Preparation method for isostatic pressure calcium-aluminum-silicon tin bath bottom brick

A tin bath bottom brick and isostatic pressing technology, applied in glass production and other directions, can solve the problems of increased porosity and risk of use, and achieve improved service life, good resistance to tin liquid penetration, and reduced glass defects. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

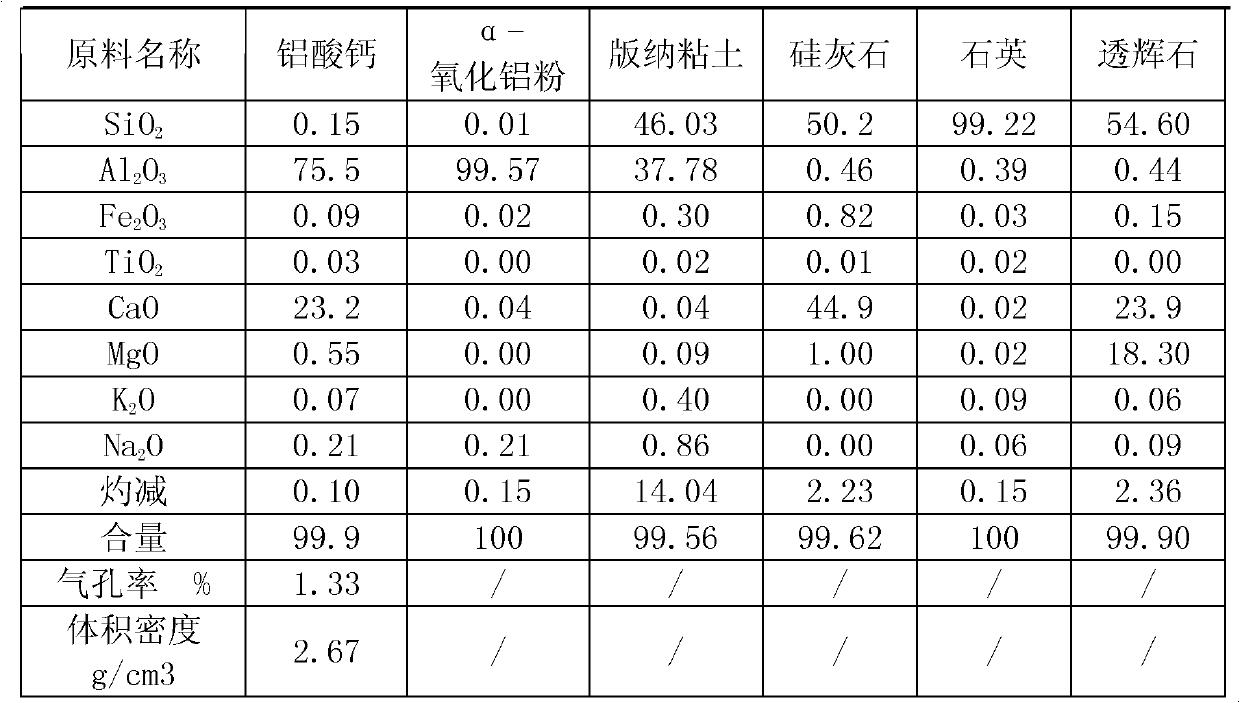

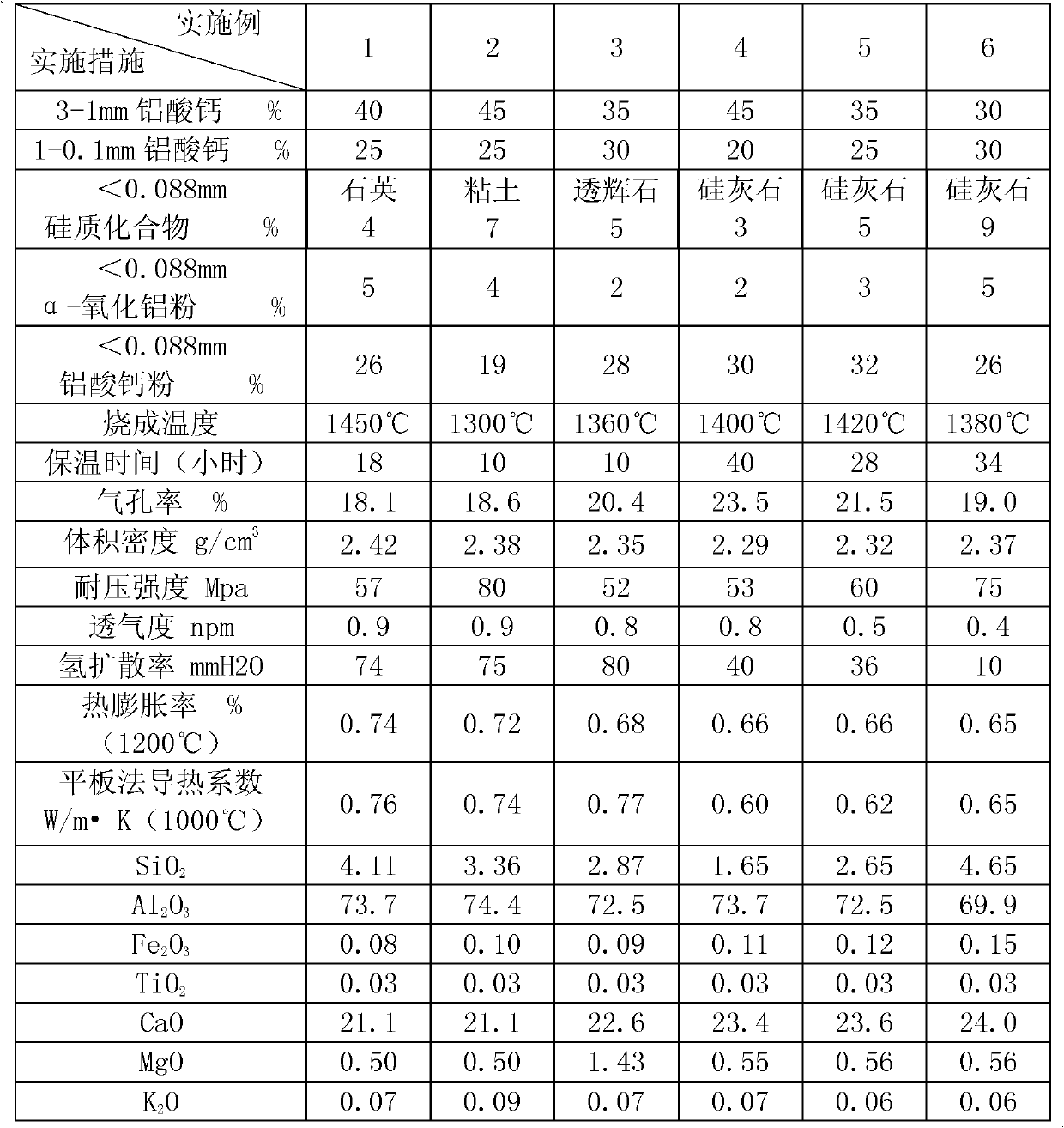

[0026] The physical and chemical indicators of raw materials such as calcium aluminate particles, α-alumina powder, and siliceous compound powder are listed in Table 1 below. Add the raw materials into the mixer in proportion, mix them for 5-15 minutes, and wait at a pressure of 50-200Mpa. Static pressure compression molding, after the green body is naturally dried for 1-3 days, it is fired at 1300°C-1450°C to obtain samples of aluminum-calcium-siliceous tin bath bottom bricks, and its chemical composition, mineral phase composition, porosity, bulk density, and resistance to corrosion are tested. Physical and chemical indicators such as compressive strength and thermal conductivity are shown in Table 2 of specific examples.

[0027] Table 1 The mass chemical percentage composition table of raw materials

[0028]

[0029] Table 2, specific embodiment table

[0030]

[0031]

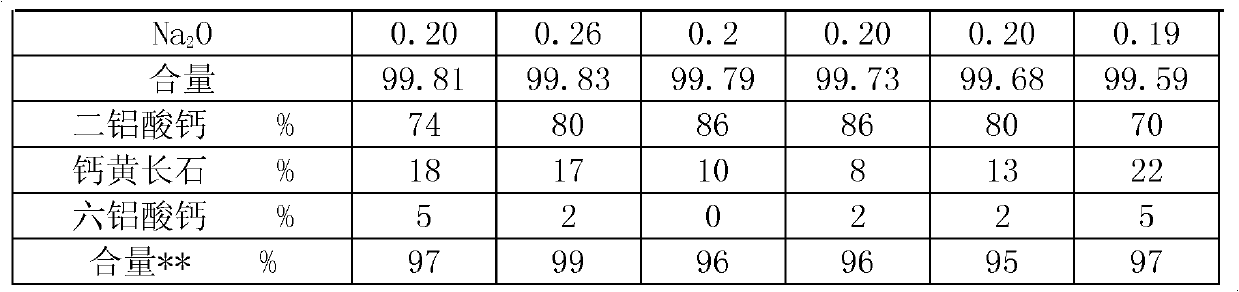

[0032] **MgO, Na in aluminum-calcium-siliceous tin bath bottom brick 2 Mineral components su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com