A Method for Determining the Repairing Interval of Hinge Joints in Hollow Slab Beams and Its Construction Method

A hollow slab girder and a technology to determine the method, applied in bridge maintenance, bridge, bridge construction, etc., can solve the problems of hinge joint durability impact, unsatisfactory, etc., to reduce the risk of stress, reduce maintenance costs, and ensure reinforcement maintenance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

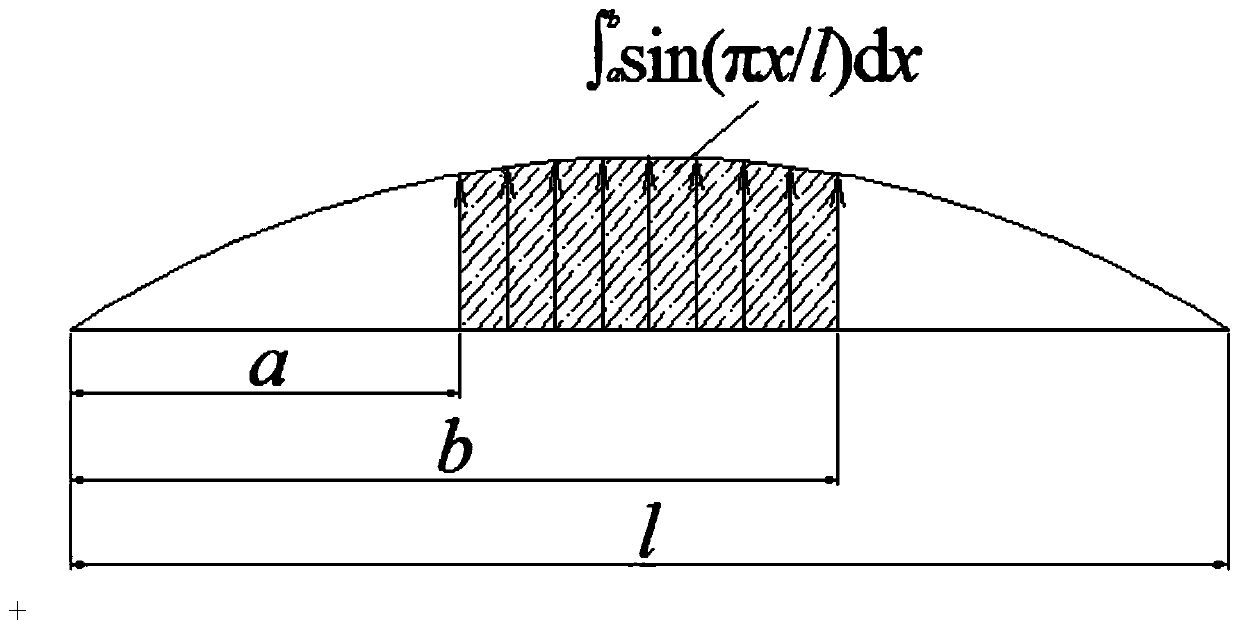

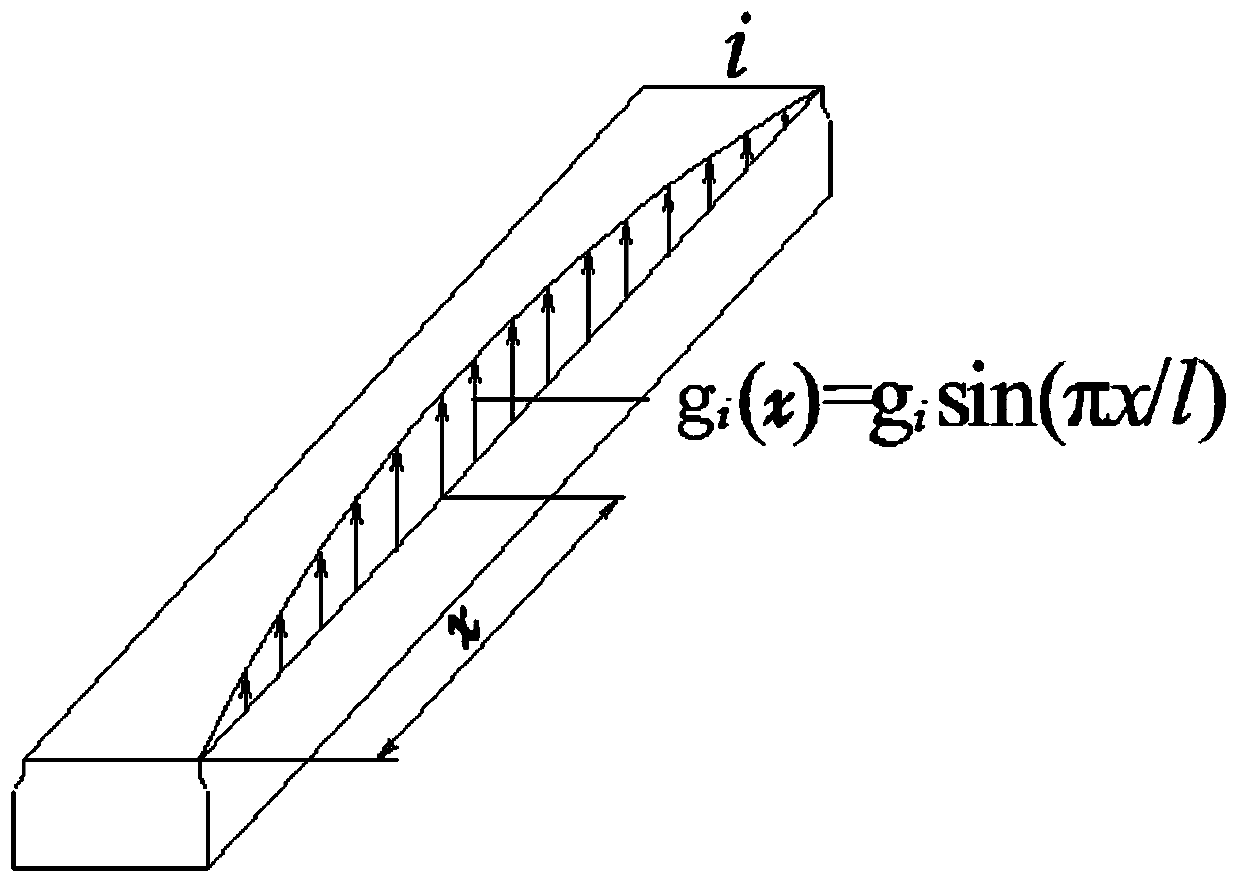

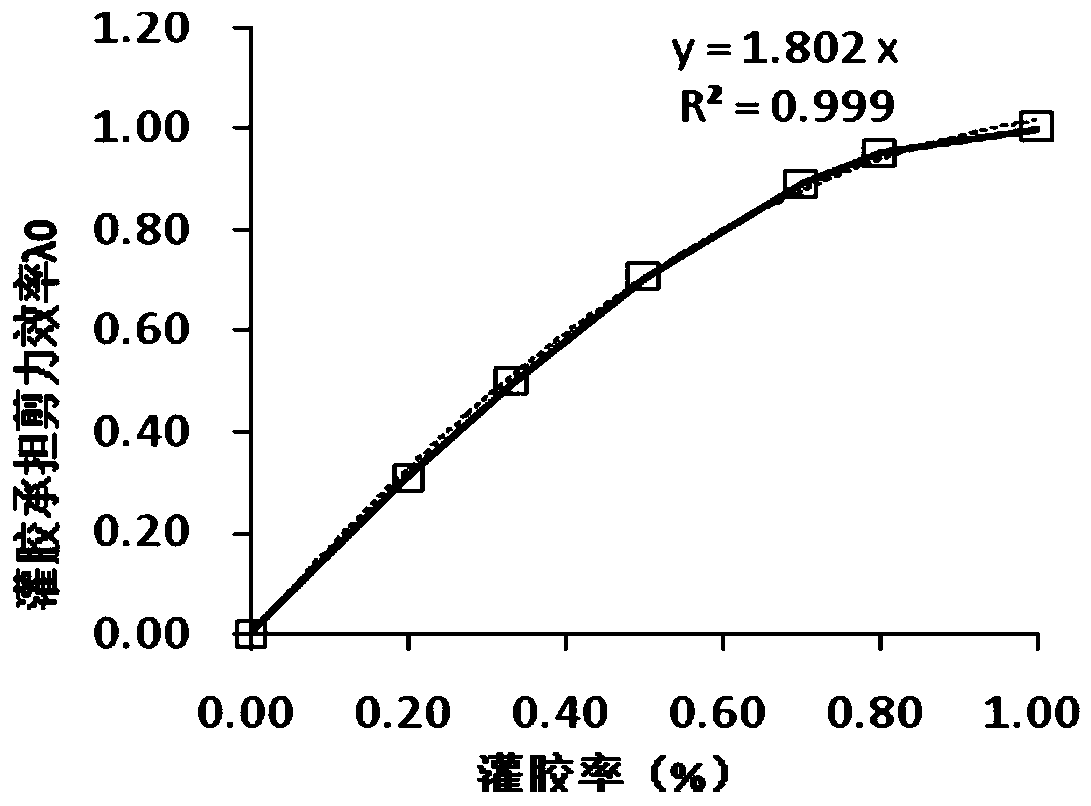

[0047] see figure 1 , figure 2 , image 3 , Figure 4 , a method for determining the repair interval of hinged joints in hollow slab beams, the hinged slab beam method is that only the shear force is transferred in the combined joint under the action of vertical load, and the lateral distribution of mid-span load follows the law of half-wave sine load;

[0048] According to the mechanical characteristics of the hinged slab bridge, the shear force of the slab girder is the largest at the mid-span, and the closer to the fulcrum, the shear force tends to zero. The change of the shear force from the mid-span to the fulcrum conforms to the sinusoidal principle, and the calculated shear force meets the following conditions:

[0049] 1) The hinge j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com