Simple preparation method of silicon-tin-graphite alloy

A graphite, simple technology, applied in the field of simple preparation of silicon-tin-graphite alloy, can solve the problems of low capacity contribution, and achieve the effects of high first efficiency, high charge and discharge capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention discloses a simple preparation method of silicon-tin-graphite alloy, comprising the following steps: comprising the following steps:

[0017] (1) Mix silicon powder and tin powder evenly: add 4-8g silicon powder and 3-5g tin powder to a ball mill to disperse, pass argon for protection, ball mill for 15-25H, and the grinding speed is 300-500rpm; then 1 - 3g PVA and 0.3-0.7g graphite were added to the ball-milling jar of the above-mentioned ball mill, ball-milled in air for 8-12H, and the grinding rate was 300-500rpm; the weight ratio of grinding balls to the mixture was kept at 10:1.

[0018] (2) Material annealing process: The above mixture is calcined in a tube furnace, calcined in an argon atmosphere at a temperature of 600-800 °C for 120-180 minutes, and the heating rate is 2-4 °C / min, and then cooled with the furnace.

Embodiment 1

[0021] A simple preparation method of silicon-tin-graphite alloy, comprising the following steps:

[0022] (1) Mix the silicon powder and tin powder evenly: add 6g of silicon powder and 4g of tin powder to the ball mill for dispersion, pass argon for protection, ball mill for 20H, and the grinding speed is 400rpm; then add 2g of PVA and 0.5g of graphite to the above ball mill In the ball-milling jar, ball-milled in air for 10H at a grinding rate of 400rpm; the weight ratio of grinding balls to the mixture was kept at 10:1.

[0023] (2) Material annealing process: The above mixture was calcined in a tube furnace, calcined in an argon atmosphere at a temperature of 700 °C for 150 minutes, and the heating rate was 3 °C / min, and then cooled with the furnace.

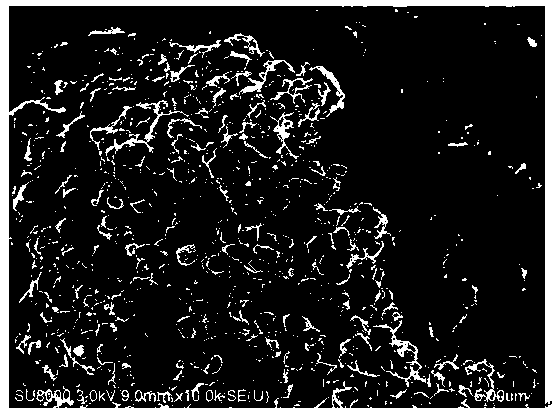

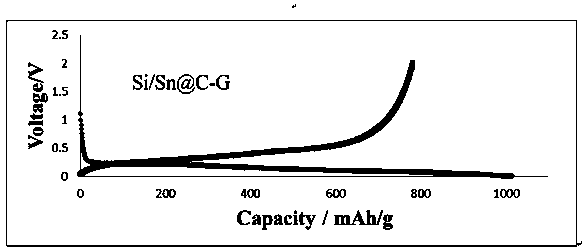

[0024] like figure 1 Shown is the scanning electron microscope image of the Si / Sn@C-G composite material obtained in this example, which is represented by figure 1 It can be seen that the microscopic morphology of the prep...

Embodiment 2

[0027] A simple preparation method of silicon-tin-graphite alloy, comprising the following steps: comprising the following steps:

[0028] (1) Mix silicon powder and tin powder evenly: add 8g silicon powder and 4g tin powder to the ball mill to disperse, pass argon for protection, ball mill for 16H, and the grinding speed is 400rpm; then add 1g PVA and 0.4g graphite to the above ball mill In the ball-milling jar, the ball was milled in air for 9H, and the grinding rate was 400 rpm; the weight ratio of grinding balls to the mixture was kept at 10:1.

[0029] (2) Material annealing process: The above mixture was calcined in a tube furnace, calcined in an argon atmosphere at a temperature of 600 °C for 130 minutes, and the heating rate was 2 °C / min, and then cooled with the furnace.

[0030] After testing, in this embodiment, the first discharge capacity is 998.67mAh / g, the first charge capacity is 739.02mAh / g, and the first effect is 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com