Film solar battery and manufacturing method thereof

A thin-film solar cell and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as unclear large-scale application prospects, and achieve easy large-scale production and application, good and stable performance, and structure. and the effect of simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

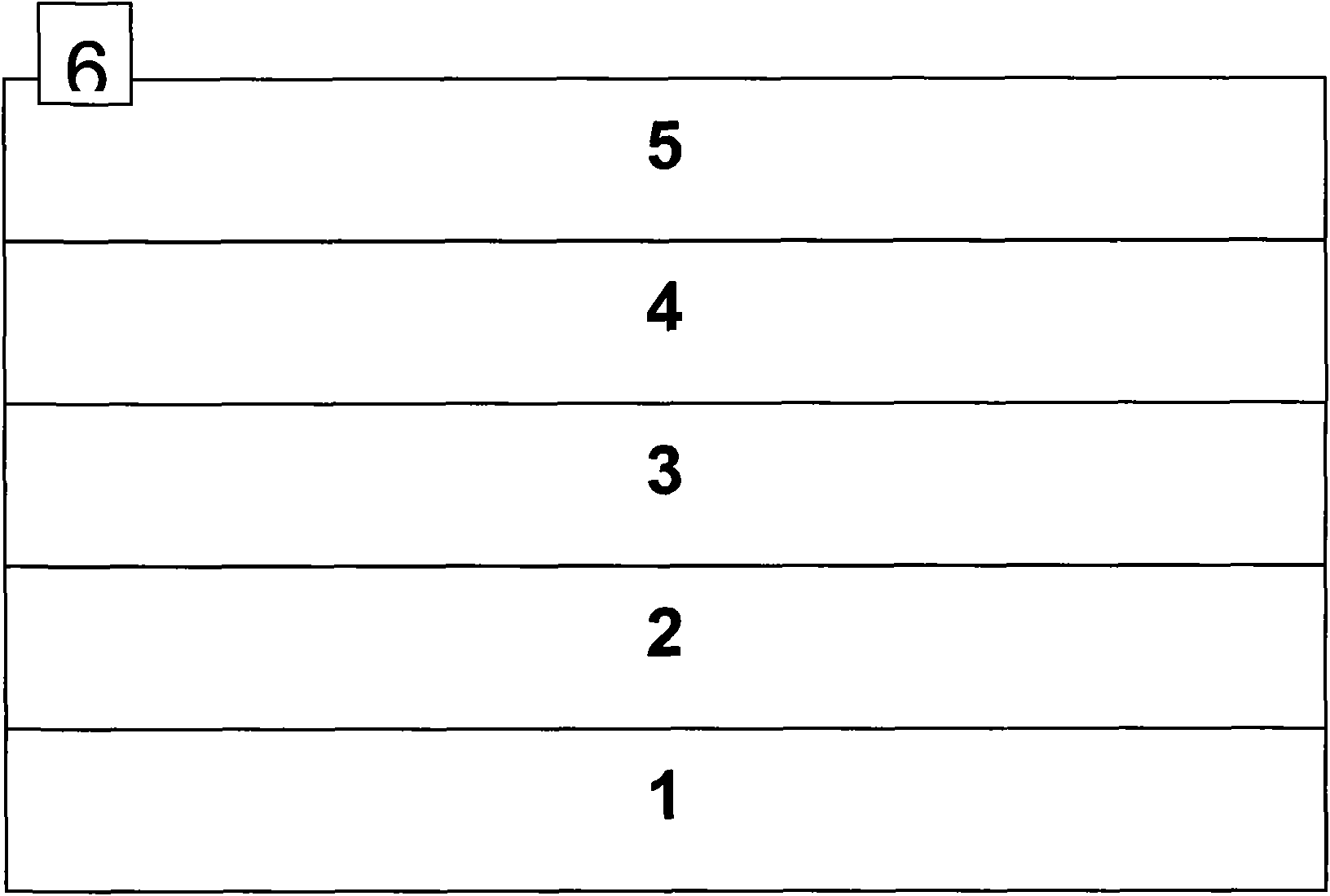

[0022] Such as figure 1 As shown, the thin film solar cell of the present invention is composed of a glass substrate 1, a back electrode 2, a light absorbing layer 3, a buffer layer 4, a window layer 5, and a top electrode 6 from bottom to top.

[0023] The back electrode of the battery is a molybdenum-copper alloy film with a thickness of 0.3-3 μm, and the copper content is 2-40%; the light-absorbing layer is a copper-silicon-tin-sulfur (CSTS) film with a thickness of 0.5-5 μm; The buffer layer is a zinc sulfide (ZnS) film with a thickness of 20-100 nm; the window layer is a zinc-aluminum oxide (ZAO) film with a thickness of 0.2-5 μm; the top electrode is a nickel-aluminum alloy film , with a thickness of 0.2-5 μm and an aluminum content of 1-100%.

[0024] The manufacture method of thin-film solar cell of the present invention carries out according to the following steps:

[0025] (1) Manufacture of the back electrode: use molybdenum-copper alloy target DC magnetron sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com