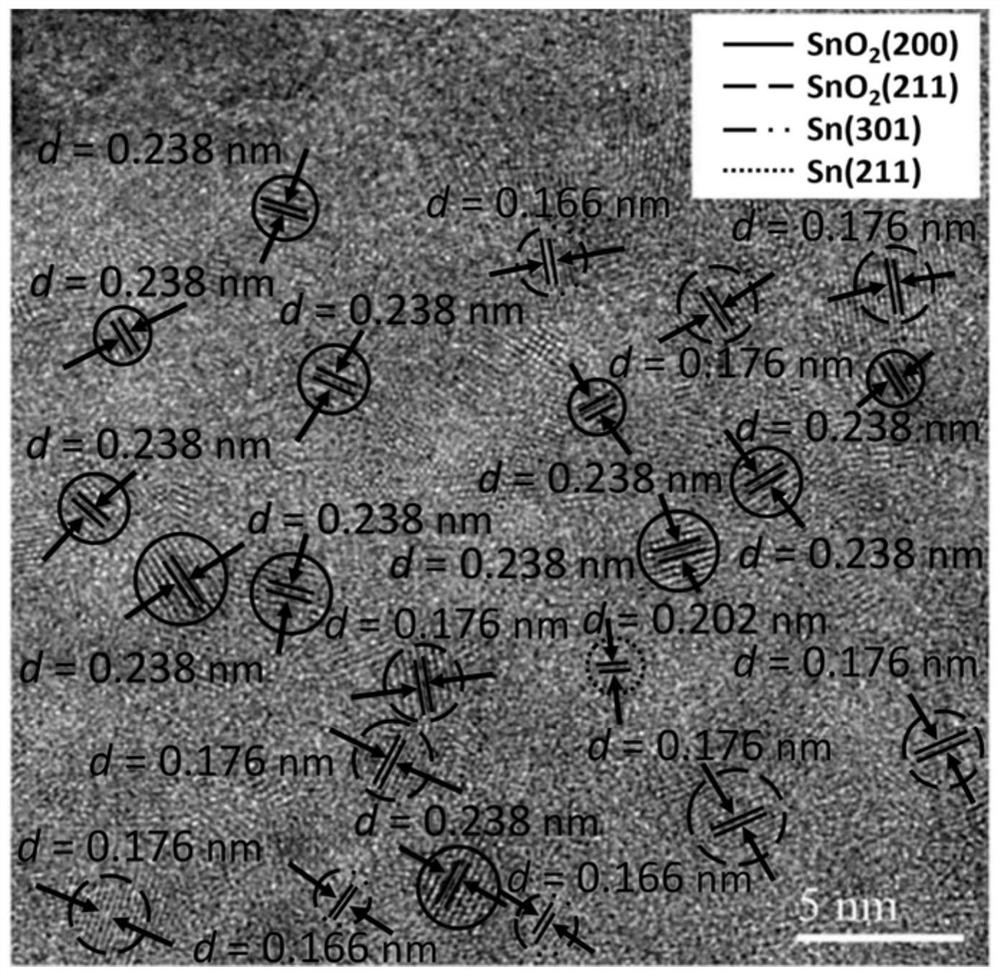

Image

Examples

Embodiment 1

[0039] In this embodiment, a silicon / tin-doped graphene-based composite electrode material is prepared, and the specific process is as follows:

[0040] (1) SiO 2 Mix it with graphene oxide at a mass ratio of 1:9 and put it into a certain container, pour N-methylpyrrolidone into the mixture as a solvent, and perform magnetic stirring at a speed of 300rpm. After stirring for 2 hours, place the container in a nanomaterial disperser In the process, ultrasonic for 2 hours, the ultrasonic power is 300W, the slurry after ultrasonic is washed with deionized water several times, put in a drying oven at 80°C and dried for 20 hours to obtain SiO 2 / graphene oxide composites, where SiO 2 The particle size D50 is about 30nm, the size of graphene is 1-5μm, and the material comes from Aladdin or Sinopharm;

[0041] (2) Pour ethylene glycol into the container, add 2 times of SnCl 2 2H 2 O, nitrogen was passed through, and after magnetic stirring for 2 h, SiO was added 2 / Graphene Oxide ...

Embodiment 2

[0046] In this embodiment, a silicon / tin-doped graphene-based composite electrode material is prepared, and the specific process is as follows:

[0047] (1) Weigh graphene oxide, grind it with a mortar, put the powder into a crucible, put it in a tube furnace, and sinter at 800°C for 6 hours under a nitrogen or argon atmosphere to obtain reduced graphene oxide;

[0048] (2) SiO 2 Mix it with reduced graphene oxide at a mass ratio of 1:9 and put it into a certain container, pour N-methylpyrrolidone into the mixture as a solvent, and perform magnetic stirring at a speed of 300rpm. After stirring for 2 hours, place the container in a nanomaterial dispersion In the device, ultrasonic 2h, ultrasonic power is 300W, the slurry after ultrasonic is washed with deionized water for many times, put into the drying oven at 80 ℃ and dried for 20h to obtain SiO 2 / graphene-based composite materials;

[0049] (3) Pour ethylene glycol into the container, add 2 times of SnCl 2 2H 2 O, nitr...

Embodiment 3

[0056] In this embodiment, a silicon / tin-doped graphene-based composite electrode material is prepared, and the specific process is as follows:

[0057] (1) Weigh graphene oxide and melamine, mix and grind them at a mass ratio of 1:5, put them into a tube furnace and sinter at 800° C. for 3 hours under a nitrogen or argon atmosphere to obtain nitrogen-doped graphene;

[0058] (2) SiO 2 Mix it with nitrogen-doped graphene at a mass ratio of 1:9 and put it into a certain container, pour N-methylpyrrolidone into the mixture as a solvent, and perform magnetic stirring at a speed of 300rpm. After stirring for 2 hours, place the container in a nanomaterial dispersion In the device, ultrasonic 2h, ultrasonic power is 300W, the slurry after ultrasonic is washed with deionized water for many times, put into the drying oven at 80 ℃ and dried for 20h to obtain SiO 2 / Nitrogen-doped graphene composite material;

[0059] (3) Pour ethylene glycol into the container, add 2 times of SnCl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com