Preparation method of carbon coated silicon-tin composite negative electrode plate

A technology of carbon coating and negative electrode sheet, which is applied in the field of electrochemical power supply to achieve the effect of stable volume, long service life and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

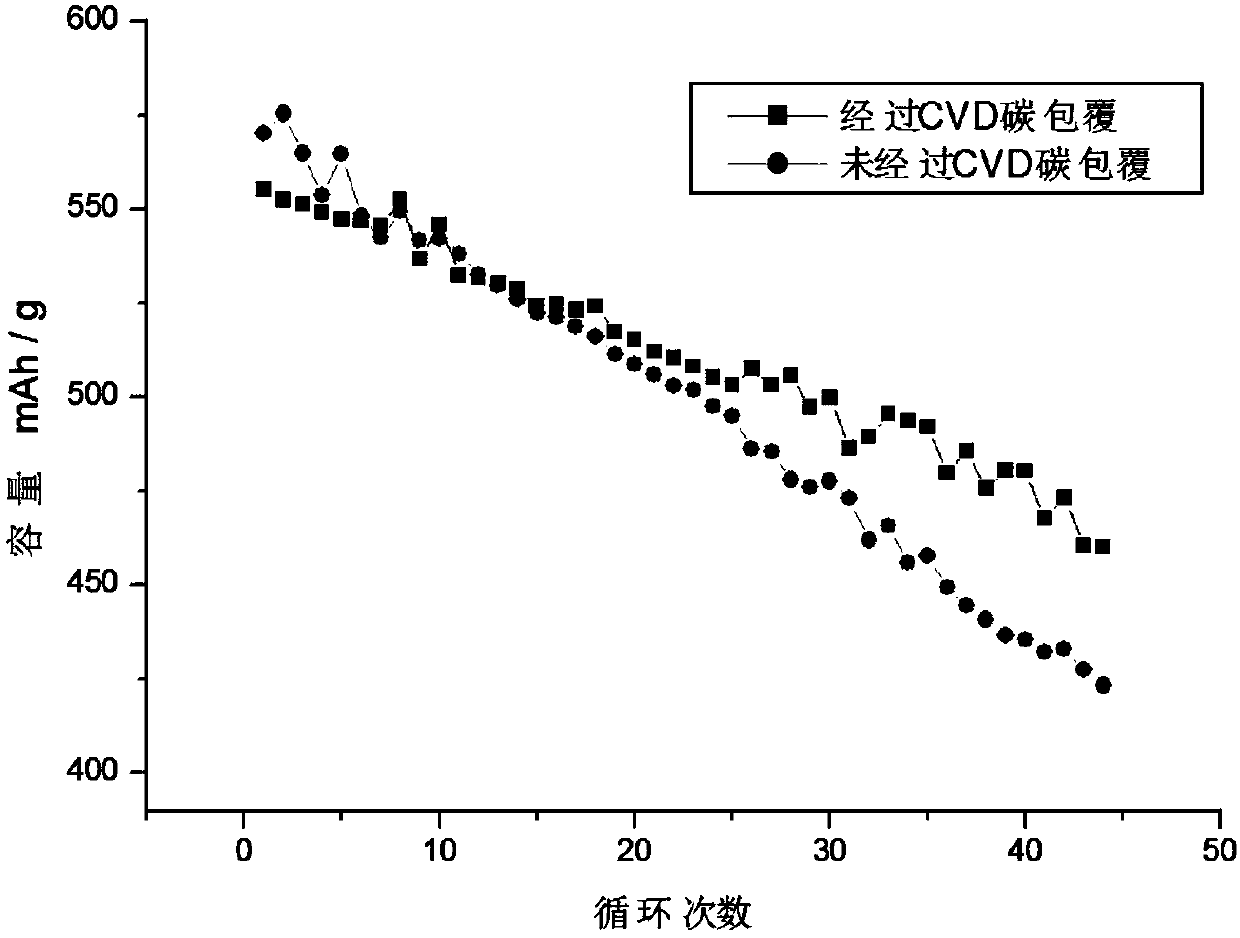

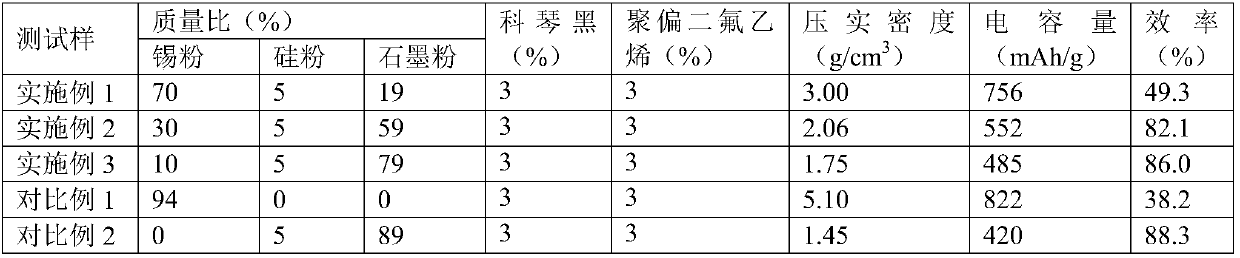

[0028] 5g of silicon powder, 70g of tin powder and 7.5g of artificial graphite powder A are subjected to mechanical high-energy ball milling in a helium atmosphere to obtain tin-silicon composite powder with a particle size of D 501.0 microns. The prepared silicon-tin composite powder and 7.74 g of artificial graphite powder B with a particle size of 10 microns were mixed in a mixer to obtain a silicon-tin composite matrix. Utilize the chemical vapor deposition method to cover the carbon layer on the surface of the silicon-tin composite substrate to obtain a carbon-coated tin-silicon composite material. The quality of the coated carbon powder is 3.76g. The chemical vapor deposition operation steps are as follows: a) silicon-tin composite Spread the substrate on the copper sheet, put the copper sheet into the quartz tube; b) place the quartz tube in the heating zone of the tube furnace; For 30 minutes, the air in the quartz tube is exhausted and the argon gas is continued to f...

Embodiment 2

[0031] 5g of silicon powder, 30g of tin powder and 3.5g of artificial graphite powder A are subjected to mechanical high-energy ball milling in a helium atmosphere to obtain tin-silicon composite powder with a particle size of D 50 1.0 microns. The prepared silicon-tin composite powder and 51.74 g of artificial graphite powder B with a particle size of 10 microns were mixed in a mixer to obtain a silicon-tin composite matrix. A carbon-coated tin-silicon composite material was obtained by covering the surface of the silicon-tin composite substrate with a carbon layer by chemical vapor deposition. The mass of the coated carbon powder was 3.76 g. The chemical vapor deposition operation steps were shown in Embodiment 1. Add 3g Ketjen Black and 3g polyvinylidene fluoride to the prepared carbon-coated tin-silicon composite material and mix them in a mixer to obtain a carbon-coated tin-silicon composite slurry. Single-sided coating on foil with a coating density of 2mg / cm 2 , and a...

Embodiment 3

[0034] 5g of silicon powder, 10g of tin powder and 1.5g of artificial graphite powder A are subjected to mechanical high-energy ball milling in a helium atmosphere to obtain tin-silicon composite powder with a particle size of D 50 1.0 microns. The prepared silicon-tin composite powder and 73.74 g of artificial graphite powder B with a particle size of 10 microns were mixed in a mixer to obtain a silicon-tin composite matrix. A carbon-coated tin-silicon composite material was obtained by covering the surface of the silicon-tin composite substrate with a carbon layer by chemical vapor deposition. The mass of the coated carbon powder was 3.76 g. The chemical vapor deposition operation steps were shown in Embodiment 1. Add 3g Ketjen Black and 3g polyvinylidene fluoride to the prepared carbon-coated tin-silicon composite material and mix them in a mixer to obtain a carbon-coated tin-silicon composite slurry. Single-sided coating on foil with a coating density of 2mg / cm 2 , and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com