Synthesis method of Ca and Fe co-doped sodium vanadium bronze electrode material based on vanadium-rich liquid

A technology of sodium vanadium bronze and electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low initial charge and discharge capacity of sodium vanadium bronze electrode materials, complex synthesis process, and long synthesis cycle, etc. The effect of low cost, simple synthesis process, and shortened synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

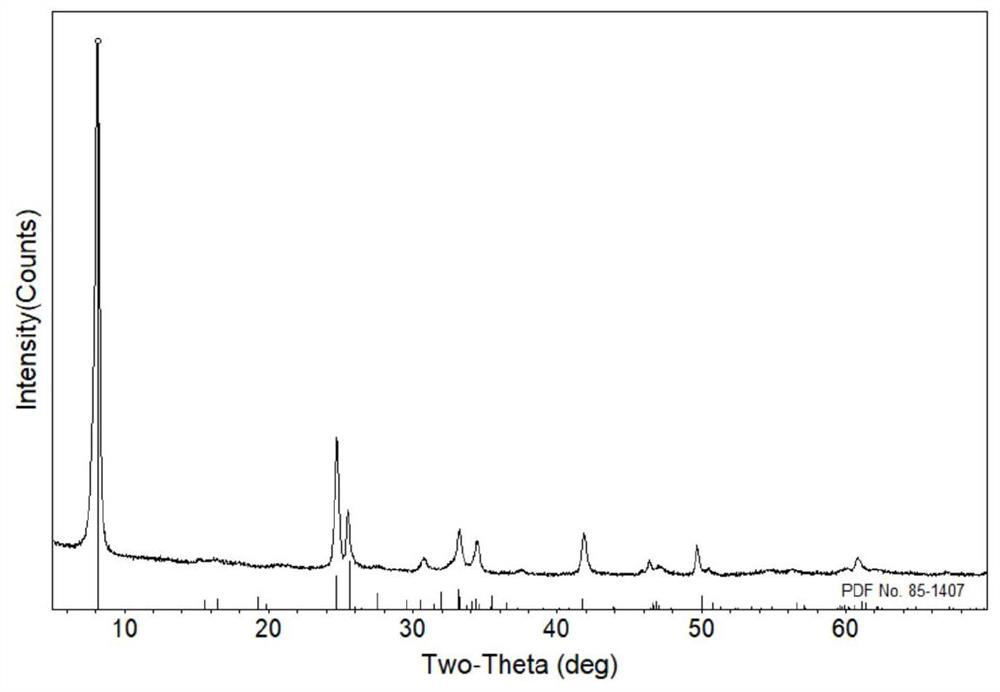

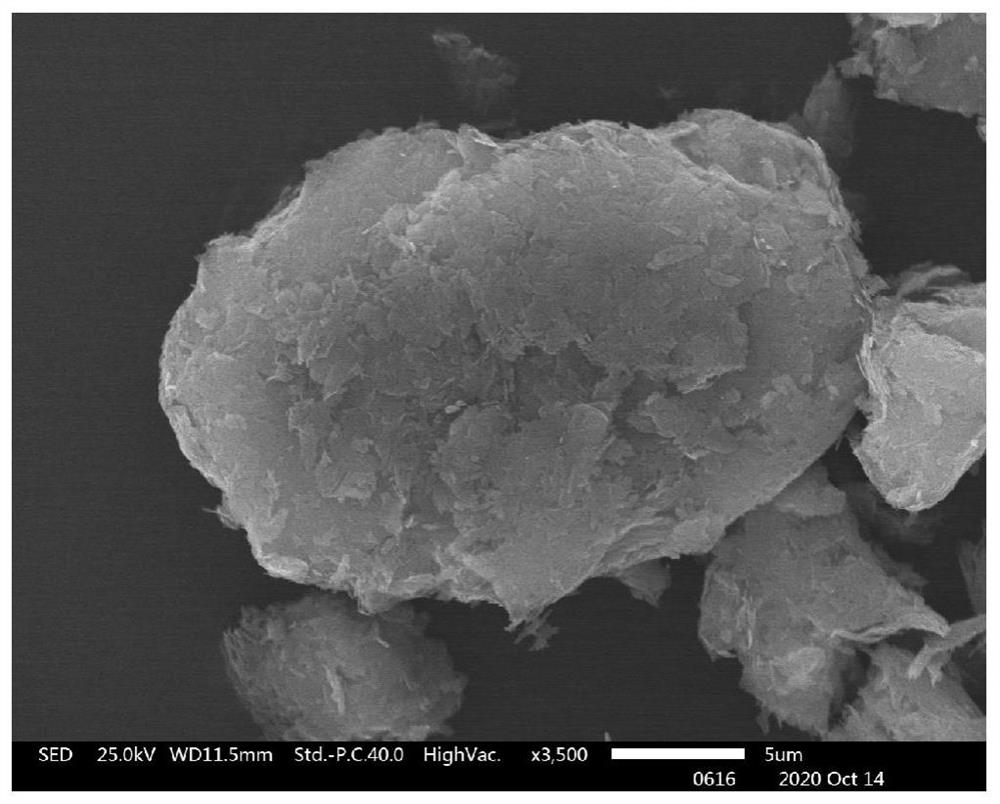

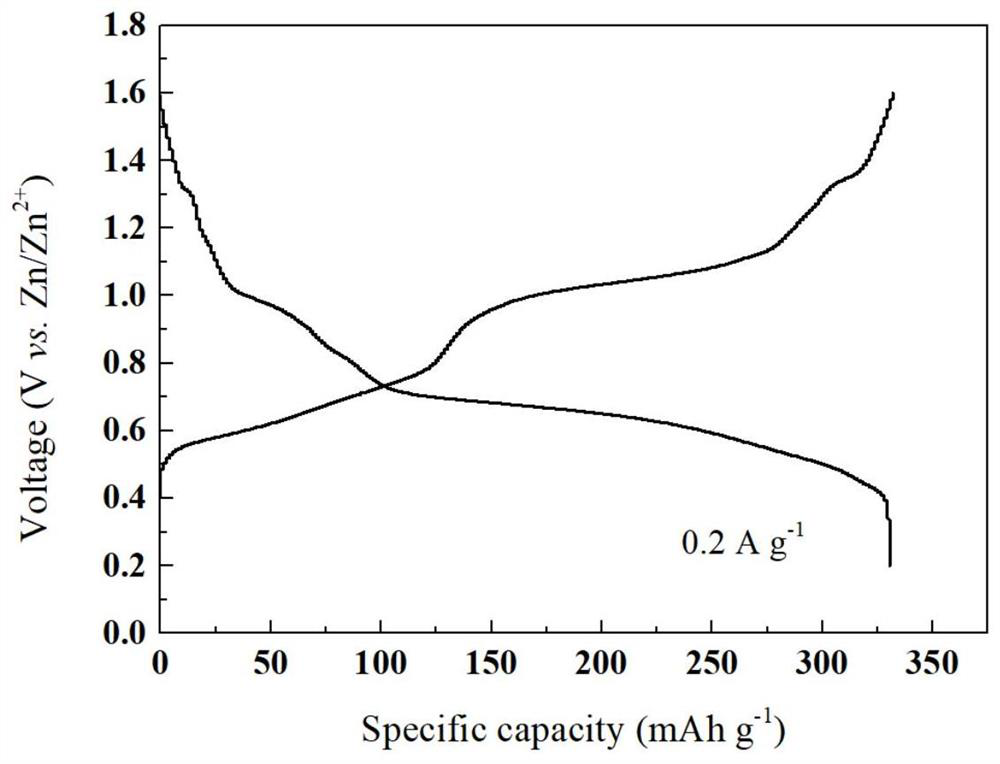

[0040] A synthesis method of Ca, Fe co-doped sodium vanadium bronze electrode material based on vanadium-rich solution. The steps of the synthetic method described in this specific embodiment are:

[0041] Step 1. According to the molar ratio of oxalate ions to vanadium ions in the vanadium-rich solution is 0.25:1, add oxalic acid dihydrate into the vanadium-rich solution and stir for 1 hour to obtain solution I.

[0042] Step 2, according to the molar ratio of vanadium ion and sodium dodecylbenzenesulfonate in the solution I is 50:1, adding the sodium dodecylbenzenesulfonate into the solution I, stirring for 0.5 hours, Mixture II is obtained.

[0043] Step 3: Put the mixed solution II in a reaction kettle, react at 160° C. for 10 hours, cool to room temperature, and separate solid and liquid to obtain a Ca and Fe co-doped sodium vanadium bronze electrode material based on a vanadium-rich solution.

[0044] The vanadium-rich solution: the vanadium concentration is 5.05g / L, t...

Embodiment 2

[0047] A synthesis method of Ca, Fe co-doped sodium vanadium bronze electrode material based on vanadium-rich solution. The steps of the synthetic method described in this specific embodiment are:

[0048] Step 1. According to the molar ratio of oxalate ions to vanadium ions in the vanadium-rich solution is 0.5:1, add oxalic acid dihydrate into the vanadium-rich solution and stir for 1.5 hours to obtain solution I.

[0049] Step 2, according to the molar ratio of vanadium ion and sodium dodecylbenzenesulfonate in the solution I is 200:1, adding the sodium dodecylbenzenesulfonate into the solution I, stirring for 0.7 hours, Mixture II is obtained.

[0050] Step 3: Put the mixed liquid II in a reaction kettle, react at 170° C. for 24 hours, cool to room temperature, and separate solid and liquid to obtain a Ca and Fe co-doped sodium vanadium bronze electrode material based on a vanadium-rich liquid.

[0051] The vanadium-rich liquid: the concentration of vanadium is 25.05g / L, ...

Embodiment 3

[0054] A synthesis method of Ca, Fe co-doped sodium vanadium bronze electrode material based on vanadium-rich solution. The steps of the synthetic method described in this specific embodiment are:

[0055] Step 1. According to the molar ratio of oxalate ions to vanadium ions in the vanadium-rich solution is 0.75:1, add oxalic acid dihydrate into the vanadium-rich solution and stir for 2.5 hours to obtain solution I.

[0056] Step 2, according to the molar ratio of vanadium ion and sodium dodecylbenzenesulfonate in the solution I is 400:1, adding the sodium dodecylbenzenesulfonate into the solution I, stirring for 0.9 hours, Mixture II is obtained.

[0057] Step 3: Put the mixed liquid II in a reaction kettle, react at 180° C. for 18 hours, cool to room temperature, and separate solid and liquid to obtain a Ca and Fe co-doped sodium vanadium bronze electrode material based on a vanadium-rich liquid.

[0058] The vanadium-enriched liquid: the concentration of vanadium is 35.55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com