Tin-containing molecular sieve with MWW topological structure and preparation and application thereof

A topology, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of low tin content, long synthesis time, low crystallinity, etc., and achieve low volatility and good quality. Catalytic performance, the effect of increasing the controllable variable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Treat 3 g of MCM-22 molecular sieve (silicon-aluminum ratio = 25) with concentrated nitric acid (concentration 65%) at 100°C for 24 hours at a liquid:solid ratio (weight ratio) of 20 to obtain Si-OH-rich MWW molecular sieves (Si-aluminum ratio>1900).

[0035] Then in a reactor, take by weighing 100g of dissolved 1-butyl-3-methyl imidazolium chloride ionic liquid, add 1.5g of tin tetrachloride and vigorously stir the reaction for 4 hours, then add the Si-rich Si- The MWW molecular sieve of OH was added, and the reaction was vigorously stirred for 4 hours to obtain a uniformly mixed crystallized mixture with a molar ratio of 1.0 SiO 2 :0.1SnO 2 .

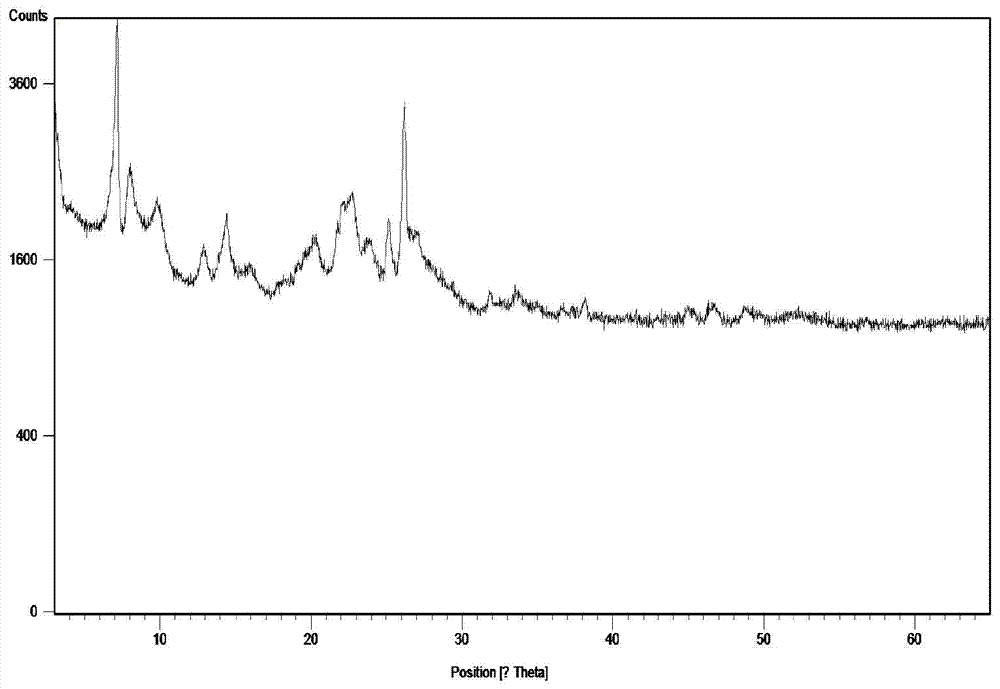

[0036] The prepared crystallization mixture was evenly mixed, then transferred to an open reaction kettle, and crystallized at 200° C. for 20 hours. After the crystallization, the reactant was cooled to room temperature, filtered, washed and dried to obtain a tin-containing MWW heteroatom molecular sieve. The reaction produ...

Embodiment 2

[0038] Treat 3 g of borosilicate MCM-49 molecular sieve (silicon-boron ratio = 25) with concentrated nitric acid (concentration 65%) at a liquid: solid ratio (weight ratio) of 20 under ultrasonically enhanced heating at 100°C for 10 hours to obtain rich MWW molecular sieves containing Si-OH (silicon-boron ratio>800).

[0039] Then in a reactor, weigh 100g of the dissolved 1-ethyl-3-methylimidazolium chloride and tetraethylammonium chloride mixture (weight ratio 1:1) ionic liquid, add 0.15g of tin tetrachloride Stir vigorously for 4 hours, then add the Si-OH-rich MWW molecular sieve obtained above, and stir vigorously for 4 hours to obtain a uniformly mixed crystallized mixture with a molar ratio of 1.0 SiO 2 :0.01SnO 2 .

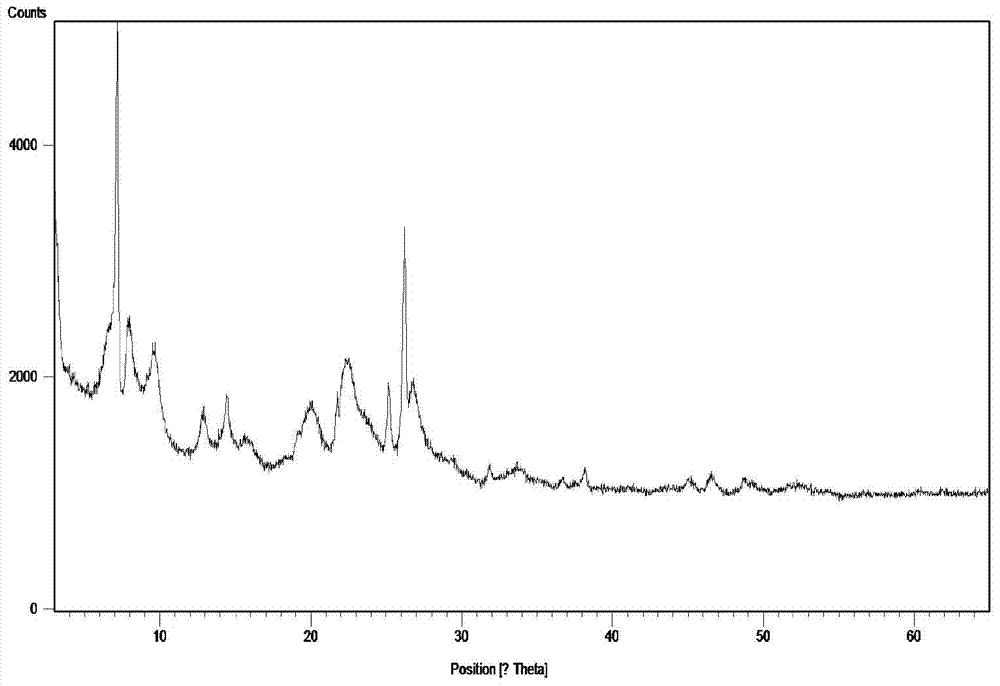

[0040] The prepared crystallization mixture was evenly mixed and then transferred to a closed reactor for crystallization at 100° C. for 240 hours. After the crystallization, the reactant was cooled to room temperature, filtered, washed and dried to obtai...

Embodiment 3

[0042] Treat 3 g of MCM-56 molecular sieve (silicon-aluminum ratio = 25) under hydrothermal conditions at 550°C for 4 hours, and then use concentrated nitric acid (concentration 65%) at 80°C according to the liquid: solid ratio of 20 (weight ratio) Under treatment for 4 hours, a MWW molecular sieve rich in Si-OH (silicon-aluminum ratio>920) was obtained.

[0043] Then in a reactor, weigh 100 g of dissolved 1-heptyl-3-methylchloropiperidinium salt ionic liquid, add 0.33 g of tin tetrachloride and vigorously stir for 4 hours, and then add the previously obtained Si-rich The MWW molecular sieve of -OH was added, and the reaction was vigorously stirred for 4 hours to obtain a well-mixed crystallized mixture with a molar ratio of 1.0 SiO 2 :0.025SnO 2 .

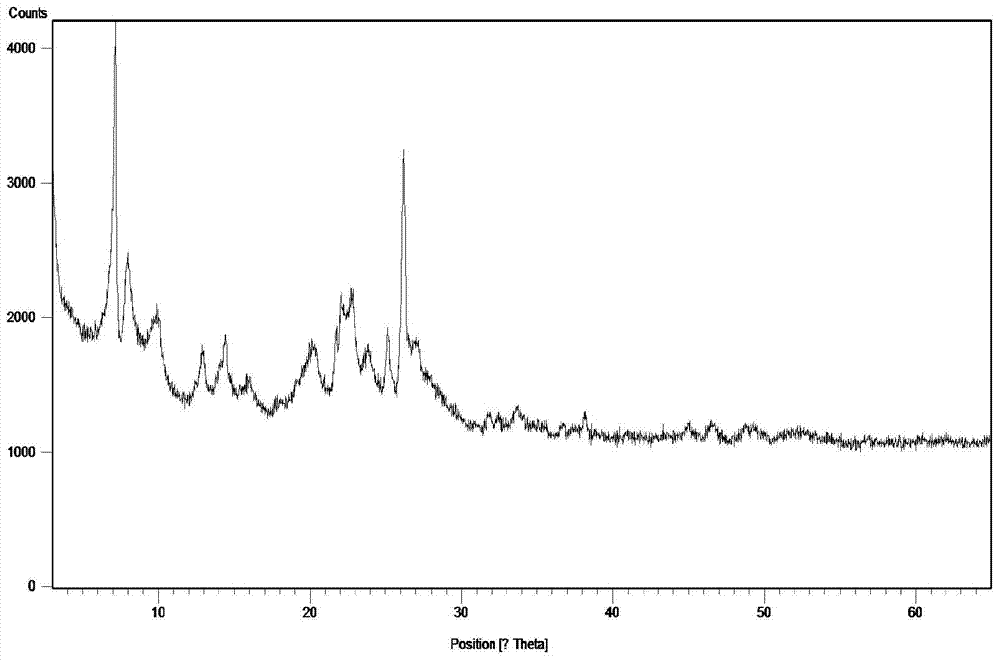

[0044] The prepared crystallization mixture was evenly mixed, then transferred to an open reaction kettle, and crystallized at 150° C. for 10 hours. After the crystallization, the reactant was cooled to room temperature, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com