Free-cutting bismuth-silicon-tin brass remelting and polishing copper ingot and manufacturing method thereof

A manufacturing method and easy-cutting technology, applied in the field of metal materials, can solve the problems affecting the internal quality of the ingot, low solid solubility, component segregation, etc., achieve excellent polishing and electroplating performance, solve low mechanical properties, and remove grain boundary impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better explain the present invention, it is further described in conjunction with the following specific examples, but the present invention is not limited to the specific examples.

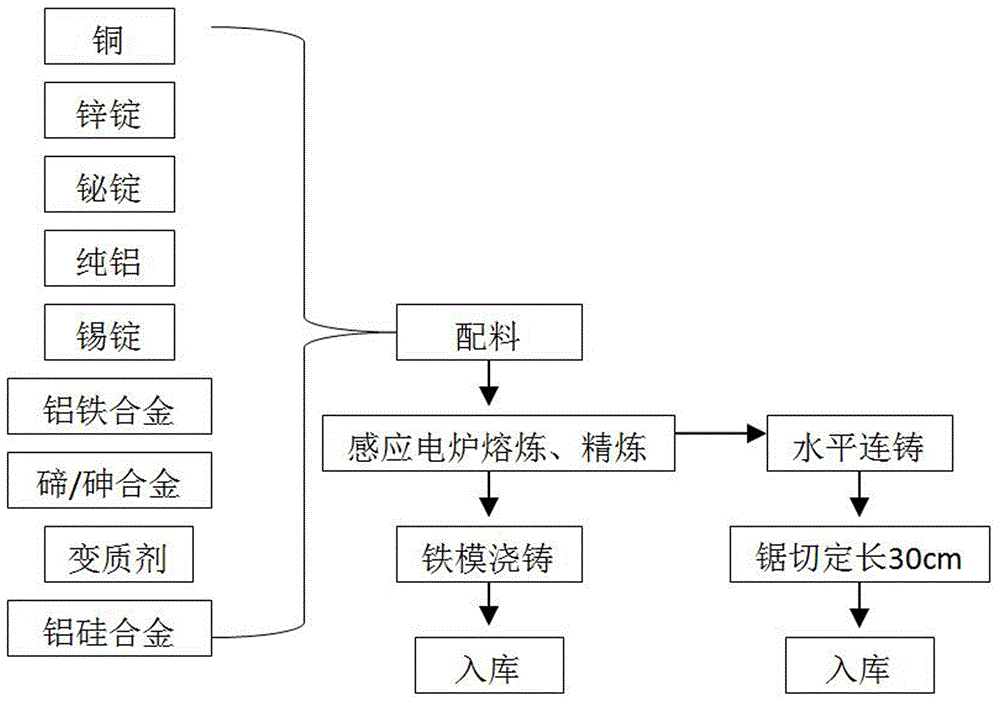

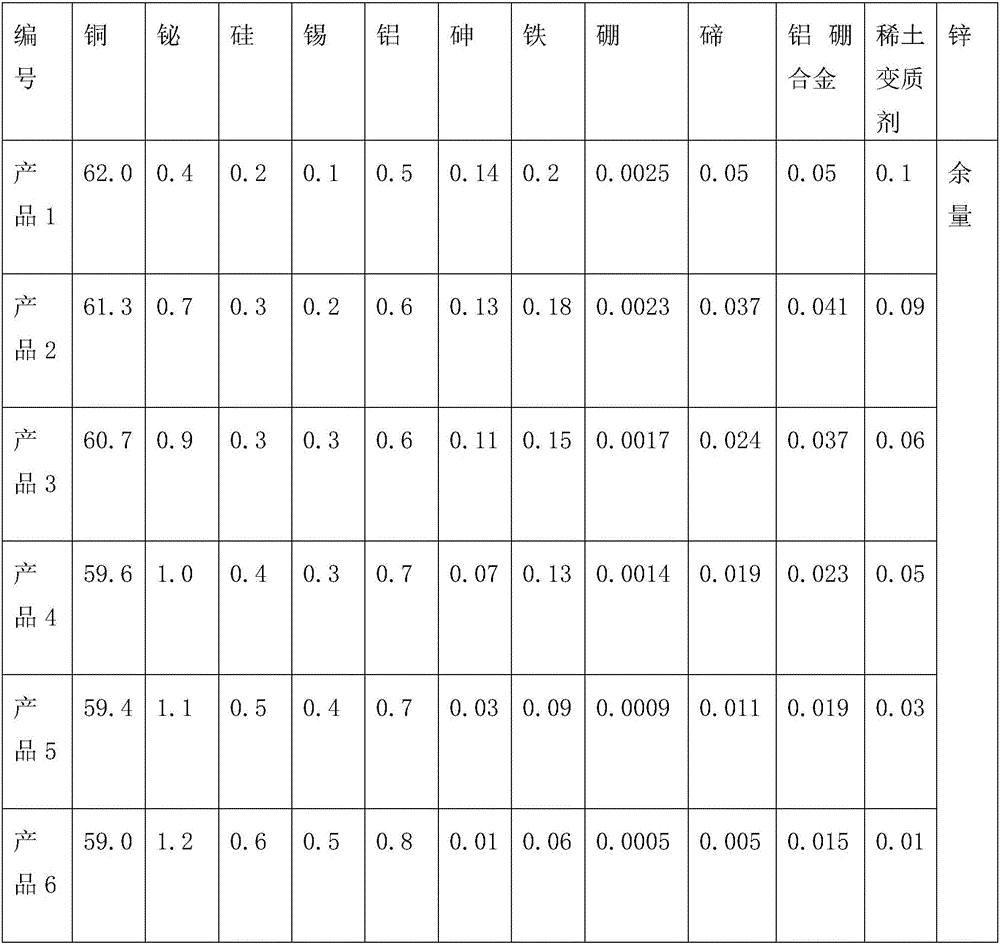

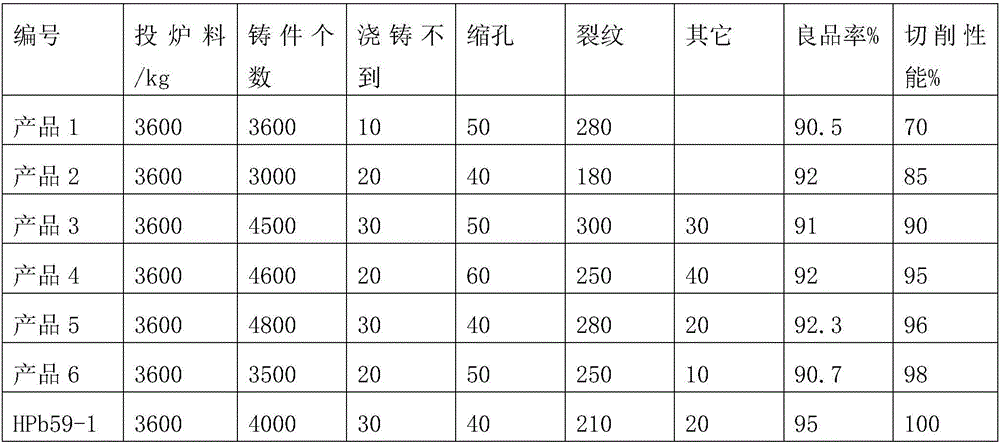

[0026] In the specific implementation process, selected six components of the distribution formula (see Table 1) to manufacture free-cutting bismuth-silicon-tin brass remelted polished copper ingots, the manufacturing method is as follows:

[0027] (1) Dosing according to the ratio of each component material;

[0028] (2) Put the first batch of copper and a small part of zinc ingot into the induction furnace to melt and stir, and add the modifier aluminum-boron alloy at the same time;

[0029] (3) continue to drop into copper in batches, after the above-mentioned copper is melted, add zinc ingot and bismuth ingot, tin ingot, aluminum-silicon alloy, pure aluminum, aluminum-iron alloy;

[0030] (4) After all melting, adjust the temperature to 1020°C, add tellurium / arsenic-copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com