Silicon-tin nano material as well as preparation method and application thereof

A nanomaterial, silicon-tin technology, applied in the field of material science, can solve the problems of difficult commercialization, many process variables, and high experimental costs, and achieve specific capacity advantages, improved cycle stability, and high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

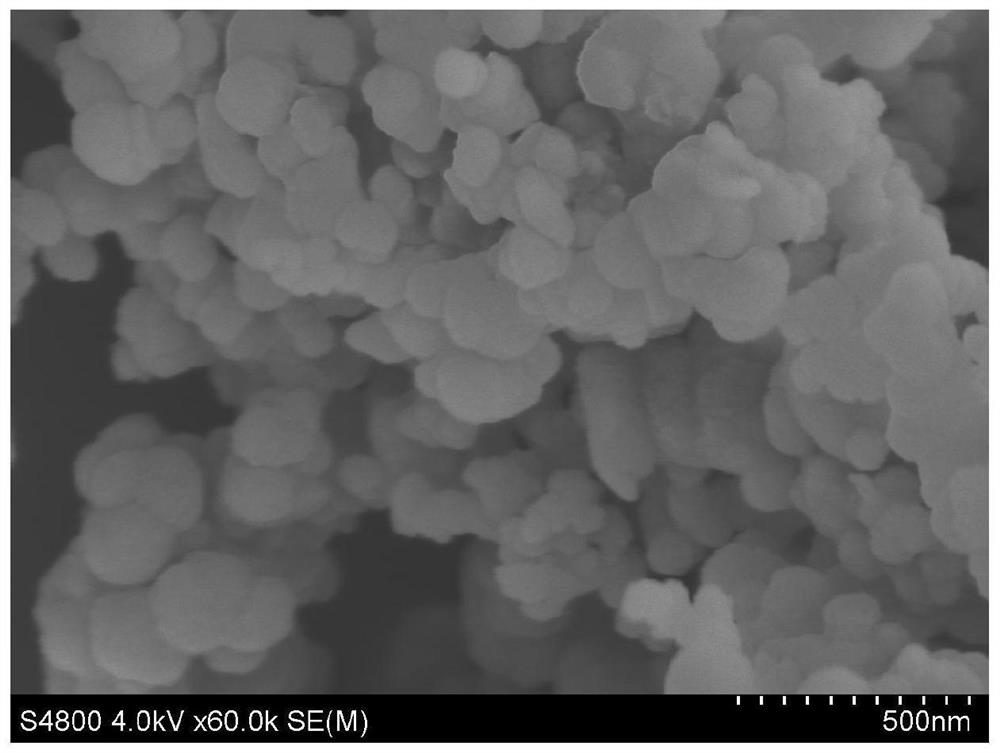

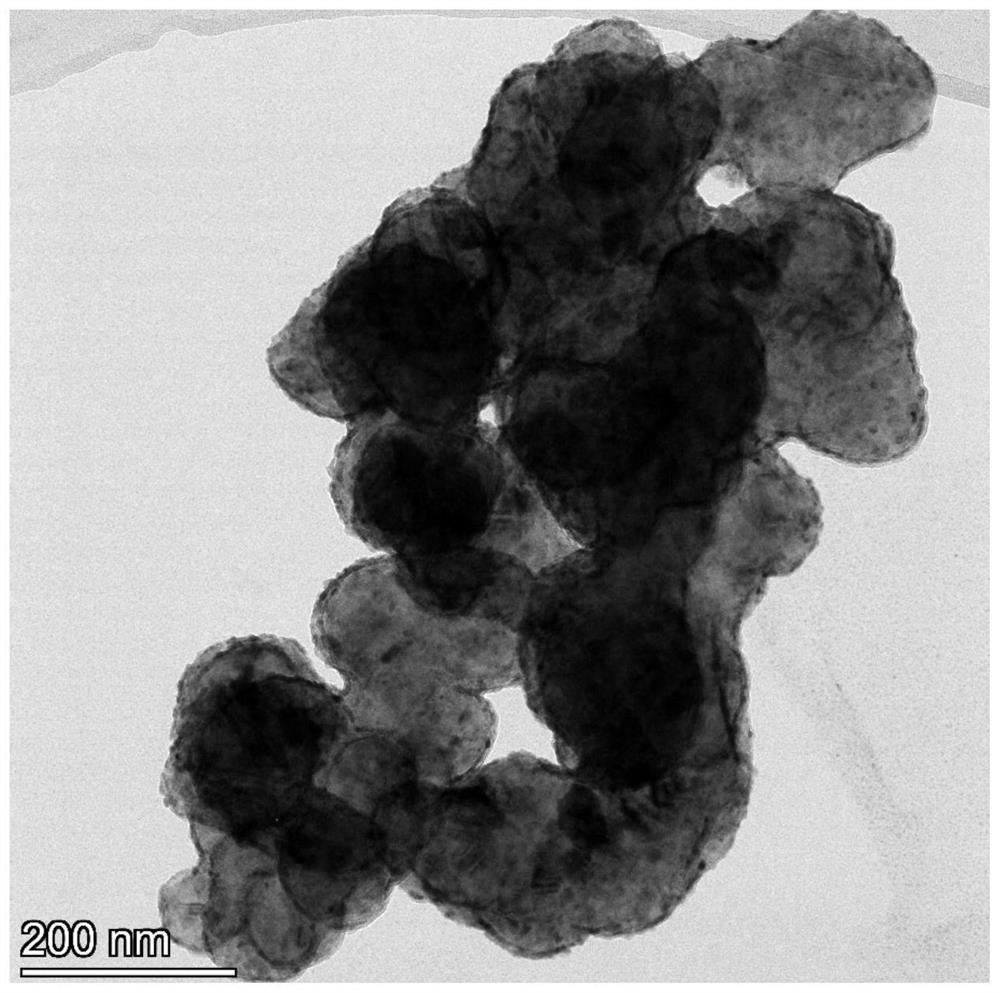

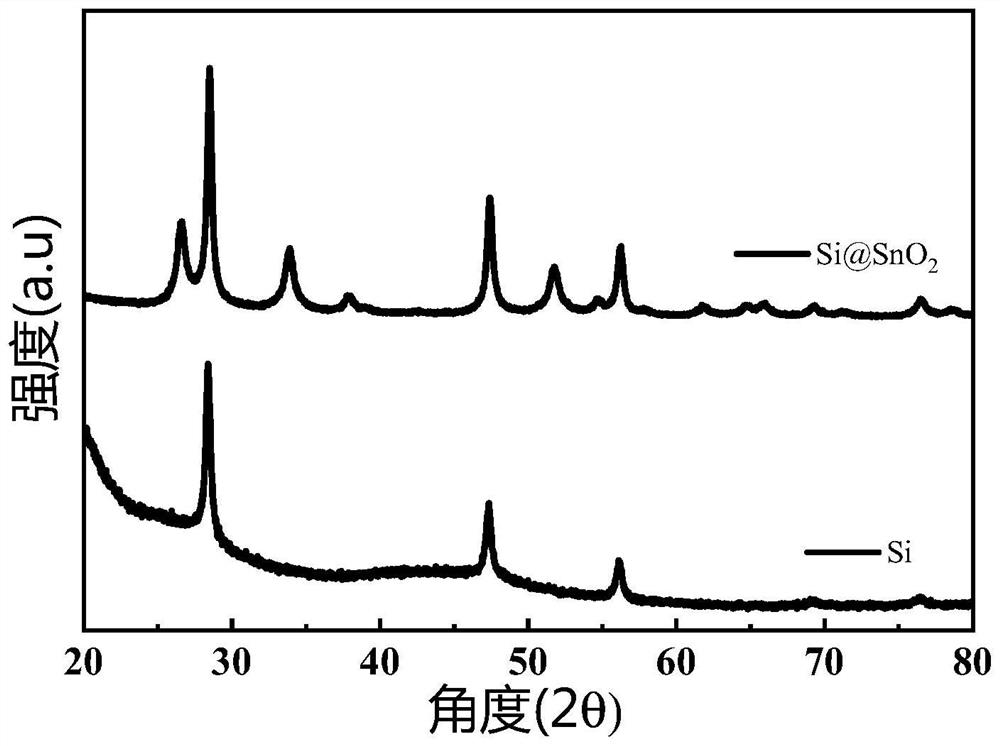

[0046] This embodiment provides a preparation method of nano-silicon tin dioxide composite electrode material, wherein the preparation method includes the following specific steps:

[0047] Weigh 500 mg of nano-silicon particles (with a particle size of 50 to 100 nm) and 250 mg of anhydrous stannous chloride, and put them into a mixer for mixing. After the mixing is uniform and complete, it is put into a mortar for grinding; the mixed material is obtained;

[0048] After grinding until there is no graininess, in an inert atmosphere (argon, flow rate 150sccm), put it into a tube furnace for high temperature melting. Calcination conditions: keep at 300℃ for 2h;

[0049] The melted mixed material was put into a muffle furnace for calcination, and the calcination conditions were as follows: heat preservation at 300° C. for 2 h to obtain the sample to be tested.

[0050] Electrode preparation process: First, the sample to be tested is used as the active material, and the conducti...

Embodiment 2

[0058] The difference between this example and Example 1 is that in Example 2, the mass ratio of nano-silicon to anhydrous stannous chloride is 1:1. The rest of the preparation method and steps are the same as in Example 1, and the nano-silicon and tin dioxide composite negative electrode material is obtained, which is marked as N-Si@SnO 2 -1, made of material N-Si@SnO 2 -1 Prepare electrode materials for testing.

Embodiment 3

[0060] The difference between this example and Example 1 is that in Example 3, the mass ratio of nano-silicon to anhydrous stannous chloride is 3:1. The rest of the preparation method and steps are the same as in Example 1, and the micro-silicon and tin dioxide composite negative electrode material is obtained, which is marked as N-Si@SnO 2 -3, made of material N-Si@SnO 2 -3 Prepare electrode materials for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com